Horizontal type defogger

A mist eliminator and horizontal technology, which is applied in the field of exhaust gas purification and treatment devices, can solve the problems of difficulty in quickly discharging condensed water and affecting the demisting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

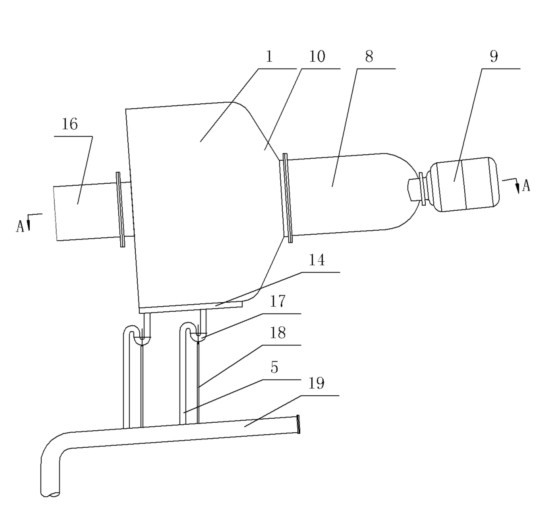

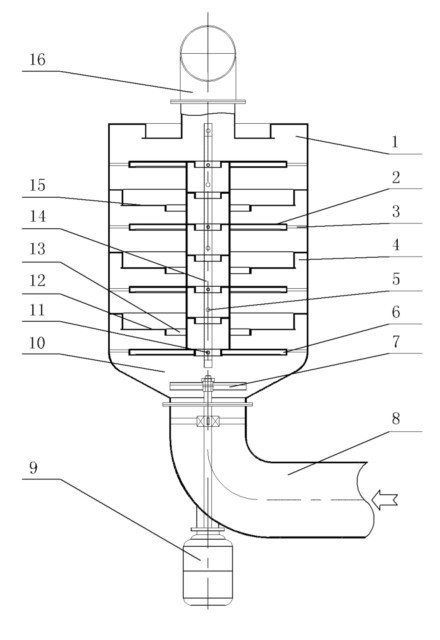

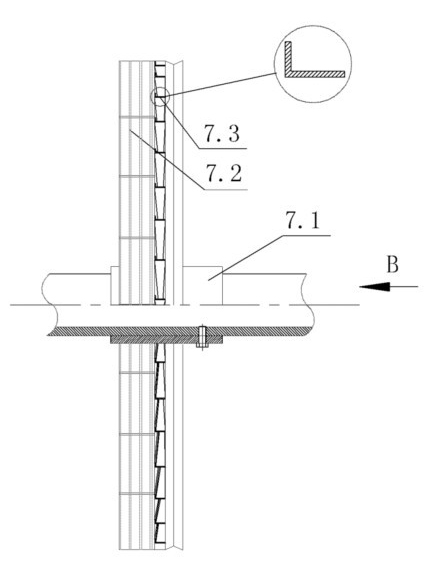

[0017] Such as figure 1 , figure 2 Shown, the present invention is a kind of horizontal mist eliminator, and it comprises that it comprises cylinder body 1 that is arranged horizontally, and the air inlet 10 of cylinder body 1 front end is connected with air inlet pipeline 8, and the exhaust port of cylinder body 1 rear end is connected with The exhaust pipe 16 is connected. A defogging motor 9 is installed at the bend of the intake pipe 8, the output shaft of the defogging motor 9 extends into the intake pipe 8 and is opposite to the barrel 1, and a defogging motor 9 is installed on the output shaft of the defogging motor 9 Fan vanes 7 , the fog-eliminating fan blades 7 are located at the air inlet 10 of the cylinder body 1 . The mixed water mist and exhaust gas are discharged from the intake pipe 8 through the induced draft fan, and after being blocked by the defogging blades 7, the fog is initially eliminated and the water mist and exhaust gas are diverted to the surroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com