Textile drying device

A drying device and textile technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of affecting the production efficiency of textiles, rapid heat loss of drying box, single heat source of drying machine, etc. The drying time is saved, the structure is simple, and the drying efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

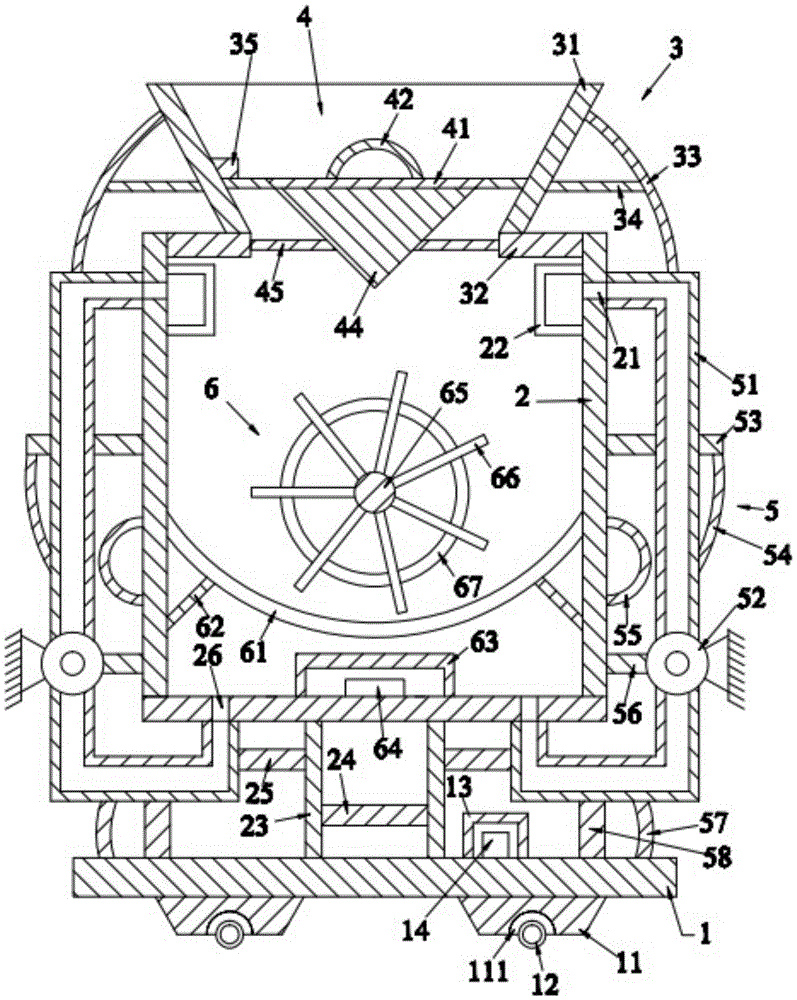

[0020] Such as figure 1 As shown, the textile drying device of the present invention includes a bottom plate 1, a frame located above the bottom plate 1, a feeding device 3 located above the frame 2, and a cover device 4 located in the feeding device 3 , Air circulation devices 5 located on the left and right sides of the frame 2 and heating devices 6 located in the frame 2.

[0021] Such as figure 1 As shown, the bottom plate 1 is a rectangular parallelepiped, the bottom plate 1 is placed horizontally, and the bottom plate 1 is provided with a first support block 11 below it, a first roller 12 located below the first support block 11, and A fixed frame 13 above the bottom plate 1 and a power source 14 located in the fixed frame 13. The first support blocks 11 are provided with two and are respectively located on the left and right sides below the bottom plate 1. The first support blocks 11 are columns with an isosceles trapezoid in cross section, and the first support blocks 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com