Intelligentized air dryer

An air dryer and dryer technology, used in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem that the molecular sieve recoil regeneration function cannot be effectively used, the molecular sieve drying function fails, and the unloading pressure of the dryer is delayed. In order to avoid the difficulty of recoil regeneration of molecular sieve, compact structure and improve lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

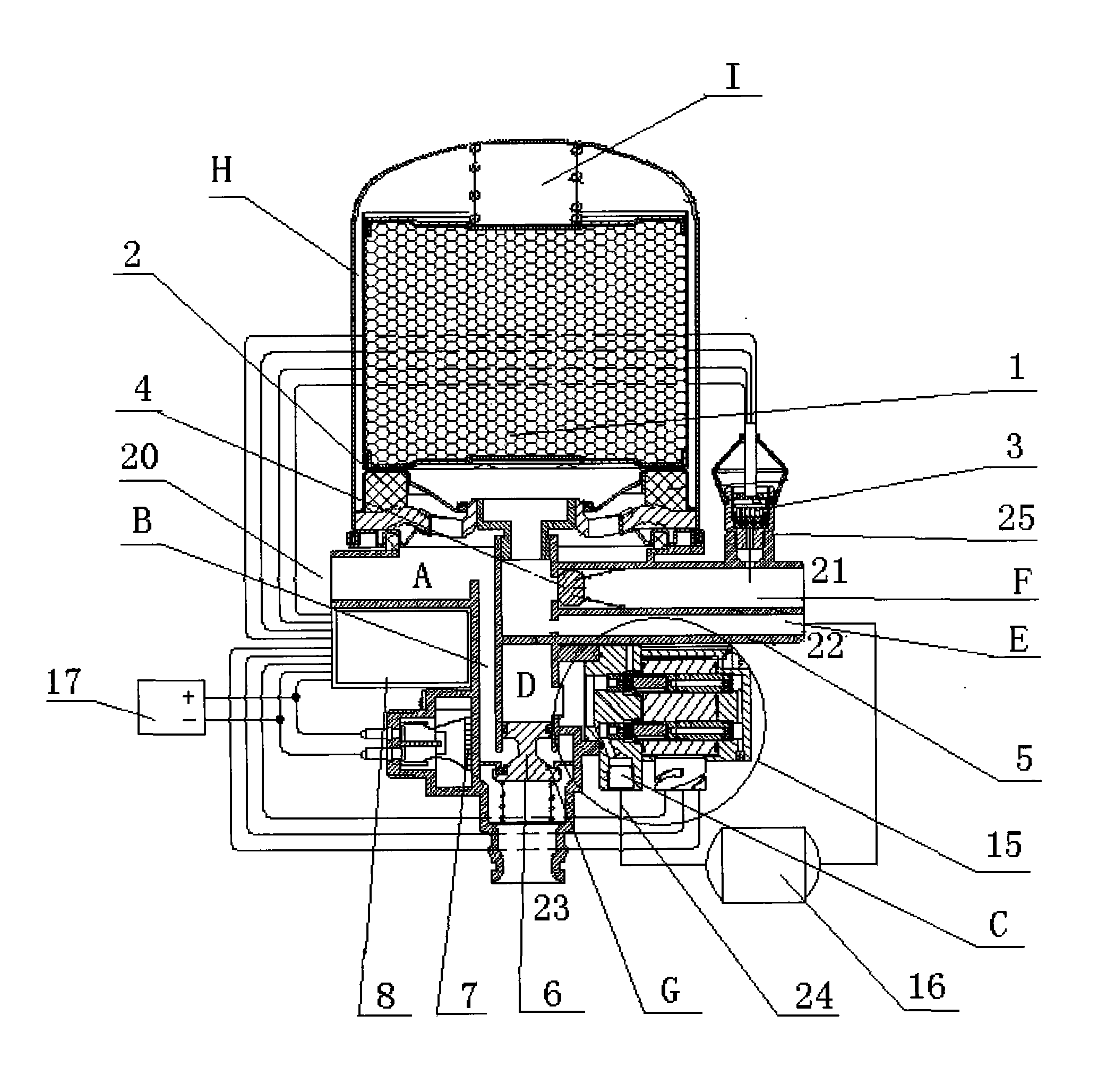

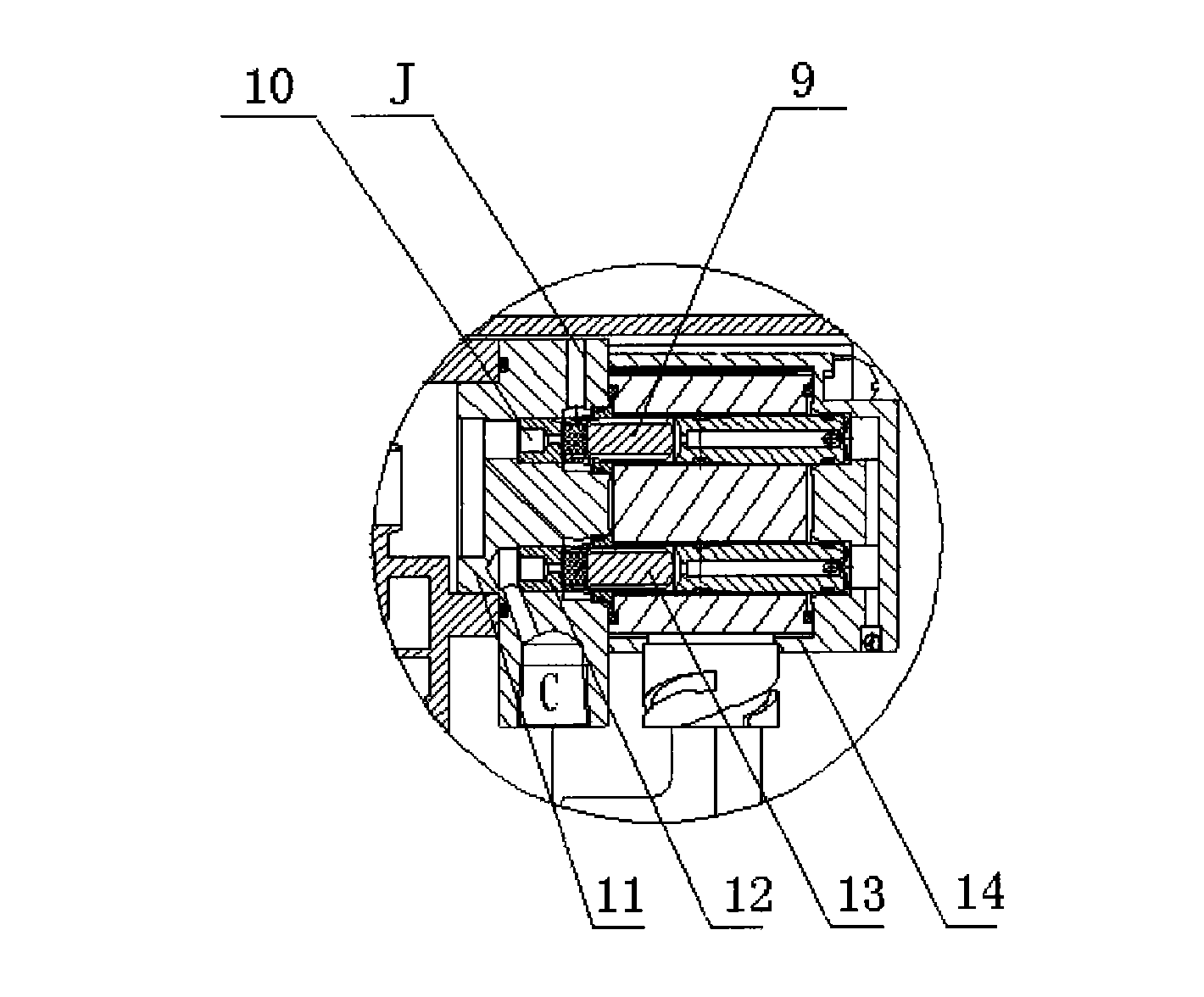

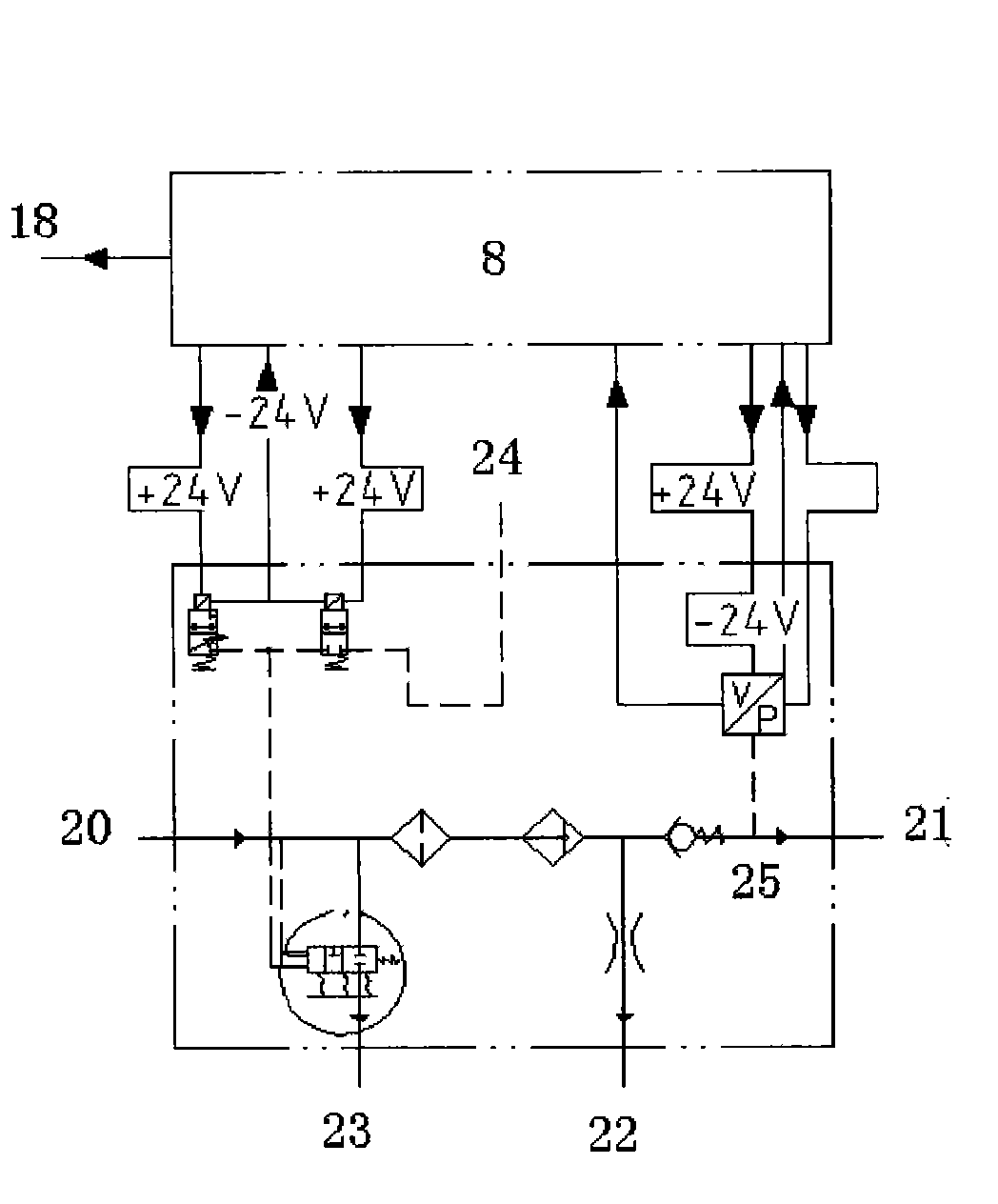

[0019] The accompanying drawings show the best embodiment of the intelligent air dryer of the present invention. As shown in the figure, the drying cylinder assembly of the air dryer is installed on the matching base assembly. The air drying cylinder assembly has a desiccant 1 for water absorption and a filter 2 for oil absorption and dust prevention, wherein the filter 2 is placed on the lower and outside of the drying cylinder assembly, and the desiccant 1 is placed on the upper part of the drying cylinder assembly. inside. An annular channel H is connected between the filter 2 and the desiccant 1 . The air inlet 20 is connected with an air compressor (not shown in the figure). The pressure reading device 3 is directly threaded on the pressure reading port 25 of the dryer valve body 5, and reads the air pressure at the upper port 21 of the air output at all times, and converts the read output air pressure signal of the dryer into a voltage signal for feedback. Give the EC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com