Preparation method and device of 4D printing material

A technology for printing materials and preparation devices, used in chemical instruments and methods, additive processing, transportation and packaging, etc., can solve problems such as poor high temperature resistance, and achieve the effects of good fluidity, small particle size and high spheroidization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

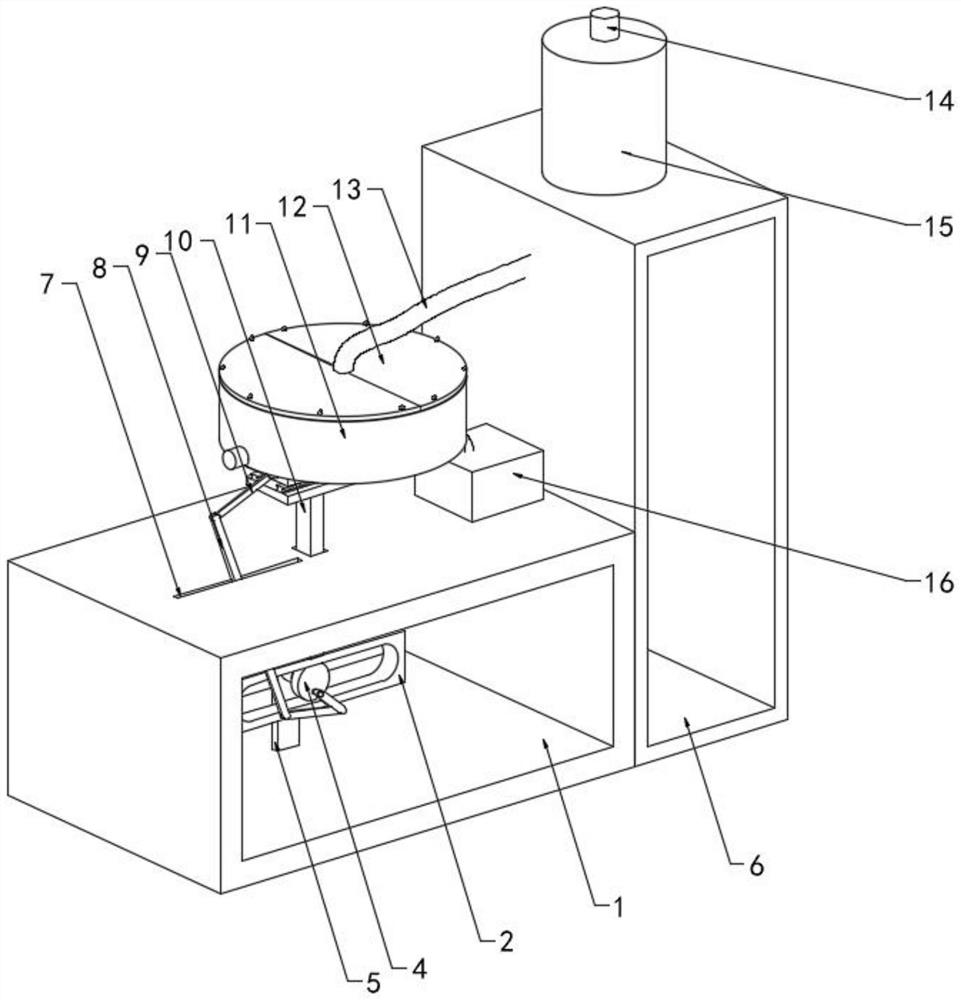

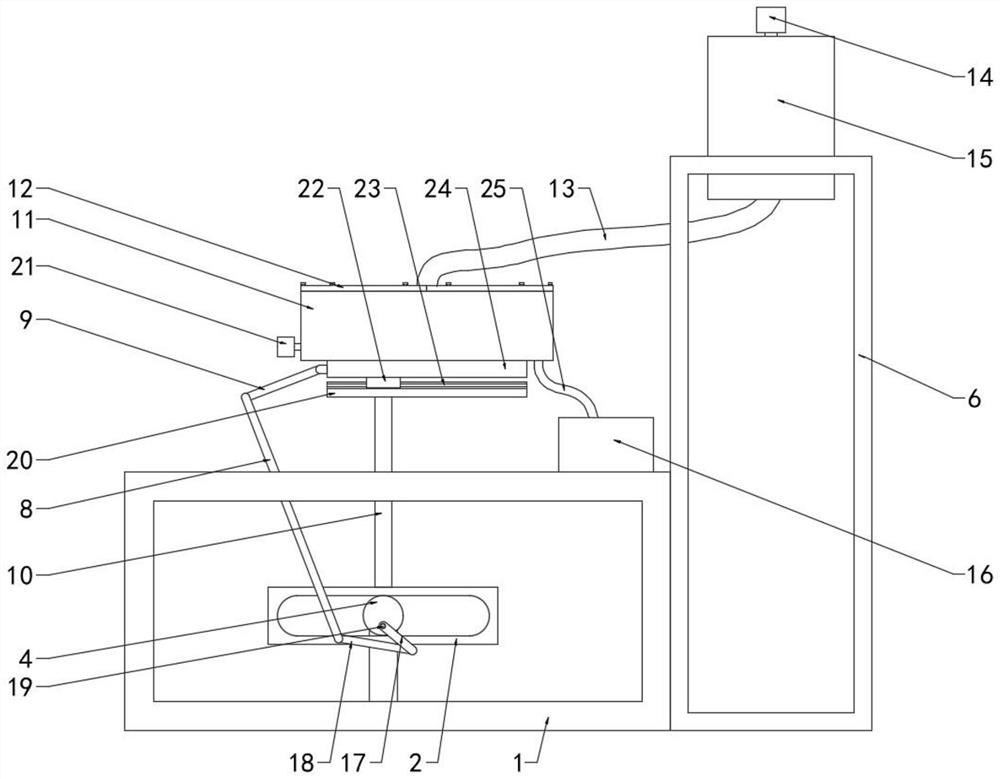

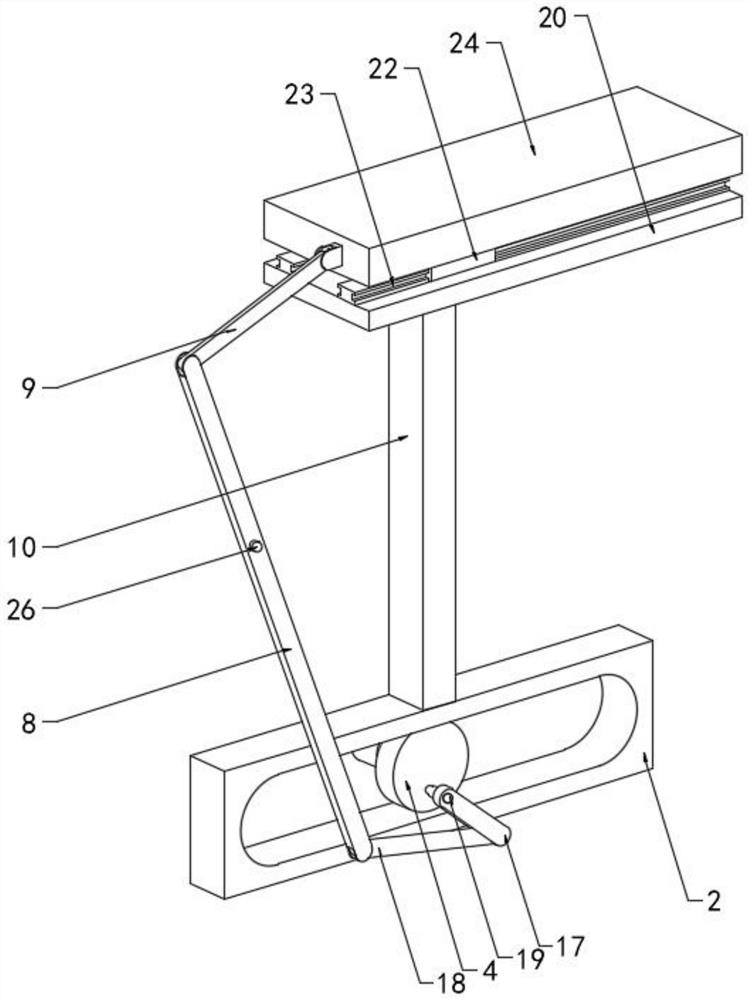

[0041] see Figure 1-8, the present invention provides a technical solution: a preparation device for 4D printing material, including a filter device, the filter device includes a bracket 1, the top of the bracket 1 is penetrated by a vertical rod 10 that moves in a vertical direction, and the top of the vertical rod 10 slides A sliding seat 24 that moves in the horizontal direction is connected, a fixed seat 20 is fixedly connected to the top of the vertical rod 10, an I-shaped guide rail 23 is fixedly connected to both sides of the top of the fixed seat 20, and the I-shaped guide rail 23 is fixedly connected to the top of the sliding seat 24. The sliding block 22 is slidably connected. The top of the sliding seat 24 is fixedly connected with the filter box 11. The top of the filter box 11 has a funnel-shaped inner cavity and the bottom has a rectangular inner cavity. The funnel-shaped inner cavity and the rectangular inner cavity are connected through a cylindrical channel. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com