Hot oil spray and drying device and method for converter transformer

A converter transformer and spray drying technology, applied in the field of transformers, can solve the problems of insulation breakdown, internal discharge of the transformer, and water discharge without reliable drying measures, and achieve fast spraying speed, improve work efficiency and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] 1. Preparation before drying

[0041] The drying of the converter body is mainly to dry the insulating parts and other materials inside the converter body. Due to the site conditions, the converter can only be slightly modified and then sprayed with hot oil.

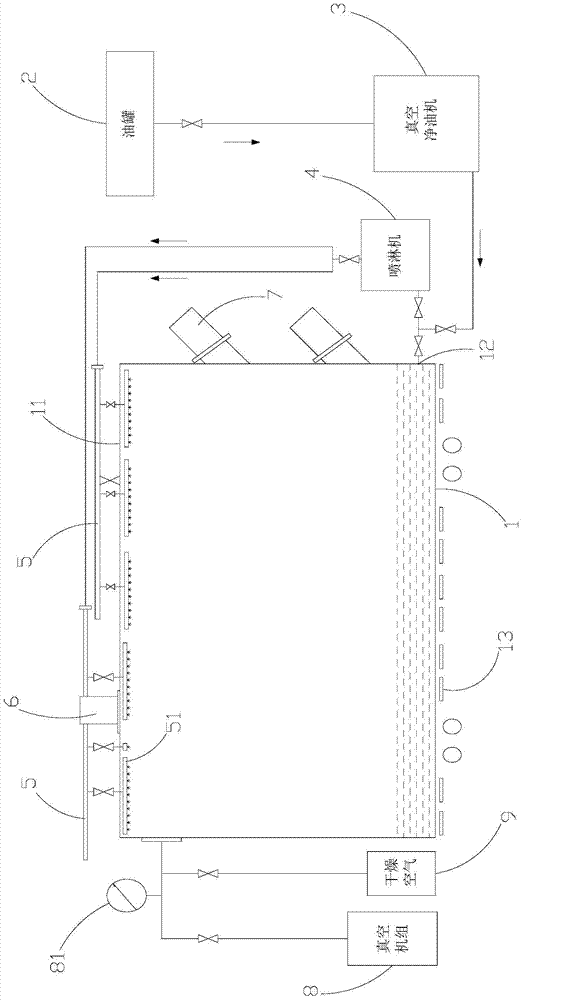

[0042] The method we adopt is to install a sprinkler head on the cover of the converter box, and spray hot oil with a temperature as high as 120°C into the sealed chamber 1 through the nozzle, so as to achieve the purpose of drying the accessories in the converter box. Each spray head is connected to each branch oil pipe, and the branch oil pipes are collectively connected to the general spray oil pipe. The general spray oil pipe is connected to the oil outlet of the hot oil sprayer, and the transformer oil after the hot oil spray is collected in the The bottom of the converter box, through the oil outlet at the bottom of the converter box, flows back into the sprayer to be heated and then flows out from the oil o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com