Yarn steaming and setting machine

A setting machine and yarn steaming technology, which is applied in the direction of liquid/gas/steam yarn/filament processing, textile material carrier processing, etc., can solve the problems of uneven heating and moisture absorption, different yarn thickness, low production efficiency, etc., and achieve shortening Steamed yarn setting time, the same thickness, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

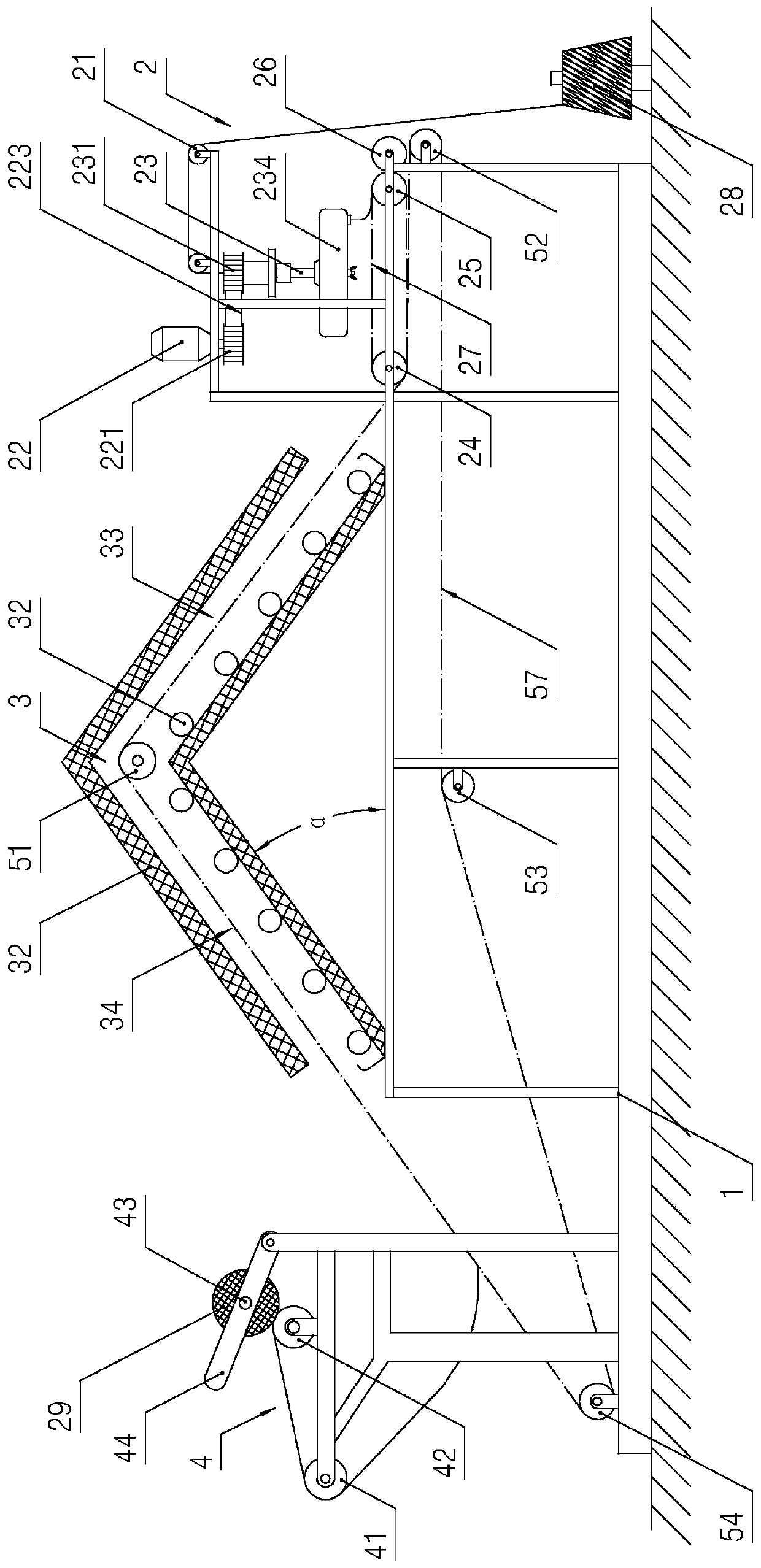

[0020] Attached below Figures 1 to 5 , describe in detail the specific implementation of a steamed yarn setting machine according to the present invention.

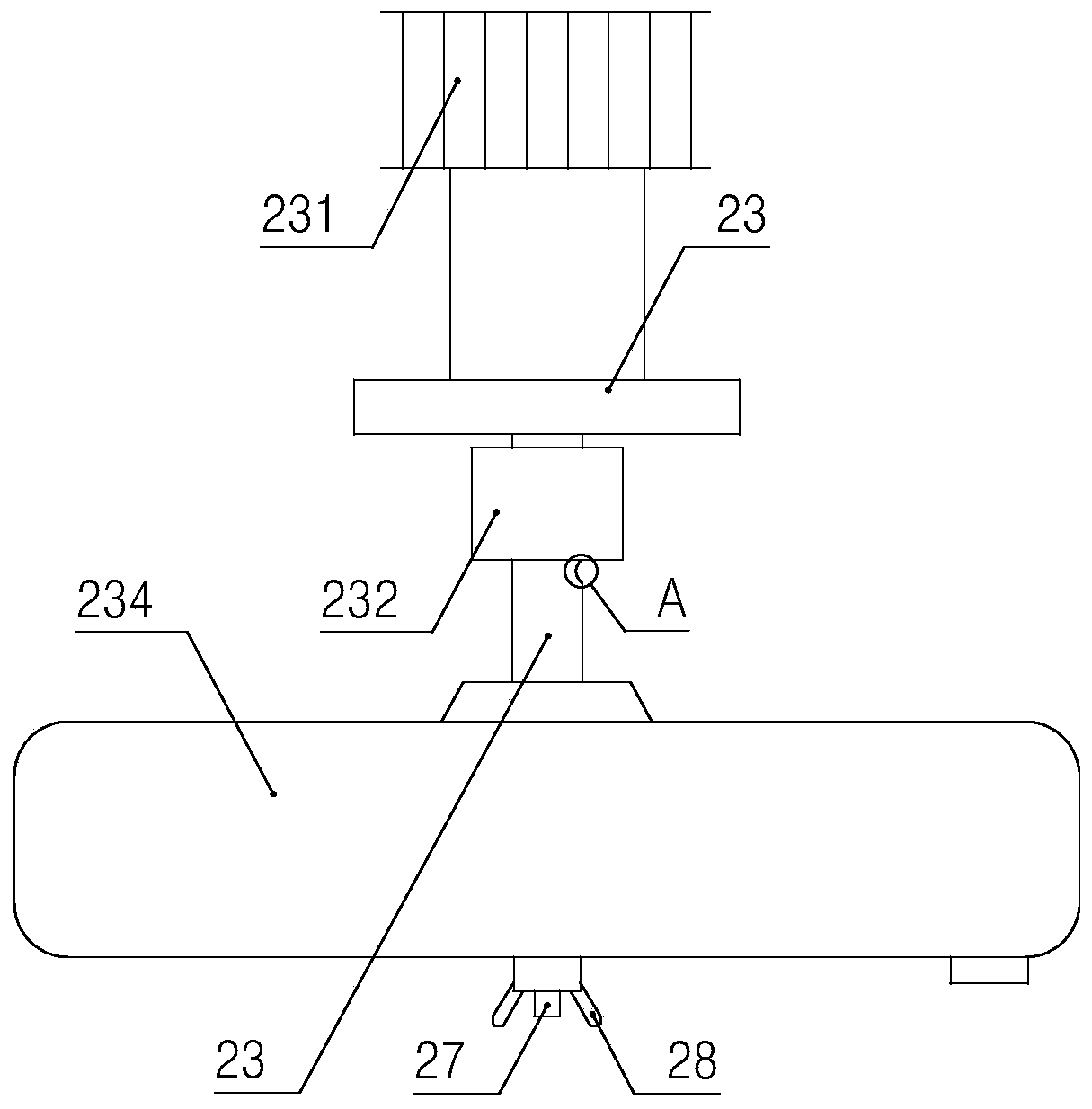

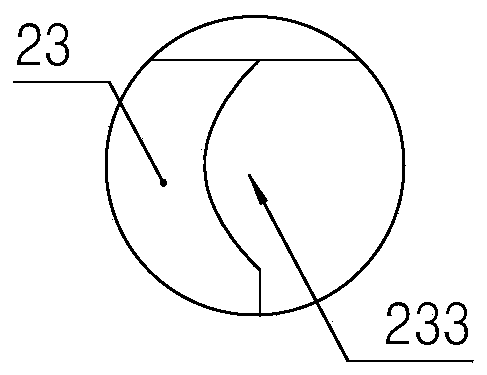

[0021] Such as figure 1 As shown, a steamed yarn setting machine according to the present invention has a structure comprising: a frame 1, and the two ends of the frame 1 are respectively provided with a yarn unwinding device for unwinding the package yarn into a yarn in a free slack state 2. And the yarn winding device 4 that winds the yarn in the free slack state into a bobbin. The middle part of the frame 1 is provided with a steaming channel 3 made of thermal insulation material 31, and the bottom of the steaming channel 3 is provided with The yarn steaming heating device constituted by the steam coil 32, along the traveling route of the yarn, the yarn steaming channel 3 includes: a symmetrically arranged upward slope section 33 and a downward slope section 34. The angle of the internal angle α formed between the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com