Fire grate plate and corresponding incinerate fire grate and refuse incinerate equipment

A technology for incinerators and grates, which is applied in the direction of combustion equipment, lighting and heating equipment, grates of hollow furnace bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

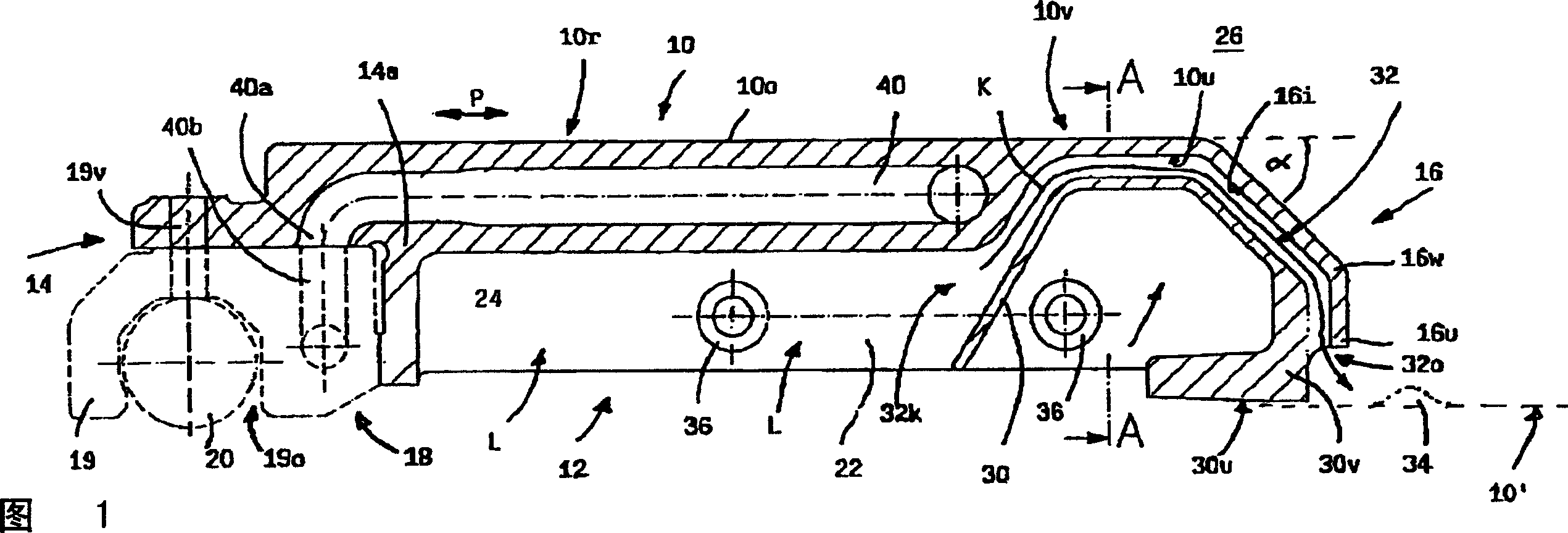

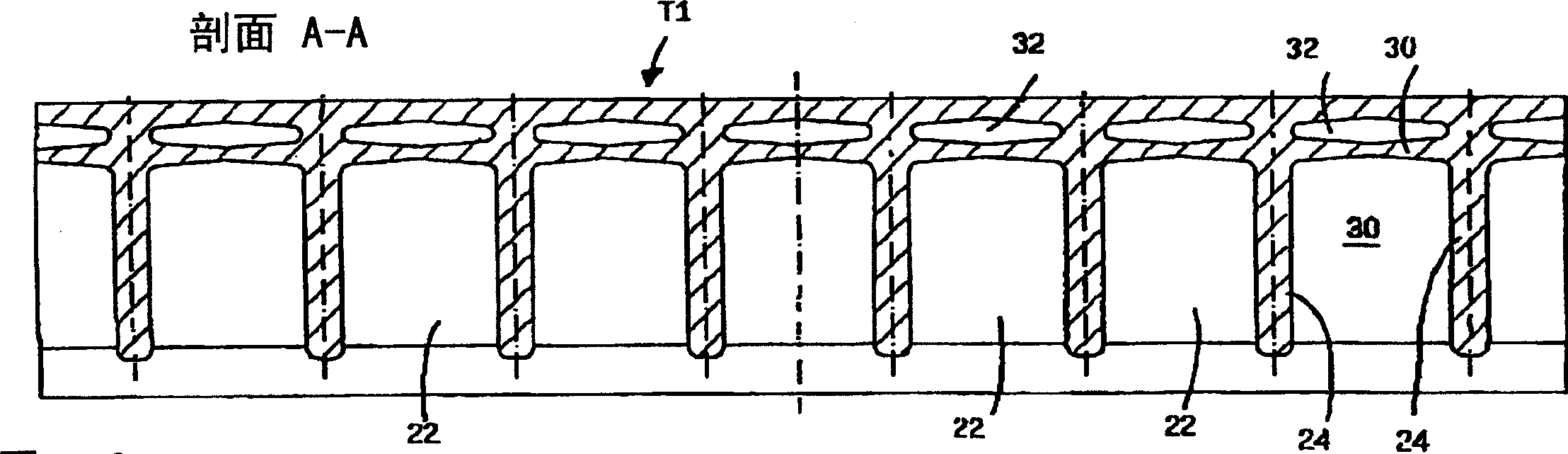

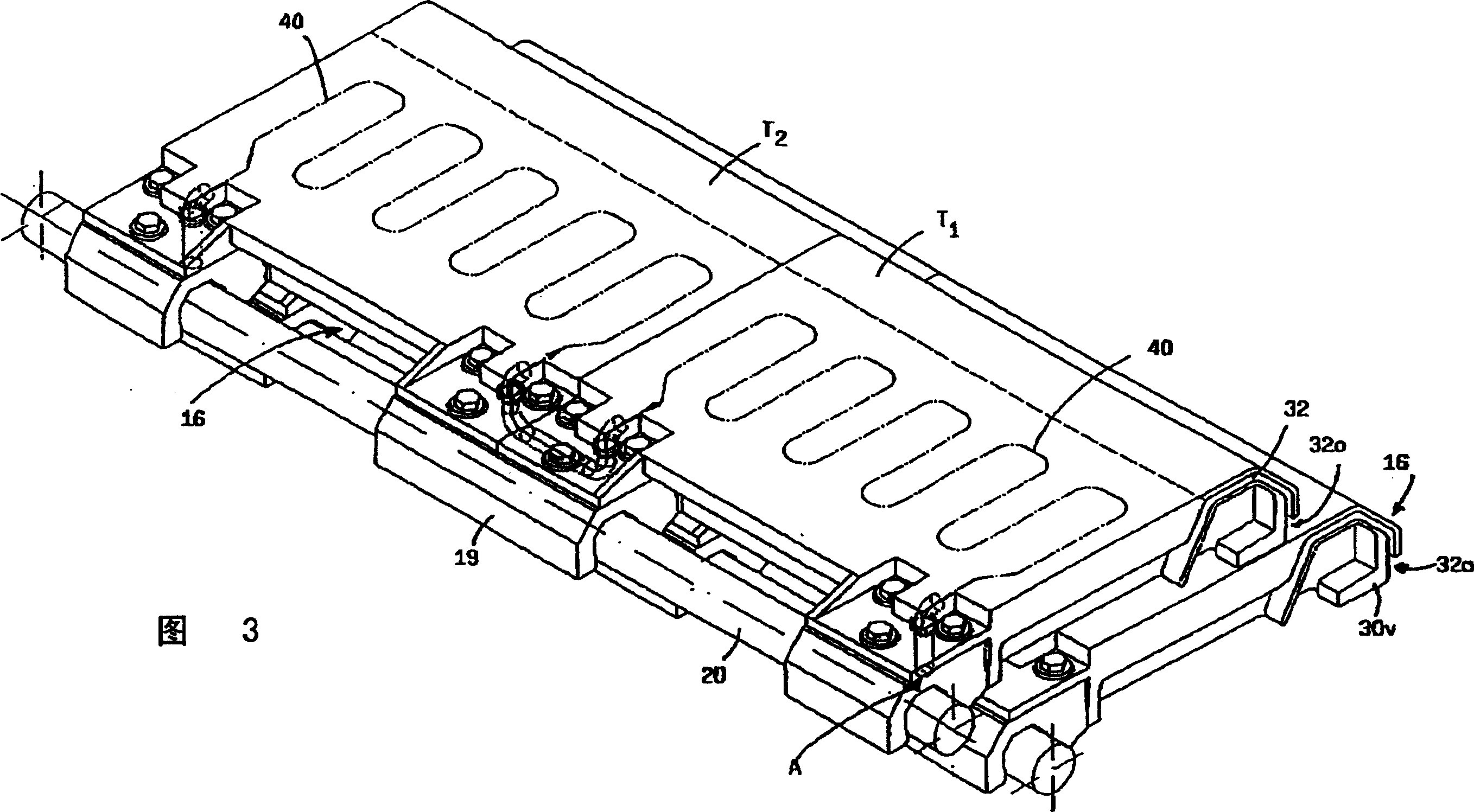

[0048] The basic design of the grate plate is described below in conjunction with FIG. 1: the grate plate has an upper side 10, a lower side 12, a rear long side 14, a front long side 16 and two wide sides that cannot be seen due to the chosen section line . The upper region 10 o of the upper side 10 is implemented in a planar manner. The second front long side 16 is angled a (about 45°) relative to the upper surface 10o and then angled at 16w.

[0049] The underside of the grate plate adjacent to the first (rear) long side 14 comprises a recess 18 extending in the longitudinal direction (into the plane of the protrusion) in which a connecting element 19 comprising a further recess 19o is placed, And wherein the round rod 20 is located in this additional recess and (indirectly) supports the grate plate. The grate plate shown in FIG. 1 can be moved in the direction of the arrow P with the help of the round rod 20 . The connecting element 19 is described in more detail below....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com