Convenient-to-assemble carved pattern type aluminum alloy door window

An aluminum alloy door and window, aluminum alloy technology, applied in windows/doors, metal processing equipment, door/window protection devices, etc., can solve the problems of cumbersome operation, lack of convenient installation mechanism, etc., achieve scientific and reasonable structure, and avoid wall strength The decline, the effect of optimizing the use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

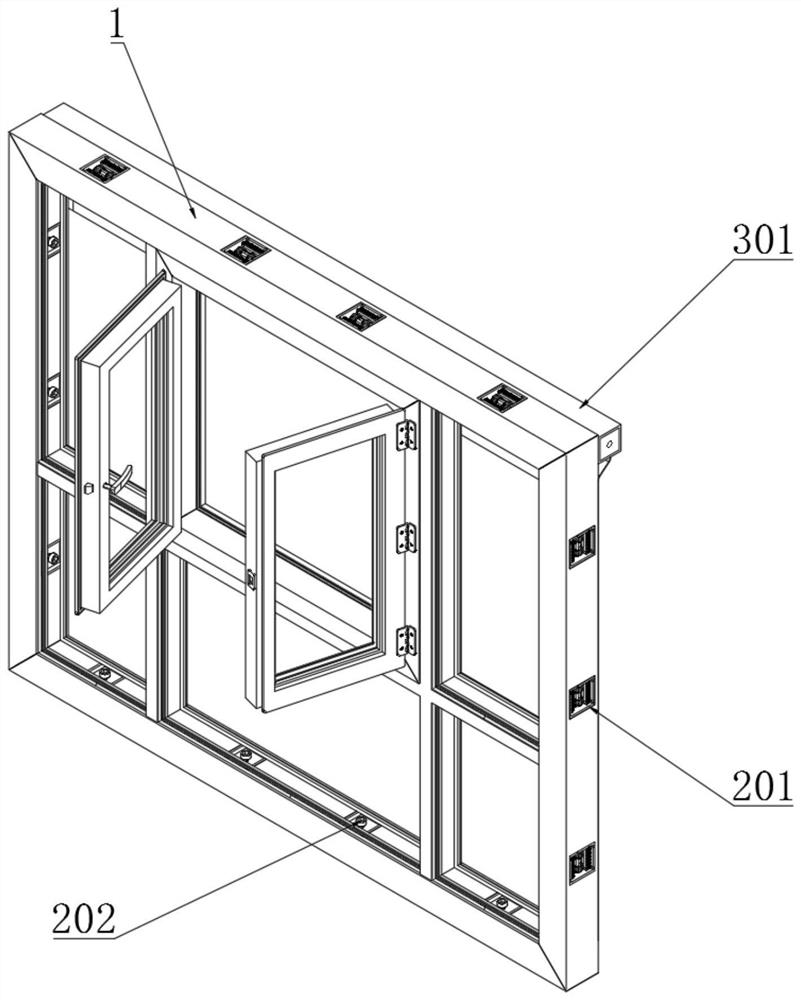

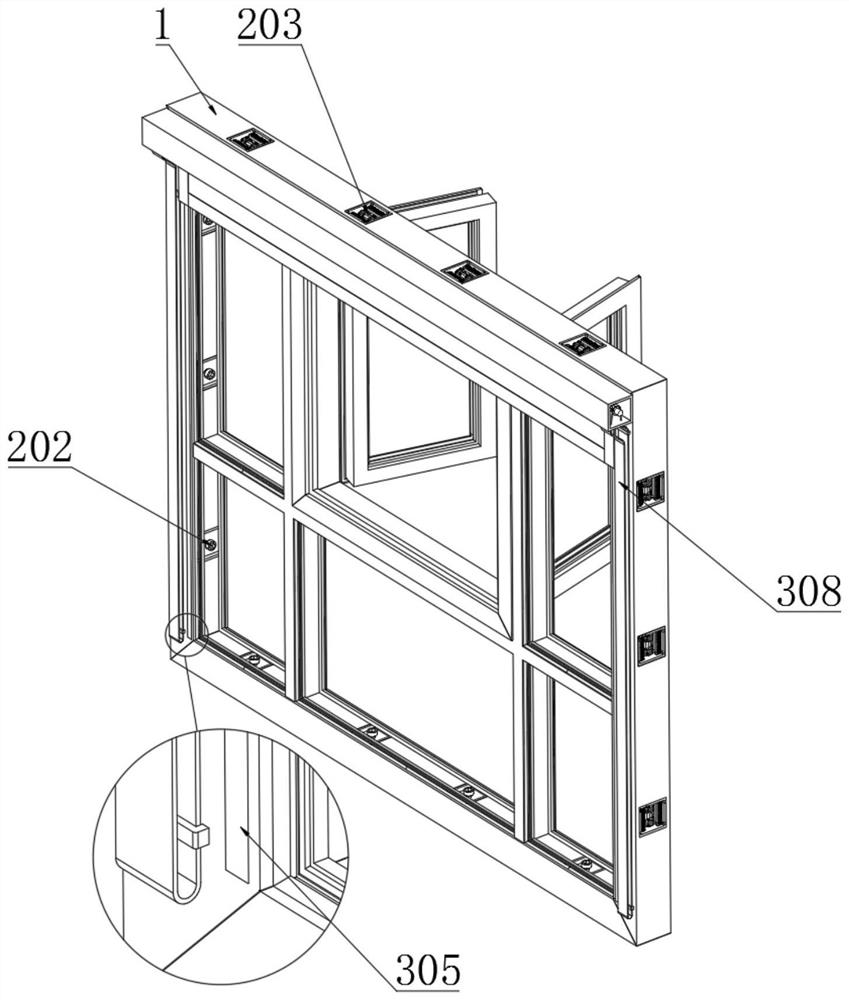

[0054] Example: such as Figure 1-13 As shown, the present invention provides a technical solution, an easy-to-install engraved aluminum alloy door and window, including an aluminum alloy window frame main body 1, and a quick installation mechanism 2 is provided on the four outer sides of the aluminum alloy window frame main body 1;

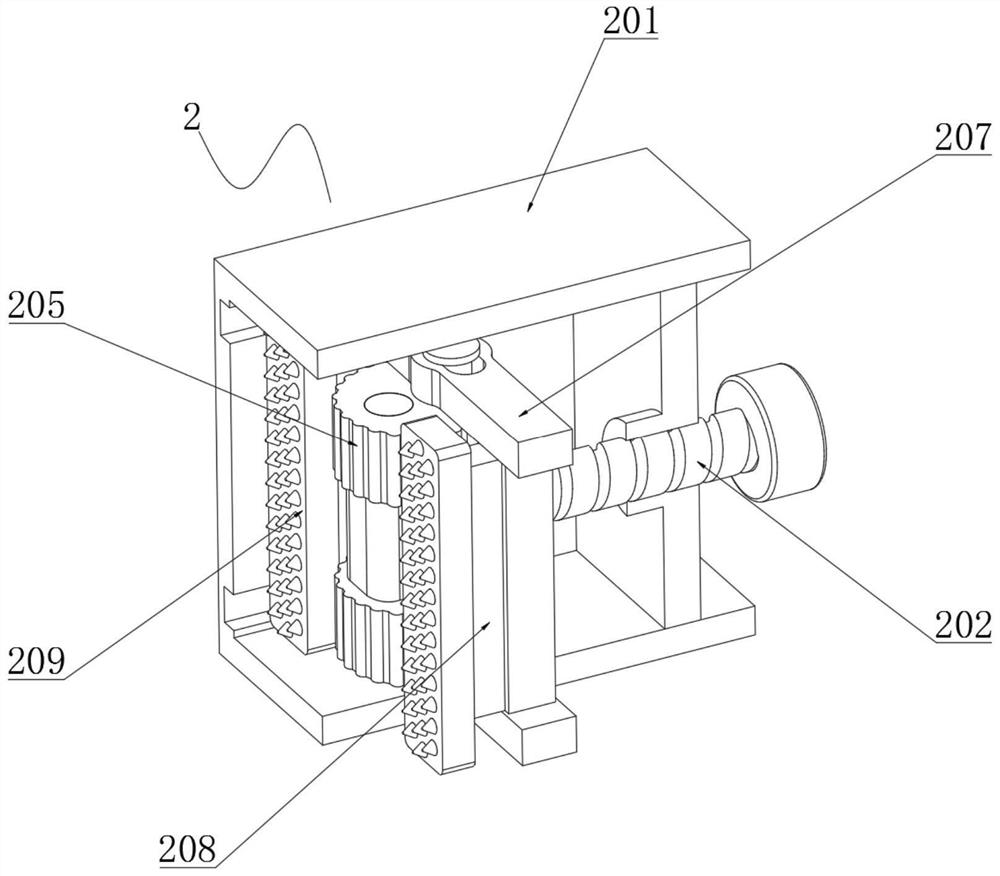

[0055] The quick installation mechanism 2 includes an installation box 201, an installation bolt 202, a driving block 203, an installation shaft 204, an eccentric installation wheel 205, a limit slide bar 206, a clamping slide bar 207, an installation block 208 and a clamping plate 209;

[0056] The four sides of the main body of the aluminum alloy window frame 1 are inlaid with installation boxes 201, and the middle part of one side of the installation box 201 is connected with installation bolts 202 through threads. The middle parts of both ends of 203 are rotatably connected with installation shaft 204, and the positions on both sides of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com