Furniture production process based on paulownia wood material and intelligent production line

A production process, the technology of paulownia wood, is applied in the direction of wood processing equipment, the joining of wooden veneers, and the machine tools suitable for grinding workpiece planes, etc. It can solve the damage of the board surface, affect the health of operators, and cannot reduce the toxicity of paint Gas pollution to the surrounding air and other issues, to achieve the effect of ensuring the health of the body and reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

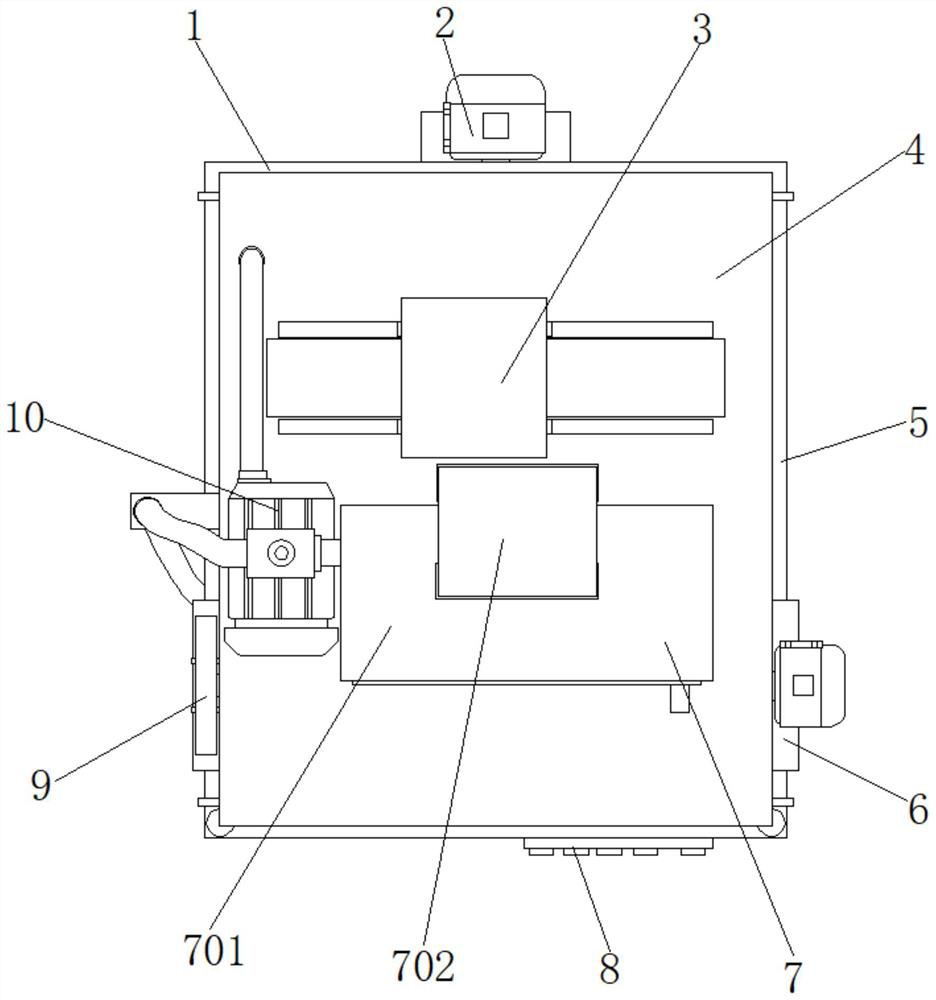

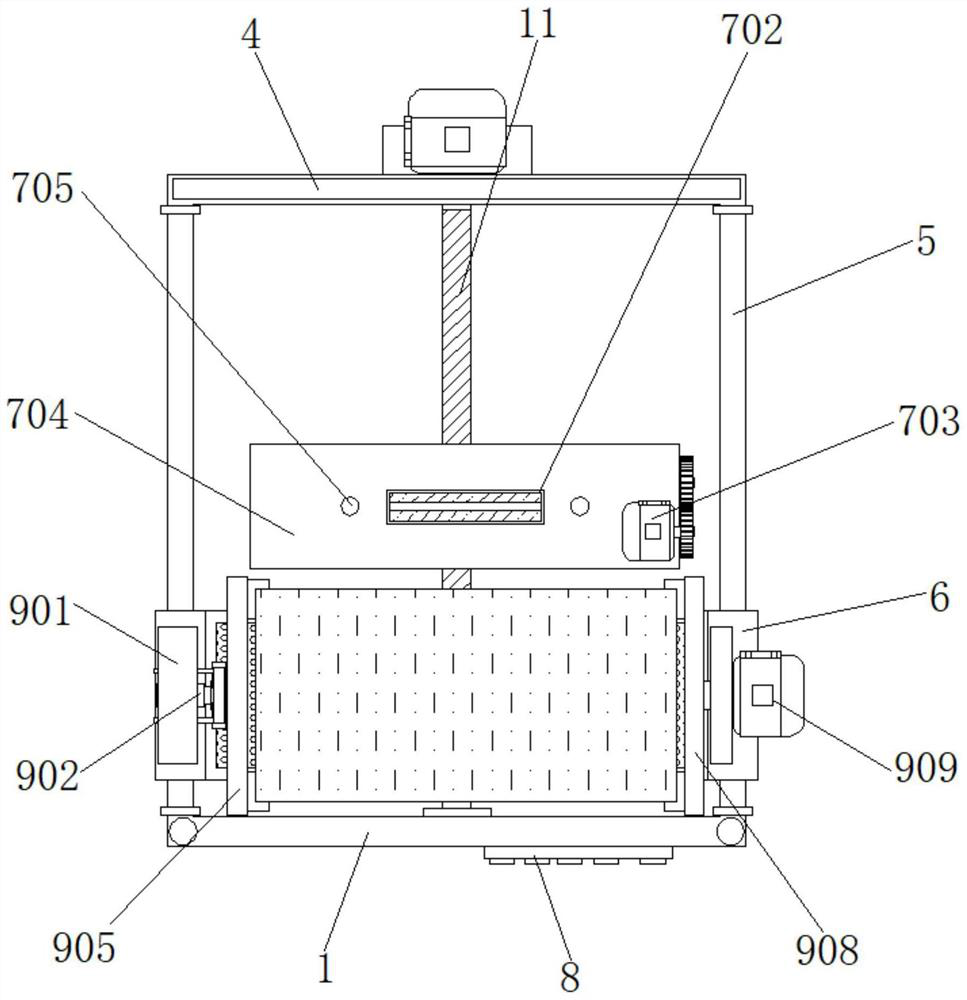

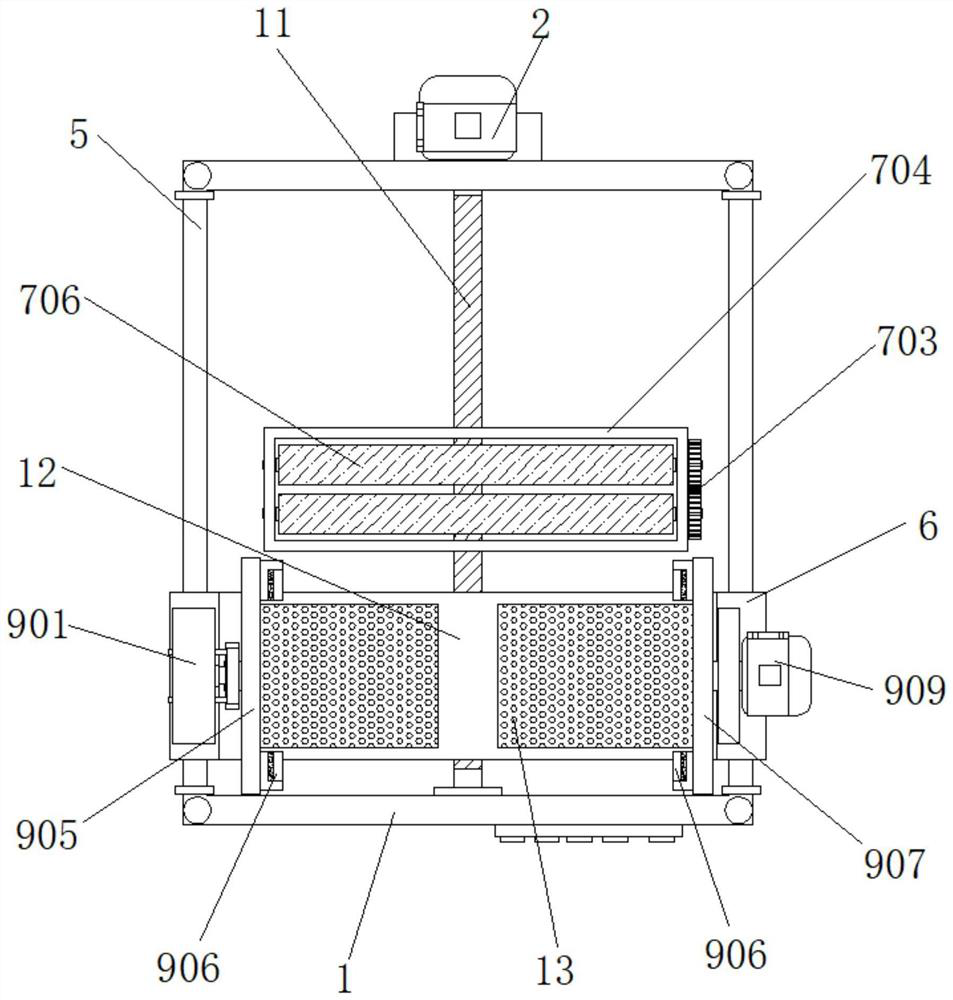

[0049] Example 1, such as Figure 1-6 As shown, in the process of two groups of grinding rollers 706 grinding the surface of Paulownia wood, the control air pump 10 starts to suck air into the filter chamber 701 and the two groups of purification chambers 15, and the debris and dust generated by grinding pass through the L-shaped connecting pipe 702 Will be sucked into the inside of the filter chamber 701, filtered by the filter screen inside the filter chamber 701, avoiding the debris and dust generated by grinding to fly around, affecting the health of the operator, and after the paint spraying device 3 sprays paint on the wood surface, the paint Most of the toxic gas mixed with the air is sucked into the interior of the purification chamber 15, and the toxic gas is filtered and absorbed by the activated carbon bag 14, thereby greatly reducing the degree of air pollution around the equipment, and after the wood is painted, control the second The servo motor 909 drives the wo...

Embodiment 2

[0050] Example 2, such as image 3 , 4 , 6, 7 and 8, since the shape of the first mounting plate 905 is a semicircular structure, the two sets of first clamping grooves 906 can always be horizontally upward, so that the operator can put the Paulownia wood into the first clamping grooves 906 and the inside of the second clamping groove 907, and after the operator manually places the Paulownia wood into the inside of the first clamping groove 906 and the second clamping groove 907, the electric push rod 902 is controlled by the control panel 8 to extend, and the electric push rod 902 forces the connected frame 903, bearing seat 904, first mounting plate 905 and first clamping groove 906 to move together towards the direction close to the second servo motor 909, thereby shortening the two pairs of the first clamping groove 906 and the second clamping groove The distance between 907 is to use two groups of first clamping grooves 906 and second clamping grooves 907 to tightly clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com