Integrated control system for humidifying, cooling and sterilizing in breeding environment

A control system and integrated technology, applied in the field of aquaculture, can solve the problems of inconvenience, low efficiency, high labor intensity, etc., and achieve the effects of simple and reasonable structure, uniform temperature distribution, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

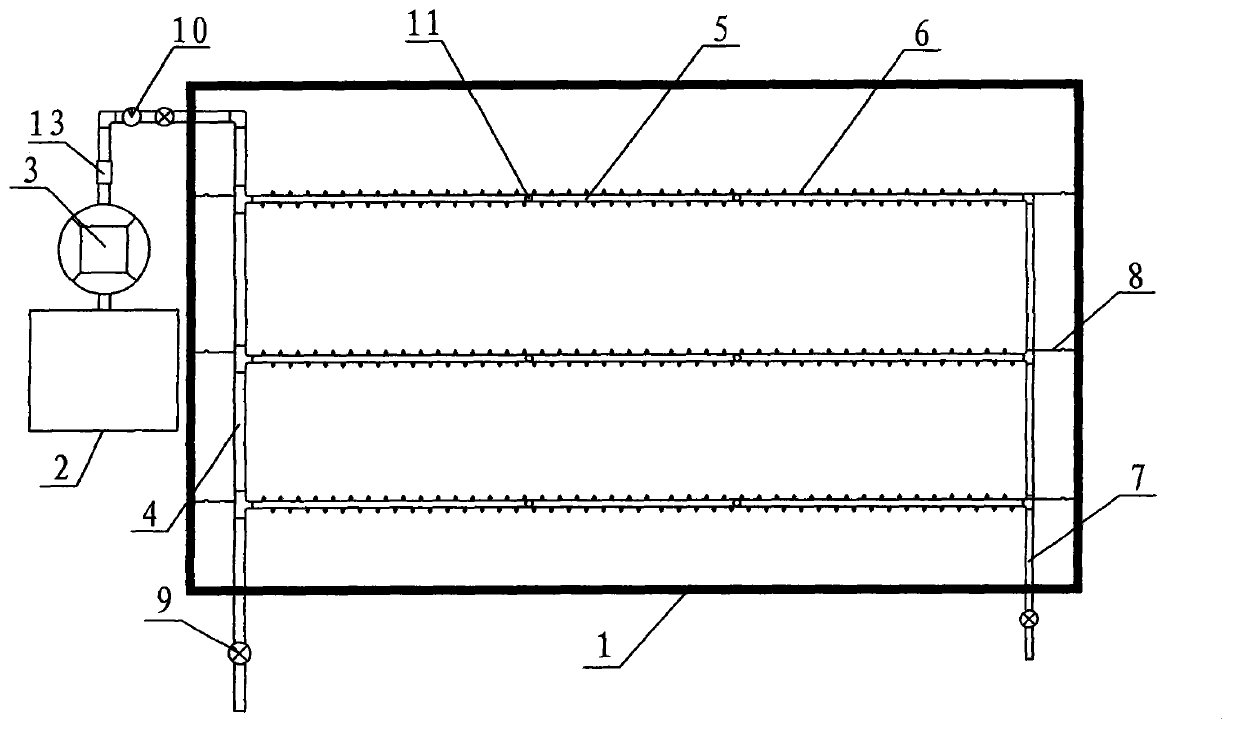

[0019] Specific embodiment one: as figure 1 As shown, a breeding environment humidification, cooling, disinfection integrated control system, the control system includes a liquid supply tank 2 installed outside the breeding room 1 and an infusion pipeline installed in the breeding room 1, the liquid supply tank 2 and the infusion tube A centrifugal pump 3 is connected between the roads; the infusion pipeline includes a main pipe 4 and a plurality of branch pipes 5 connected with the main pipe 4, the main pipe 4 is connected with the liquid outlet of the centrifugal pump 3, and each branch pipe 5 has A number of atomizers 6 evenly distributed are provided.

[0020] In order to realize the disinfection, humidification and cooling of the entire space of the breeding room 1, one end of the above-mentioned branch pipeline 5 is connected with the main pipeline 4, and the other end is connected with the sewage pipe 7; One end of chamber 1 top, blowdown pipe 7 is installed in the oth...

specific Embodiment 2

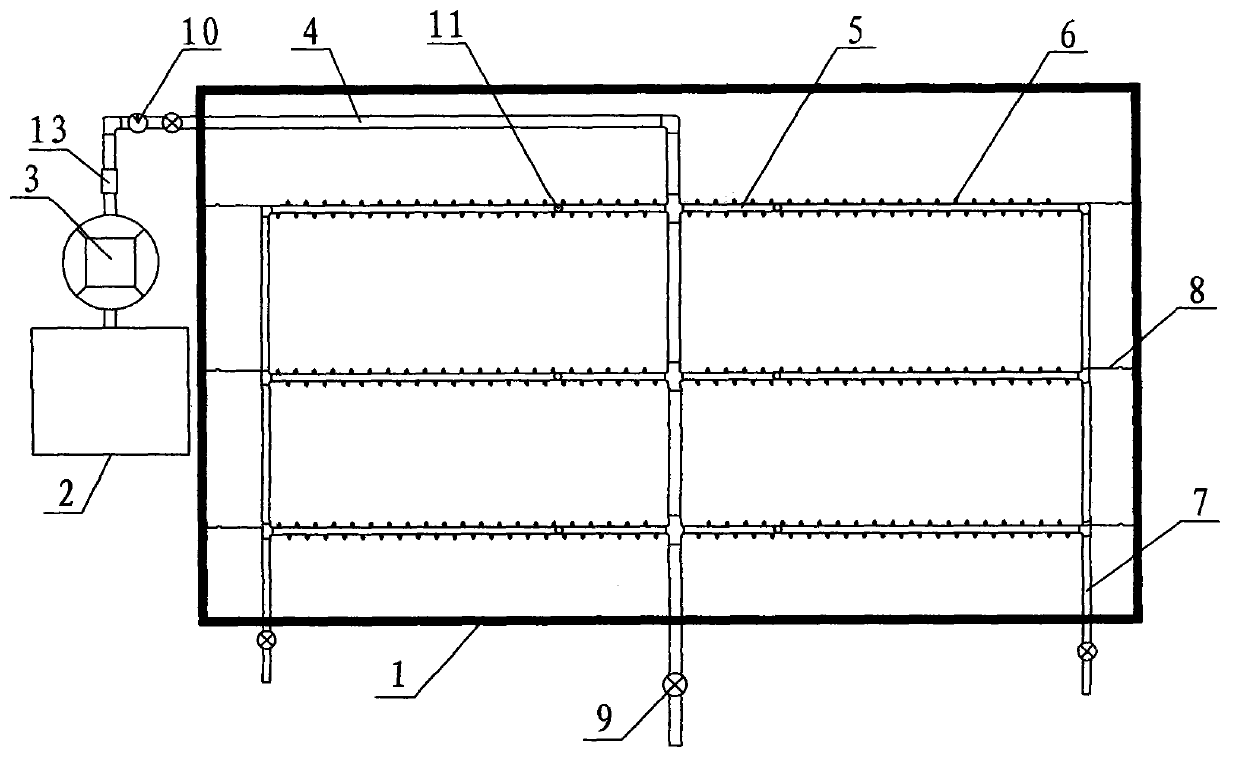

[0028] Specific embodiment two: as figure 2 As shown, a breeding environment humidification, cooling, disinfection integrated control system, the control system includes a liquid supply tank 2 installed outside the breeding room 1 and an infusion pipeline installed in the breeding room 1, the liquid supply tank 2 and the infusion tube A centrifugal pump 3 is connected between the roads; the infusion pipeline includes a main pipe 4 and a plurality of branch pipes 5 connected with the main pipe 4, the main pipe 4 is connected with the liquid outlet of the centrifugal pump 3, and each branch pipe 5 has A number of atomizers 6 evenly distributed are provided.

[0029] In order to realize the disinfection, humidification and cooling of the entire space of the breeding room 1, one end of the above-mentioned branch pipeline 5 is connected with the main pipeline 4, and the other end is connected with the sewage pipe 7; In the middle of the top of the chamber 1, the sewage pipe 7 is ...

specific Embodiment 3

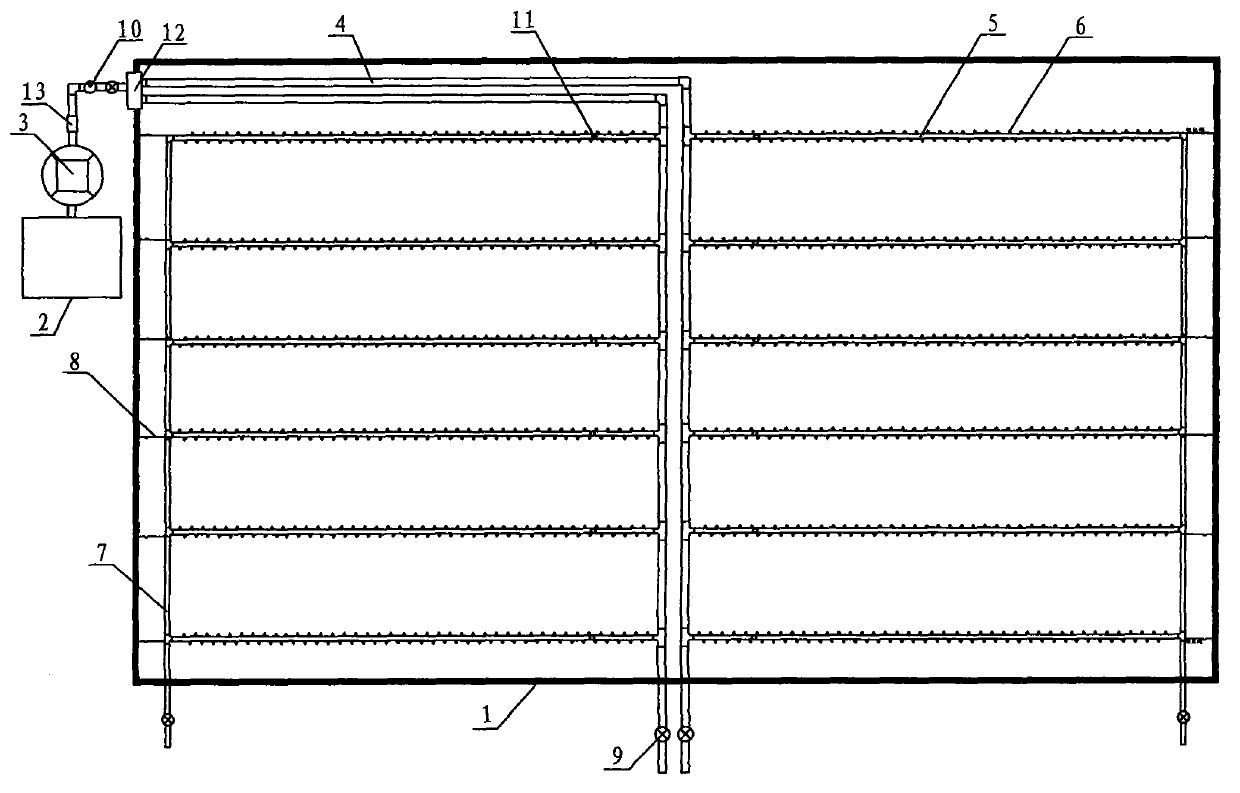

[0037] Specific embodiment three: as image 3 As shown, a breeding environment humidification, cooling, and disinfection integrated control system, the control system includes a liquid supply tank 2 installed outside the breeding room 1 and an infusion pipeline installed in the breeding room 1, the liquid supply tank 2 and the infusion tube A centrifugal pump 3 is connected between the pipelines; the infusion pipeline includes two main pipelines 4 and a plurality of branch pipelines 5 connected to the main pipeline 4, the main pipeline 4 is connected to the liquid outlet of the centrifugal pump 3, and each branch pipeline 5 is connected to the outlet of the centrifugal pump 3. Each is provided with a plurality of atomizers 6 evenly distributed.

[0038] In order to realize the disinfection, humidification and cooling of the entire space of the breeding room 1, one end of the above-mentioned branch pipeline 5 is connected with the main pipeline 4, and the other end is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com