Mop cleaning and drying drum

A mop cleaning and drying bucket technology, applied in the field of sanitary cleaning appliances, can solve the problems of poor cleaning effect of agitating discs, complex transmission mechanism, etc., and achieves the effects of compact structure, good cleaning effect and reduced maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

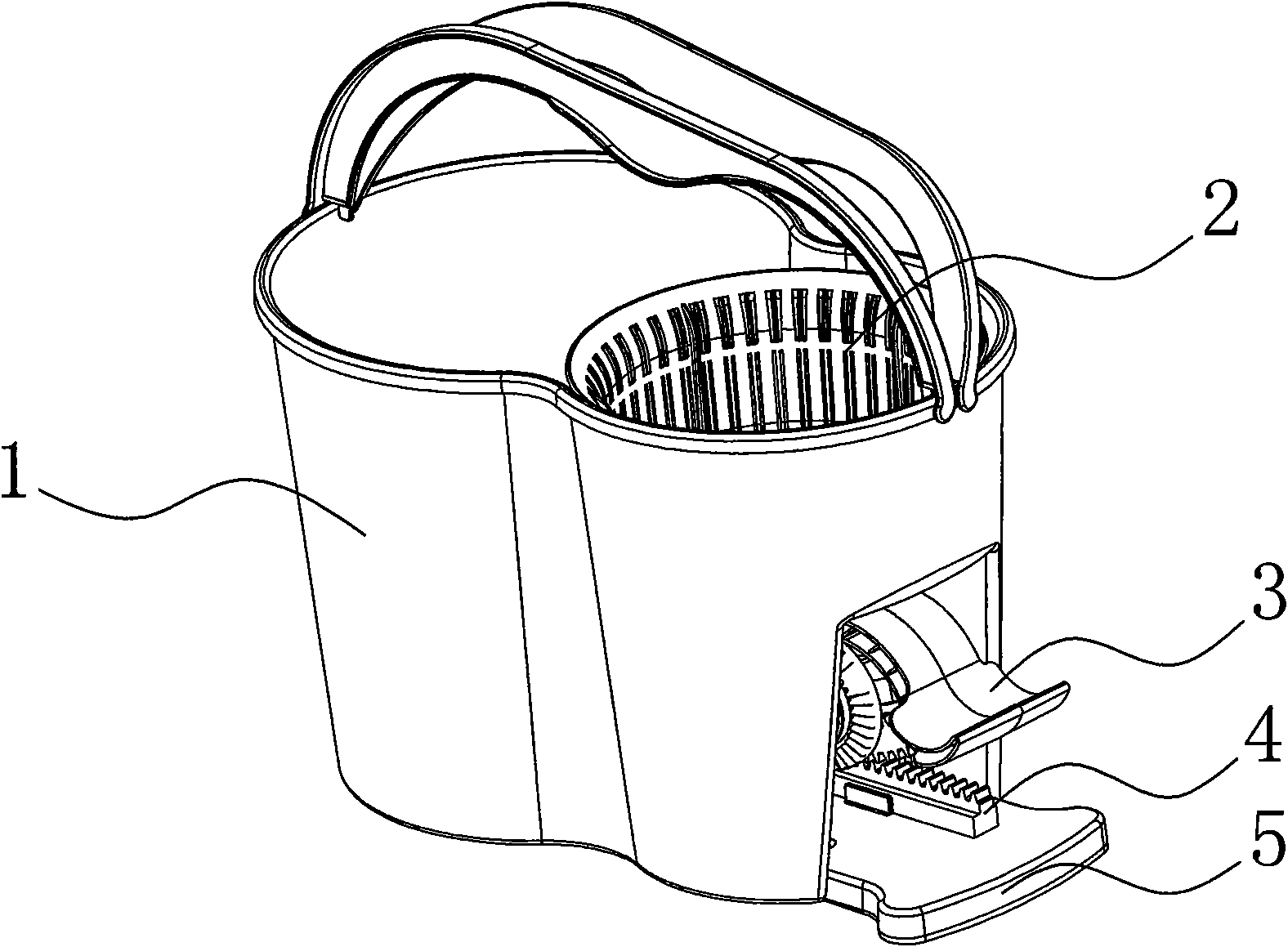

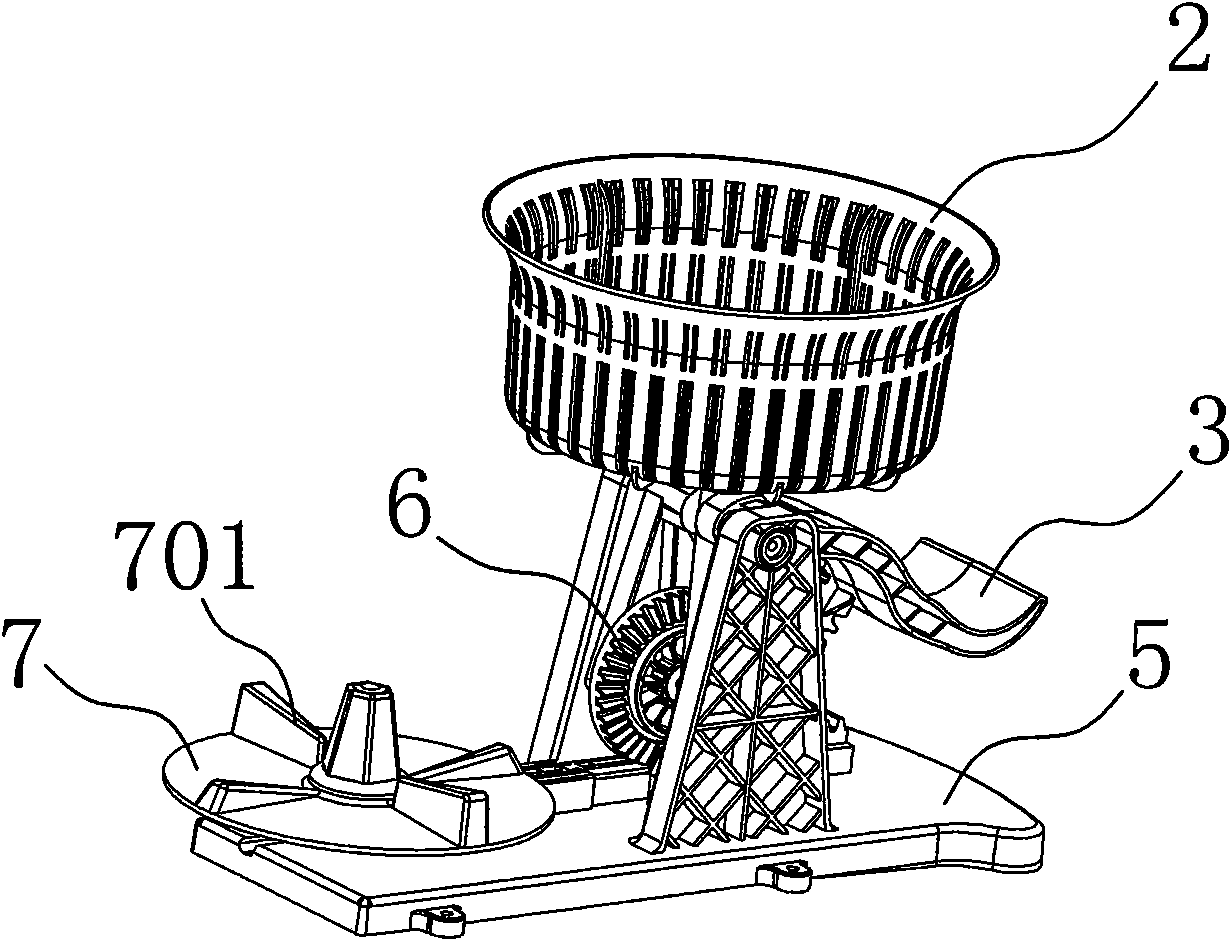

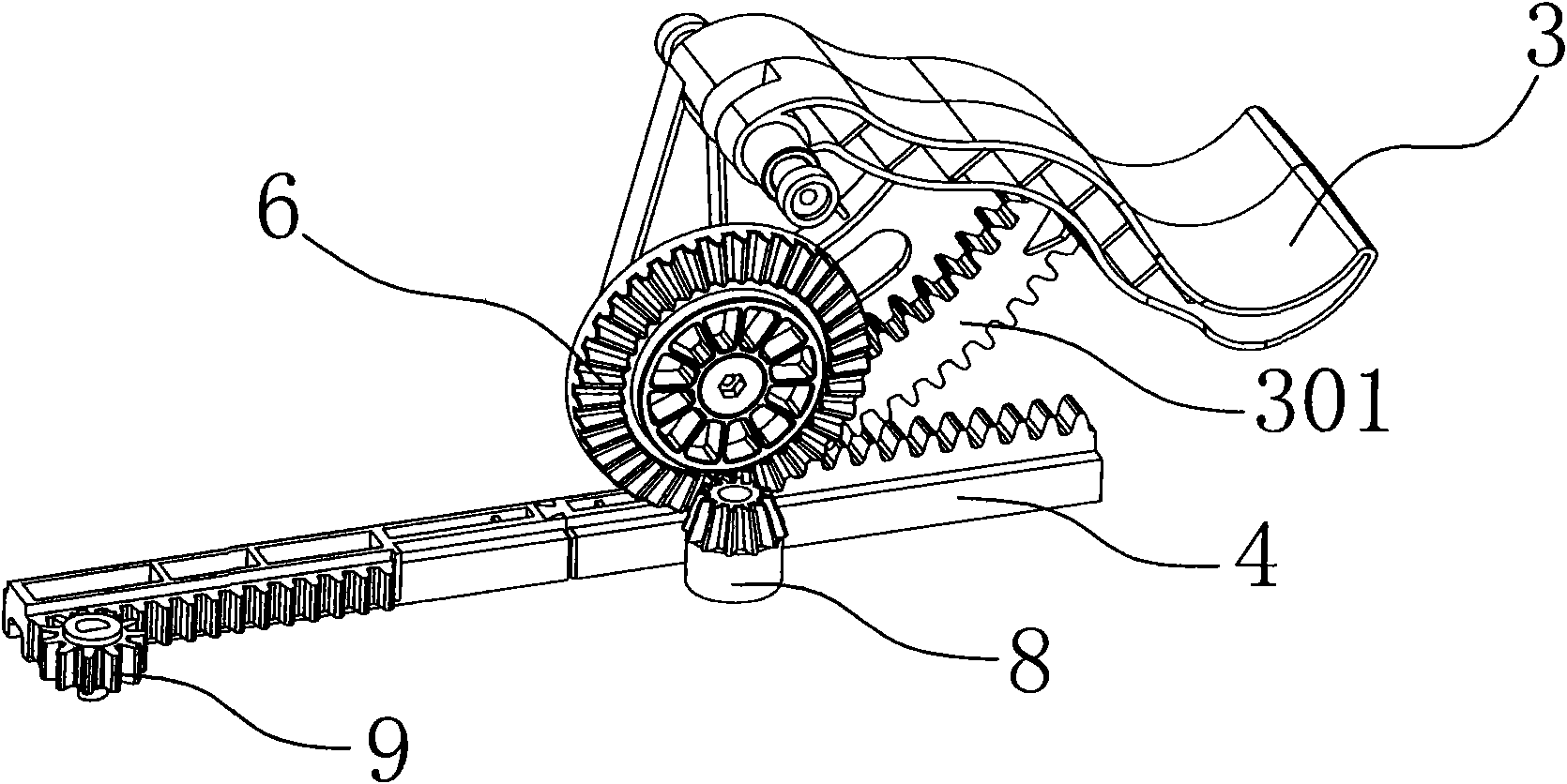

[0023] The present invention will be further described now in conjunction with accompanying drawing. The names of the serial numbers in the figure are: bucket body 1, water throwing frame 2, pedal 3, sector gear 301, guide groove 302, rack 4, base 5, bracket 501, slideway 502, spring stopper 503, spring groove 504 , guide block 505, extended boss 506, combined gear 6, large bevel gear 601, small cylindrical gear 602, rotating shaft 603, stirring disc 7, stirring blade 701, bevel gear 8, stirring disc gear 9.

[0024] Such as Figure 1 to Figure 6 As shown, the mop cleaning and drying barrel is composed of a barrel body 1, a treadle mechanism, a water rejection frame 2, and an agitation plate 7, wherein the treadle mechanism includes a treadle 3, a base 5, a rack 4, a combined gear 6, a bevel gear 8, Agitating disc gear 9, bevel gear is connected to the water throwing frame by bar shaft, and agitating disc gear is connected agitating disc by bar shaft. The specific connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com