Apparatus and method for fractionating alternative solid fuels

a technology of alternative solid fuels and apparatus, which is applied in the direction of combustible gas production, gasification process details, combustion process, etc., can solve the problems of reducing the production of crumb. cost as much as coal or cok

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention will now be described referring to a preferred embodiment thereof, illustrated in the accompanying drawings wherein the same signs and numbers, refer to the same parts of the shown figures.

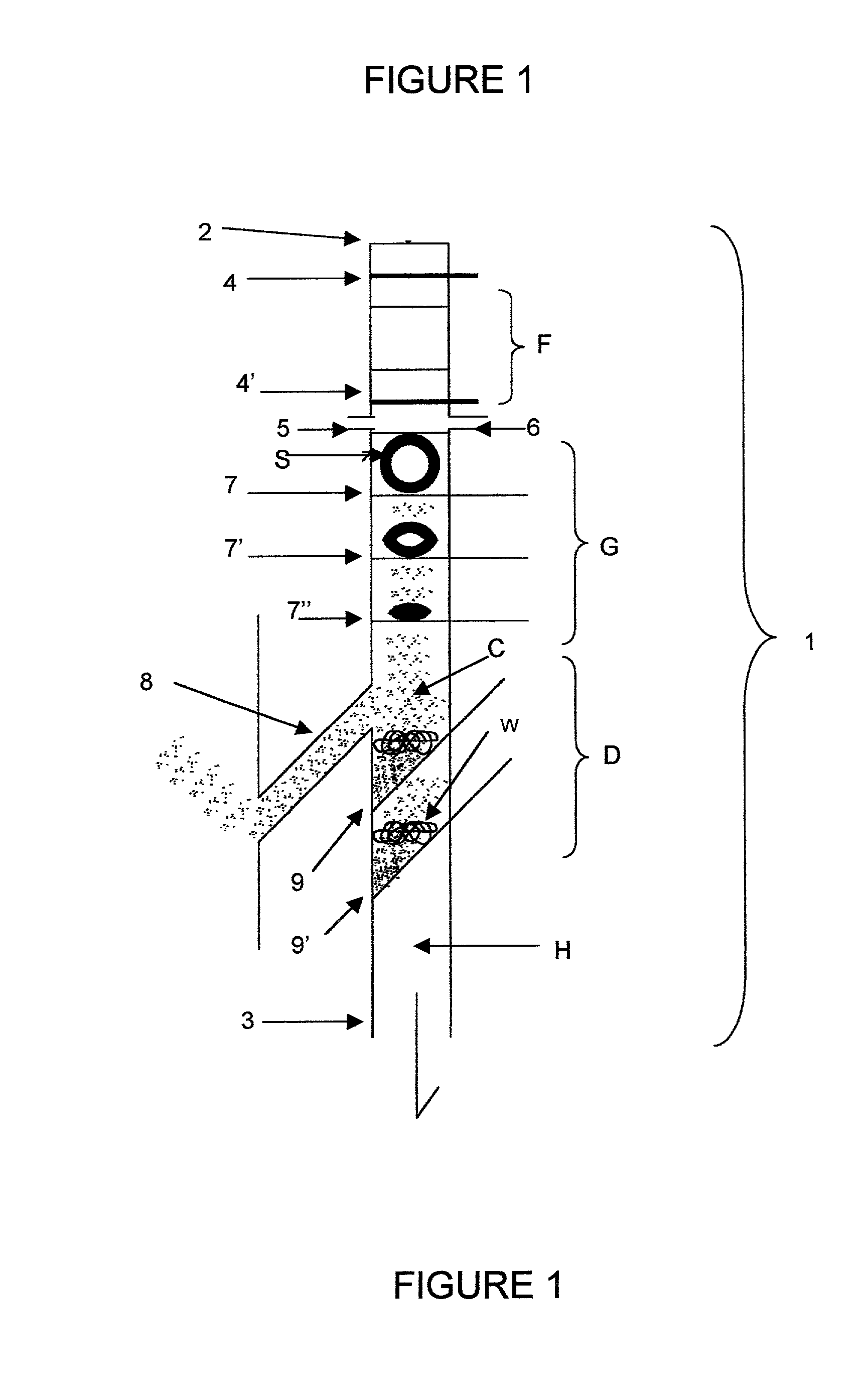

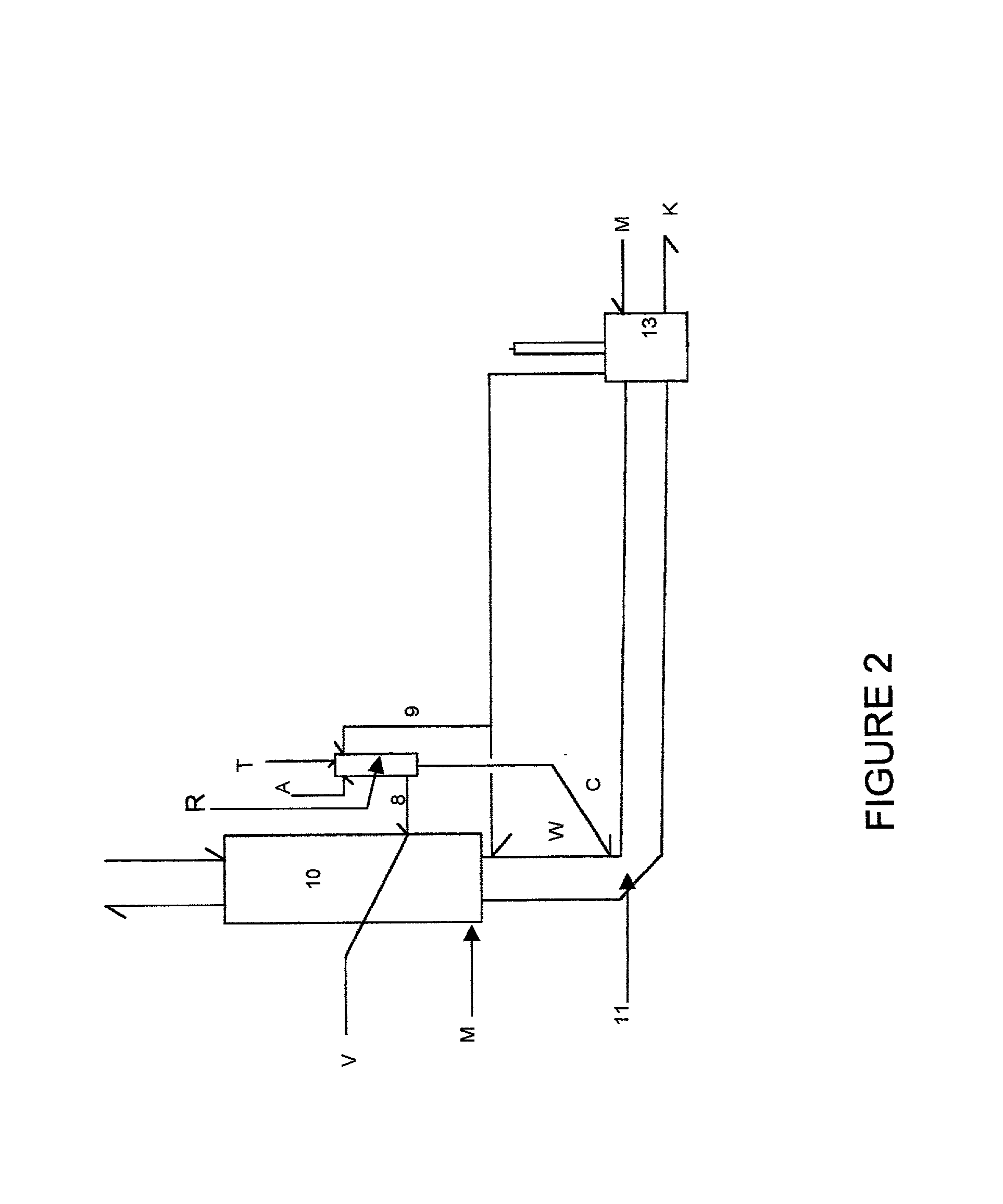

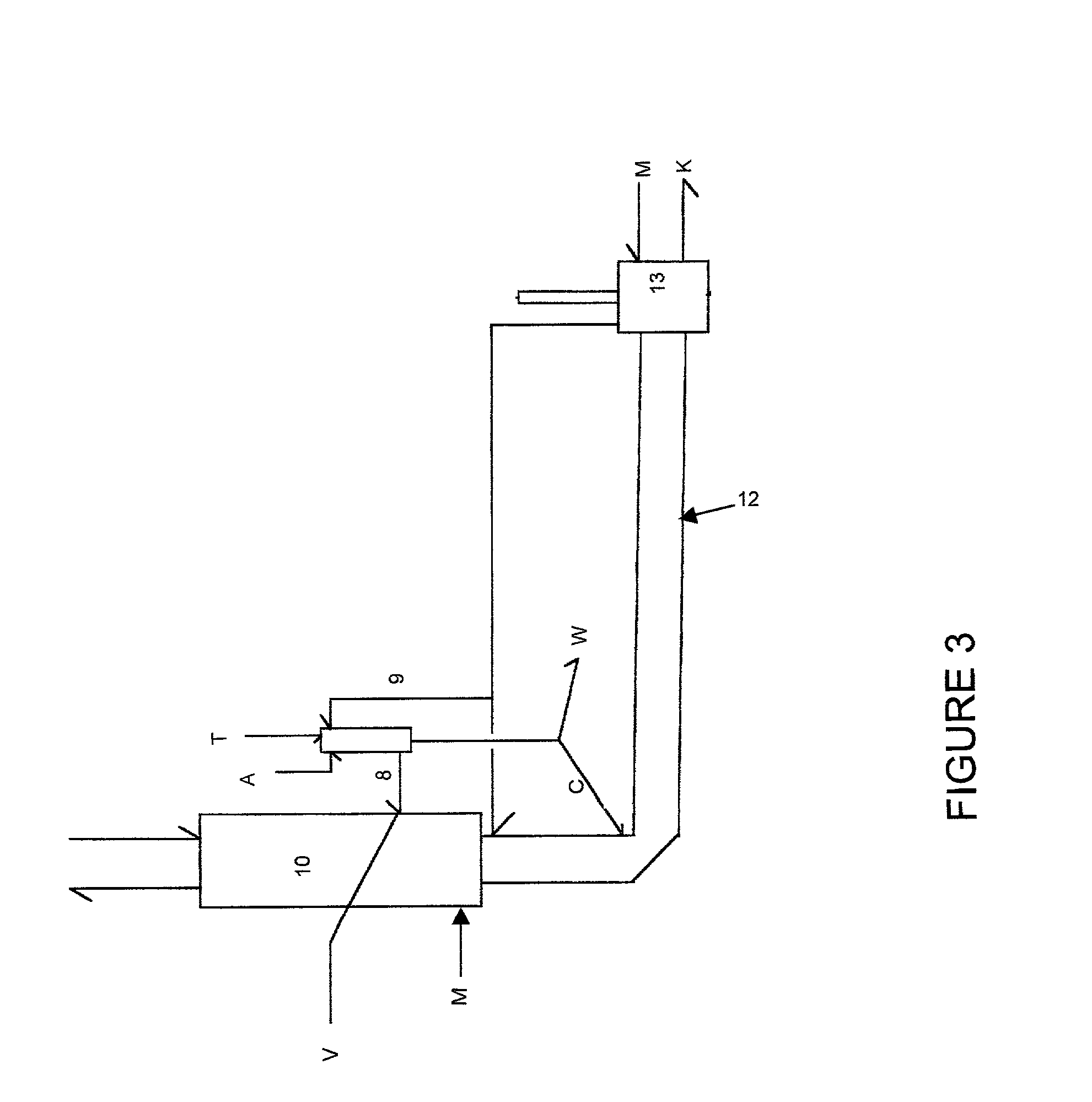

[0042] Referring to FIG. 1, the apparatus for fractionating alternative solid fuel comprises:

[0043] gasifying means consisting of a main column 1 having a first end 2 and a second end 3, and including:

[0044] a feeding zone F, having:

[0045] valve means including one or more feeding valves

[0046] comprising gates 4, 4', located at the feeding zone F, in which the solid fuels S are fed, and which are opened and closed for a convenient time and sequence in order to feed the solid fuels S to the place wherein the combustion will take place;

[0047] driving means for the feeding valves (not shown) which could be hydraulic motors, to open (lifting) and close (lowering) said feeding valves 4,4';

[0048] a gasifying zone G located below the feeding zone F, having:

[0049] input means for hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com