Method for repairing environmental hormone contaminated soil

A technology for polluted soil and environmental hormones, applied in the field of environmental hormone-contaminated soil remediation, can solve the problems of low efficiency of hormone technology, difficult to control operation, secondary pollution, etc., and achieve the effect of reducing secondary pollution, simple method and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Preparation method of nanometer zero-valent iron.

[0032] S1. Preparation of electrolyte system: prepare ferrous sulfate solution with deionized water, so that the concentration of ferrous ion is 1mol / L, add povidone, thiourea and boric acid, so that the concentration in the electrolyte system is 0.5g respectively / L, 3g / L, 5g / L;

[0033] S2. Electrodeposition process: use industrial pure iron as the anode, stainless steel as the cathode, and the surface finish of the cathode material is ▽9, place it in the electrolyte system prepared in step S1, and electro-deposit under the action of the pulse field of the ultrasonic field and the alternating magnetic field After 3 hours of deposition, the electrodeposition temperature is 40°C, and a layer of uniform and fine black powder is obtained on the cathode plate, which is quickly detached under the action of an ultrasonic field;

[0034] Among them, the frequency of the ultrasonic field is 20KHz, the power is 3...

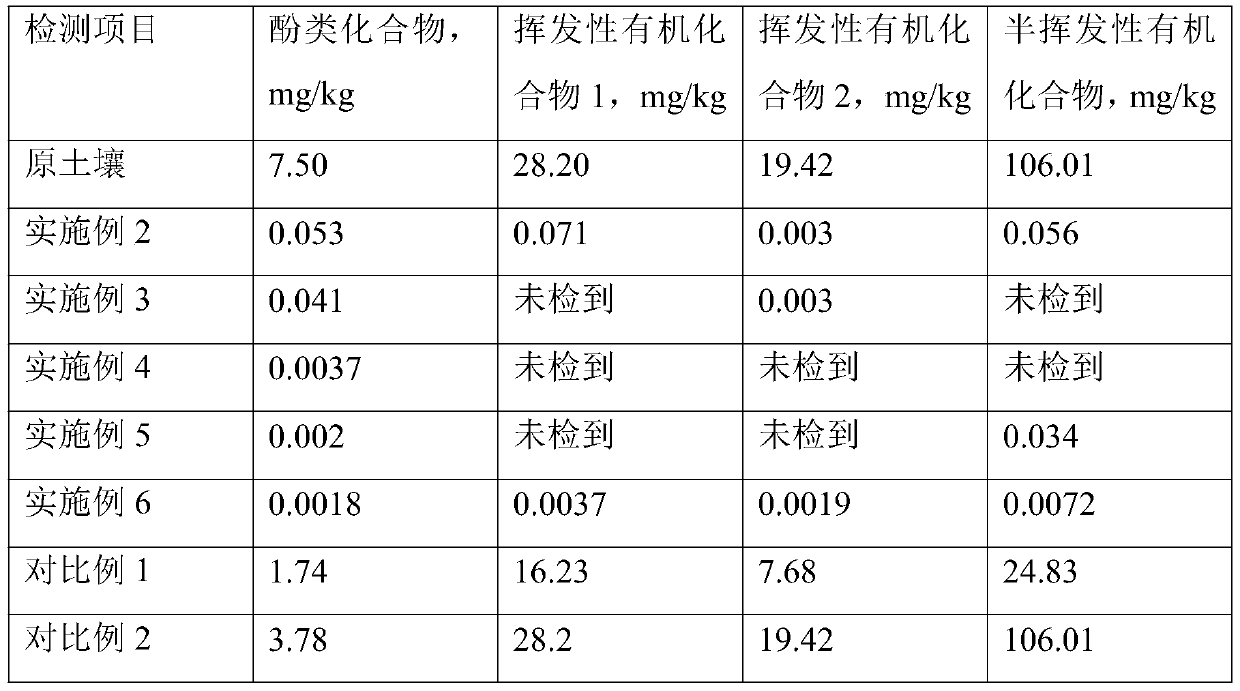

Embodiment 2

[0036] Embodiment 2 remediation method of environmental hormone polluted soil

[0037] S1. Preparation of iron slurry: Mix 20 parts of nano-zero-valent iron powder with 200 parts of deionized water, 1 part of sodium dodecylsulfonate, and 2 parts of bone glue, and stir to prepare nano-zero-valent iron slurry;

[0038] S2. Carrier treatment: Remove impurities from the uncontaminated soil, pass through an 80-mesh sieve, dry at 100°C until the moisture content of the soil particles is less than 5%, and crush it into soil particles with a uniform particle size and a particle size of less than 80 mesh, accounting for more than 80%;

[0039] S3. Loading: Mix the nano-zero-valent iron slurry prepared in S1 with the soil particles prepared in step S2 at a mass ratio of 1:8, stir at a stirring speed of 180 rpm, and stir for 3 hours until uniform to obtain a loaded composite material;

[0040] S4. Restoration: Sprinkle the loaded composite material obtained in step S3 evenly on the hormo...

Embodiment 3

[0042] Embodiment 3 repairs the method for environmental hormone polluted soil

[0043] S1. Preparation of iron slurry: Mix 15 parts of nano-zero-valent iron powder with 180 parts of deionized water, 1 part of sodium dodecylsulfonate, and 1 part of bone glue, and stir to prepare nano-zero-valent iron slurry;

[0044] S2. Carrier treatment: remove impurities from uncontaminated soil, pass through a 70-mesh sieve, dry at 80°C until the moisture content of the soil particles is less than 5%, and crush it into soil particles with a uniform particle size and a particle size of less than 80 mesh, accounting for more than 80% of the soil particles;

[0045] S3. Loading: Mix the nano-zero-valent iron slurry prepared in S1 with the soil particles prepared in step S2 at a mass ratio of 1:6, stir at a stirring speed of 120 rpm, and stir for 2 hours until uniform to obtain a loaded composite material;

[0046] S4. Restoration: Sprinkle the loaded composite material obtained in step S3 evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com