Gas outburst spinning dive desulfurization dust cleaning apparatus

A technology for desulfurization, dust removal, and cyclone devices, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problem of reducing the service life of the bubbling tube, increasing the strength of equipment maintenance, and easily accumulating dust in the bubbling tube. Fouling and other problems, to improve the grade, reduce the construction cost and construction difficulty, and easily control the liquid level accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

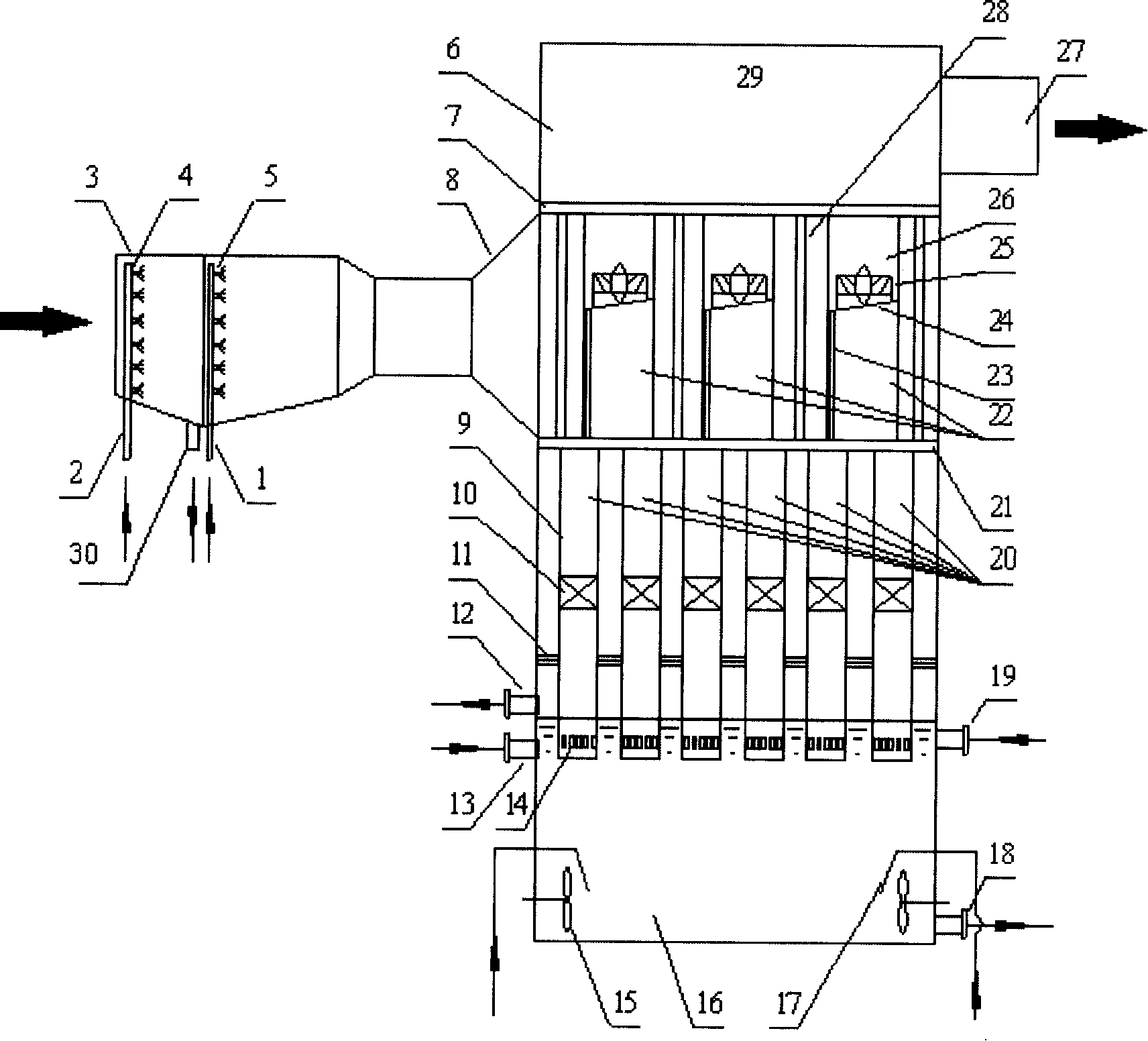

[0058] In this specific embodiment, limestone slurry is used as the absorbent lye, and the flue gas is taken from power station boilers, heating furnaces, sintering machines, chemical equipment or other similar equipment containing SO 2 exhaust gas.

[0059] Depend on figure 1 It can be seen that the external cooling defluorination device 3 is located before the flue gas inlet of the desulfurization absorption tower, and includes two sections with different functions. The fresh limestone slurry from the slurry tank in the front section is driven into the slurry pipeline 2 and sprayed out from the slurry nozzle 4 to cover the entire section of the cooling defluorinator. Most of the HF in the flue gas is removed in this section, thereby effectively Minimize the fluorine corrosion in the absorption tower. In the latter stage, the process water from the process water tank is pumped into the process water pipe 1, and sprayed out from the process water nozzle 5 to cover the entire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elevation angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Elevation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com