Device and method for eliminating colored smoke plume generated during wet desulphurization

A wet desulfurization and non-ferrous technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of reduced service life of heat exchangers, large volume of flue gas coolers outside the tower, and high dew point temperature. The effect of reducing the heat load of heating and eliminating colored plume and gypsum rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

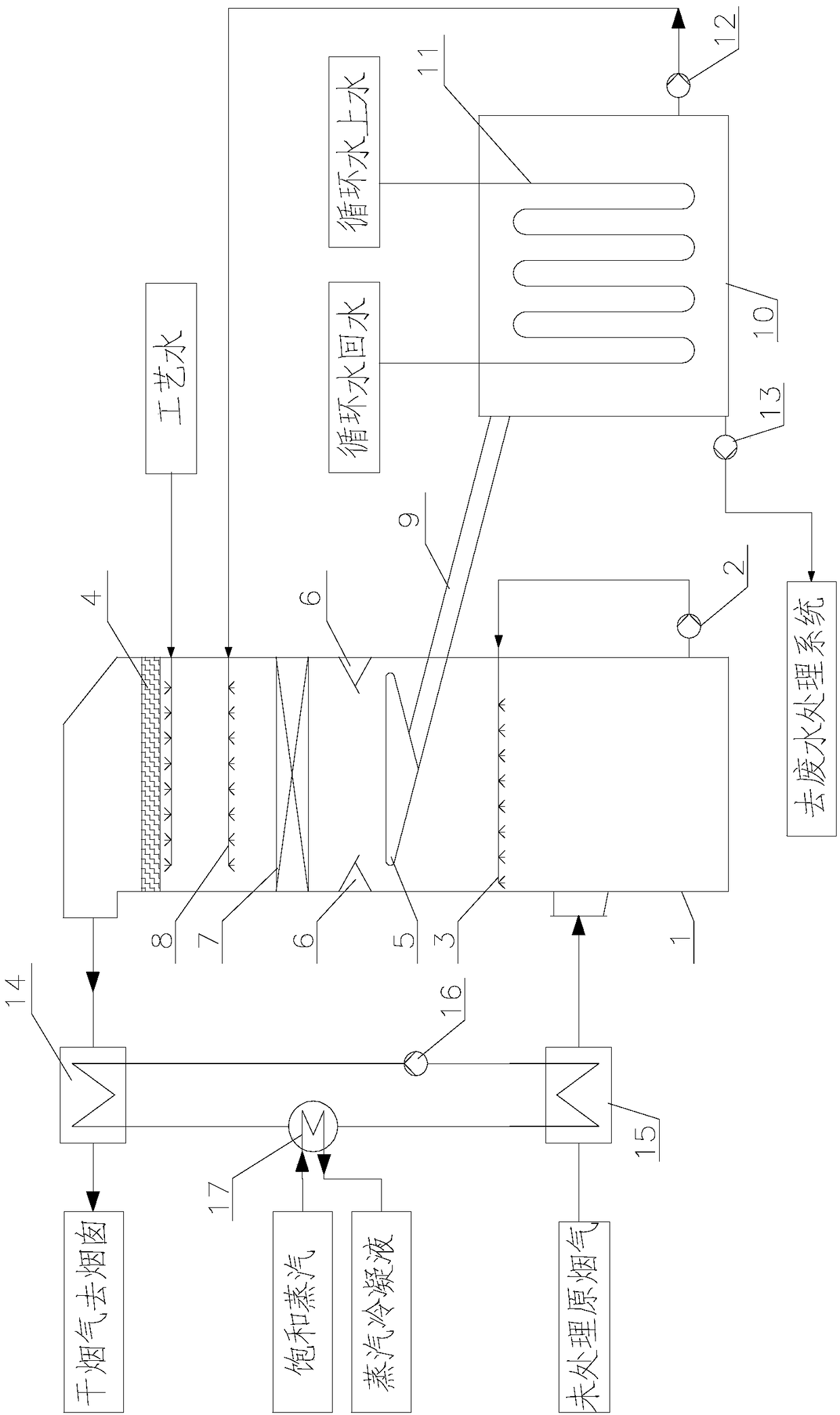

[0032] The boiler flue gas volume of a 300MW unit is 1.1 million Nm 3 / h, the temperature is 145°C, the concentration of sulfur dioxide is 2400mg / Nm 3 , the particle concentration is 30mg / Nm 3 . The desulfurization process adopts the limestone gypsum method, and the water washing cooling system and the flue gas heat exchange system of the present invention are added on the basis of the traditional and mature limestone gypsum method.

[0033] The flue gas first enters the flue gas cooler 15 on the inlet flue of the wet desulfurization absorption tower 1, and transfers heat to the heat medium water, so that the temperature of the heat medium water rises, and the flue gas temperature decreases to about 110°C and enters the wet desulfurization absorption tower 1. The above-mentioned flue gas passes through the desulfurization spray layer 3 upward in the wet desulfurization absorption tower 1, and is in countercurrent contact with the absorption liquid sprayed by the desulfurizat...

Embodiment 2

[0038] One 435m 2 Sintering machine with flue gas volume of 1.6 million Nm 3 / h, the temperature is 135°C, the concentration of sulfur dioxide is 1500mg / Nm 3 , the particle concentration is 50mg / Nm 3 . The desulfurization process adopts the limestone gypsum method, and the water washing cooling system and the flue gas heat exchange system of the present invention are added on the basis of the traditional and mature limestone gypsum method.

[0039] The flue gas first enters the flue gas cooler 15 on the inlet flue of the wet desulfurization absorption tower 1, and transfers heat to the heat medium water, so that the temperature of the heat medium water rises, and the flue gas temperature decreases to about 110°C and enters the wet desulfurization absorption tower 1. The above-mentioned flue gas passes through the desulfurization spray layer 3 upward in the wet desulfurization absorption tower 1, and is in countercurrent contact with the absorption liquid sprayed by the desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com