Rotary combined tray for forklift transmission assembly

A gearbox and pallet technology, which is applied in the field of rotary combined pallets, can solve the problems of time-consuming and laborious changing operation positions back and forth, low assembly efficiency, difficulty in manual lifting and turning over, etc., and achieves the effect of wide applicability of pallets and improved assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

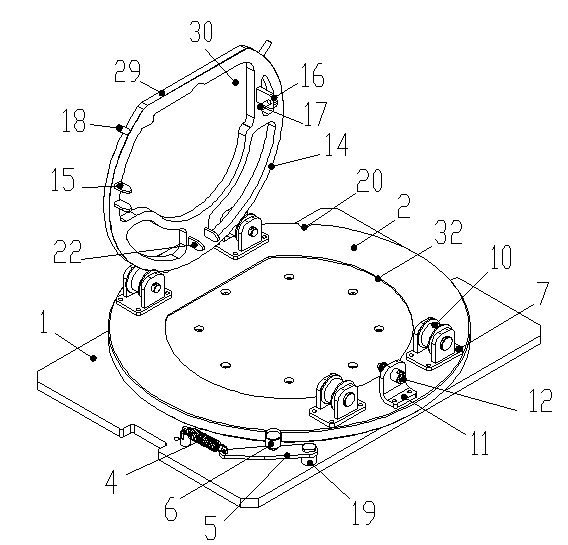

[0026] see figure 2 When in use, the auxiliary tray 14 is placed in the groove 32 in the middle of the main tray 2 at first. The hoisting gearbox 21 is placed on the upper end surface of the auxiliary pallet 14, and the side limit block 15 and the lower limit block 22 on the auxiliary pallet 14 limit the workpiece from two directions. The side compression block 16 on the auxiliary pallet 14 is equipped with a compression bolt 17, and the compression bolt 17 locks the gearbox 21 and the auxiliary pallet 14 into one body. Now the gearbox is positioned on the main tray 2 with an upright posture, and the assembly operation of the gearbox 21 top can be carried out, such as the dismounting of the upper support 31 of the gearbox, the installation of the screw umbrella in the upper chamber of the gearbox, etc.

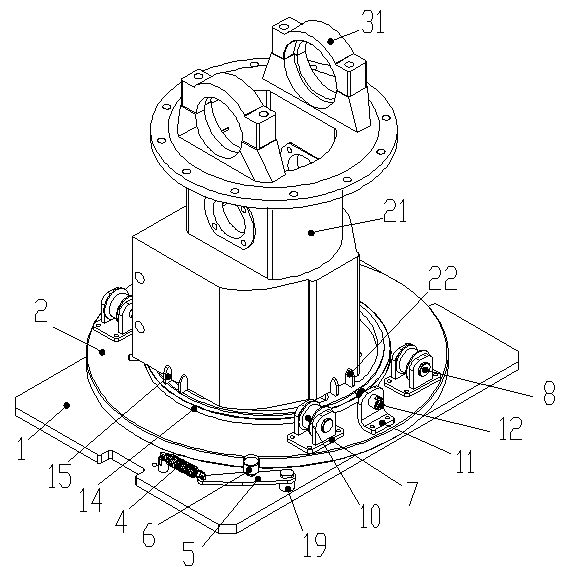

[0027] see image 3 , when performing the operation on the other end of the gearbox, place the connected gearbox 21 and auxiliary tray 14 upside down on the main tray 2, th...

Embodiment 2

[0029] see Figure 4 , when it is necessary to assemble the inner chamber of the gearbox, place the connected gearbox 21 and auxiliary tray 14 components on the main tray 2 lying down, and place the flange of the gearbox 21 on a pair of rollers 10. The positioning pin 12 is inserted into the flange hole on the flange of the gearbox 21, and the auxiliary tray 14 is placed on the other pair of rollers 10. At this time, the gearbox 21 is positioned on the main tray 2 in a lying state, and one end of the auxiliary tray 14 The straight rib 29 is just in time flush with the outer plane of the gearbox inner cavity. Assembly operations for gearbox cavity accessories, such as the installation of the shift fork assembly 26, can be performed from above.

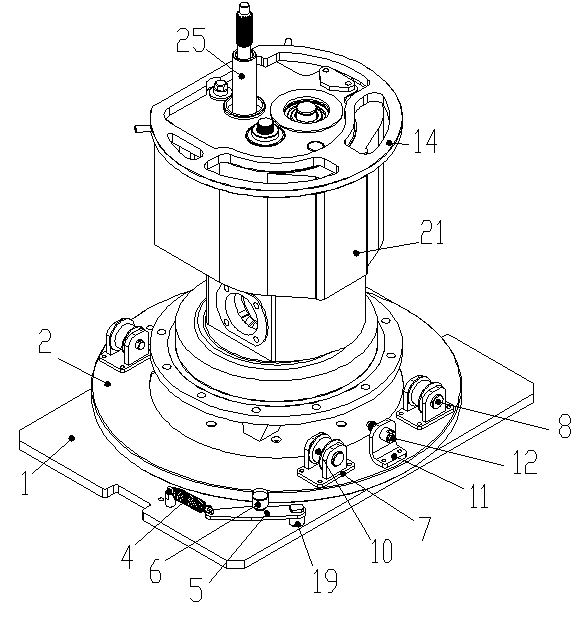

[0030] see Figure 5 When assembling the large end 27 of the helical gear assembly of the gearbox, the positioning pin 12 is pulled out, and the double circle formed by the gearbox 21 through its flange and the auxiliary tray 14 rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com