Method and system for deeply removing dust from flue gas after wet desulfurization

A technology for wet desulfurization and dust removal system, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problem of low dust removal efficiency of flue gas, achieve enhanced heat exchange and demisting effect, low cost, flue gas Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

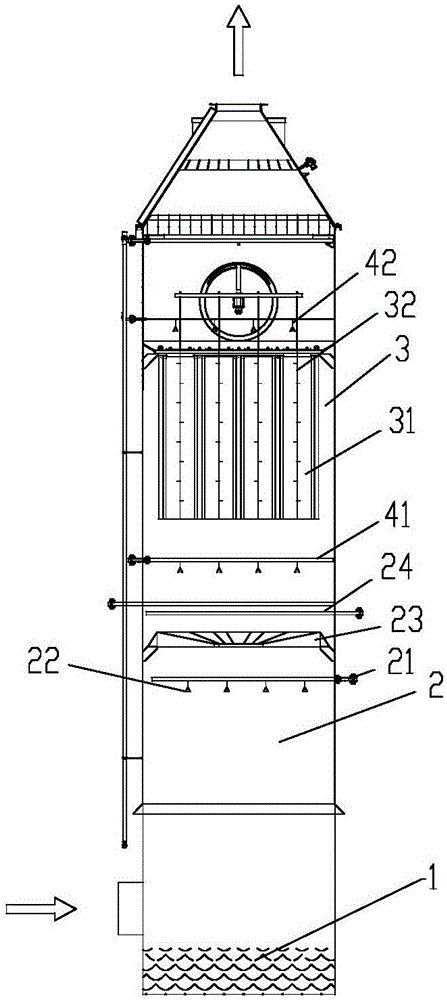

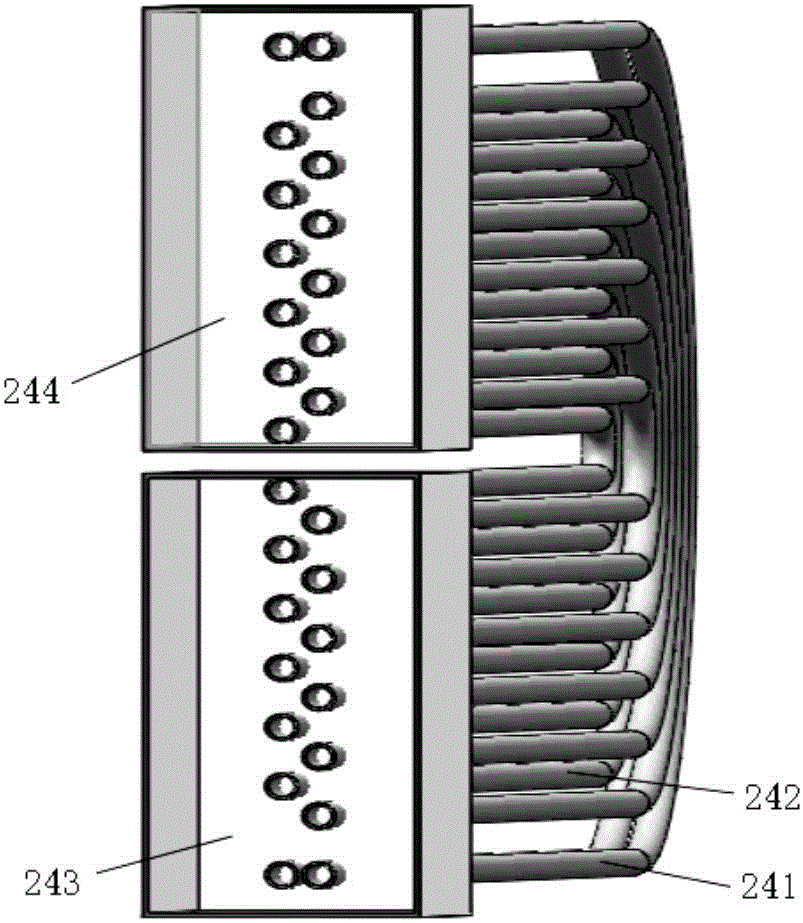

[0034] see figure 1 , the flue gas deep dust removal system shown in the figure is a preferred embodiment of the present invention, mainly including a phase change condensation chamber 2 and a wet electrostatic precipitator 3, the phase change condensation chamber 2 is arranged above the desulfurization absorption tower 1, and inside is arranged The steam distribution pipe 21 is provided with a number of steam nozzles 22, behind the nozzles of the steam distribution pipe 21 there are a swirl plate 23 and a condensing pipe type demister 24, and the wet electrostatic precipitator 3 is arranged in the phase change condensing The exit position of the combining chamber 2 mainly includes an anode plate assembly 31 and a cathode line 32 .

[0035] A flushing device is respectively provided above the condensing demister 24 and the wet electrostatic precipitator 3, wherein a first spray flushing pipe 41 is provided on the condensing demister 24, and a second spray flushing pipe 41 is p...

example 1

[0050] After the flue gas of a coal-fired power plant undergoes wet desulfurization, the dust concentration is 30-50mg / Nm 3 , mainly sulfurous acid droplets, gypsum and PM2.5 and other fine particles, the flue gas directly enters the wet electrostatic precipitator, affected by the nature of the fine particles, it is difficult to achieve efficient dust removal and ultra-low emissions. Using the above-mentioned embodiment, the flue gas after wet desulfurization is nearly saturated or in a state of saturated flue gas. The flue gas first passes through the steam phase change chamber, and is sprayed into the power plant waste steam or secondary steam with a steam saturation of 1.20 through the nozzle to establish a water The supersaturated environment required for the nucleation and condensation of gas on the surface of PM2.5 fine particles, so that the fine particles in the coal-fired flue gas will condense and become larger, and the particle size will increase to more than 20 micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com