Drying device for water jet loom

A technology of drying device and water jet loom, which is applied in drying, drying machine, heating device, etc., can solve the problems of huge boiler equipment, incomplete drying of cloth, unfavorable long-term storage of cloth rolls, etc., and achieve long-term The effects of preservation and drying are thorough, and the equipment occupies a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

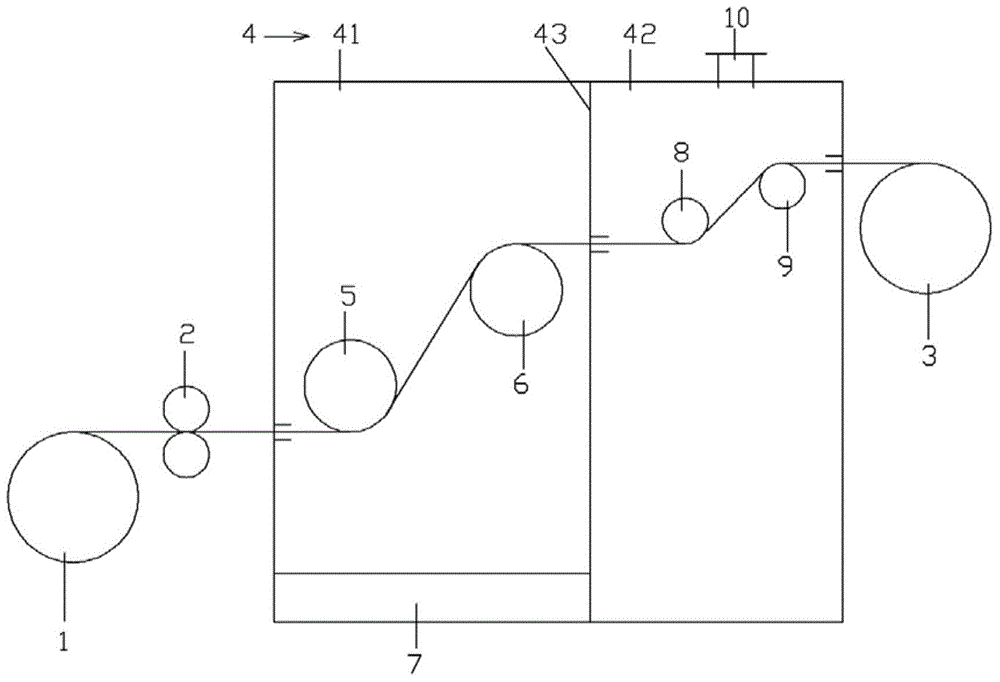

[0014] Example: see figure 1 , 2 As shown, the drying device of the water jet loom includes a cloth feeding roller 1, a cloth feeding pressure roller 2 and a cloth receiving roller 3, and the drying box 4 is divided into a main drying chamber 41 and an auxiliary drying chamber by a partition 43 42. The first front drying roll 5 and the first back drying roll 6 are installed in the main drying chamber 41, and the second front drying roll 8 and the second back drying roll 9 are installed in the attached drying chamber 42;

[0015] The lower part of the main drying chamber 41 is provided with a water receiving tank 7, and the attached drying chamber 42 is provided with an air outlet 10 communicating with the outside;

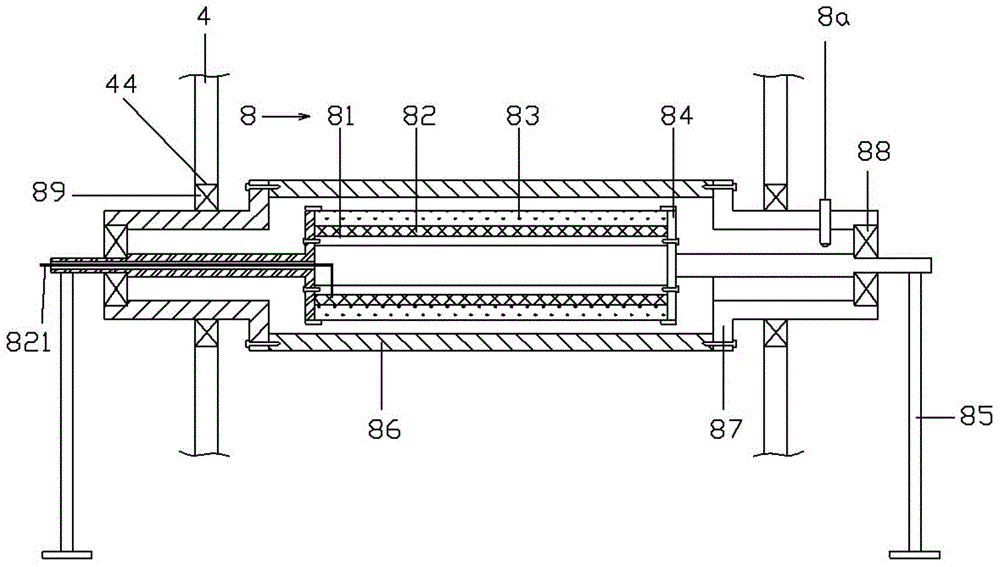

[0016] The first front drying roller 5, the first back drying roller 6, the second front drying roller 8 and the second back drying roller 9 have the same structure and are all electromagnetic heating rollers, and the cloth is released by the cloth feeding roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com