Secondary processing device for caking feed

A technology for secondary processing and feed, applied in heating devices, feed, drying solid materials, etc., can solve the problems of inability to dry feed, low screening efficiency, poor screening effect, etc., and achieve a high degree of automatic processing and screening efficiency. High, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

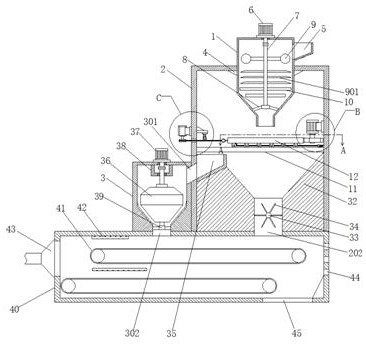

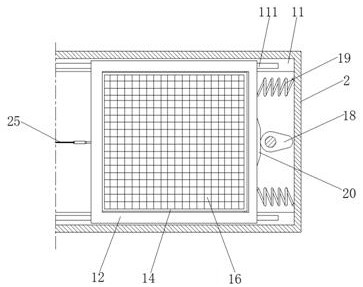

[0037] Embodiment 1 has introduced a kind of agglomerated feed secondary processing device, with reference to attached figure 1 , its main structure includes a crushing cylinder 1, a screening box 2 and a grinding cylinder 3. Among them, the crushing cylinder 3 is fixedly installed on the upper surface of the screening box 2, and in order to strengthen the connection stability between the two, there are also several welded joints between the outer circular surface of the crushing cylinder 3 and the top wall of the screening box 2. Triangular reinforcing ribs 4.

[0038] A feeding hopper 5 is arranged on the upper end of the outer circle of the crushing cylinder 3, and the feeding hopper 5 is arranged above the screening box 2, so that it is convenient to put agglomerated feed into it, and a discharge pipe is connected to the lower end of the crushing cylinder 3 5. Its discharge pipe 5 can lead the crushed feed into the screening box 2. The upper surface of the crushing cylin...

Embodiment 2

[0046] Embodiment 2 is a further improvement made on the basis of Embodiment 1, which mainly increases the drying structure of the whole secondary processing equipment for the sieved or crushed feed. Attached below figure 1 Describe it in detail.

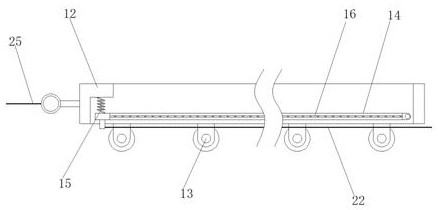

[0047] First of all, the similarities between the present embodiment 2 and the embodiment 1 will not be described again, and the difference is that the present embodiment 2 is also provided with a drying box 40 below the screening box 2 and the grinding cylinder 3, and the drying box 40 is provided with conveyor belt 41, and conveyor belt 41 is arranged on the below of fine material outlet 202, grinding material outlet 302, and the feed that both of them are discharged can fall on conveyor belt 41 and carry out transportation. A resistance heating wire 42 is arranged in the drying box 40, the left side of the drying box 40 is connected with an air supply pipe 43, and the right side of the drying box 40 is provided with an air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com