Flute-shaped grate, application thereof and flute-shaped grate boiler

A grate boiler and flute-shaped technology, applied in the field of flute-shaped grate boilers, can solve the problems of incomplete combustion, limited combustion mode, and inability to meet environmental protection standards, reduce the use of chemical fertilizers, save transportation costs, and be beneficial to consumption. effect of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

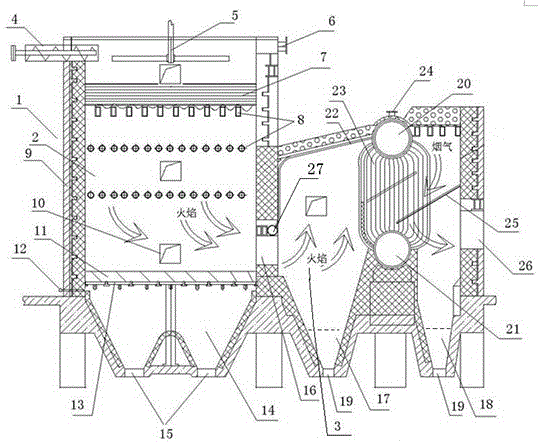

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

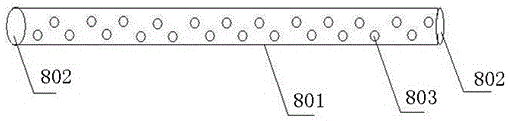

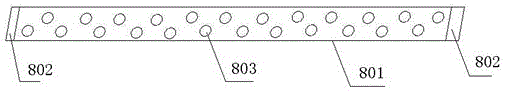

[0023] like figure 2 , image 3 As shown, a flute-shaped grate includes a flute-shaped pipe body 801, the thickness of the flute-shaped pipe body 801 is 3-15mm, and the flute-shaped pipe body 801 is made of high temperature resistant and cheap silicon carbide or silicon nitride or resistant Made of hot steel; the flute-shaped pipe body 801 is a hollow pipe body with air inlets 802 at both ends, and a single row or two exhaust air outlets are set on one side of the flute-shaped pipe body 801, and the air outlet 803 is a circular opening. The material fuel sets the number of air outlets, the aperture size of the air outlets, and the distance between adjacent air outlets. For example, when the material fuel is straw, the number of air outlets 802 is small, the aperture is small, and the distance between adjacent air outlets is large. The fuel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com