Medical testing and sterilization device based on opposite-injection spray-wash technology

The technology of a disinfection device and a spray washing device is applied in the direction of disinfection, water supply equipment, and sanitary equipment for toilets. Improve the quality of disinfection and ensure the effect of disinfection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

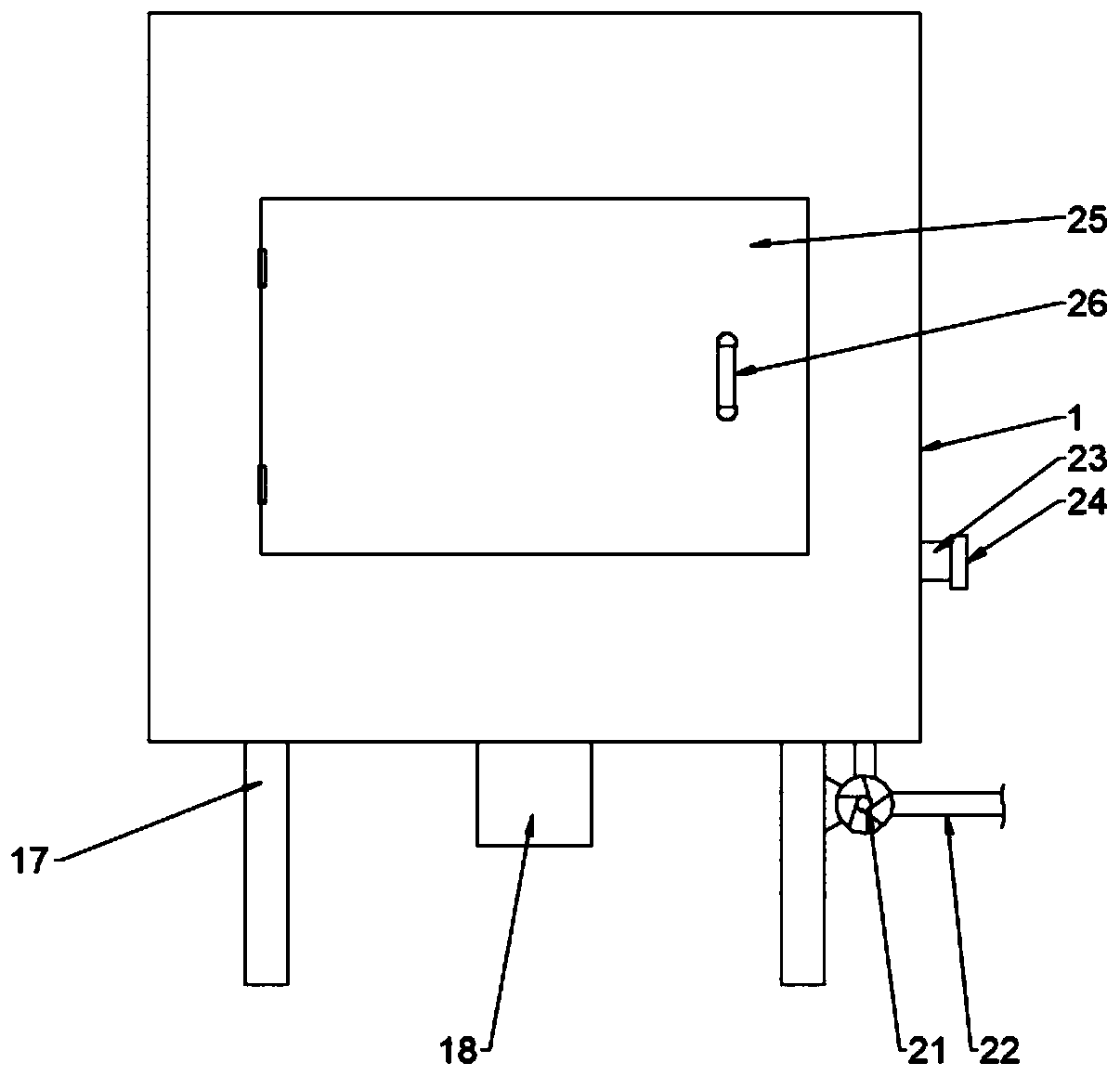

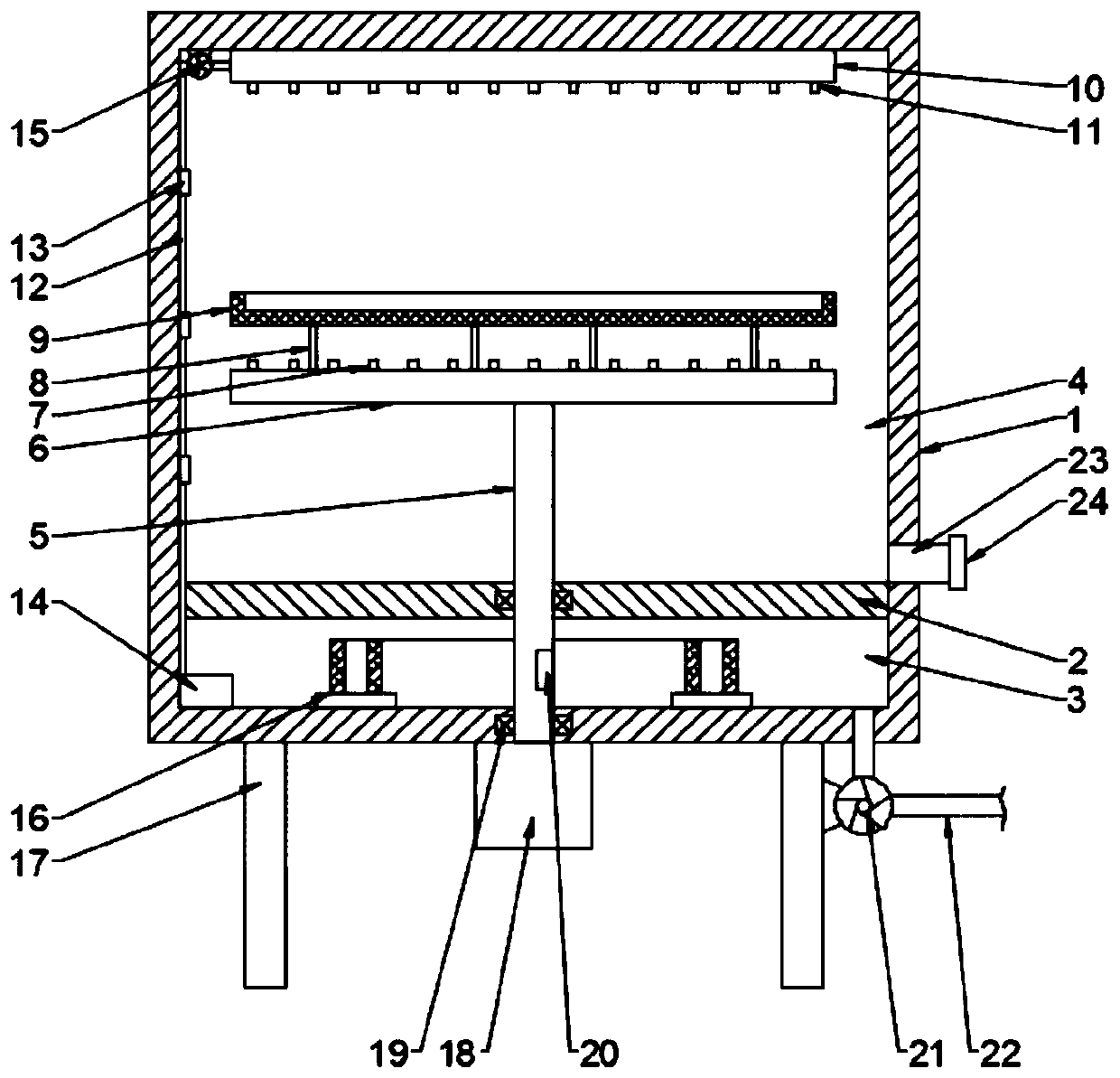

[0026] see Figure 1~3 , a medical inspection and disinfection device based on spray-washing technology, comprising a box 1, the bottom of the inner cavity of the box 1 is provided with a partition 2, and the partition 2 divides the inner cavity of the box 1 into Water chamber 3 and disinfection chamber 4, described water inlet chamber 3 is arranged at the bottom of disinfection chamber 4, is embedded with rotating shaft 5 on the water inlet chamber 3, and the fixed connection of described rotating shaft 5 is sprayed wash dish 6, and the spray wash dish 6 The top is evenly provided with several lower nozzles 7, and the top of the spray washing plate 6 is evenly provided with several leg rods 8, and the top of the leg rods 8 is fixedly connected to the tray 9, and the tray 9 is made of net. The top wall of the inner chamber of 4 is provided with a spray washing device 10 matched with the tray 9, and the spray washing device 10 is evenly provided with several upper nozzles 11, a...

Embodiment 2

[0028] This embodiment is a further elaboration on the basis of Embodiment 1. The rotating shaft 5 is a hollow shaft, and the rotating shaft 5 is connected through the spray washing plate 6. The bottom end of the rotating shaft 5 penetrates the water inlet chamber 3 and is fixedly connected to the motor. 18 on the motor shaft, the rotating shaft 5 is connected to the box body 1 and the partition 2 through the bearing 19, and the motor 18 is fixedly connected to the bottom of the box body 1, and the rotating shaft 5 is driven by the motor 18 to rotate, and then drives the spray washing plate 6 And the tray 9 rotates, and the tray 9 rotates, so that the medical instrument rolls on the tray 9 under the action of centrifugal force, thereby realizing the flipping of the medical instrument, so that the medical instrument is sprayed and disinfected more comprehensively.

[0029] One side of the outer circular surface of the rotating shaft 5 is connected with a water inlet hole 20 matc...

Embodiment 3

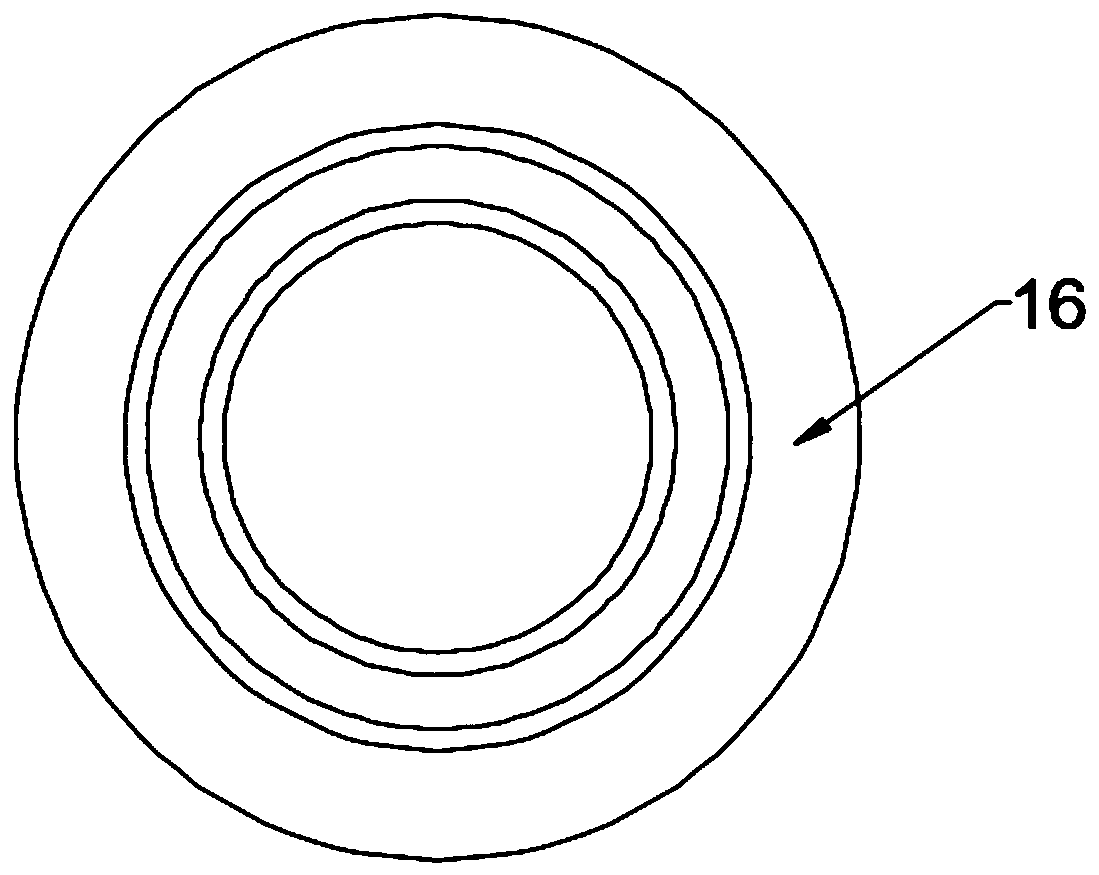

[0031] This embodiment is a further elaboration on the basis of Embodiment 2. The bottom wall of the inner cavity of the water inlet chamber 3 is provided with an electric heating device 6. The electric heating device 6 is a ring structure, and the electric heating device 6 is sleeved on the rotating shaft 5. On the outside, the disinfectant solution is heated by the electric heating device 6 to increase the temperature of the disinfectant solution, thereby improving the disinfection effect of the disinfectant solution and ensuring the quality of disinfection.

[0032] The left side of the inner cavity bottom wall of the water inlet chamber 3 is provided with a water suction box 14, the top of the water suction box 14 is connected to the water pipe 12, and the other end of the water pipe 12 passes through the partition plate 2 and is connected to the spray washing device 10. Above, the water pipe 12 is fixedly connected to the inner chamber wall of the box body 1 through the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com