Circuit board processing table

A workbench and circuit board technology, applied in printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of wasting human resources, increasing product production costs, and not being able to adapt to automated production, so as to save processing time and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the technical solution of the present invention will be described in detail through specific examples.

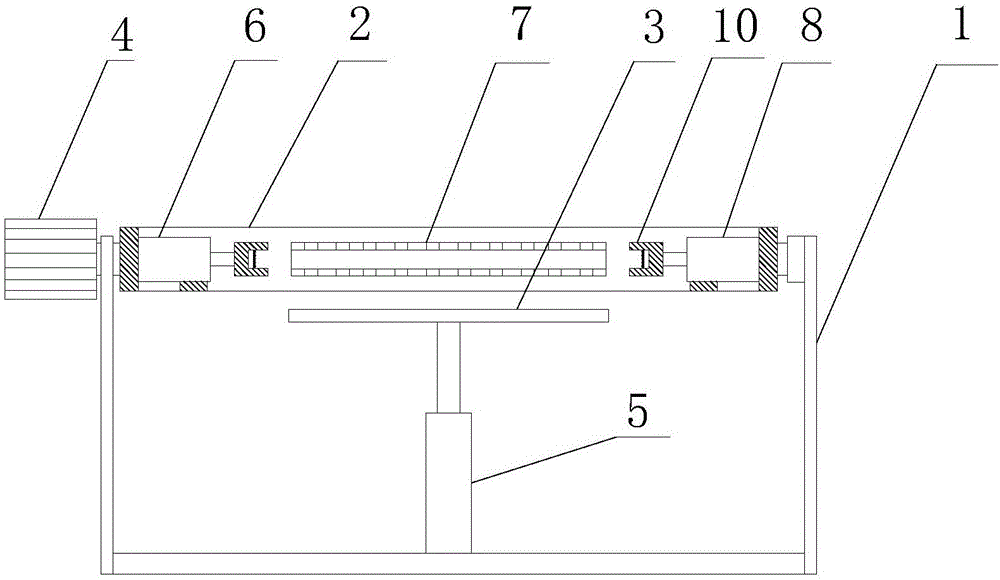

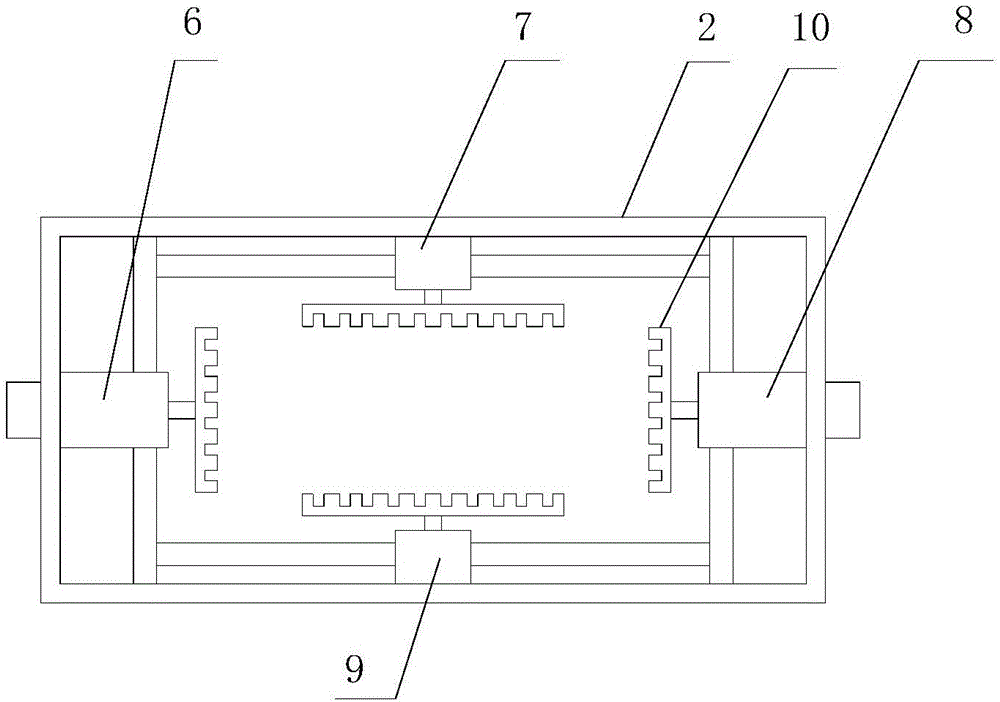

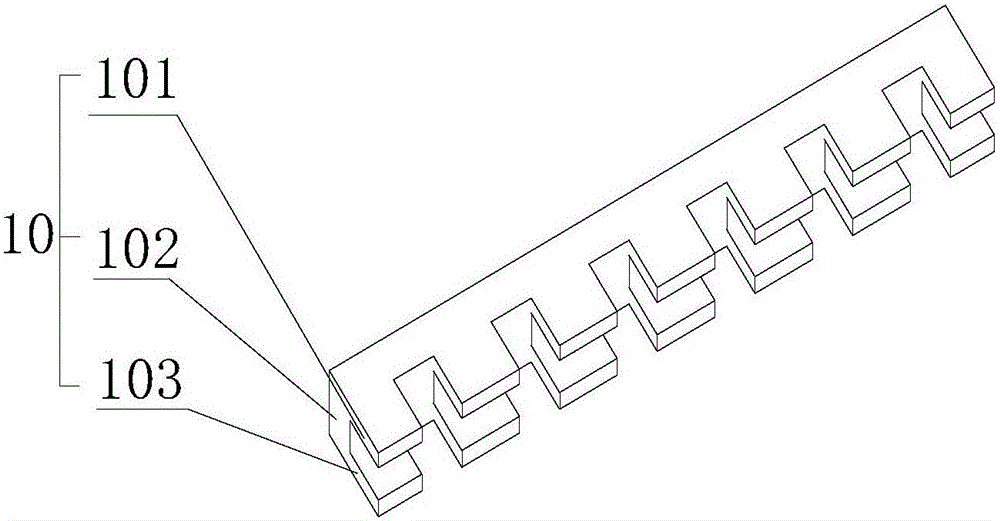

[0026] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a circuit board processing workbench proposed by the present invention; figure 2 It is a structural schematic diagram of the movable frame in a circuit board processing workbench proposed by the present invention; image 3 It is a structural schematic diagram of the clamping head in a circuit board processing workbench proposed by the present invention.

[0027] refer to Figure 1-2 , a circuit board processing workbench proposed by an embodiment of the present invention includes: a fixed frame 1, a movable frame 2, a pallet 3, a first drive mechanism 4 and a second drive mechanism 5, wherein:

[0028] The fixed frame 1 comprises a first stand and a second stand oppositely arranged, and an underframe located between the first stand and the second stand and connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com