Binocular wet sludge drying equipment

A wet sludge and equipment technology, applied in the field of urban sewage sludge drying, can solve the problems of low heat exchange efficiency, high dust volume, large heat loss, etc., and achieve the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

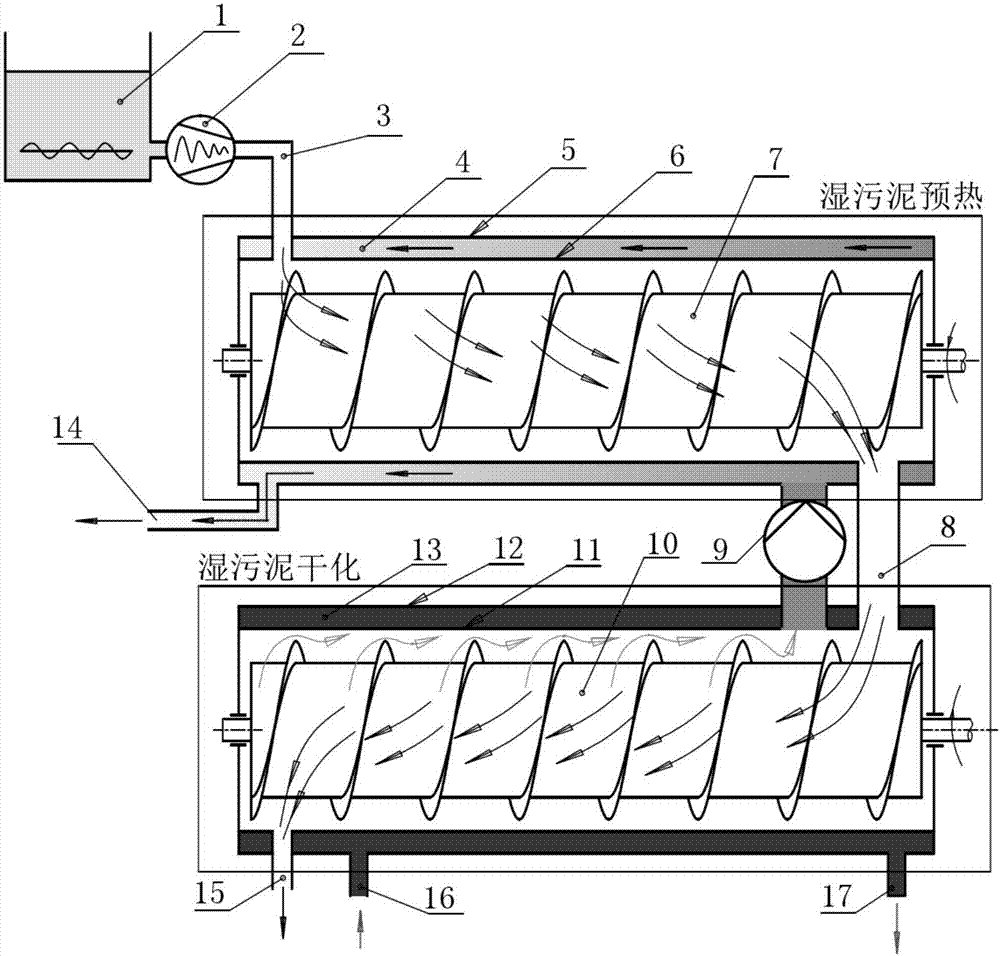

[0014] The double-tube wet sludge drying equipment involved in this embodiment is as follows: figure 1 As shown: the equipment includes a sludge pump 2, a preheating cylinder liner 6, a pipe 3 connecting the sludge pump and the preheating cylinder liner, a preheating cylinder interlayer 4, a sludge pushing shaft I7, and a drying cylinder liner 11 , the sludge feeding pipe 8 connecting the inner tank of the preheating cylinder and the inner tank of the drying cylinder, the interlayer of the drying cylinder 13, the sludge pushing shaft II 10, the high-temperature fan 9 connecting the interlayer of the preheating cylinder and the inner tank of the drying cylinder, the preheating Heat cartridge shell 5 and drying cartridge shell 12.

[0015] The wet sludge 1 is transported by the sludge pump 2 to the liner 6 of the preheating cylinder, pushed toward the wet sludge outlet of the preheating cylinder under the action of the sludge pushing shaft I7, and enters the drying cylinder thro...

Embodiment 2

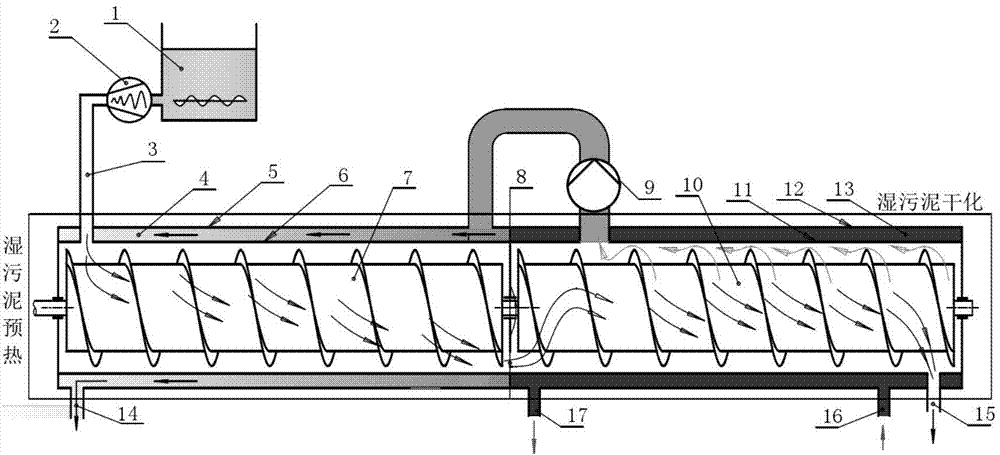

[0019] The double-tube wet sludge drying equipment involved in this embodiment is as follows: figure 2 As shown, the wet sludge preheating cylinder and the wet sludge drying cylinder are connected as a coaxial body, the preheating cylinder liner 6 and the drying cylinder liner 11 are separated by an intermediate layer, and the preheating cylinder interlayer 4 and The interlayer 13 of the drying cylinder is also separated by the above-mentioned middle spacer, and the middle spacer is provided with a sludge discharge channel 8 .

Embodiment 3

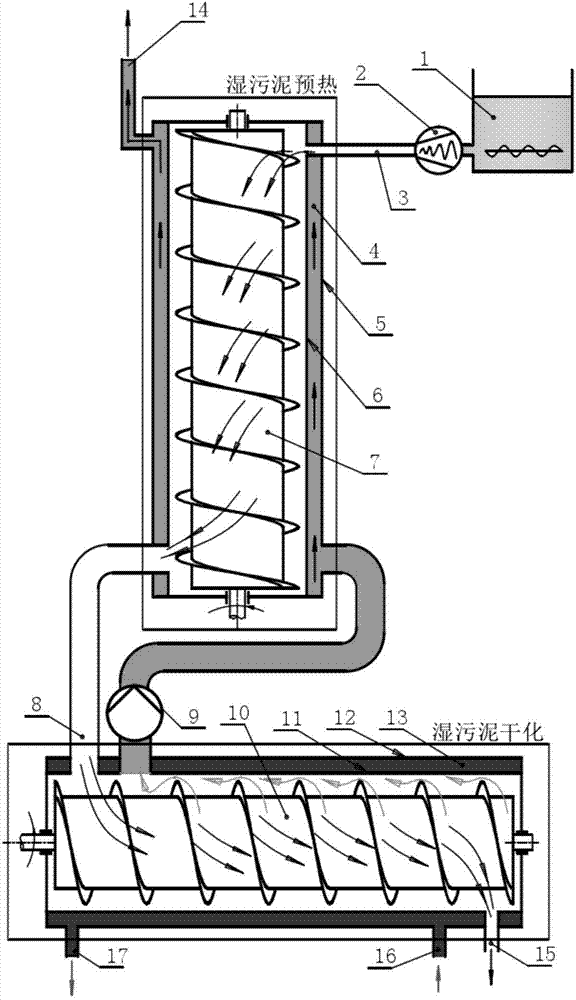

[0021] The double-tube wet sludge drying equipment involved in this embodiment is as follows: image 3 As shown, the wet sludge preheating cylinder is arranged vertically, and the wet sludge drying cylinder is arranged horizontally.

[0022] The preheating stage and water evaporation stage in the wet sludge drying process of the above embodiment are carried out in two devices respectively, which improves the drying efficiency, and at the same time, the energy of the high-temperature steam generated in the water evaporation stage is used for the preheating stage The required heat improves energy efficiency. At the same time, this energy recovery method without intermediate links also greatly simplifies the entire drying system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com