Heat-pump clothes dryer and clothes drying method

A clothes dryer and clothes drying technology, which is applied in the field of clothes dryers, can solve problems such as insufficient lint filtration, reduced drying efficiency, blockage of evaporator aluminum sheets, etc., to shorten drying time, improve drying efficiency, The effect of reducing drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

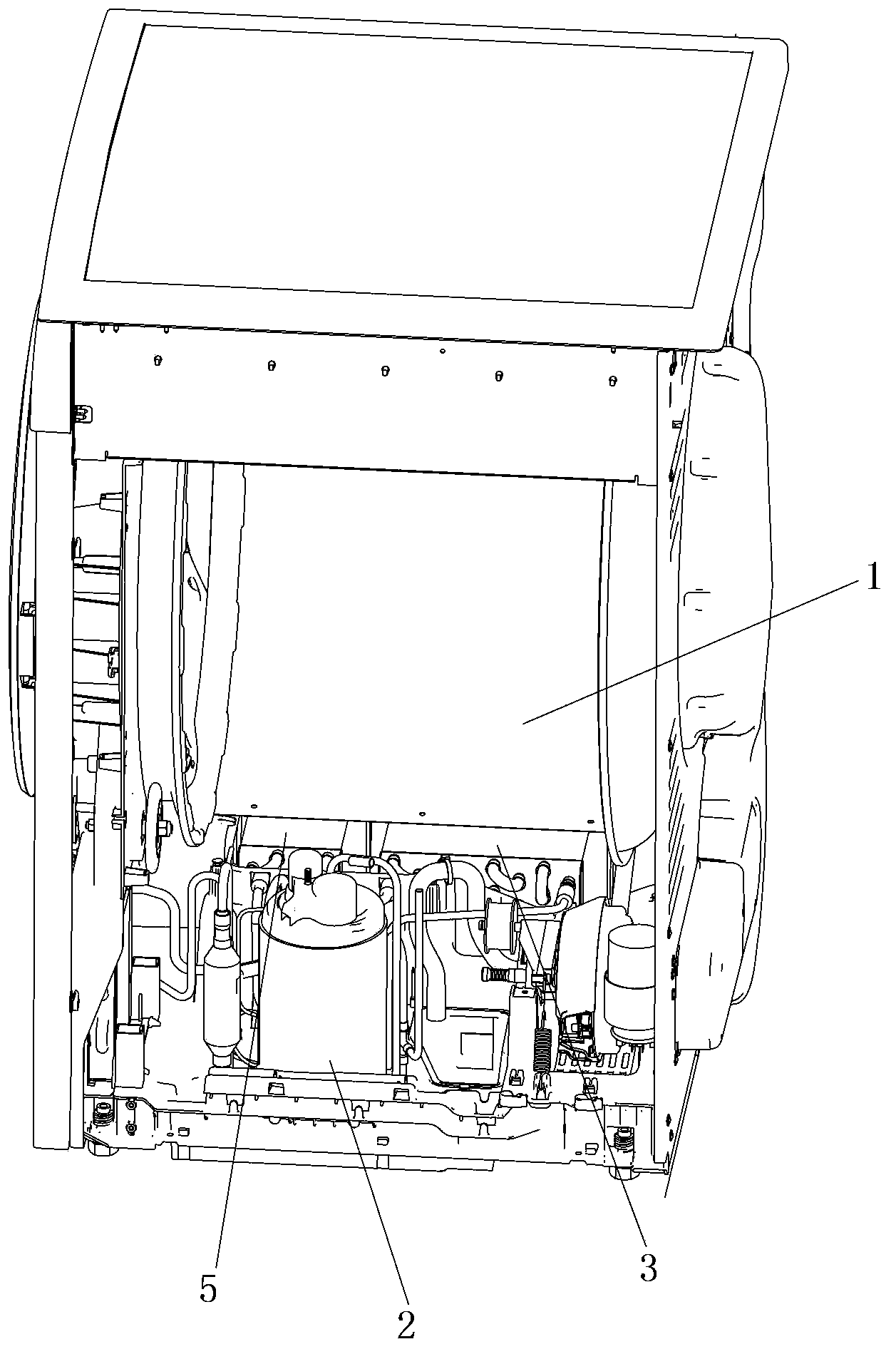

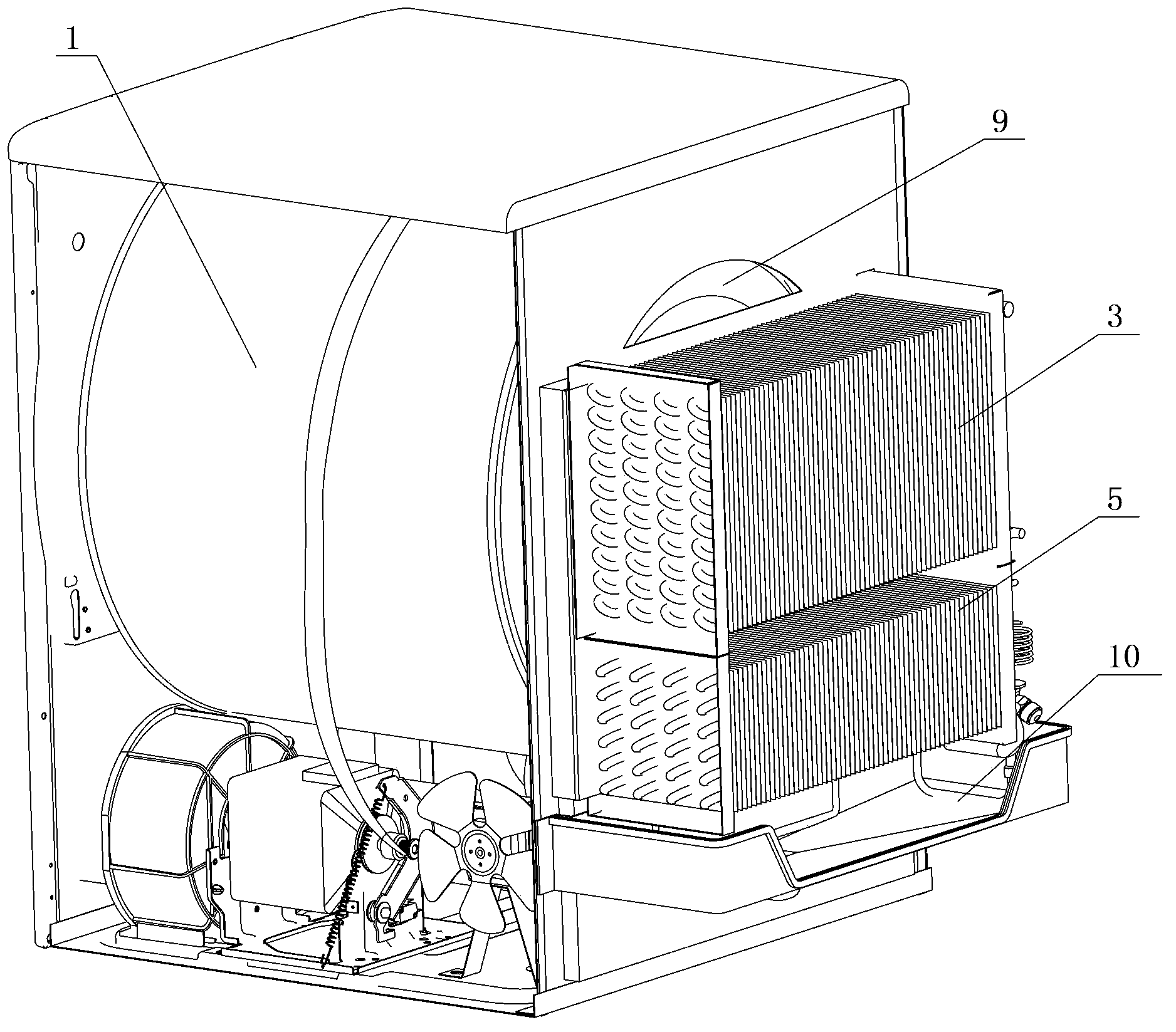

[0038] Such as figure 2 As shown, a heat pump dryer includes a rotatable drying drum 1, a heat pump system, and a circulating air system. The heat pump system includes a compressor 2, a condenser 3, a throttling device 4, and an evaporator 5. The condenser 3 and the evaporator 5 are arranged at the rear of the clothes drying drum 1 .

[0039] There is also a motor driving the rotation of the drying drum 1 below the drying drum 1. The output end of the motor is connected to a belt, and the belt is also connected to the drying drum 1. The rotation of the output end of the motor drives the belt to rotate, and then drives the drying drum to rotate. , so that the clothes inside the drying drum 1 are tumbled and fully contacted with dry and hot air.

[0040] A heat dissipation fan is also arranged under the drying drum 1. When the internal load of the compressor exceeds the rated load, it plays a role in regulating the load. A temperature sensor can be installed to control the ope...

Embodiment 2

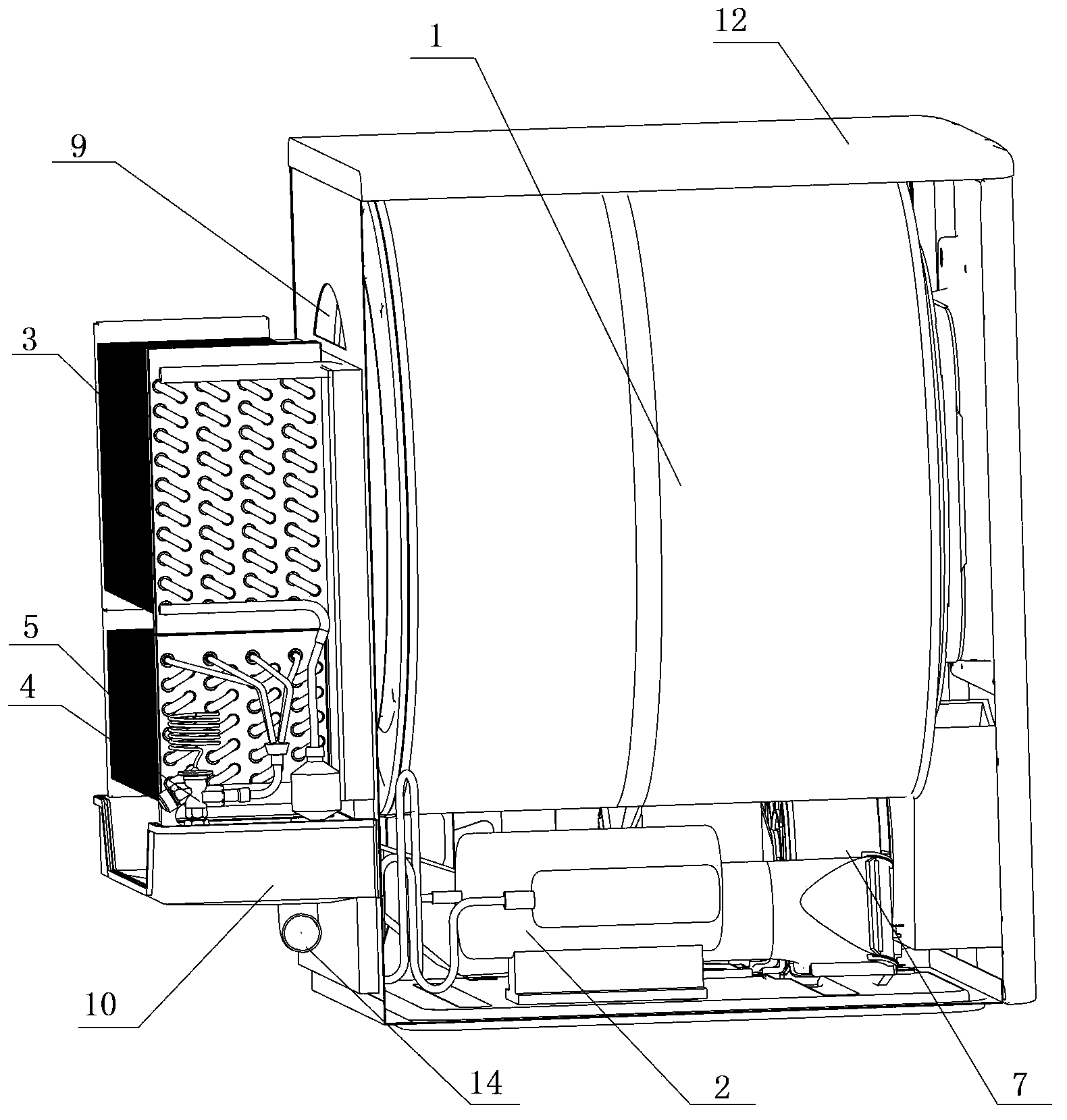

[0043] Such as image 3 As shown, a heat pump dryer includes a rotatable drying drum 1, a heat pump system, and a circulating air system. The heat pump system includes a compressor 2, a condenser 3, a throttling device 4, and an evaporator 5. The condenser 3 and the evaporator 5 are arranged at the rear of the clothes drying drum 1 .

[0044] A compressor 2 is also arranged under the drying drum 1, and the compressor 2 compresses the refrigerant, transfers the generated high-temperature and high-pressure refrigerant to the condenser 3, and the refrigerant releases heat after passing through the condenser 3, and the released heat is used for In order to heat the working air flow passing through the condenser 3, the refrigerant passes through the condenser and is regulated by the throttling device 4 to become a low-pressure and low-temperature humid gas. , absorb heat from the hot and humid air, turn it into a low-temperature and low-pressure saturated gas, enter the compressor...

Embodiment 3

[0048] The drying method of the heat pump clothes dryer described in this embodiment starts with the drying of clothes, the working airflow in the air duct 6 passes through the condenser 3, and the condenser 3 dissipates heat to heat the working airflow and passes through the dry heat of the drying drum 1 The air inlet 9 enters the inside of the drying drum 1, mixes with the water vapor of the clothes to form hot and humid air, enters the air duct 6 through the hot and humid air outlet 8, passes through the evaporator 5, and the evaporator 5 condenses the water vapor in the hygroscopic hot air into condensed water , the condensed water flows down into the water collecting box 10, and the working air flow passes through the condenser 3 again to be heated, and a new drying cycle starts until the drying ends.

[0049] During the drying process, the lint in the clothes enters the air duct 6 with the hot and humid air, and adheres to the windward side of the lower part of the evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com