Full-automatic power shell ultrasonic cleaning machine

An ultrasonic, fully automatic technology, applied in cleaning methods and utensils, cleaning methods using liquids, drying of solid materials, etc., can solve the problems of workpiece quality damage, cleaning liquid residue, incomplete drying of workpieces, etc., to improve quality, reduce Residual, dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

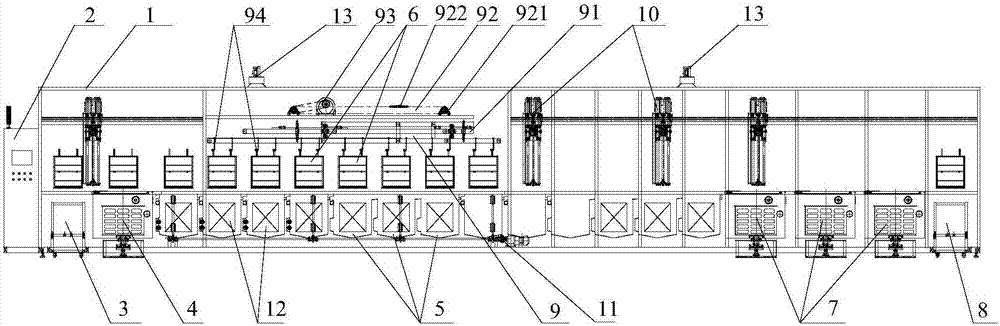

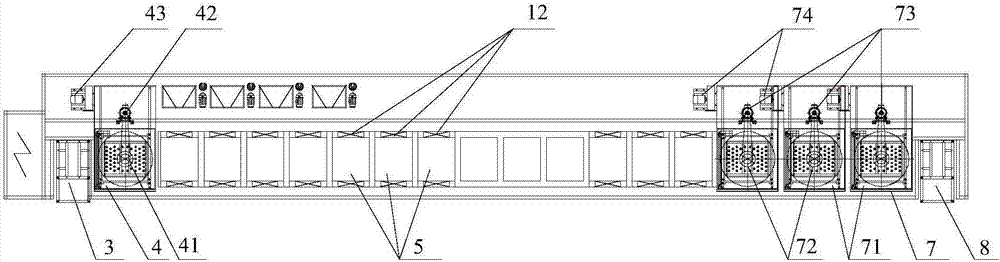

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 1-2 As shown, a fully automatic power shell ultrasonic cleaning machine includes a frame 1, a feeding table 3 arranged in sequence along the feeding direction on the frame 1, at least one cleaning tank 5 for holding cleaning liquid, and a Dry tank 7, unloading table 8, the fully automatic power shell ultrasonic cleaning machine also includes a cleaning container 6 hollowed out on the surface for loading workpieces, and a drive set on the frame 1 for driving the cleaning container 6 to move along the feeding direction mechanism, and the drive mechanism is also used to drive the cleaning container 6 to lift up and down in the vertical direction. The fully automatic power shell ultrasonic cleaning machine is controlled as a whole through the main control electric cabinet 2.

[0021] In this embodiment, a loading trolley and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com