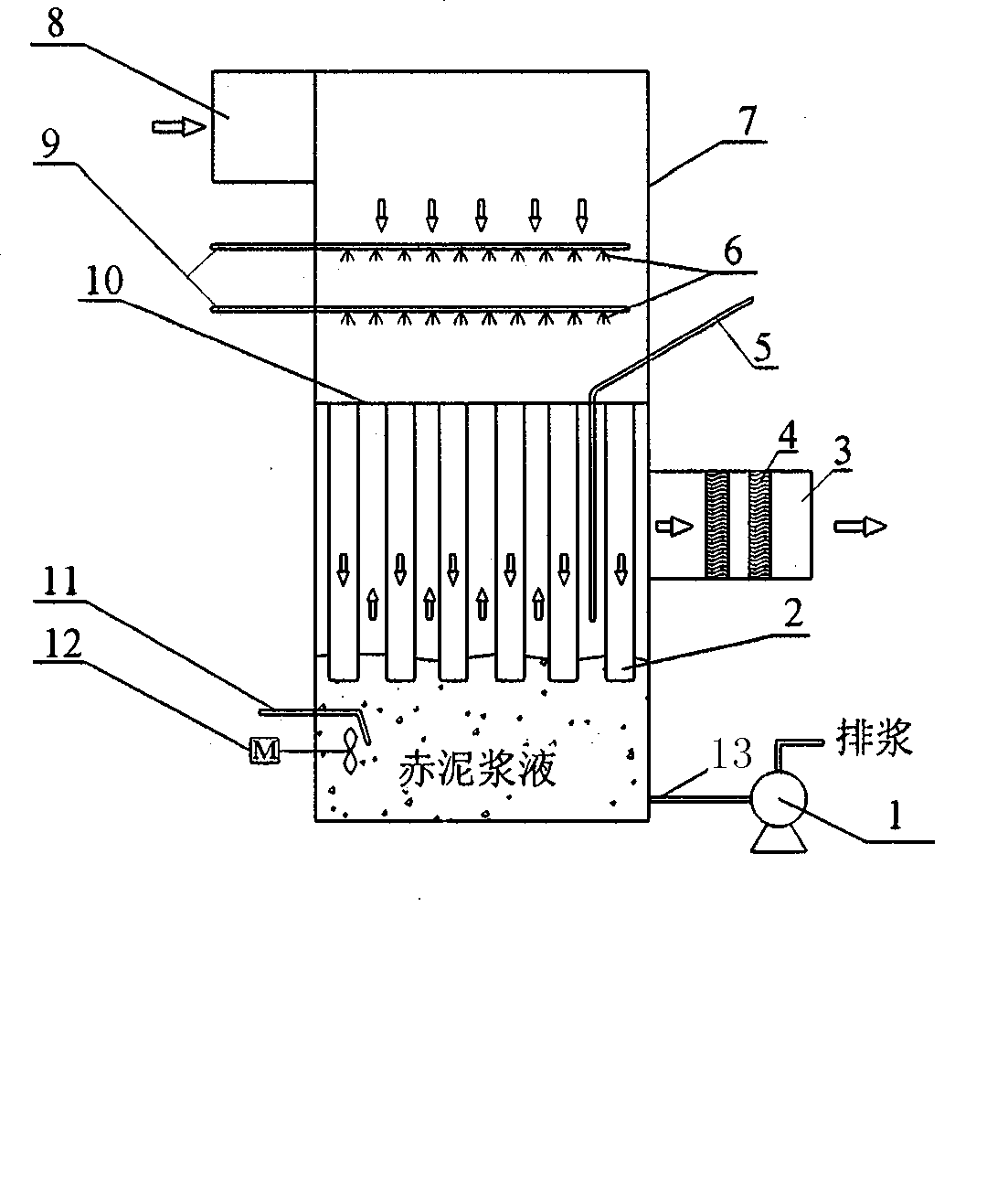

Bubble tower as desulfurizer and use thereof

A bubbling tower, a technology for use, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as scaling and blockage, system shutdown, and packing towers prone to scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The flue gas volume at the inlet of the desulfurization unit is 10000Nm 3 / h, SO 2 The concentration is 4000mg / Nm 3 , the temperature is 120°C; the pH value of the red mud absorption slurry is 12.5, and the solid content of the slurry is 20%; the immersion depth of the bubbling tube is 150 mm, and the pH value of the slurry in the absorption tower is 7.0. Under the above conditions, the SO at the outlet of the absorption tower 2 The content is 280mg / Nm 3 , The desulfurization efficiency can reach 93%.

Embodiment 2

[0028] The flue gas volume at the inlet of the desulfurization unit is 10000Nm 3 / h, SO 2 The concentration is 4000mg / Nm 3 , the temperature is 120°C; the pH value of the red mud absorption slurry is 12.5, and the solid content of the slurry is 20%; the immersion depth of the bubbling tube is 100 mm, and the pH value of the slurry in the absorption tower is 7.0. Under the above conditions, the SO at the outlet of the absorption tower 2 The content is 350mg / Nm 3 , The desulfurization efficiency can reach 91%.

Embodiment 3

[0030] The flue gas volume at the inlet of the desulfurization unit is 10000Nm 3 / h, SO 2 The concentration is 4000mg / Nm 3 , the temperature is 120°C; the pH value of the red mud absorption slurry is 13, and the solid content of the slurry is 20%; the immersion depth of the bubble tube is 100 mm, and the pH value of the slurry in the absorption tower is 7.0. Under the above conditions, the SO at the outlet of the absorption tower 2 The content is 320mg / Nm 3 , The desulfurization efficiency can reach 92%.

[0031] The biggest feature of the present invention is that there is a spray layer above the partition to cool the flue gas and prevent the hot flue gas from directly contacting the partition and the injection pipe, which will cause the partition and the injection pipe to burn. Because both the partition and the injection pipe are made of organic materials with anti-corrosion function, relatively speaking, they are lighter in weight, corrosion-resistant, and cheaper than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com