Textile sterilization device

A disinfection device and technology for textiles, applied in textiles and papermaking, disinfection, mechanical cleaning, etc., can solve the problems of poor disinfection effect, weak ultraviolet penetration ability, poor disinfection effect of textiles, etc., achieve good disinfection effect and improve disinfection Effect, the effect of improving the bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

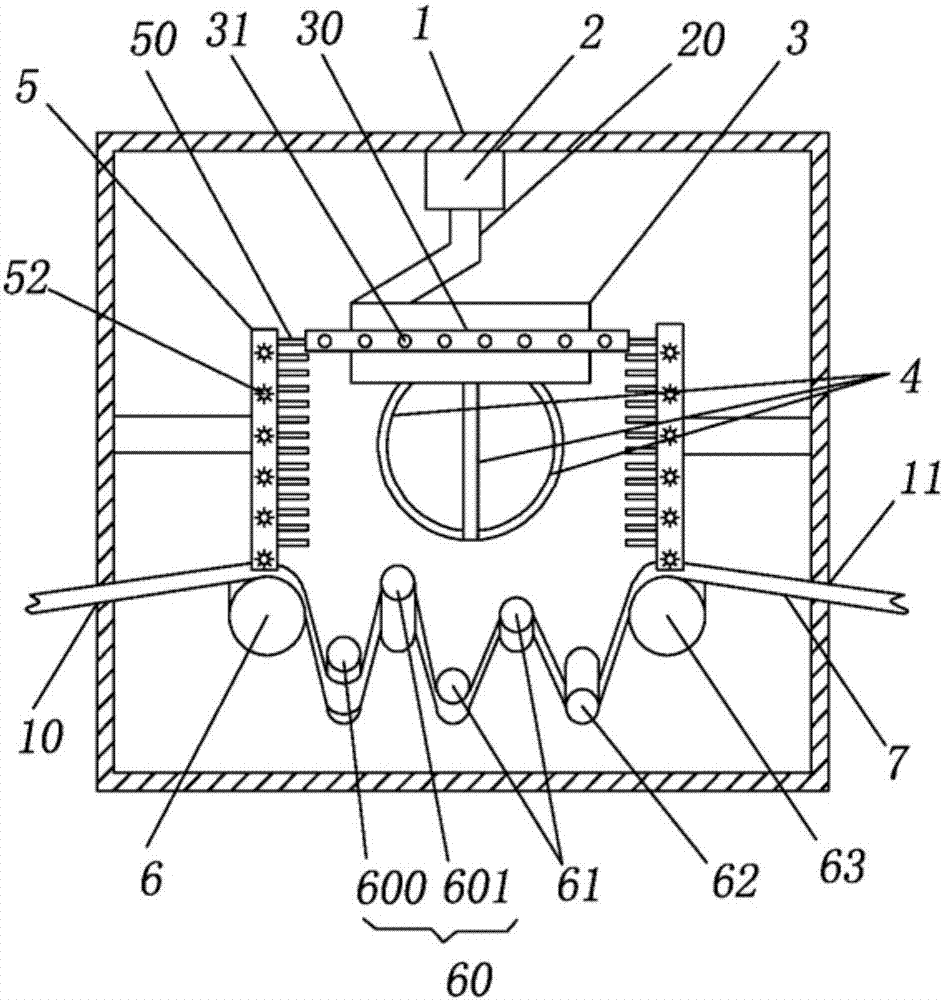

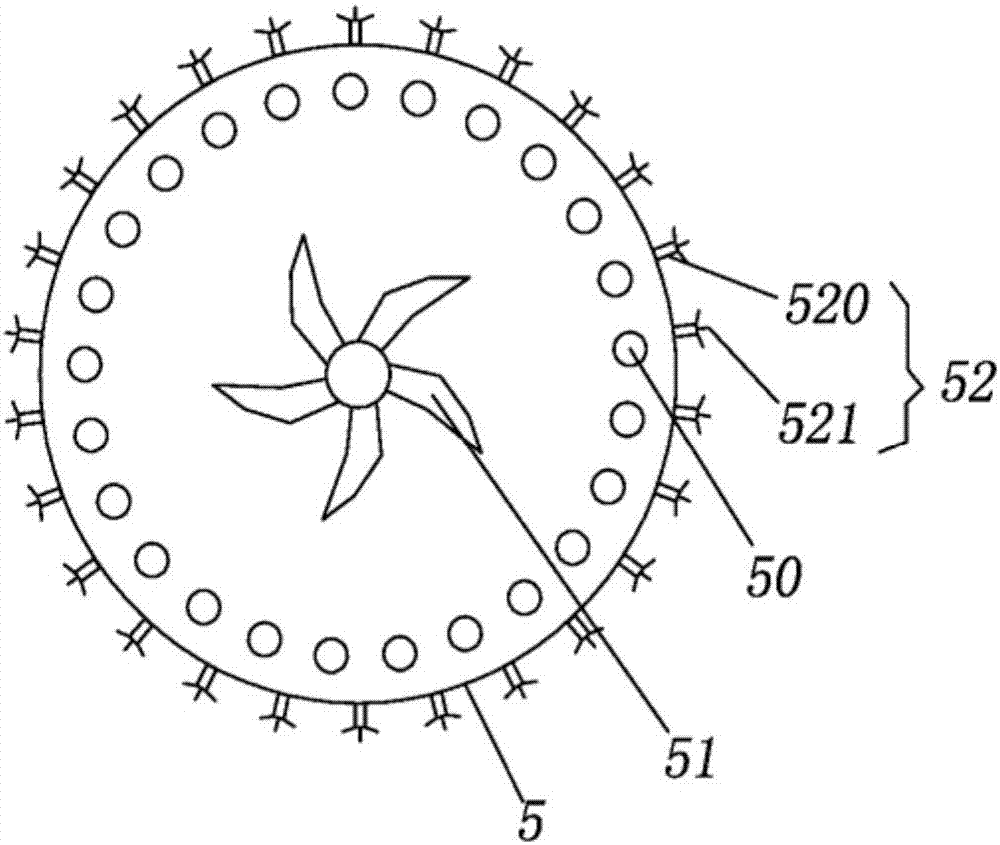

[0020] The reference signs in the drawings of the description include: disinfection chamber 1, material inlet 10, material outlet 11, motor 2, turning lever 20, rotating disk 3, gear ring 30, pinhole 31, ultraviolet lamp 4, cleaning disk 5 , convex pin 50, rotating blade 51, brush 52, connecting column 520, perforated hair 521, feed roller 6, first turning roller pair 60, turning roller one 600, turning roller two 601, second turning roller pair 61, End turning roller 62, discharge roller 63, textile 7.

[0021] The embodiment is basically as figure 1 As shown: a textile disinfection device, including a disinfection chamber 1, the left side wall of the disinfection room 1 is provided with a material inlet 10, and the right side wall is provided with a material outlet 11. The disinfection chamber 1 is provided with a motor 2, a rotating disc 3, an ultraviolet lamp 4, a transmission roller group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com