Flue gas decarbonization system of stepped absorption and regeneration

A technology of absorption system and regeneration system, which is applied in the field of flue gas purification to achieve the effect of increasing regeneration speed, reducing steam consumption and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

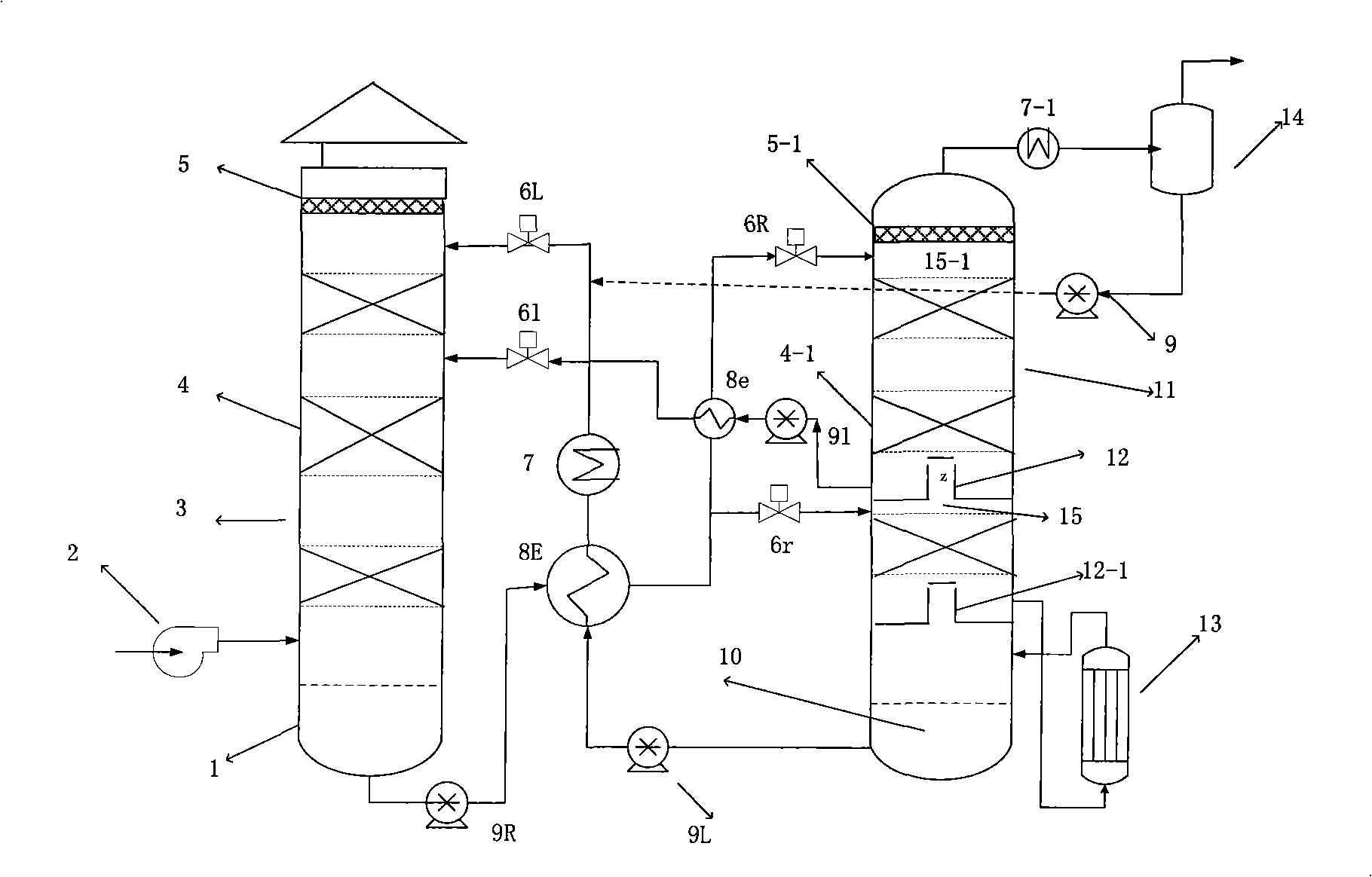

[0015] The working principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] see figure 1 , the present invention is made up of absorption system, regeneration system and heat exchange system, and described absorption system comprises the absorption tower 3 that is connected with induced draft fan 2 and is arranged at the absorption tower 3 bottom rich liquid tank 1, the absorption tower packing 4 in the middle And the absorption tower mist eliminator 5 at the upper end;

[0017] The regeneration system includes a regeneration tower 11, a lean liquid tank 10 arranged at the bottom of the regeneration tower 11 and a regeneration tower demister 5-1 at the upper end, and the upper end of the lean liquid tank 10 is provided with upper and lower two-stage liquid accumulation tanks 12 , 12-1, between the upper and lower two stages of effusion tanks 12, 12-1 and the upper end of the upper effusion tank 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com