Patents

Literature

37results about How to "Simple and accurate method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

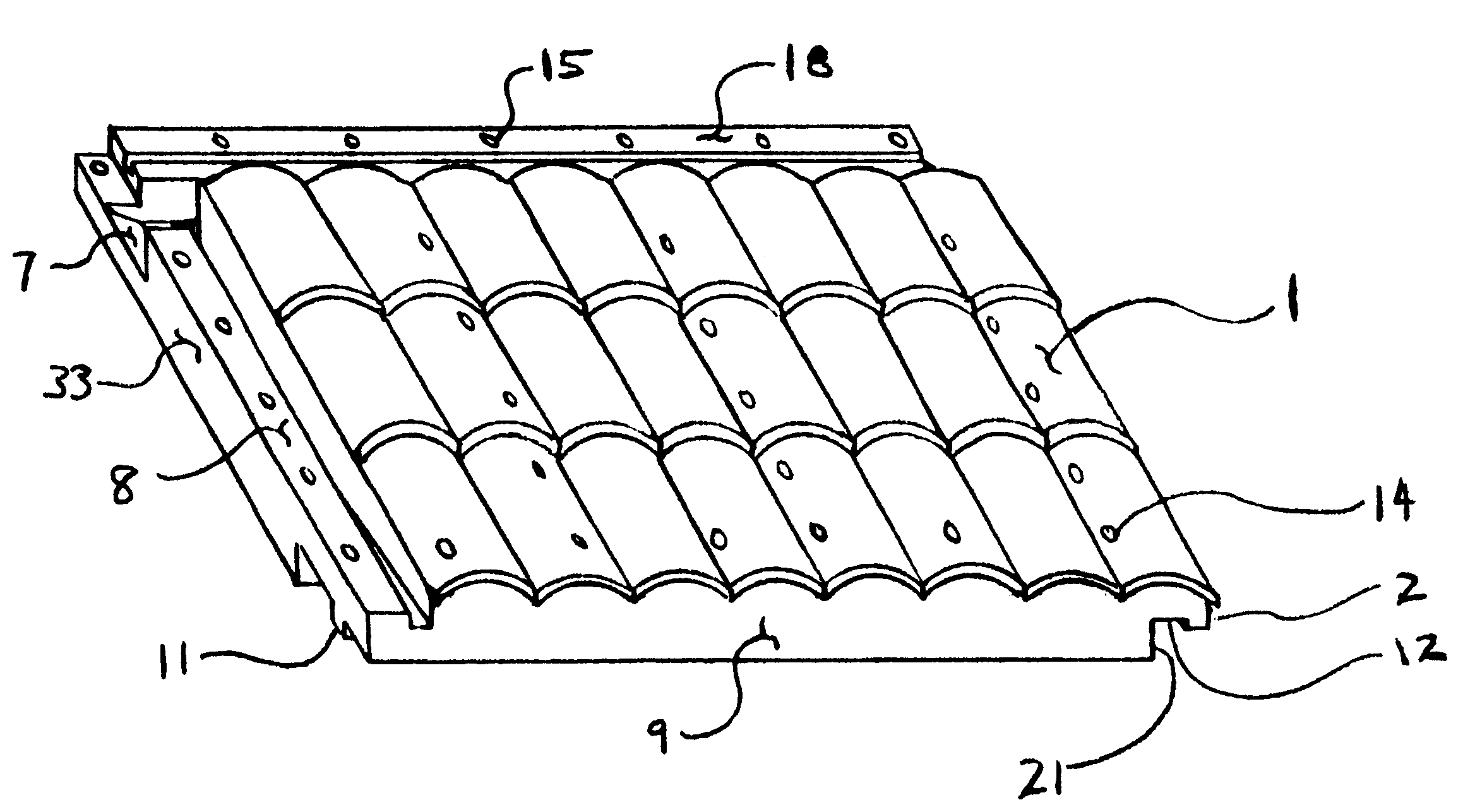

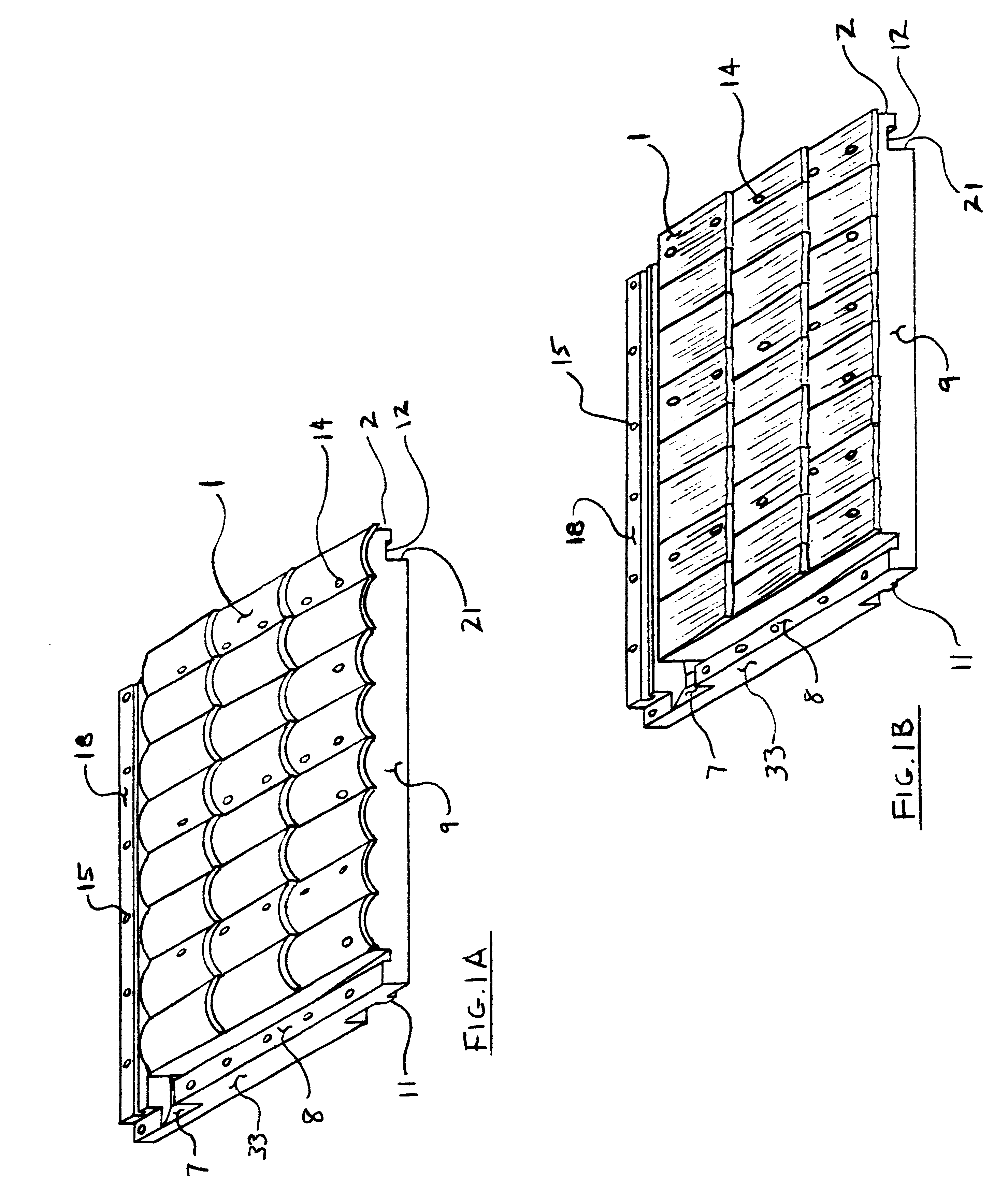

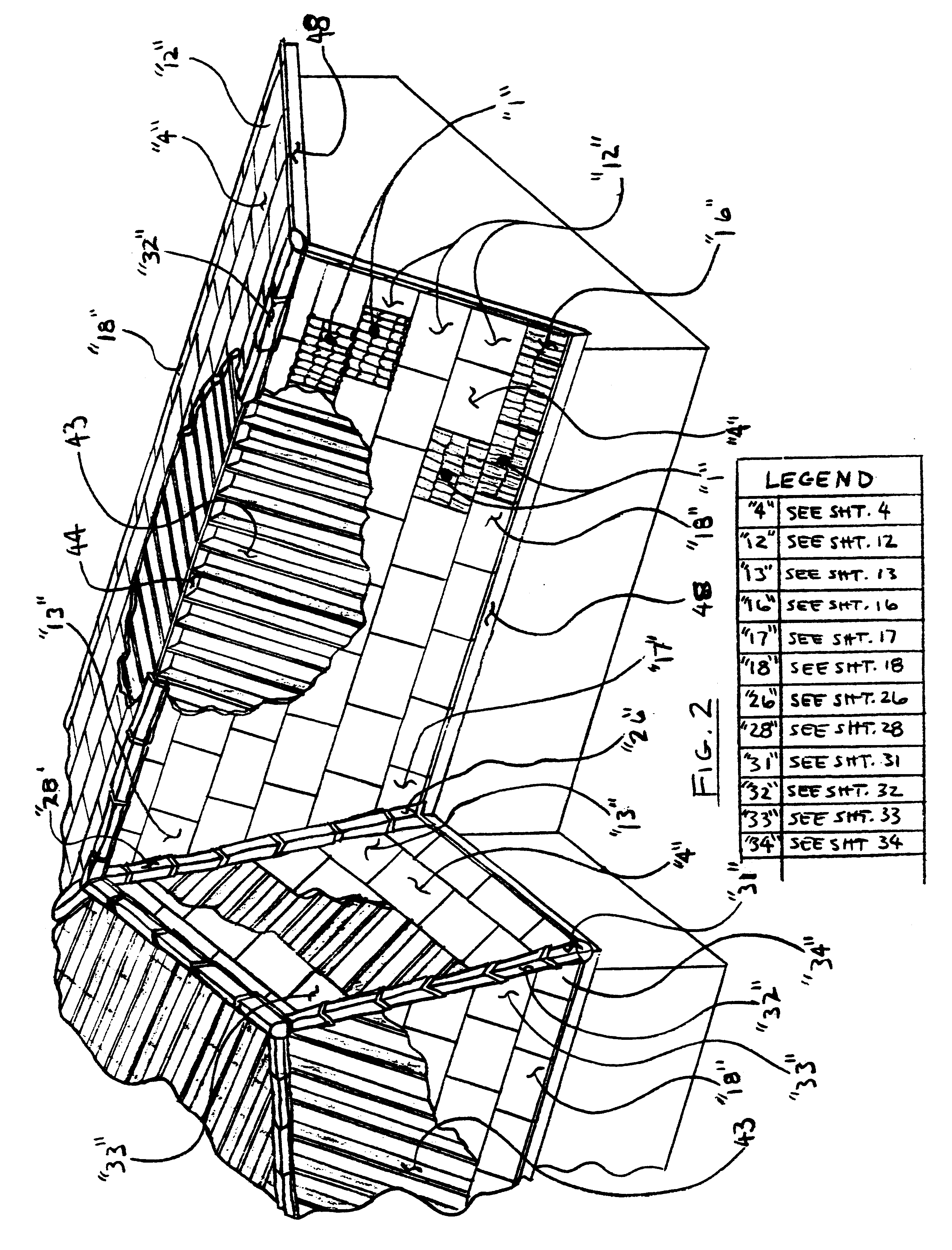

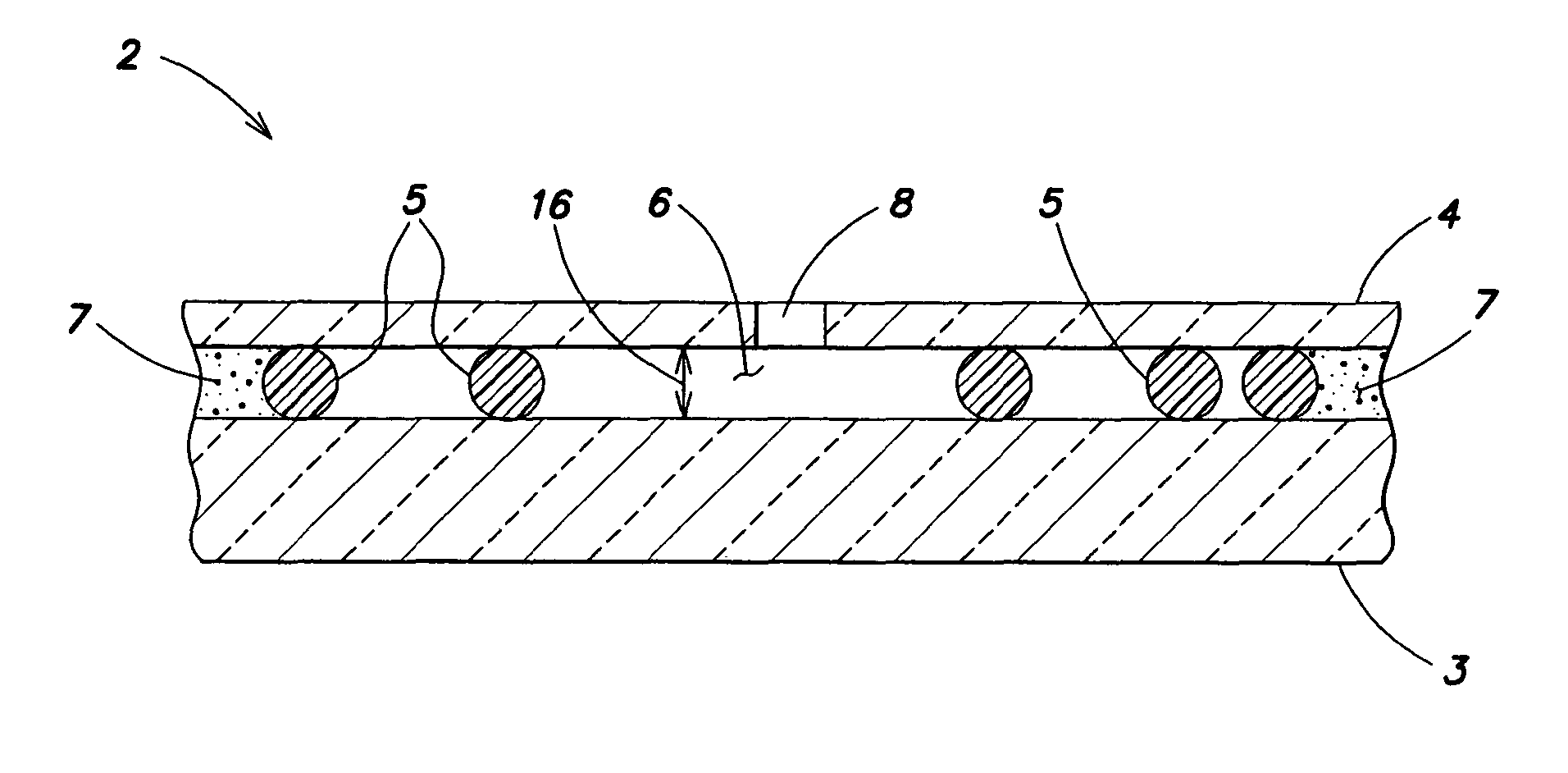

Roofing panel system and method for making same

InactiveUS6282858B1Eliminate needSimple and accurate methodRoof covering using tiles/slatesWallsFiberglass meshWater channel

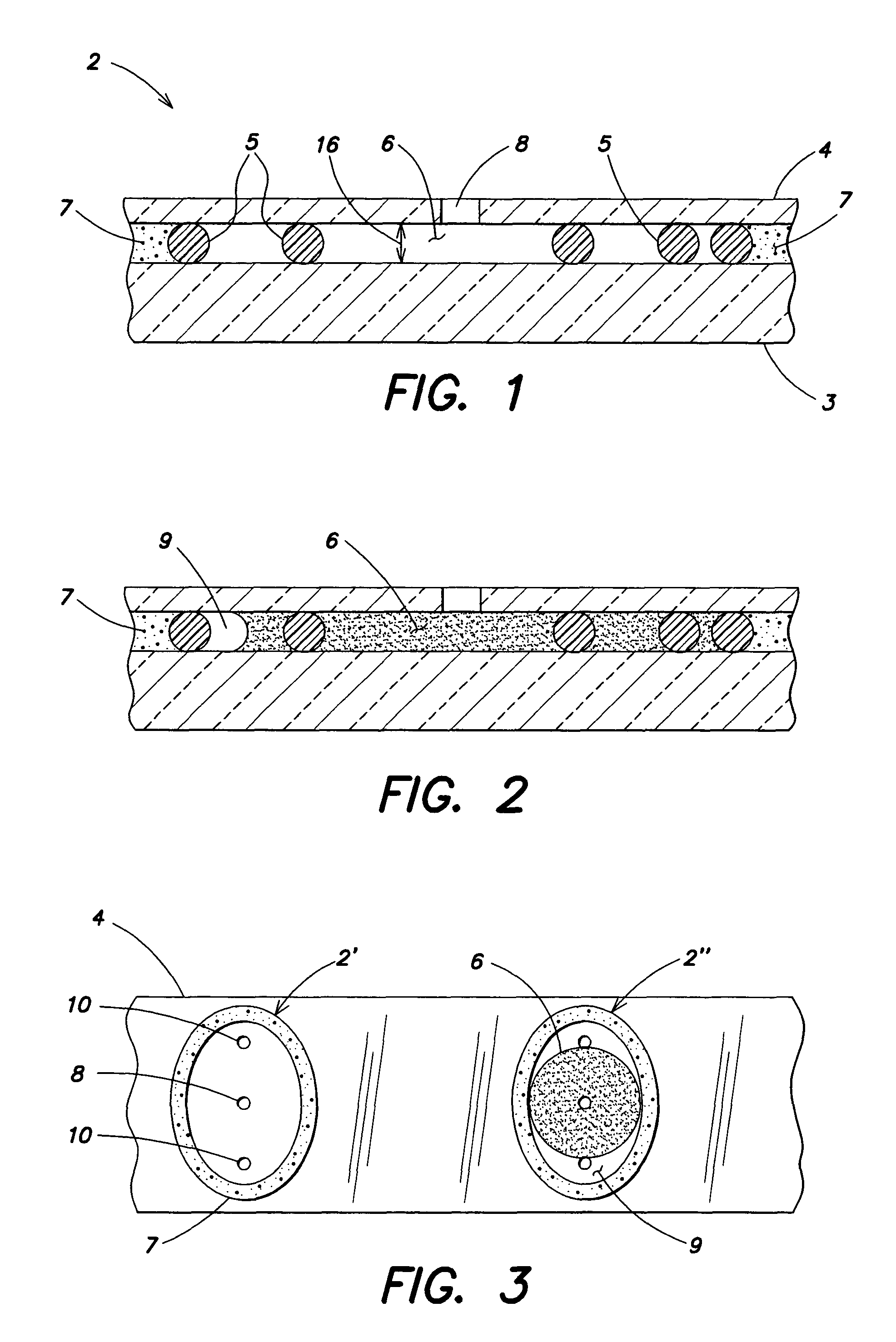

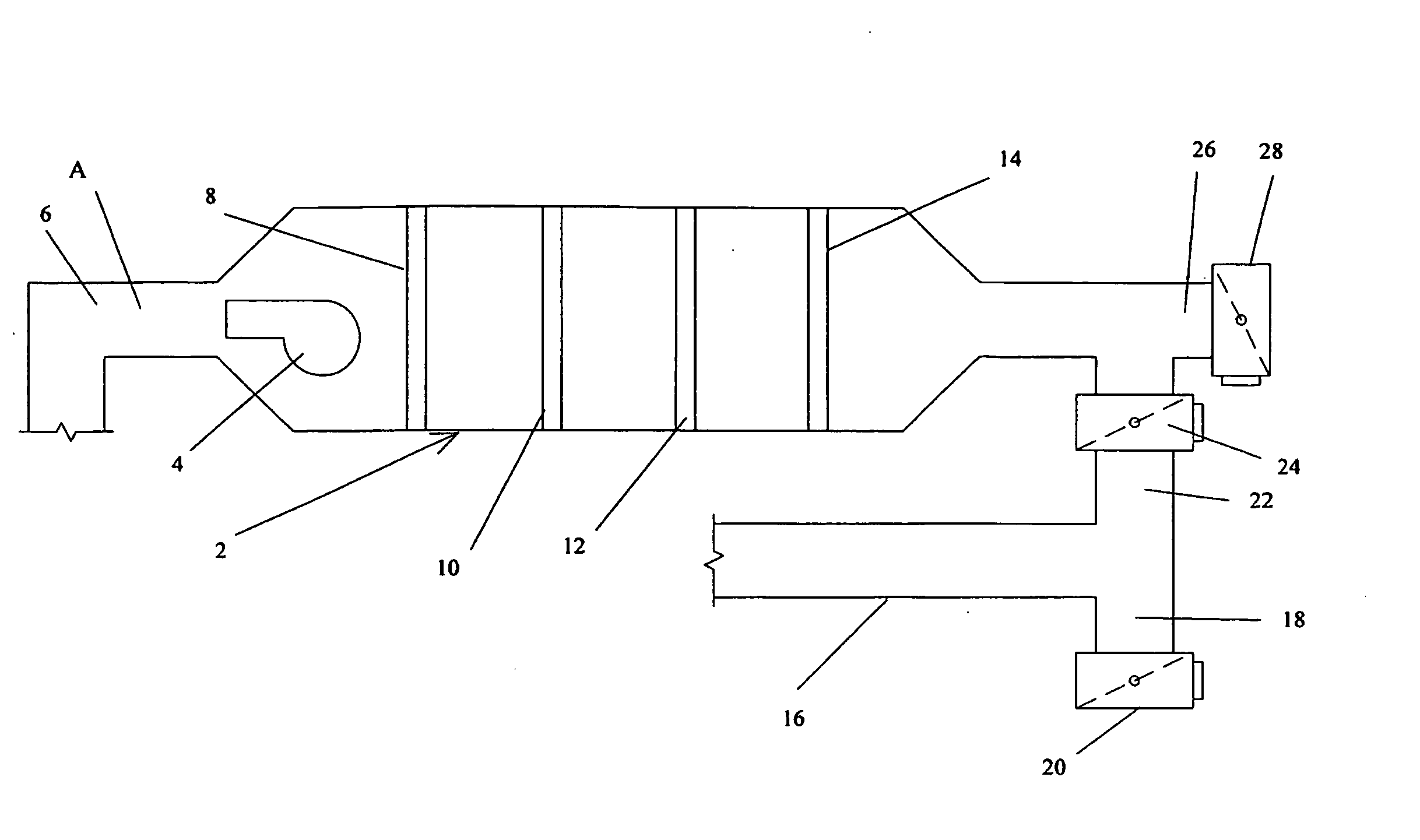

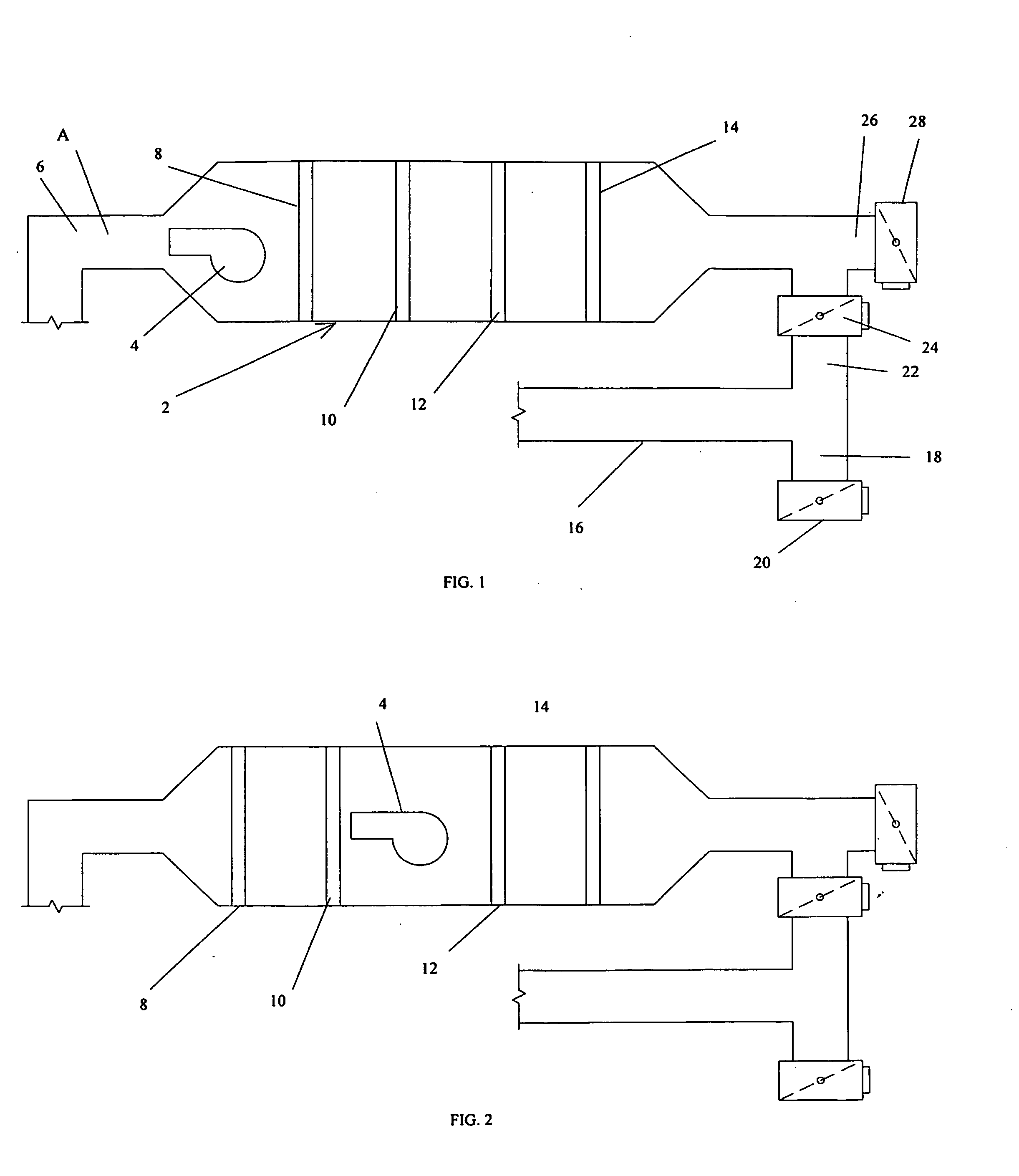

An injection molded rigid roof panel system for constructing pitched roof structures of the type affixed directly to roof trusses or rafters and needing no structural or supporting sheathing surface or moisture barrier. Comprised of no less than (23) standard roof panel components of varying shapes, sizes, colors and exposed surfaces replicating conventional roofing surfaces. Panels overlap, underlap and interlock by means of an array of shoulders, locating ribs and clearance channels creating a unitized roof system utilizing integral seals at the seams, subsurface water channels and self sealing, threaded fasteners whose molded-in, counter-bored holes are further sealed by composite plugs. Panels are produced by mixing, extruding and pelletizing a compound of over 60% recycled materials and encapsulating a semi-rigid fiberglass mesh sheet in the panels during the injection molding process producing a roofing product that is fire retardant, impervious to moisture, insects, ultraviolet rays and winds in excess of 130 mph.

Owner:SWICK ANDREW C

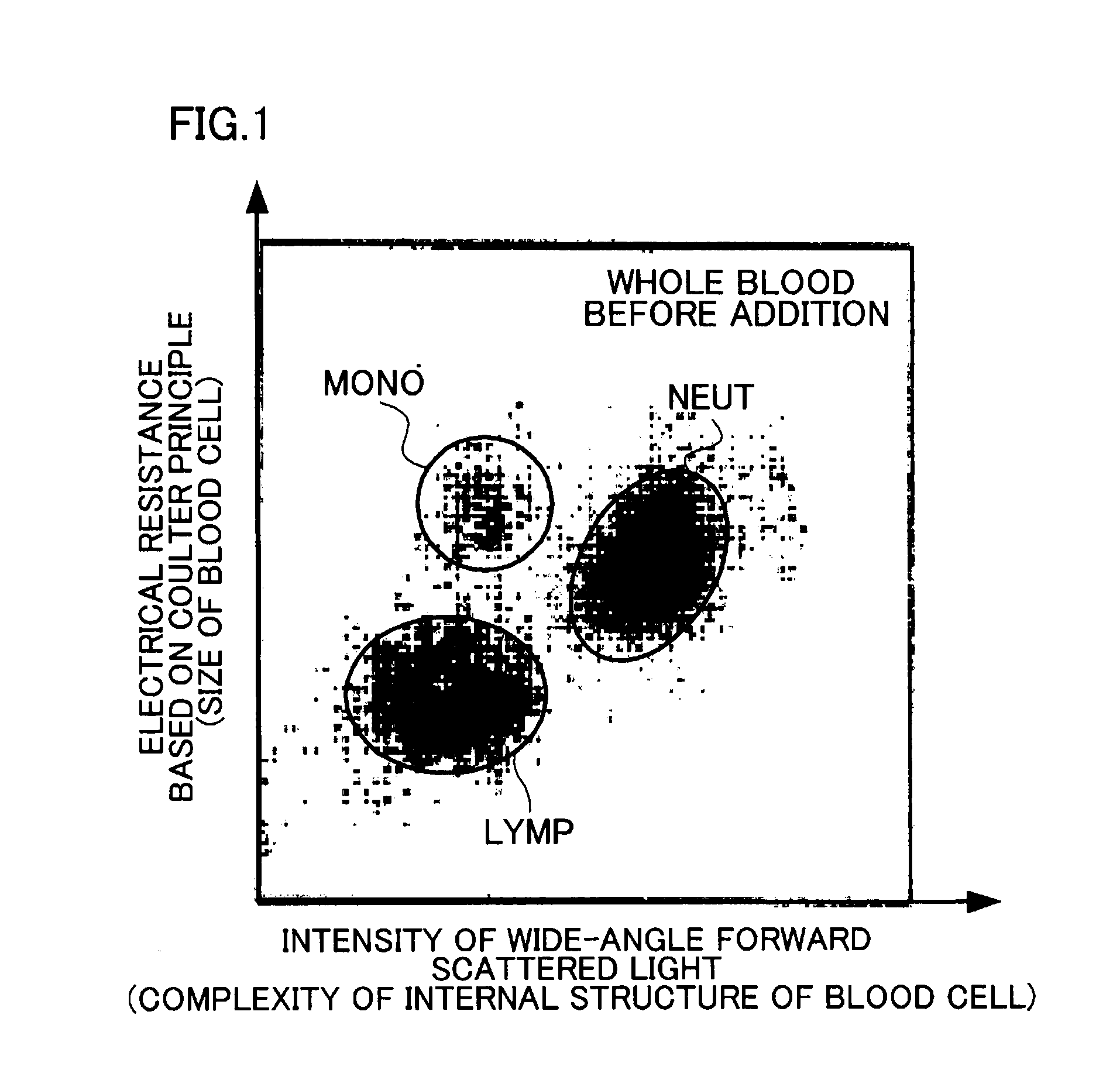

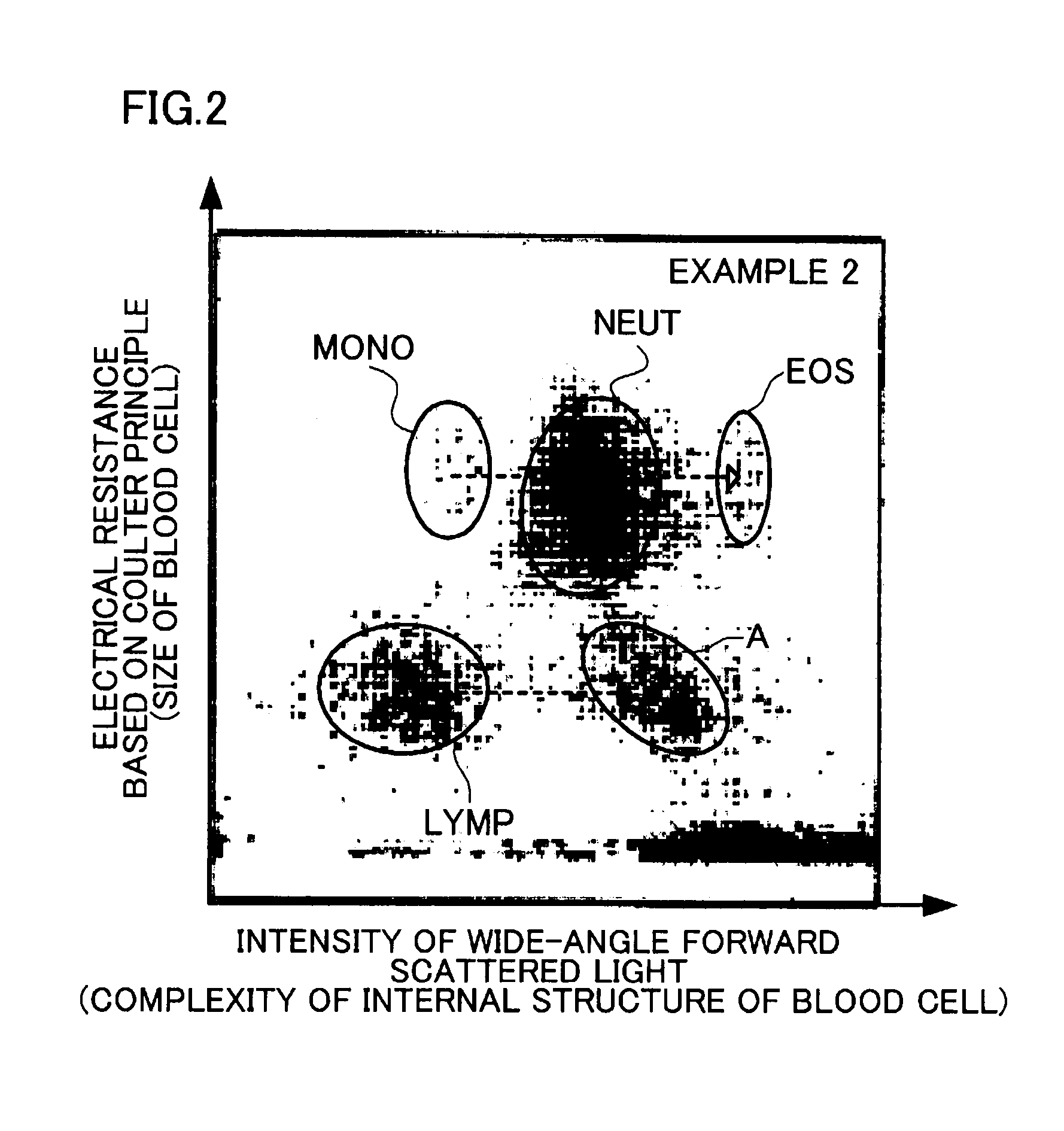

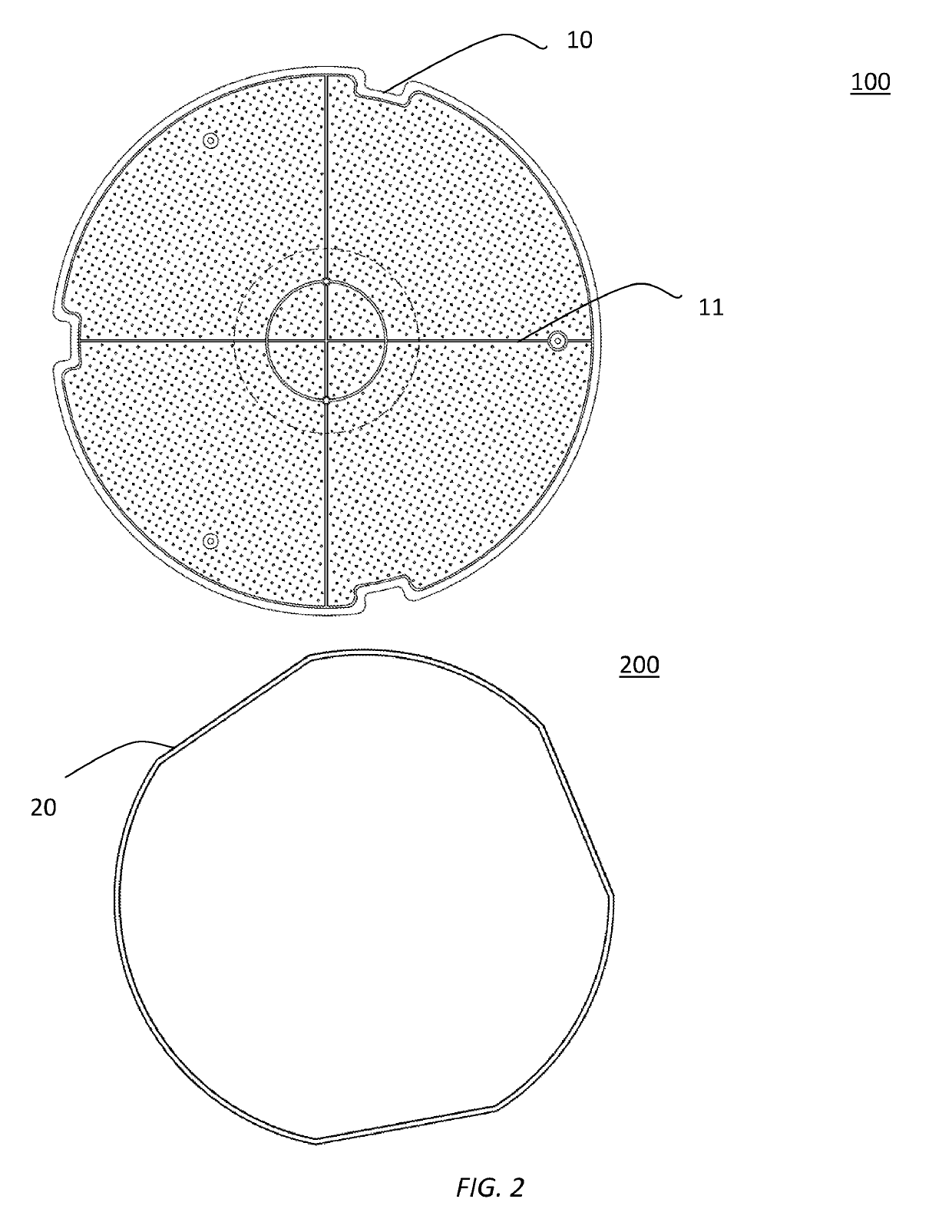

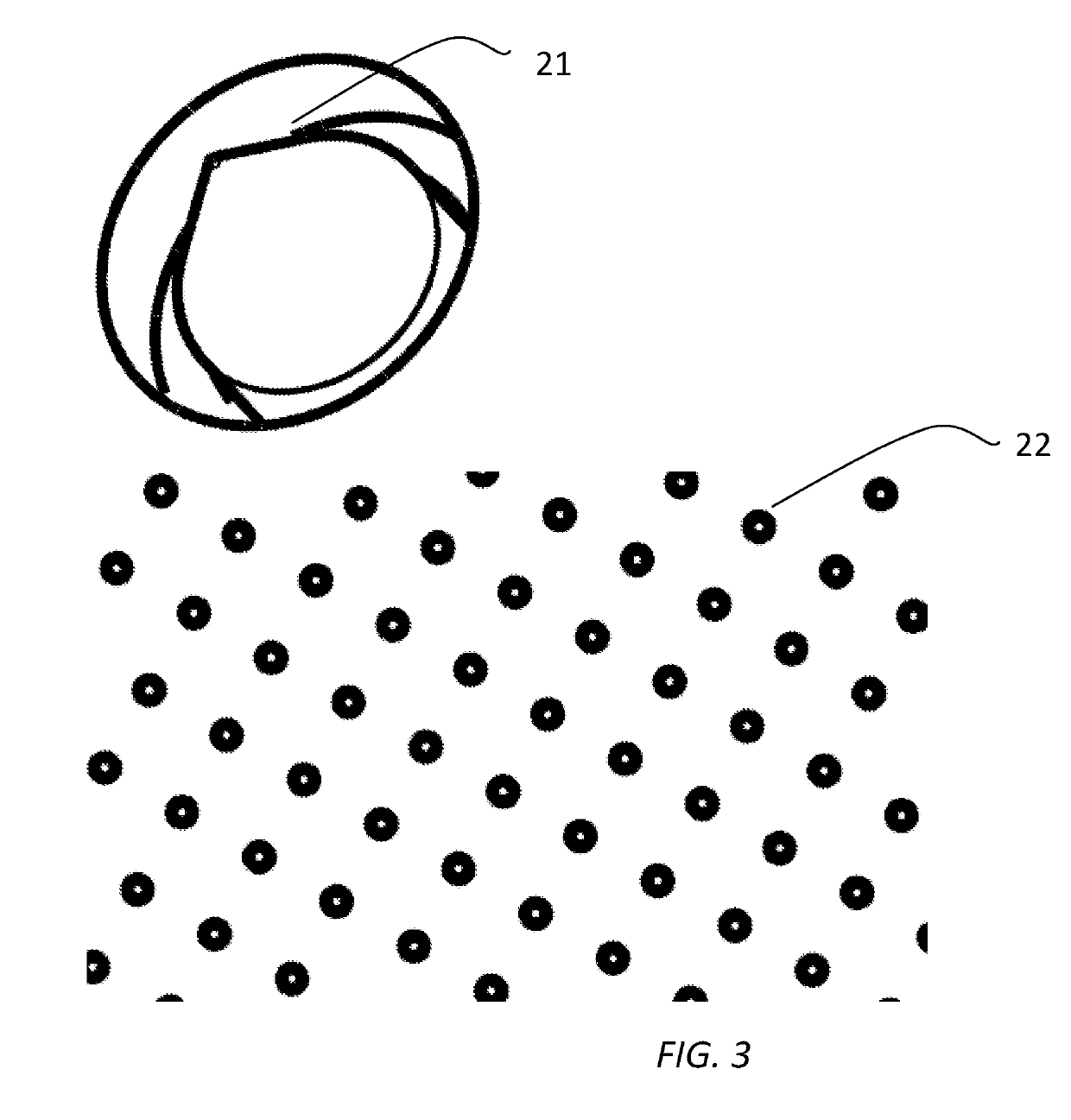

Apparatus and method for performing counts within a biologic fluid sample

ActiveUS7731901B2Low costSimple and accurate methodSpecific gravity using centrifugal effectsMaterial analysis by optical meansEngineeringBiological fluids

A method and an apparatus for enumerating one or more specific elements within a biologic fluid sample are provided. An embodiment of the method includes the steps of: a) providing a chamber formed between a first planar member that is transparent and a second planar member, which members are separated from one another by a substantially uniform height; b) introducing the biologic fluid sample into the chamber, wherein the chamber height is sized such that the sample extends between the first and second members, and sized relative to the specific elements within the sample such that the specific elements non-uniformly distribute within the sample upon introduction into the chamber; c) examining substantially all of the sample within the chamber and enumerating all of at least one of the specific elements; d) determining the volume of sample contained within the chamber; and e) determining the number of the at least one of the specific elements per unit volume.

Owner:WARDLAW PARTNERS +2

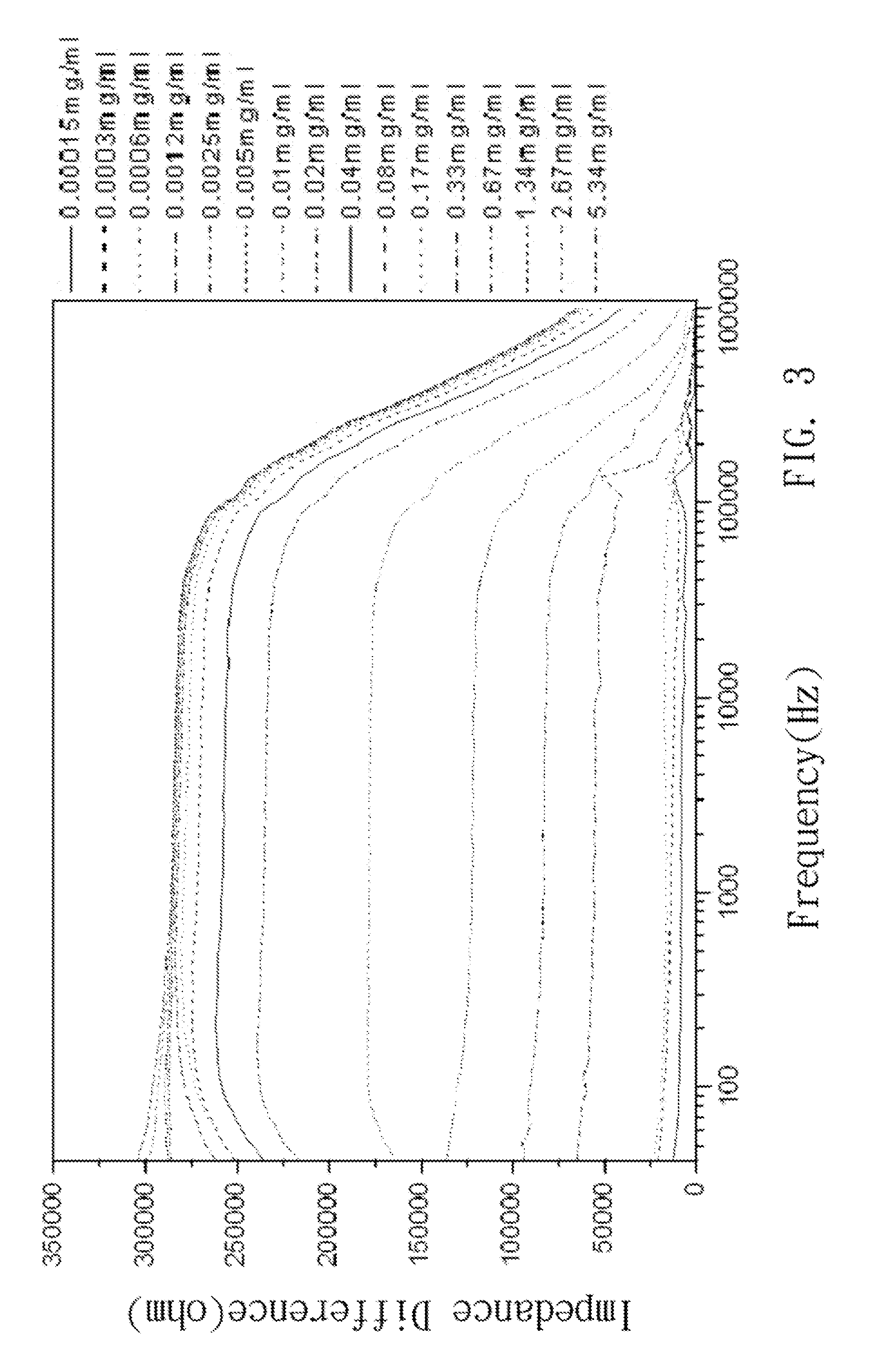

Method of measuring glycosylated protein proportion by ac impedance method

ActiveUS20130233727A1Simple and accurate methodQuick simple and accurate methodWeather/light/corrosion resistanceVolume/mass flow measurementChemistryAc impedance

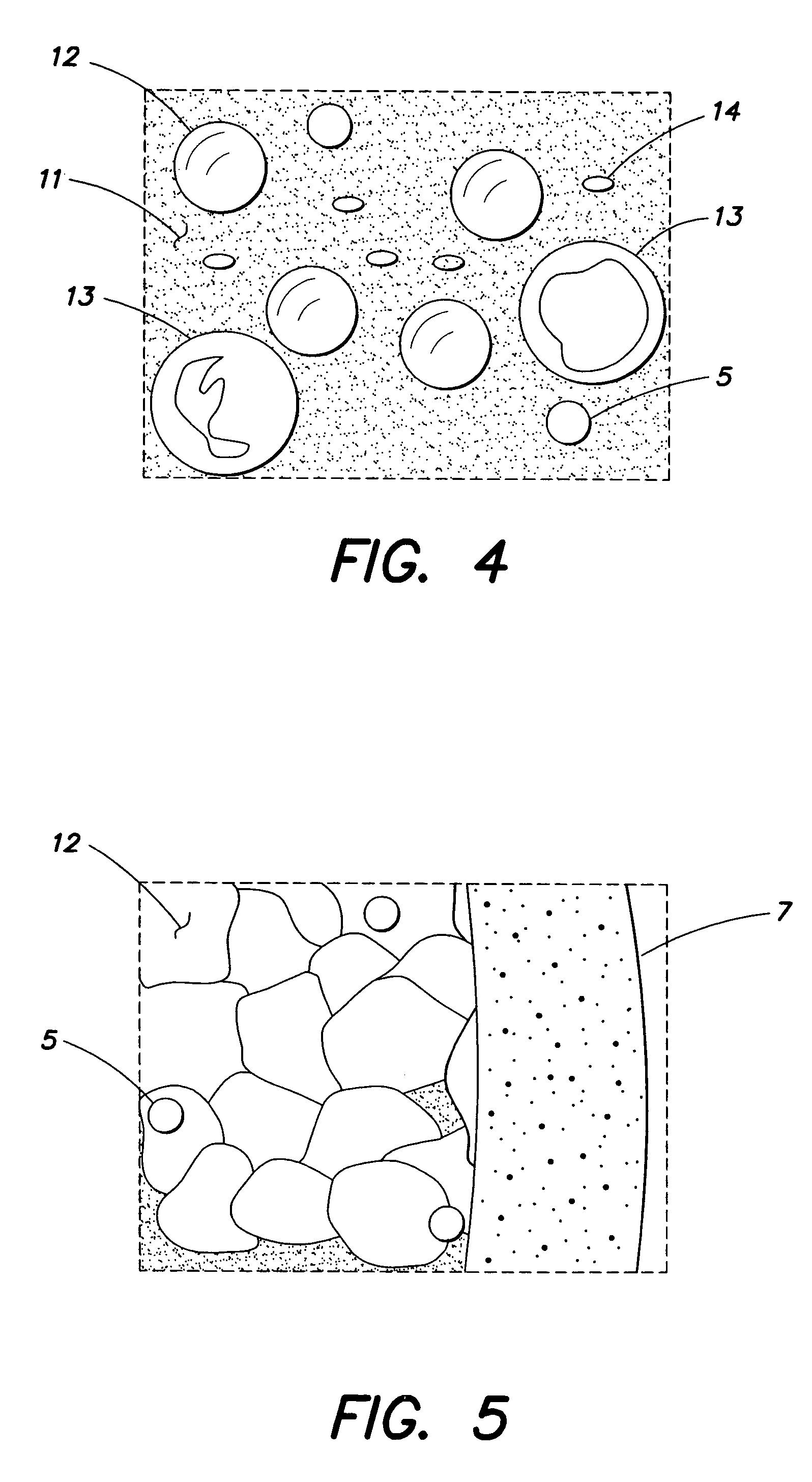

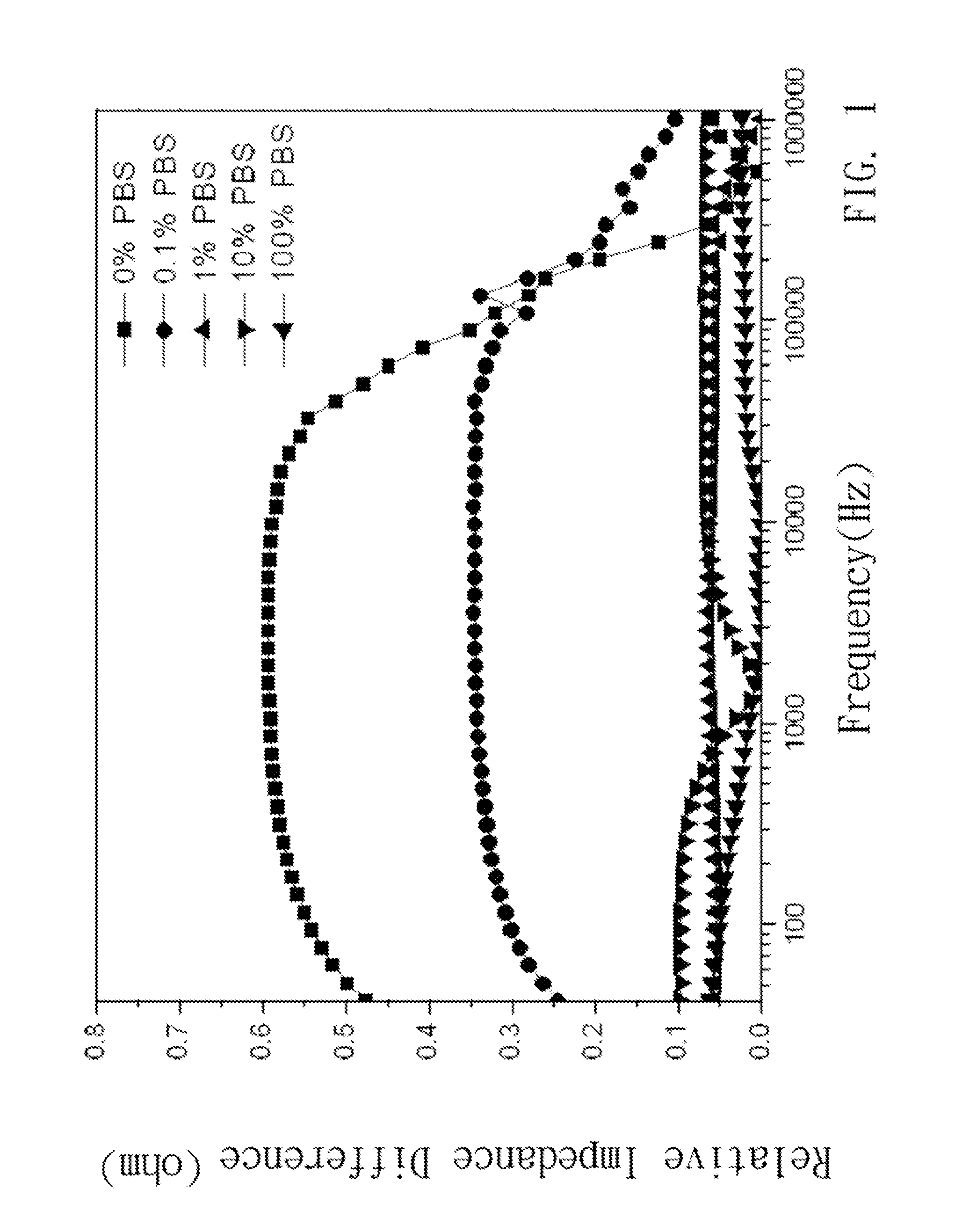

A method of measuring a glycosylated protein proportion by an AC impedance method includes passing an AC voltage or AC to two inspecting electrodes; covering a solution containing glycosylated protein completely onto the inspecting electrodes; measuring an impedance value between the electrodes and calculating the difference between the impedance value and an impedance value of a solution without glycosylated protein by an AC impedance inspection device; comparing the impedance difference with AC impedance difference / glycosylated protein concentration to obtain the proportion of the glycosylated protein in the solution containing glycosylated protein. The solution without glycosylated protein includes a salt solution and a non-glycosylated protein; the proportion of glycosylated protein in the solution containing glycosylated protein refers to the proportion of glycosylated protein in the total quantity of protein in the salt solution; and the proportion of glycosylated hemoglobin of the total quantity of hemoglobin in the salt solution.

Owner:NAT CENT UNIV

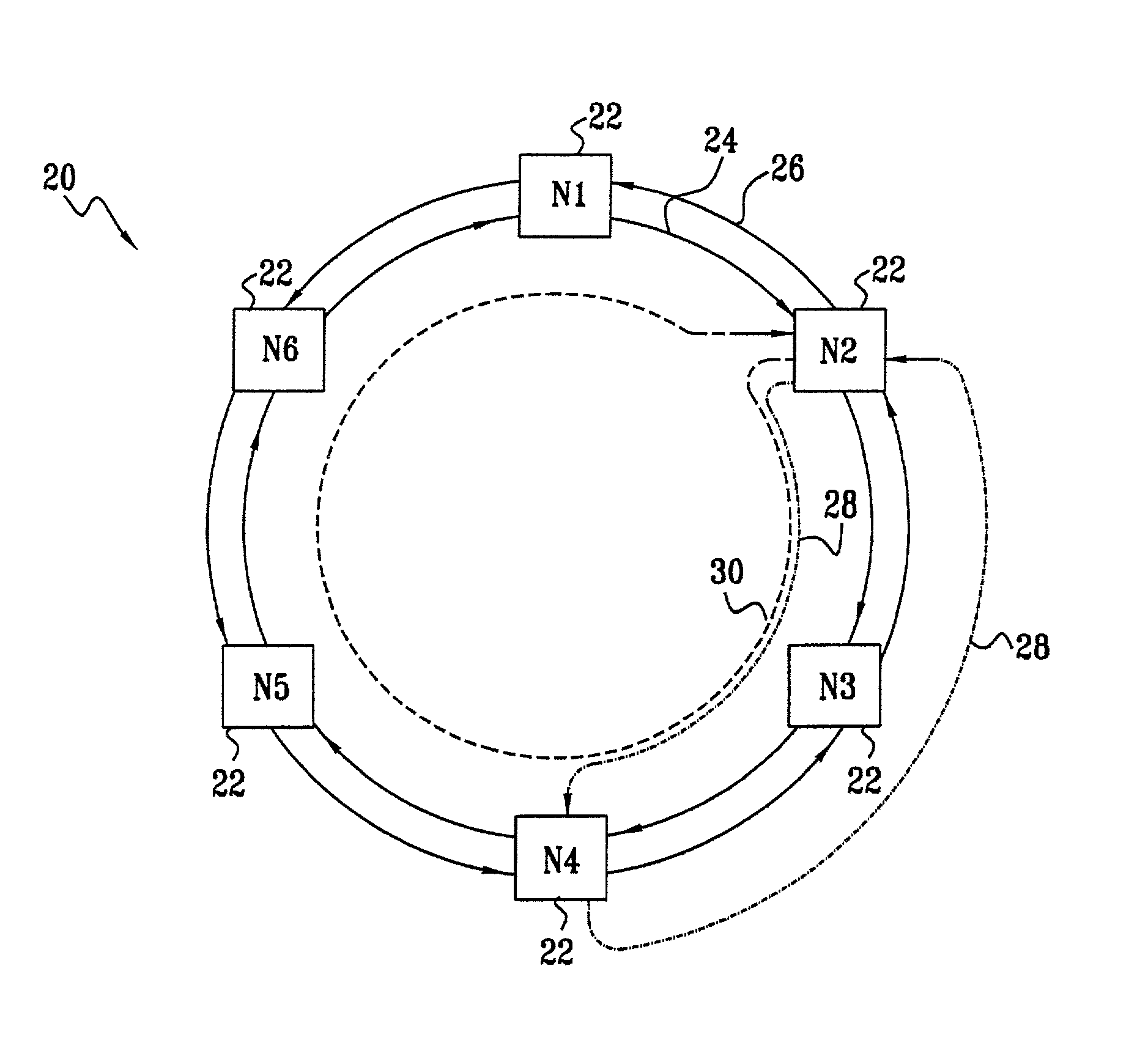

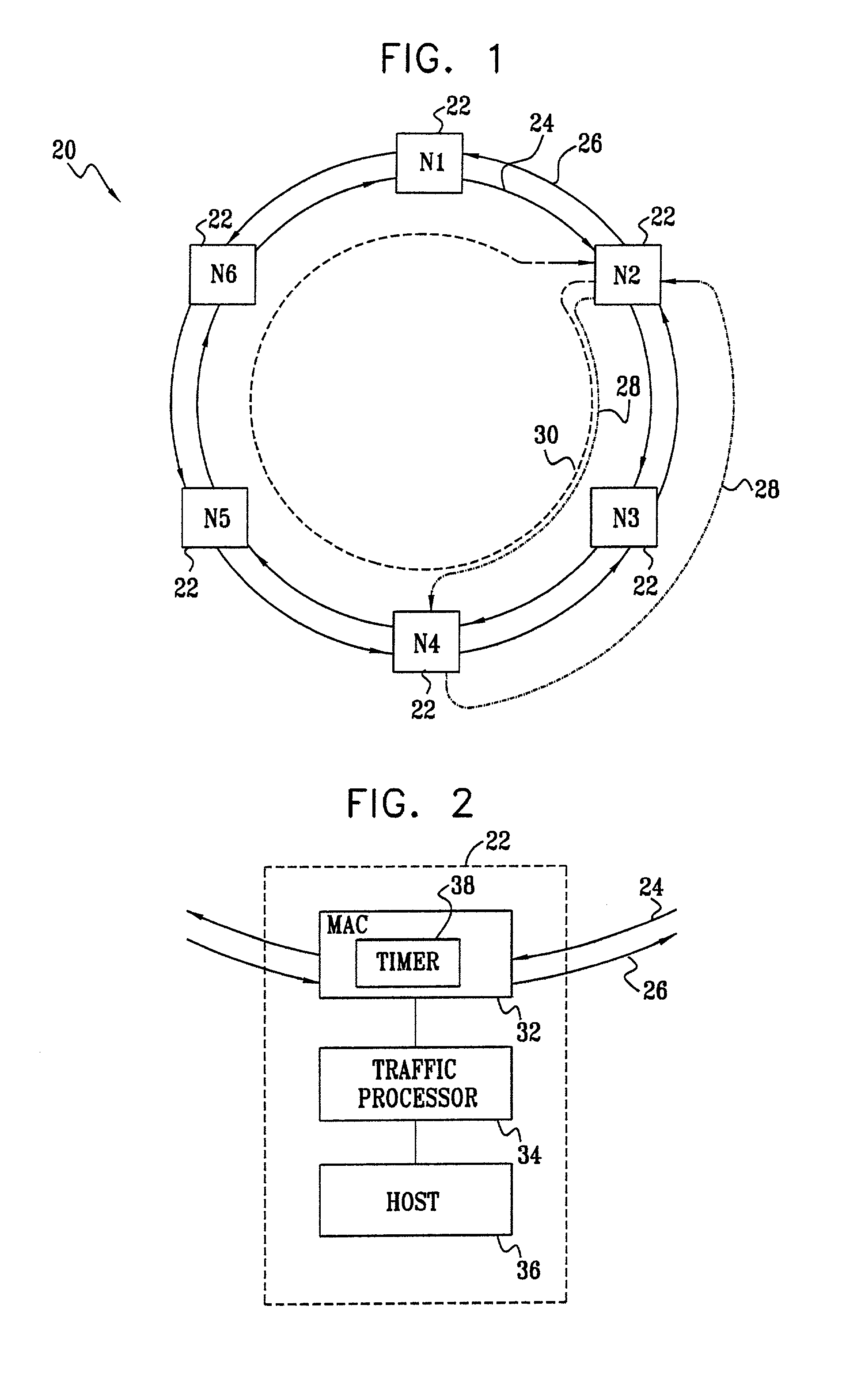

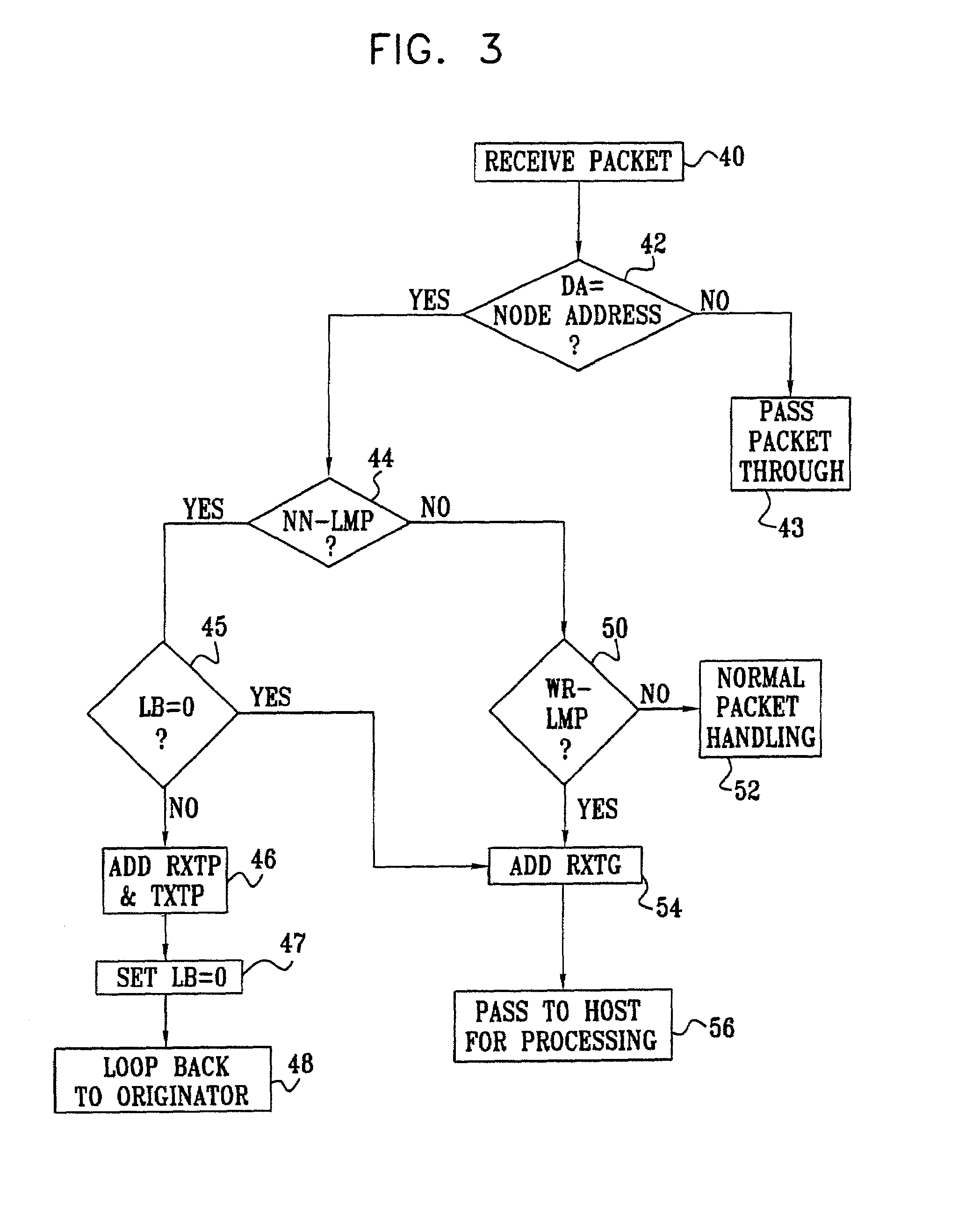

Latency evaluation in a ring network

ActiveUS7113485B2Simple and accurate methodMonitor variationError preventionTransmission systemsNetwork packetRing network

A method for measuring latency in a bi-directional ring network includes transmitting a latency measurement packet from an originating node to a peer node and noting a time of receipt of the packet at the peer node. The packet is then transmitted back to the originating node in the opposite direction, while recording in the packet an indication of a peer node difference between a time of transmission of the packet from the peer node to the originating node and the time of receipt of the packet at the peer node. A time of return of the packet to the originating node is noted, so as to determine an originating node difference between a time of transmission of the packet from the originating node to the peer node and the time of return of the packet to the originating node. The latency is calculated by taking a difference between the originating node difference and the peer node difference.

Owner:CORRIGENT CORP

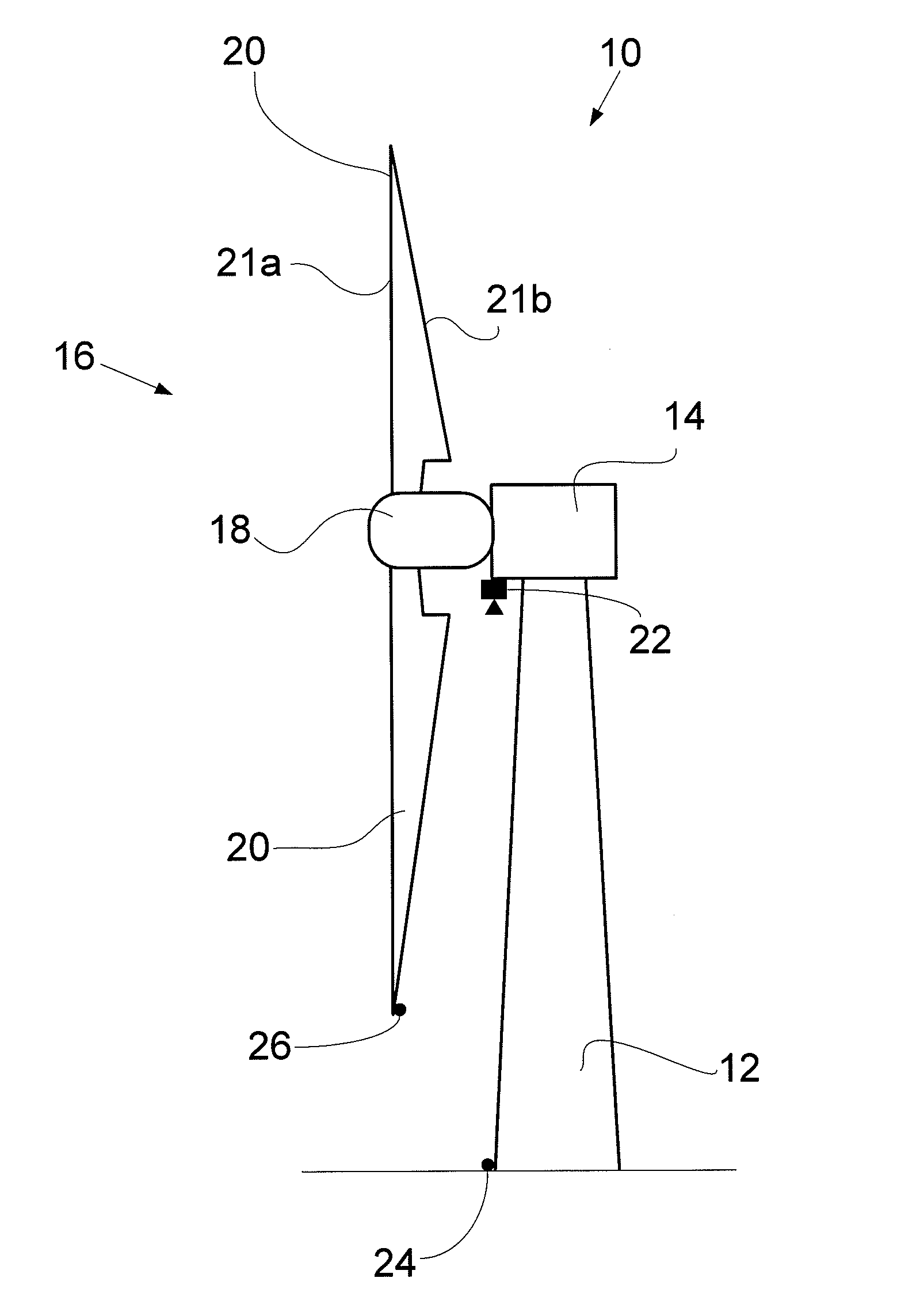

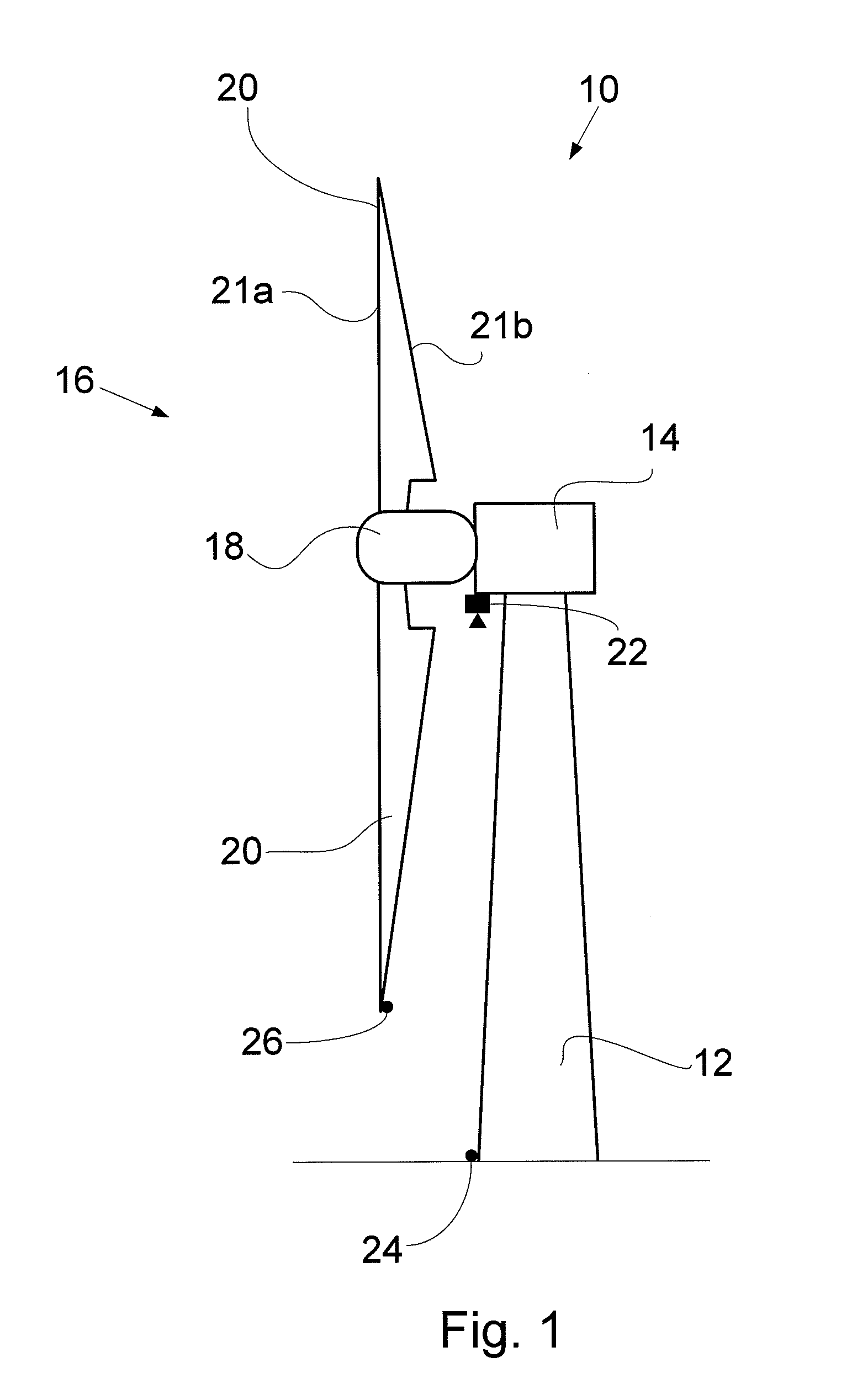

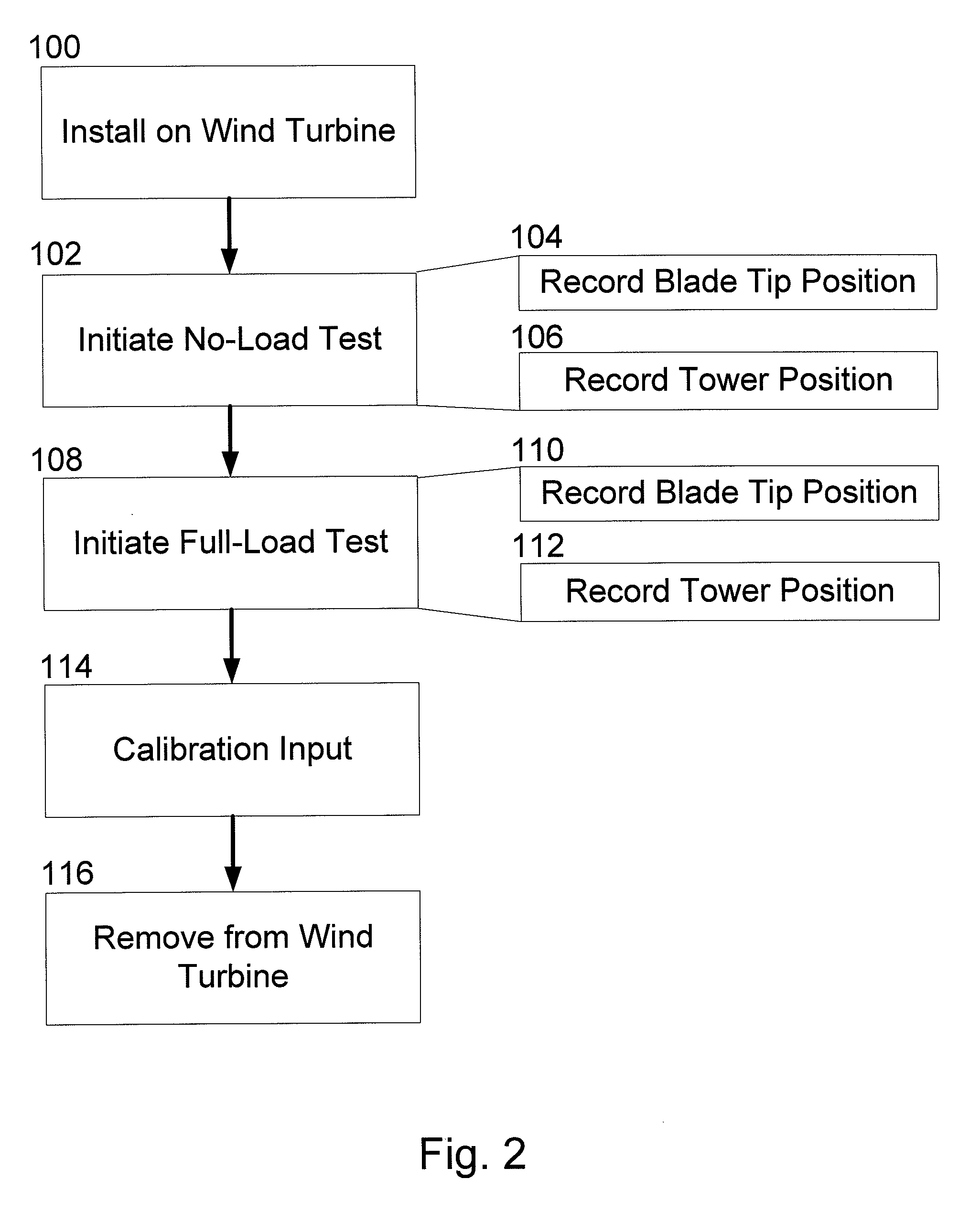

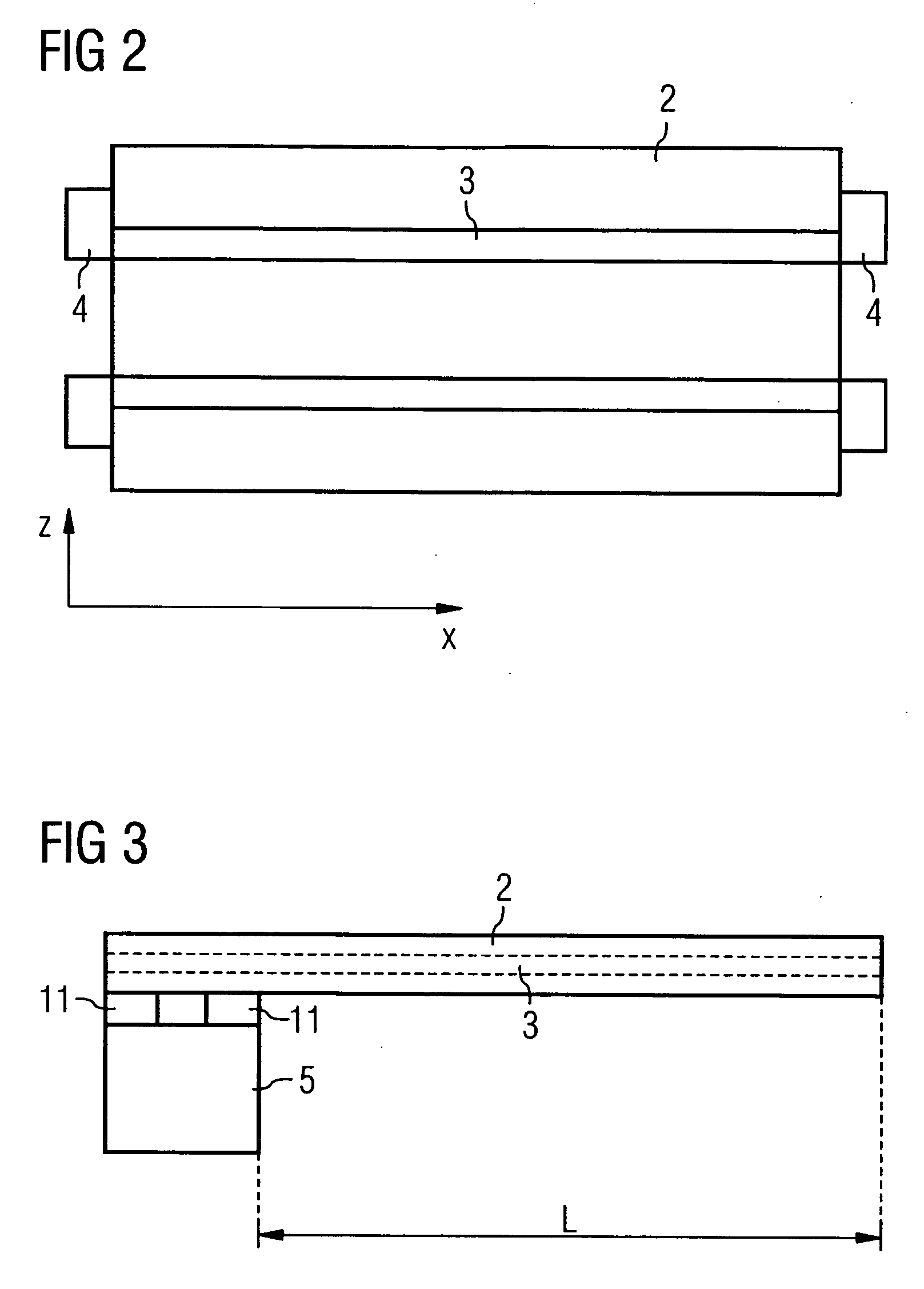

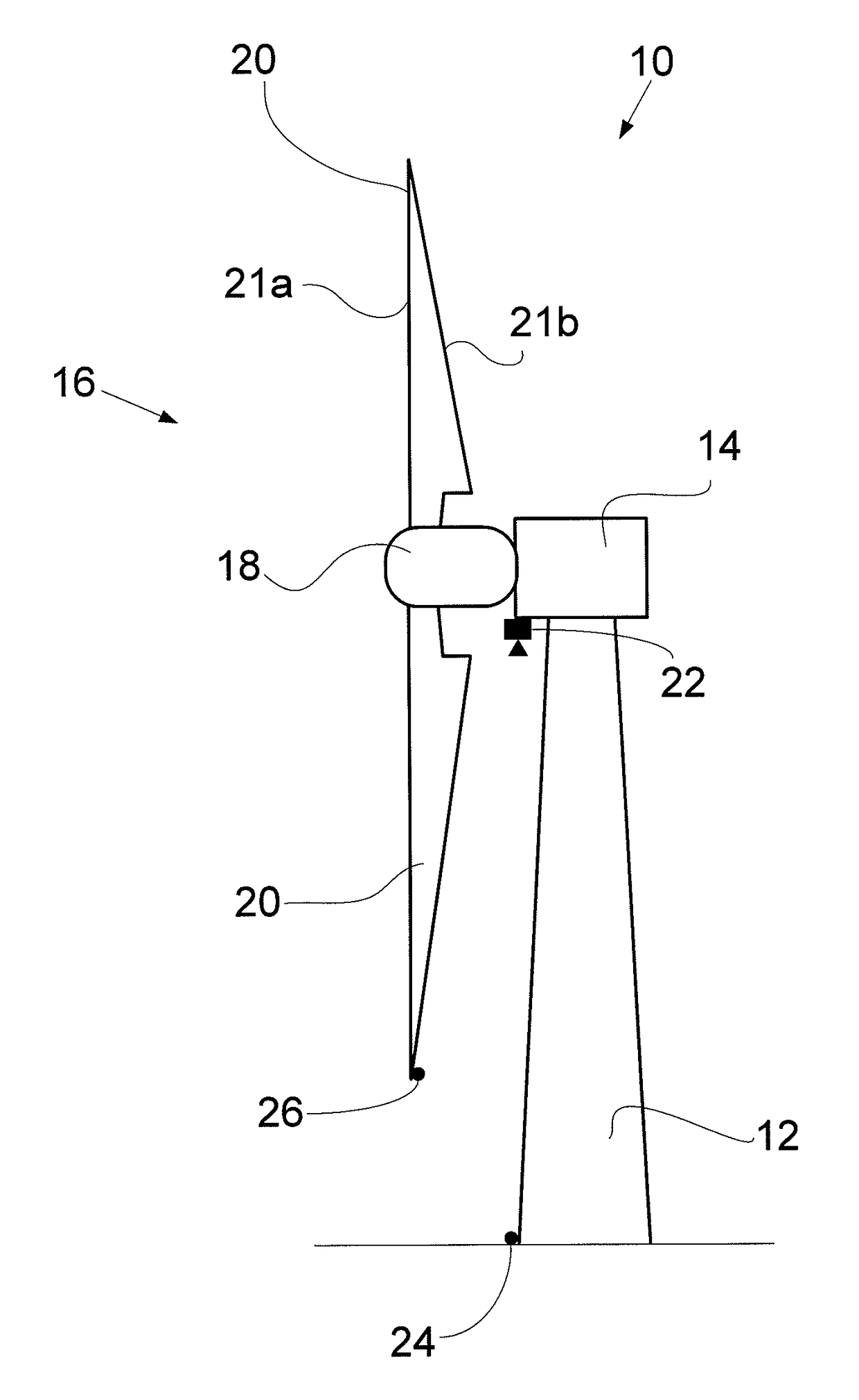

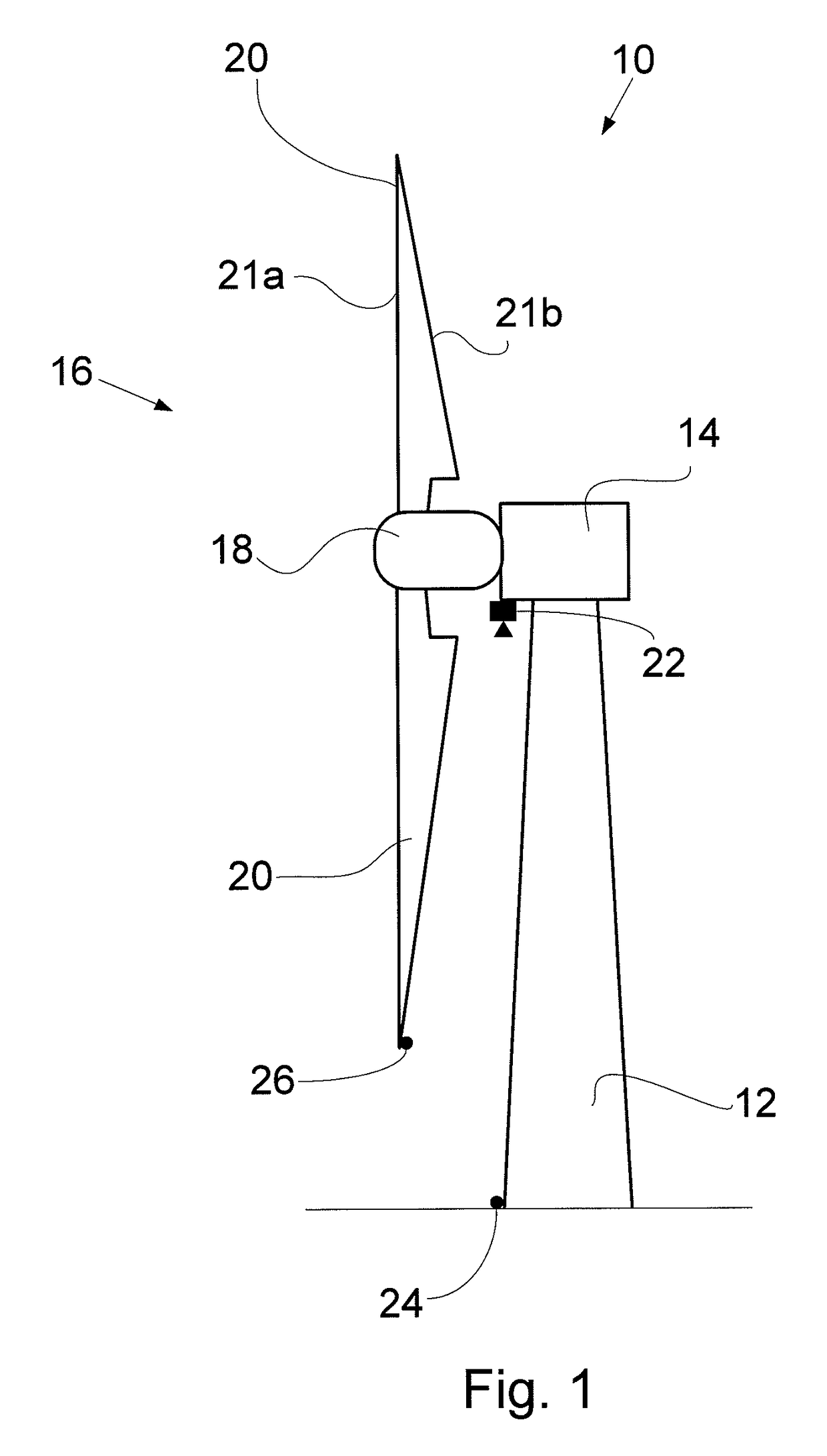

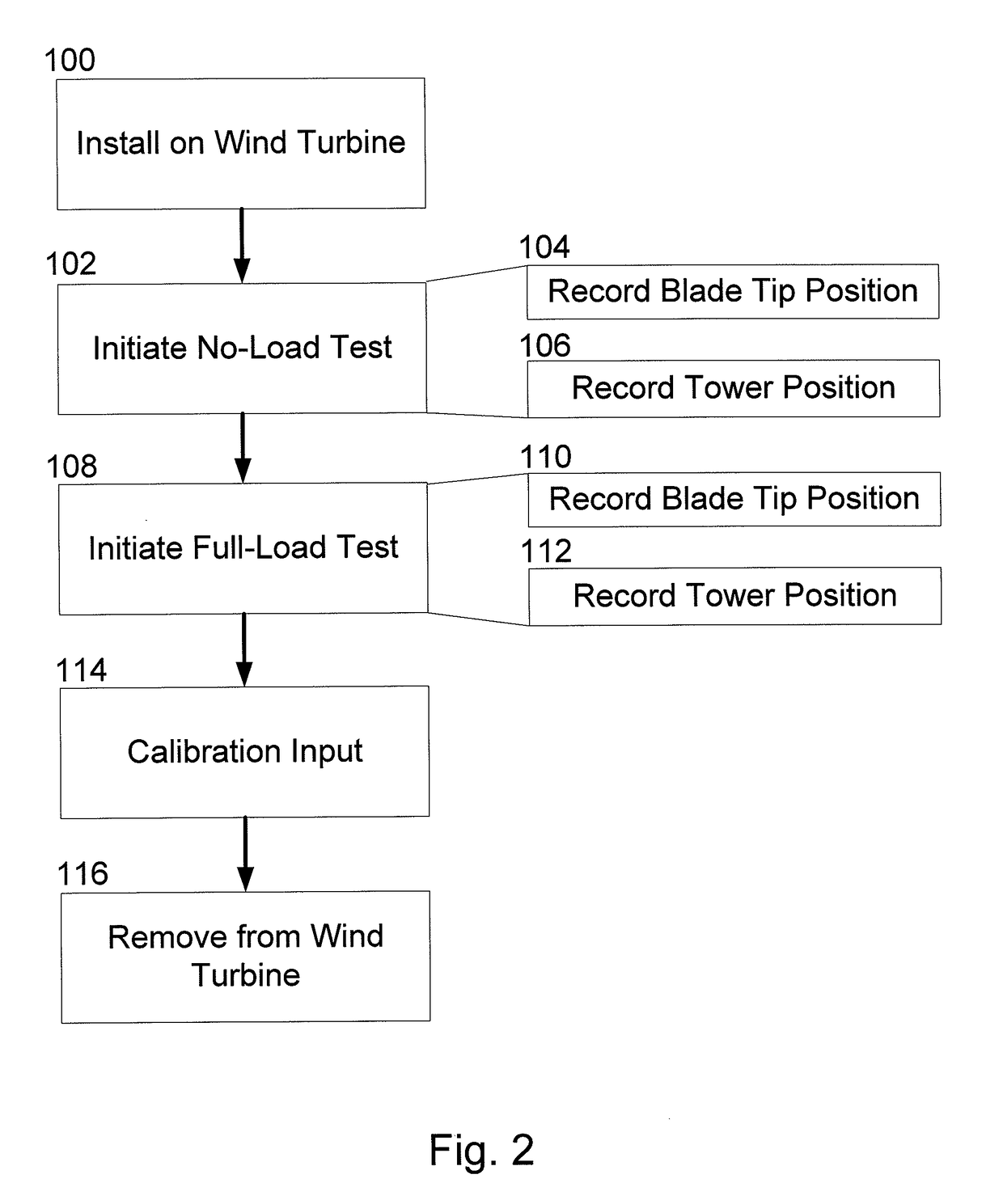

A system and method for wind turbine sensor calibration

ActiveUS20150322925A1High degree of accuracyImprove reliabilityPropellersWind motor controlEngineeringRelative motion

A system and method for the verification and calibration of wind turbine sensor systems is provided. The system comprises an optical capture device provided on a wind turbine which is arranged to record the position of at least one light source provided at the wind turbine during operation of the wind turbine. The motion of the light source relative to the optical capture device can provide an indication of relative motion of a portion of the wind turbine during operation, which can then be used as an input to a calibration and / or a verification system for a sensor system of the wind turbine.

Owner:LM WP PATENT HLDG

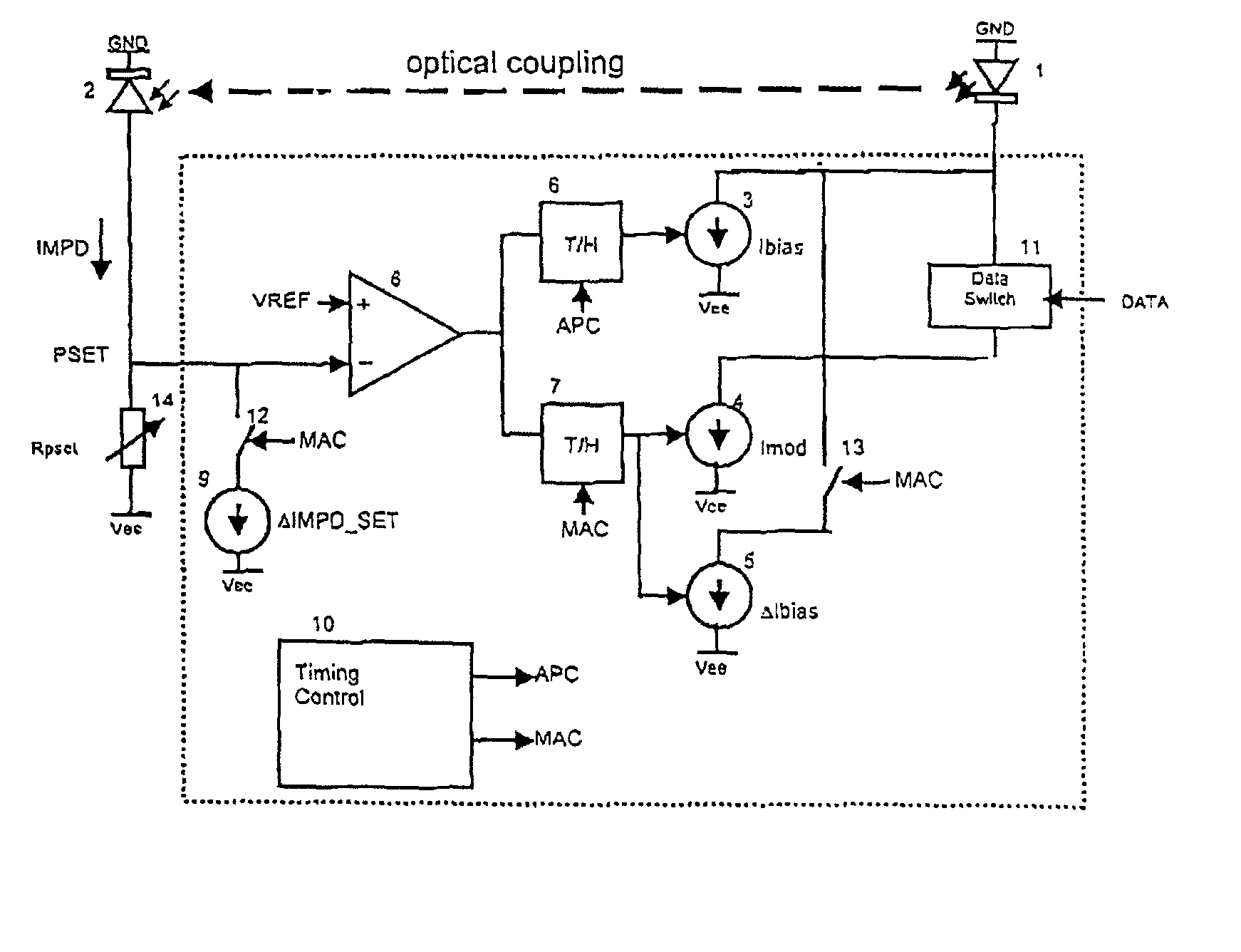

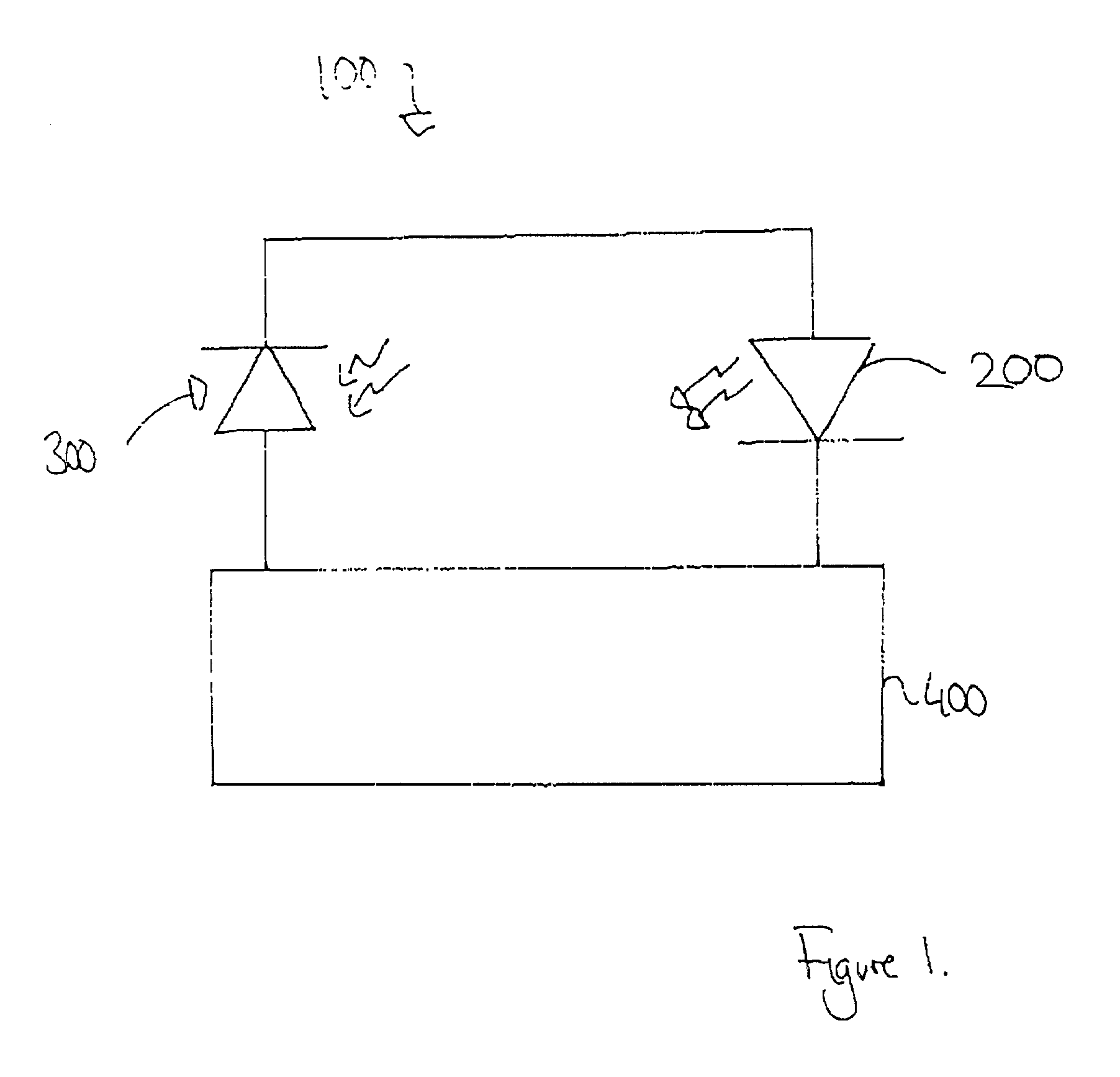

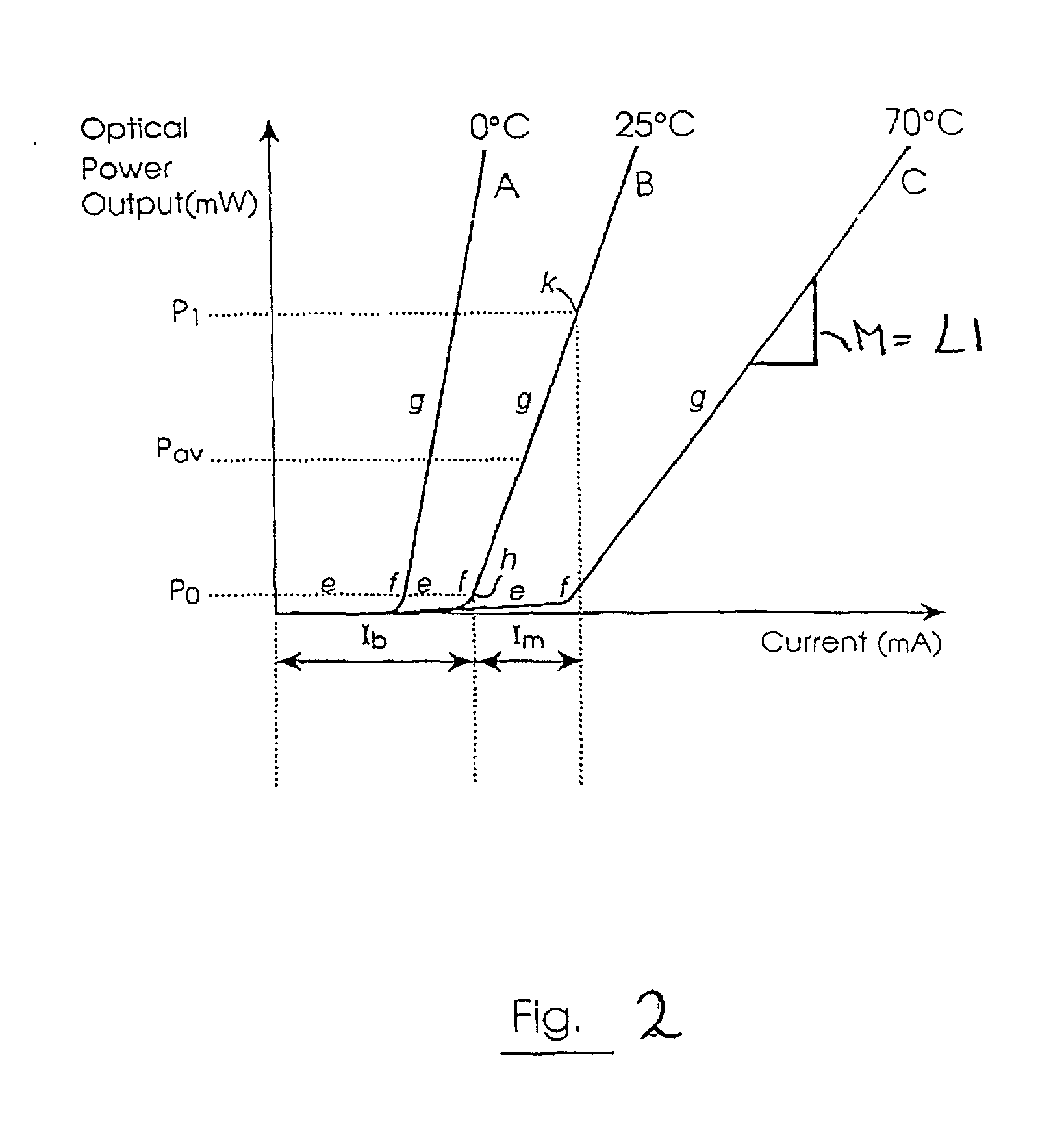

Method and circuit for measuring the optical modulation amplitude (OMA) in the operating region of a laser diode

InactiveUS20030090289A1Accurate measurementAccurate operationLaser detailsSemiconductor lasersOptoelectronicsOptical modulation amplitude

A method and circuit for measuring the optical modulation amplitude in the operating region of a laser diode is described. The method utilises two measurements of OMA, each measurement being related to the slope in a specific portion of the operating region of the power / current characteristic curve of the laser diode. By combining the two measurement values, the invention provides a 1 measurement for OMA in the operating region of the laser diode that allows for the presence of a non-linear response in the region.

Owner:ANALOG DEVICES INC

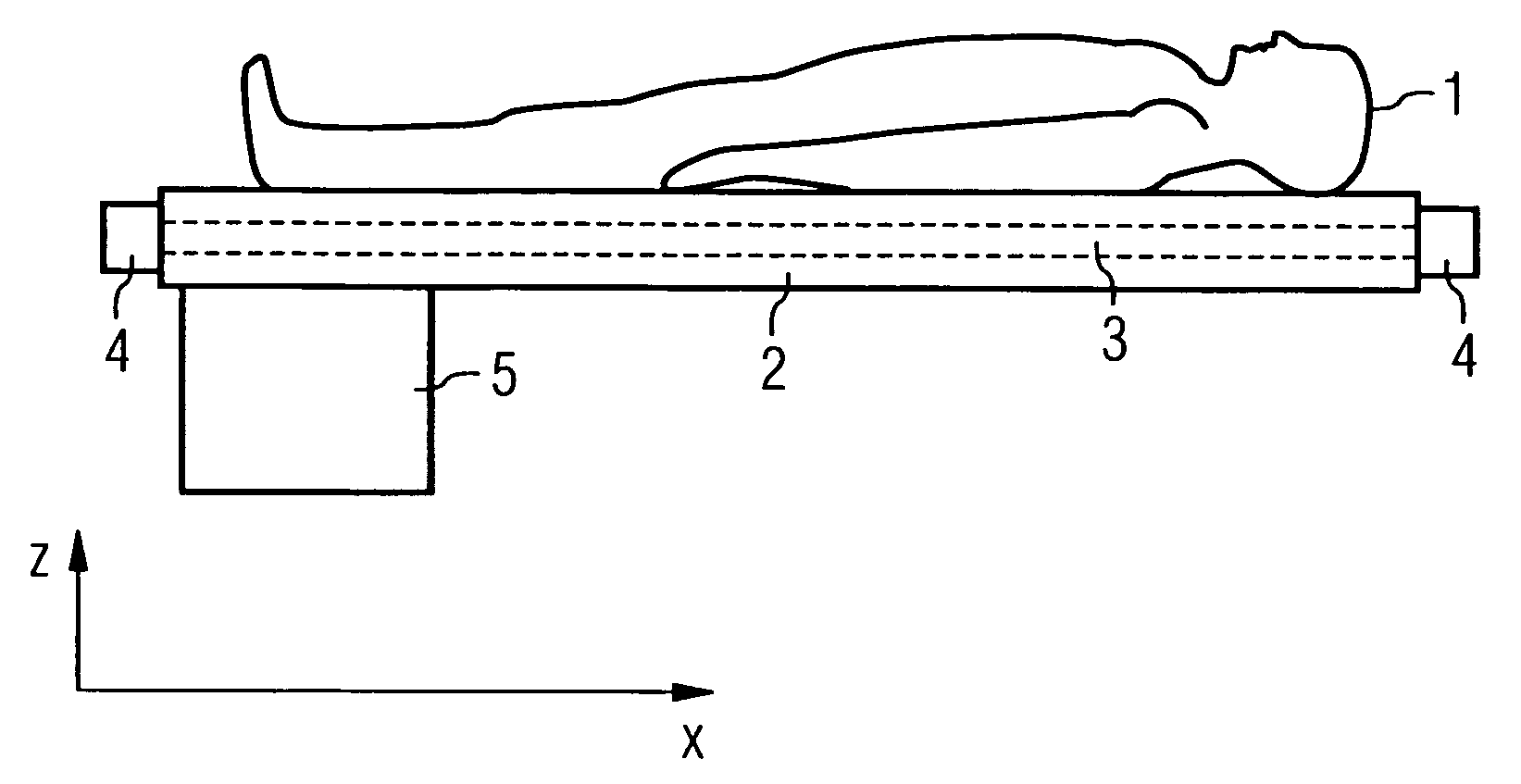

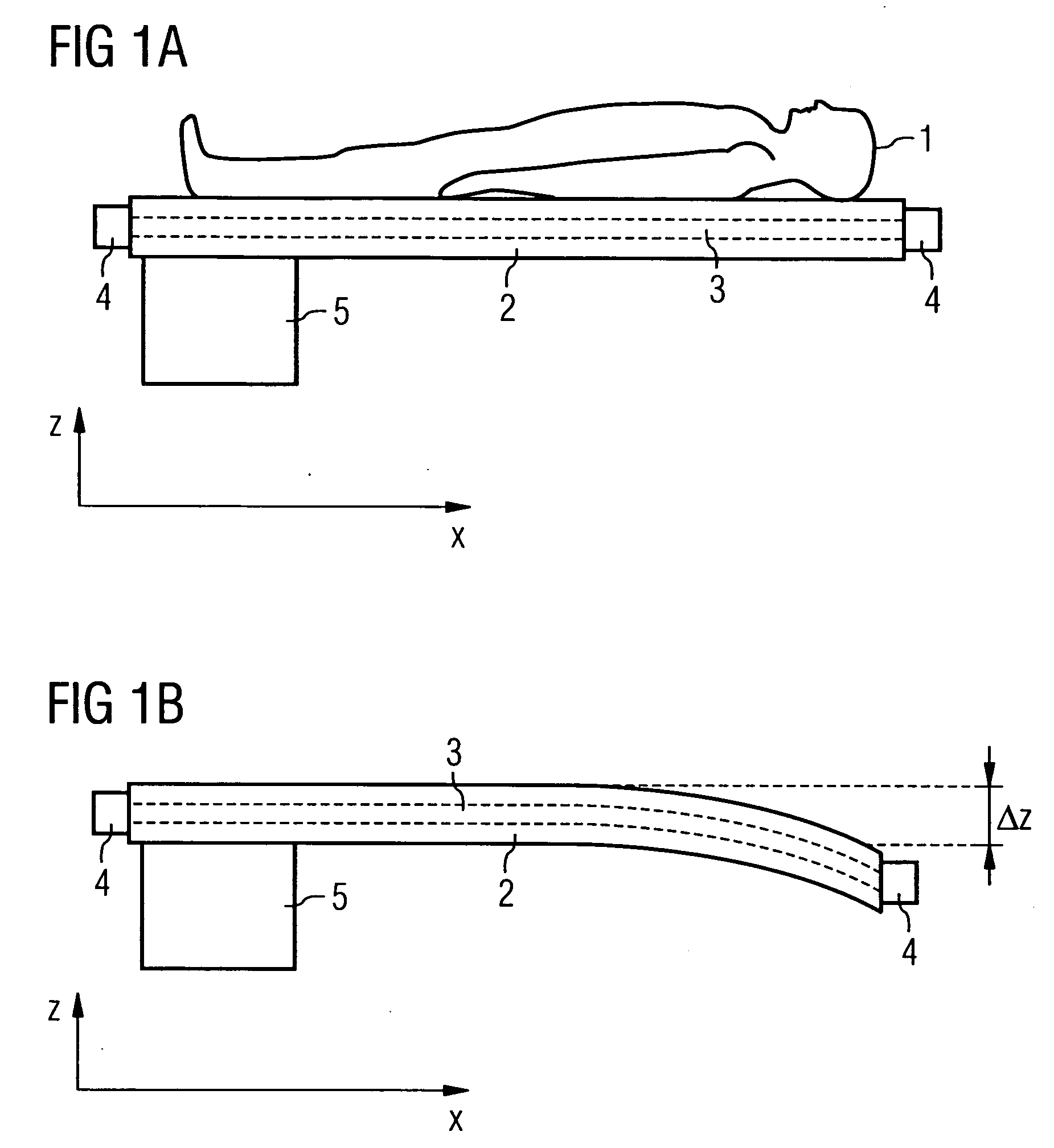

Apparatus and method for determining a position of a patient in a medical examination

InactiveUS20060193443A1Simple and accurate methodSimple and accurate and apparatusSurgeryForce measurementEngineeringStrain gauge

An apparatus and a method are provided for determining a position of a patient during medical examinations. The apparatus comprises a tabletop operable to support the patient, at least one elongatable strain gauge which is integrated into the tabletop, and tabletop sensors operable to detect a sagging of the tabletop as a function of a change in length of the at least one elongatable strain gauge due to the sagging.

Owner:SIEMENS HEALTHCARE GMBH

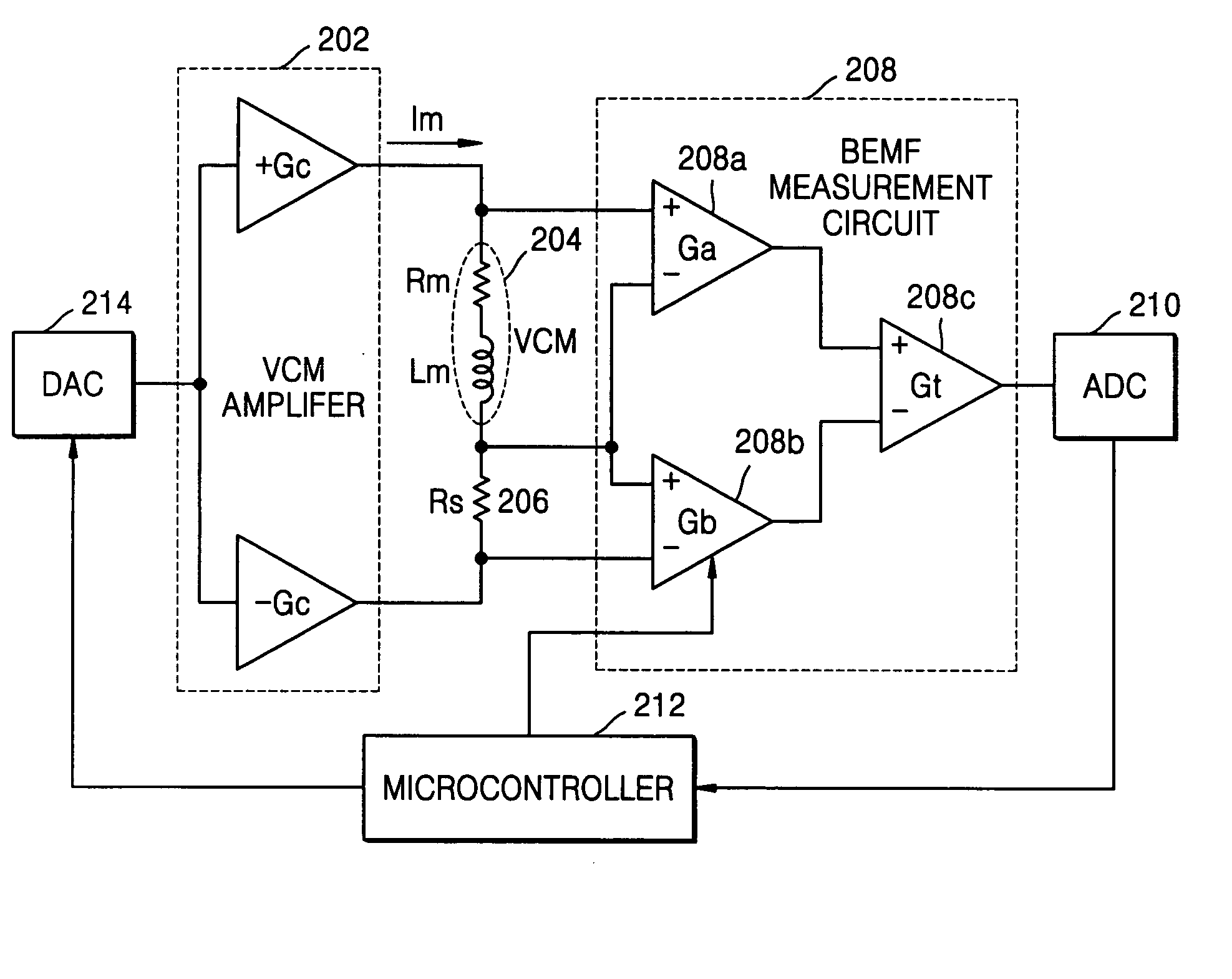

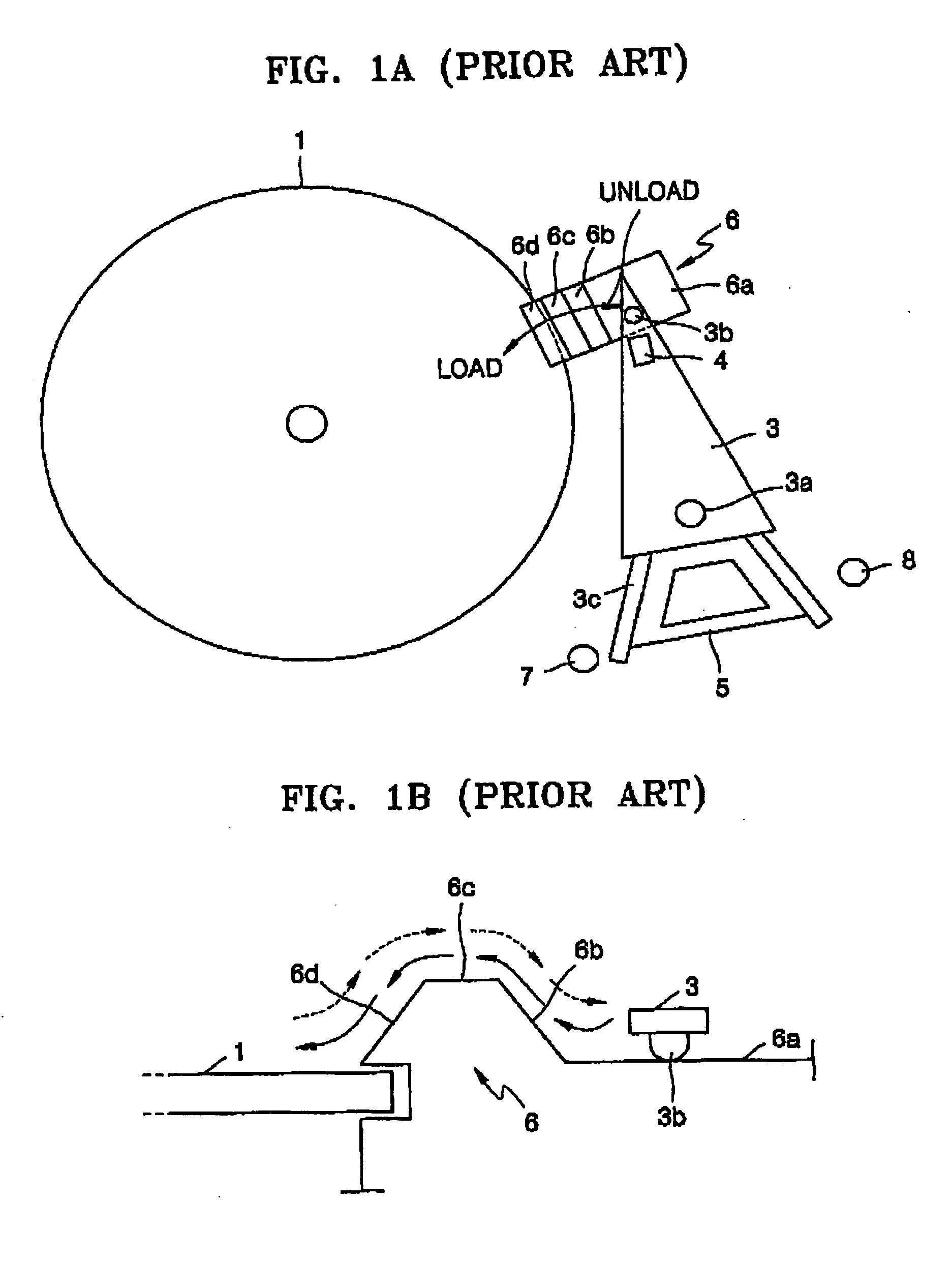

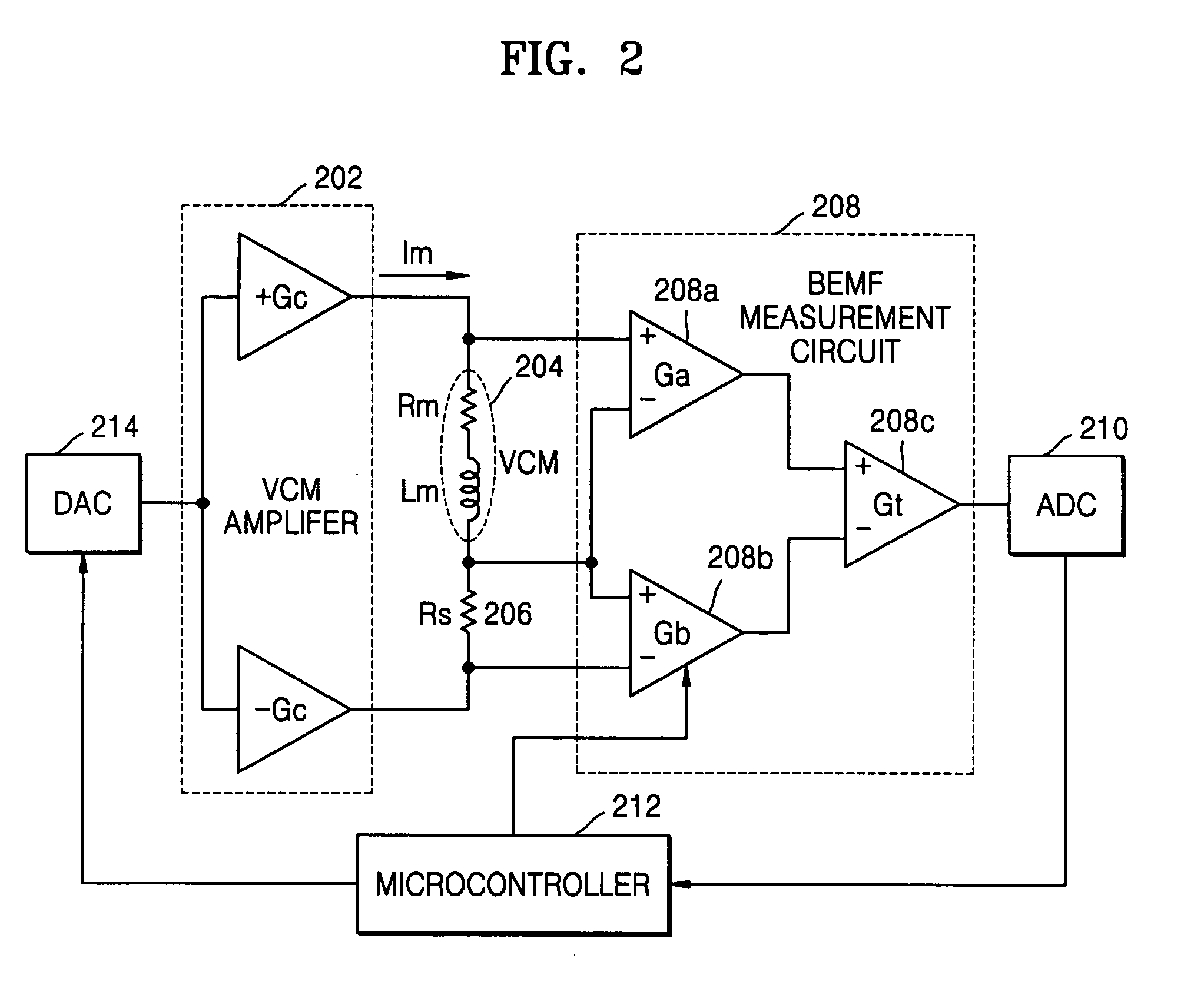

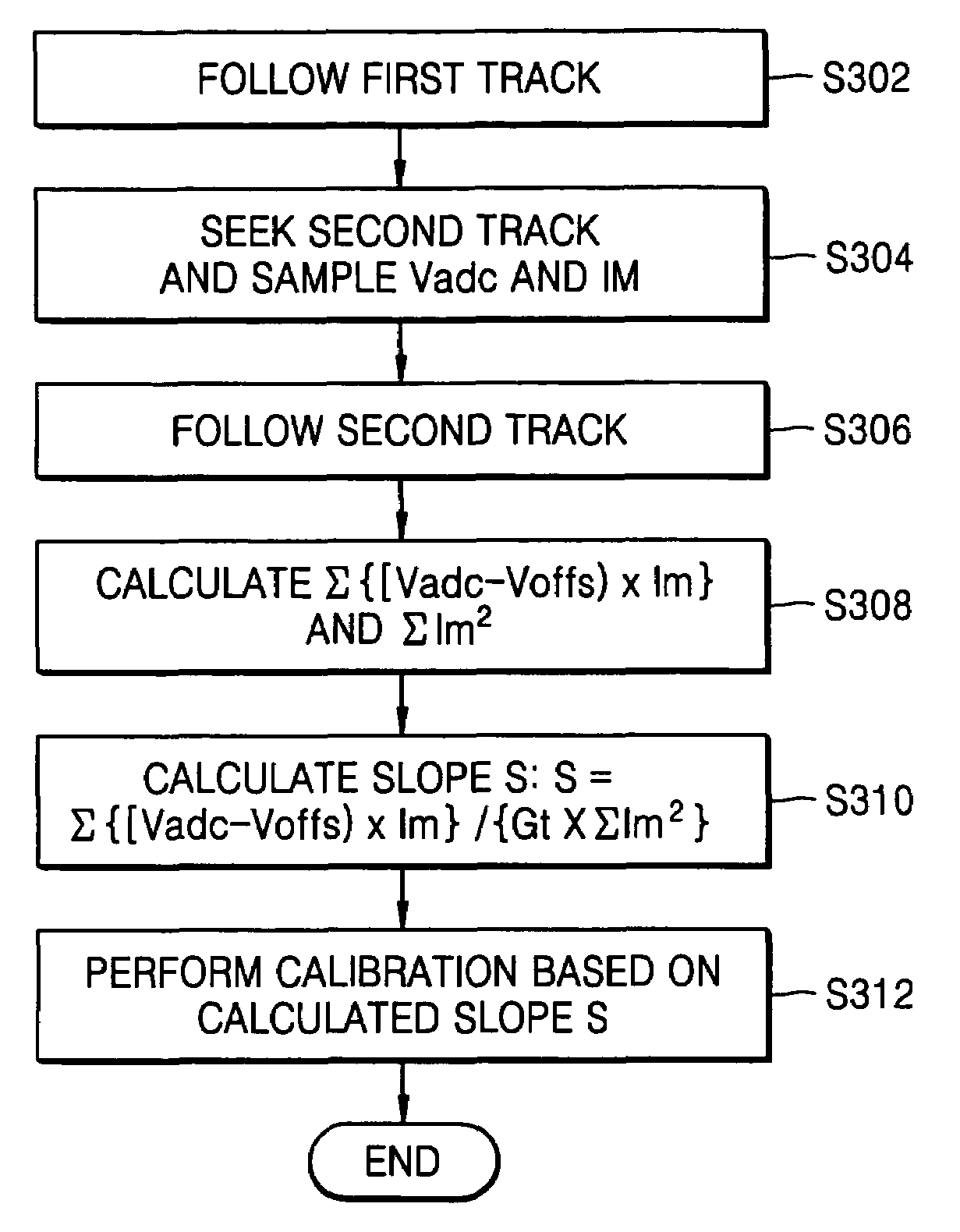

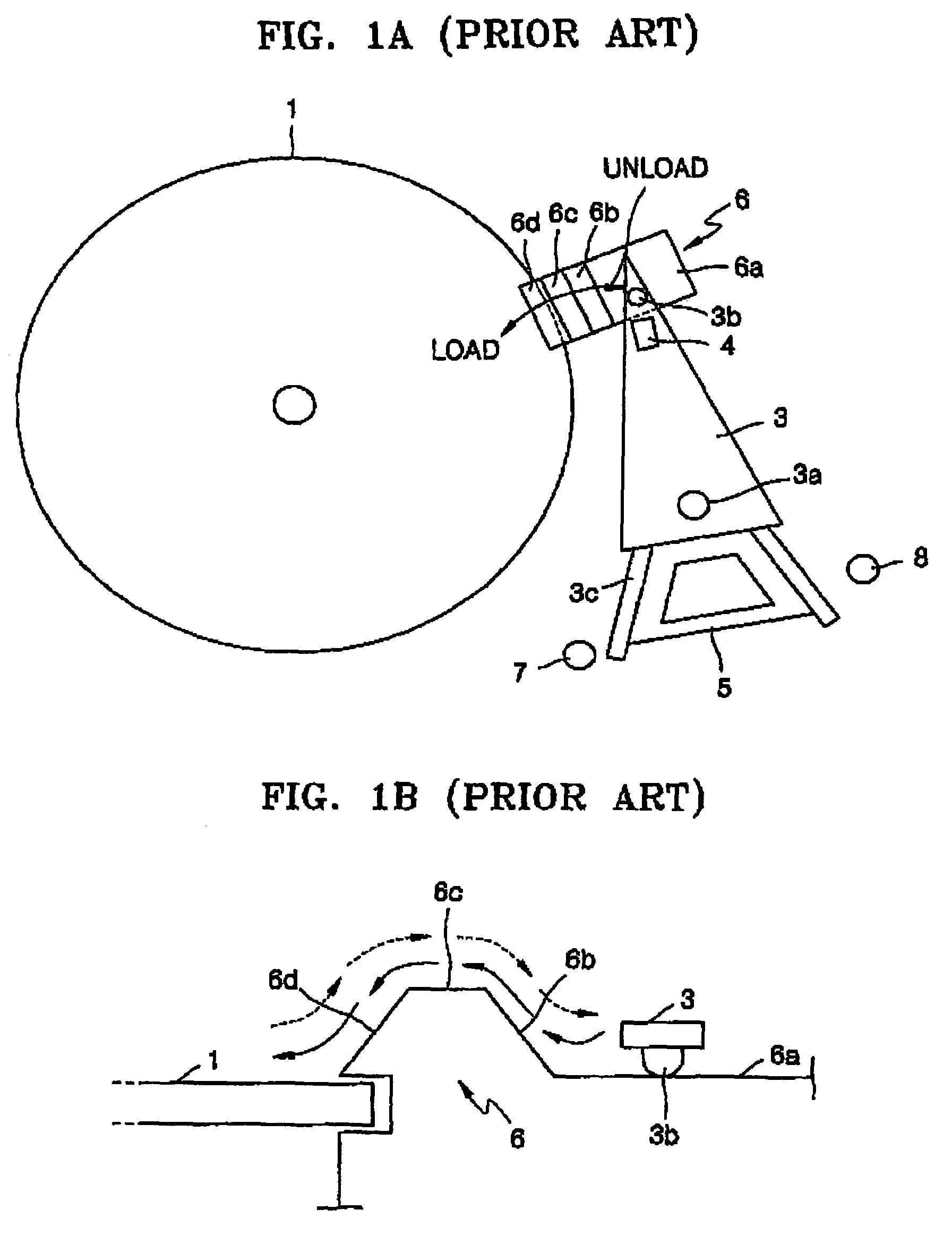

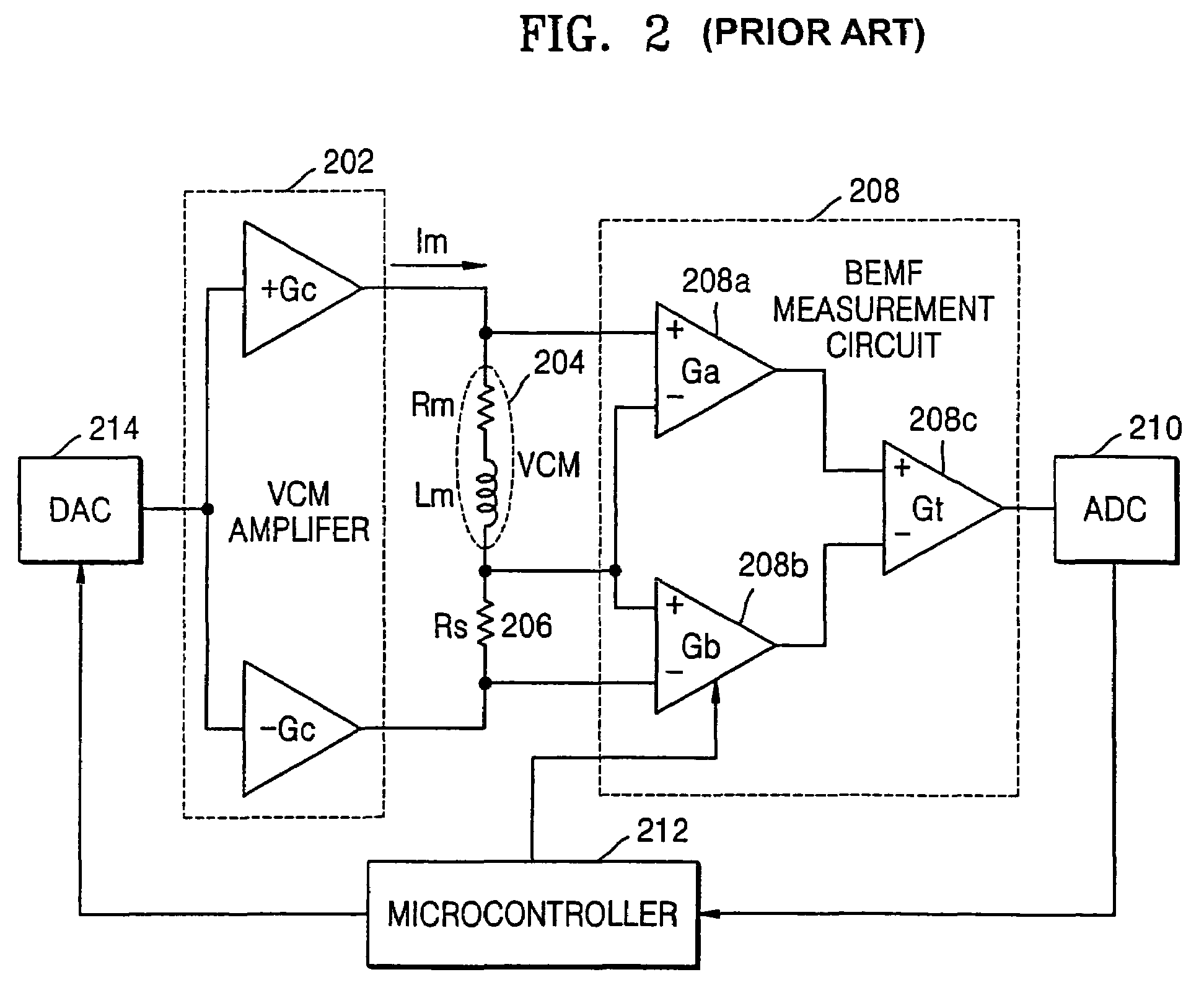

Hard disk drive calibration method and apparatus

InactiveUS20050168862A1Simple and accurate calibration methodSimple and accurate methodTrack finding/aligningDisposition/mounting of recording headsHard disc driveDriving current

A method of calibrating parameters of an apparatus for measuring a back electromotive force (BEMF) of a voice coil motor (VCM) for moving a head on a disk, the apparatus including the VCM having a coil resistance Rm, a coil inductance Lm, and a sensing resistance Rs, including: controlling the VCM to sequentially perform a track following operation of the head on a first track, a transferring operation of the head from the first track to a second track, and a track following operation of the head on the second track; sampling a differential voltage Vadc between a voltage across the VCM and a voltage across the sensing resistance Rs and a VCM driving current Im during the transferring operation; calculating a slope S based on a ratio of a first integration value to a second integration value, where the first integration value is obtained by integrating a product of the sampled differential voltage Vadc and the VCM driving current Im during the transferring operation, the second integration value being obtained by integrating a square of the VCM driving current Im during the transferring operation, the slope S being defined by the equation S=Rm−Gb×Rs, Gb being a gain of an amplifier for amplifying the voltage across the sensing resistance Rs; and calibrating the parameters of the apparatus using the slope S.

Owner:SAMSUNG ELECTRONICS CO LTD

Hard disk drive calibration method and apparatus

InactiveUS7042673B2Simple and accurate methodTrack finding/aligningDisposition/mounting of recording headsHard disc driveCoil inductance

A method of calibrating parameters of an apparatus for measuring a back electromotive force (BEMF) of a voice coil motor (VCM) for moving a head on a disk, the apparatus including the VCM having a coil resistance Rm, a coil inductance Lm, and a sensing resistance Rs, including: controlling the VCM to sequentially perform a track following operation of the head on a first track, a transferring operation of the head from the first track to a second track, and a track following operation of the head on the second track; sampling a differential voltage Vadc between a voltage across the VCM and a voltage across the sensing resistance Rs and a VCM driving current Im during the transferring operation; calculating a slope S based on a ratio of a first integration value to a second integration value, where the first integration value is obtained by integrating a product of the sampled differential voltage Vadc and the VCM driving current Im during the transferring operation, the second integration value being obtained by integrating a square of the VCM driving current Im during the transferring operation, the slope S being defined by the equation S=Rm−Gb×Rs, Gb being a gain of an amplifier for amplifying the voltage across the sensing resistance Rs; and calibrating the parameters of the apparatus using the slope S.

Owner:SAMSUNG ELECTRONICS CO LTD

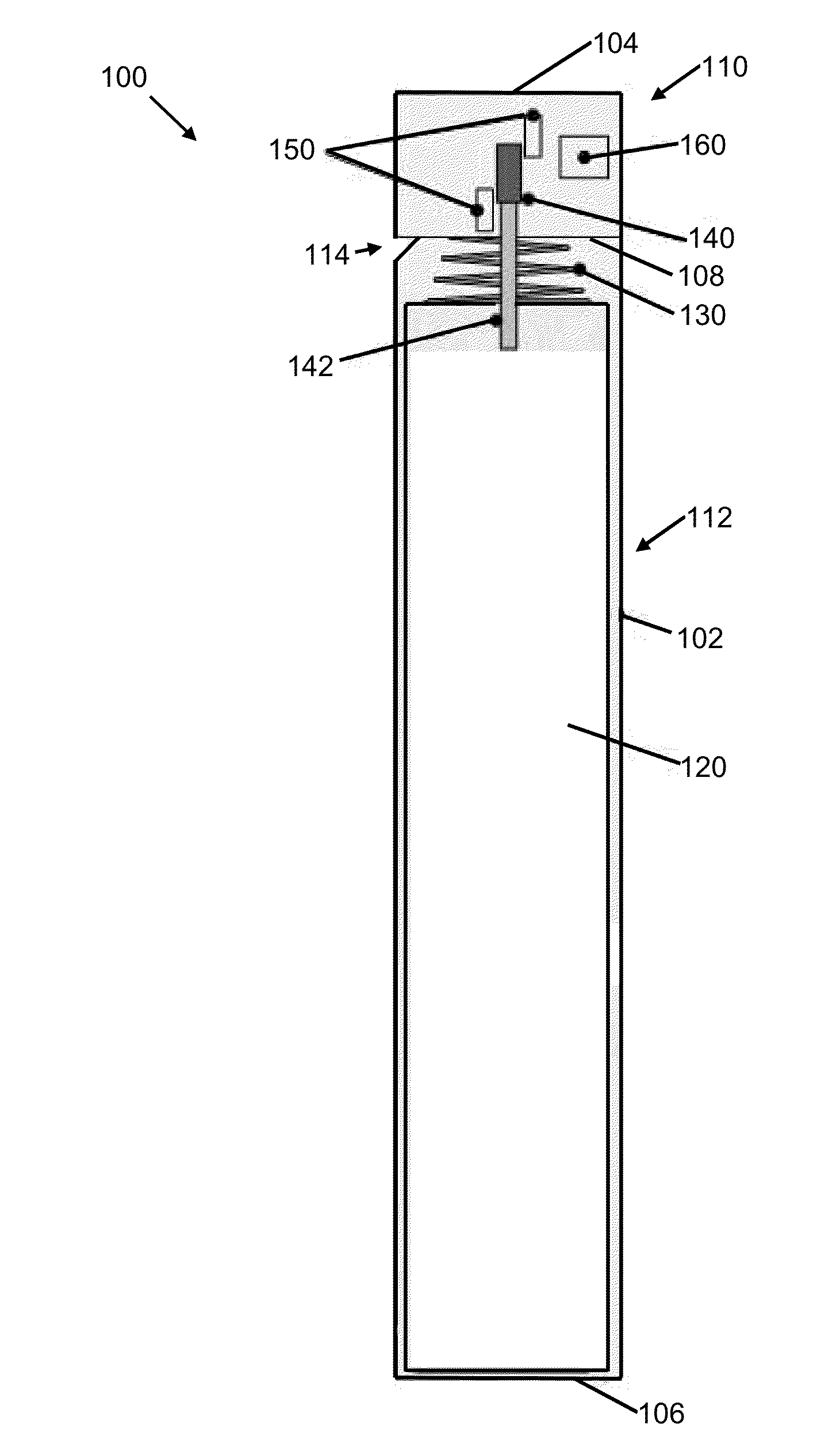

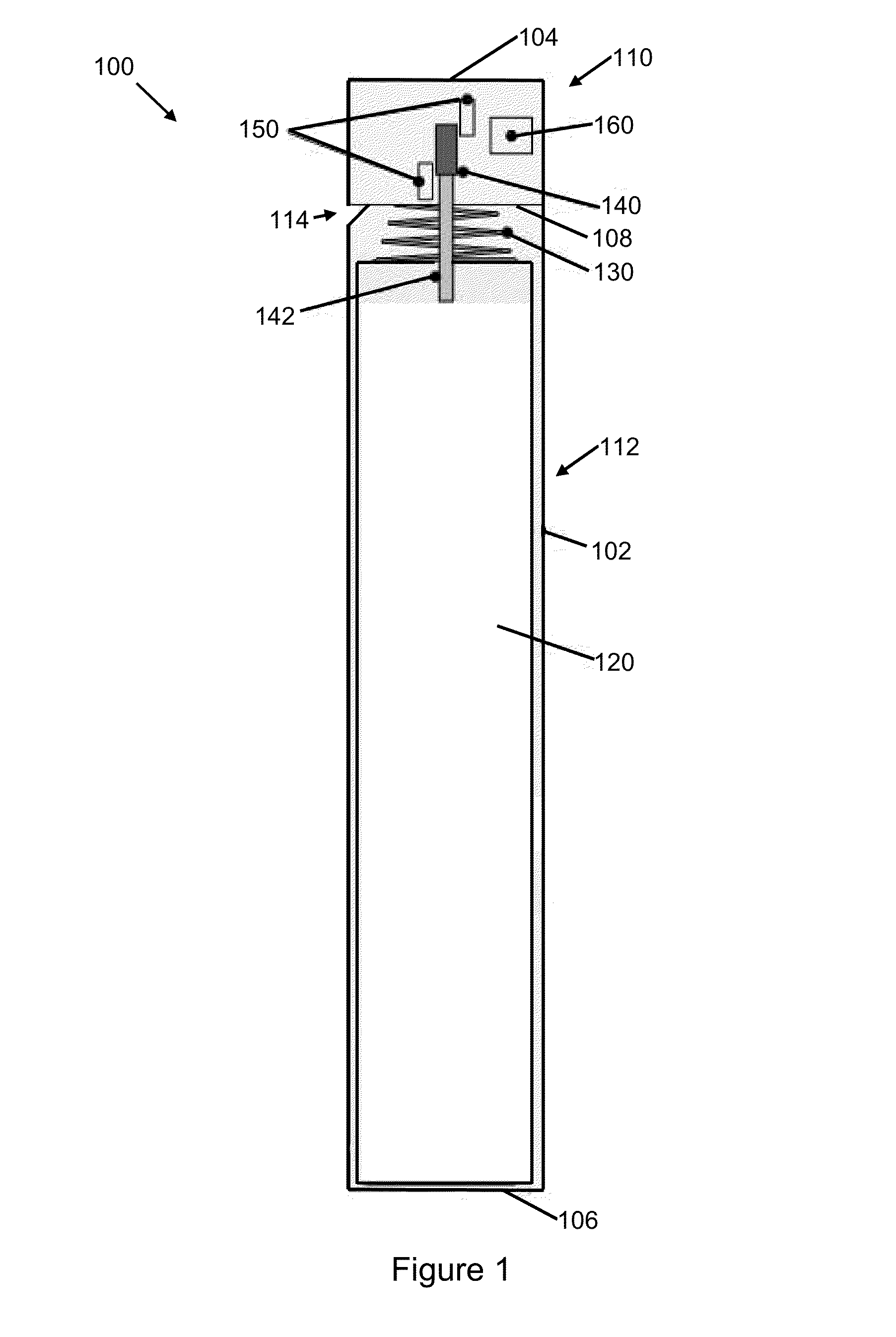

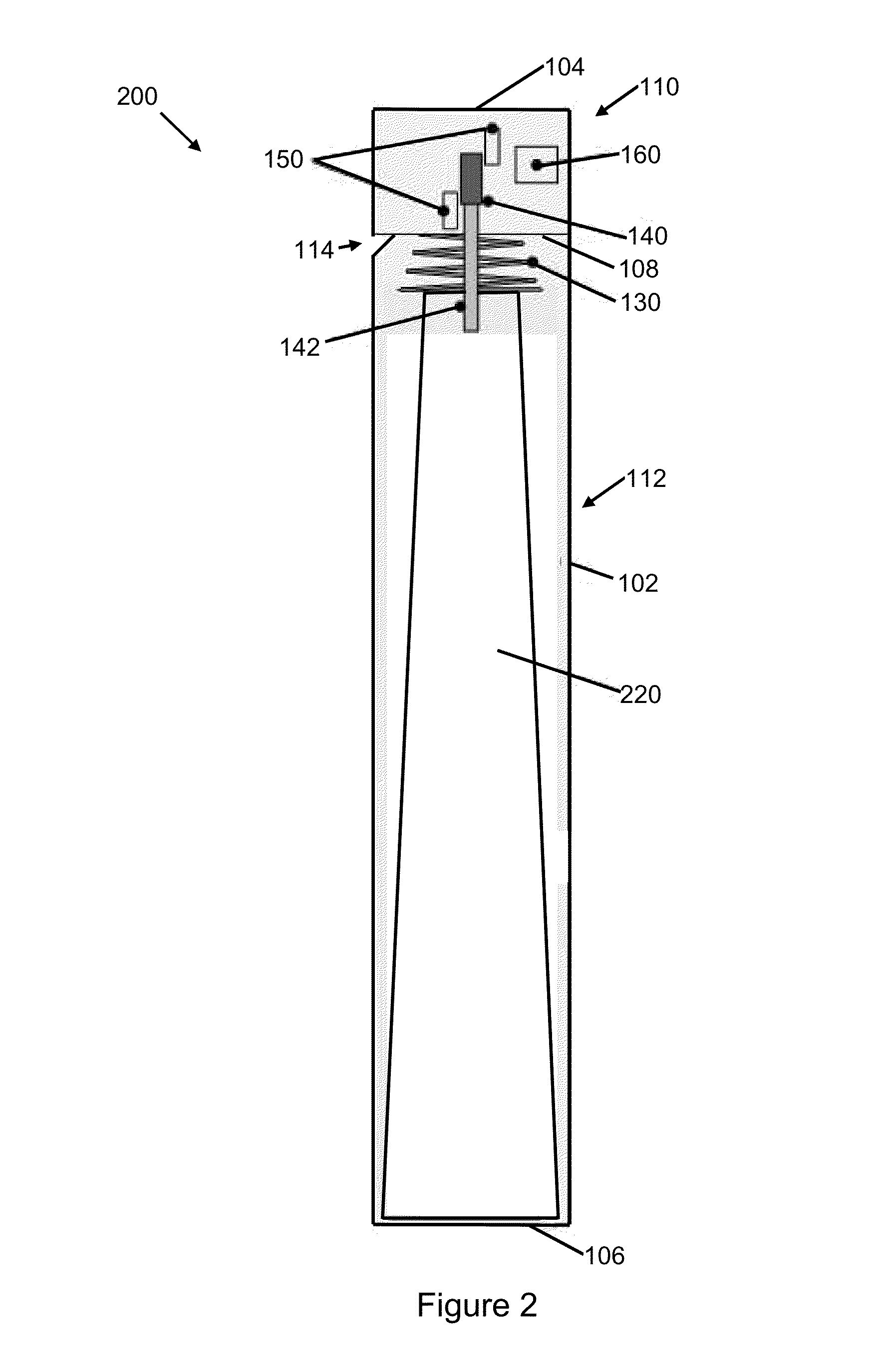

Accurate fluid level measurement device

InactiveUS20140096603A1Simple and accurate methodMachines/enginesLubrication indication devicesMicrocontrollerMeasurement device

A fluid level measurement system for sensing fluid level in a tank is disclosed that includes a float that moves vertically in the interior of the tank, and a force measuring mechanism coupled to the float that generates an output based on the upward force on the float. The system can include an outer tube where the float is contained in the outer tube. A microcontroller can compute fluid level using the force measuring mechanism output. Altitude and other factors can be accounted for. Exemplary force measuring mechanisms can include a Hall Effect sensor sensing position of a magnet coupled to the float, or a force sensor coupled to the float. The length of the float, or the float and uncompressed spring can be substantially equal to the height of the tank. The float can have a generally uniform or non-uniform outside diameter.

Owner:DEERE & CO

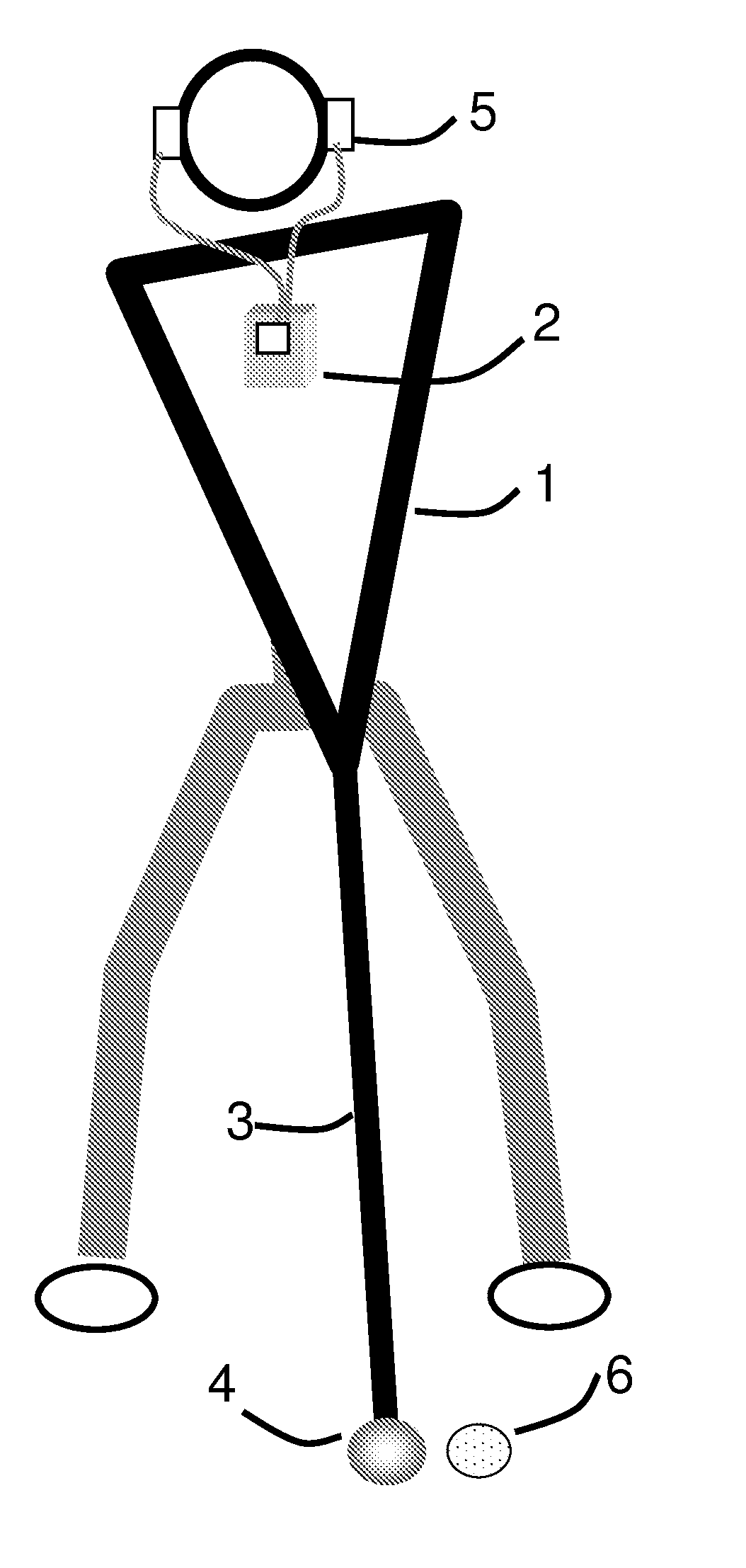

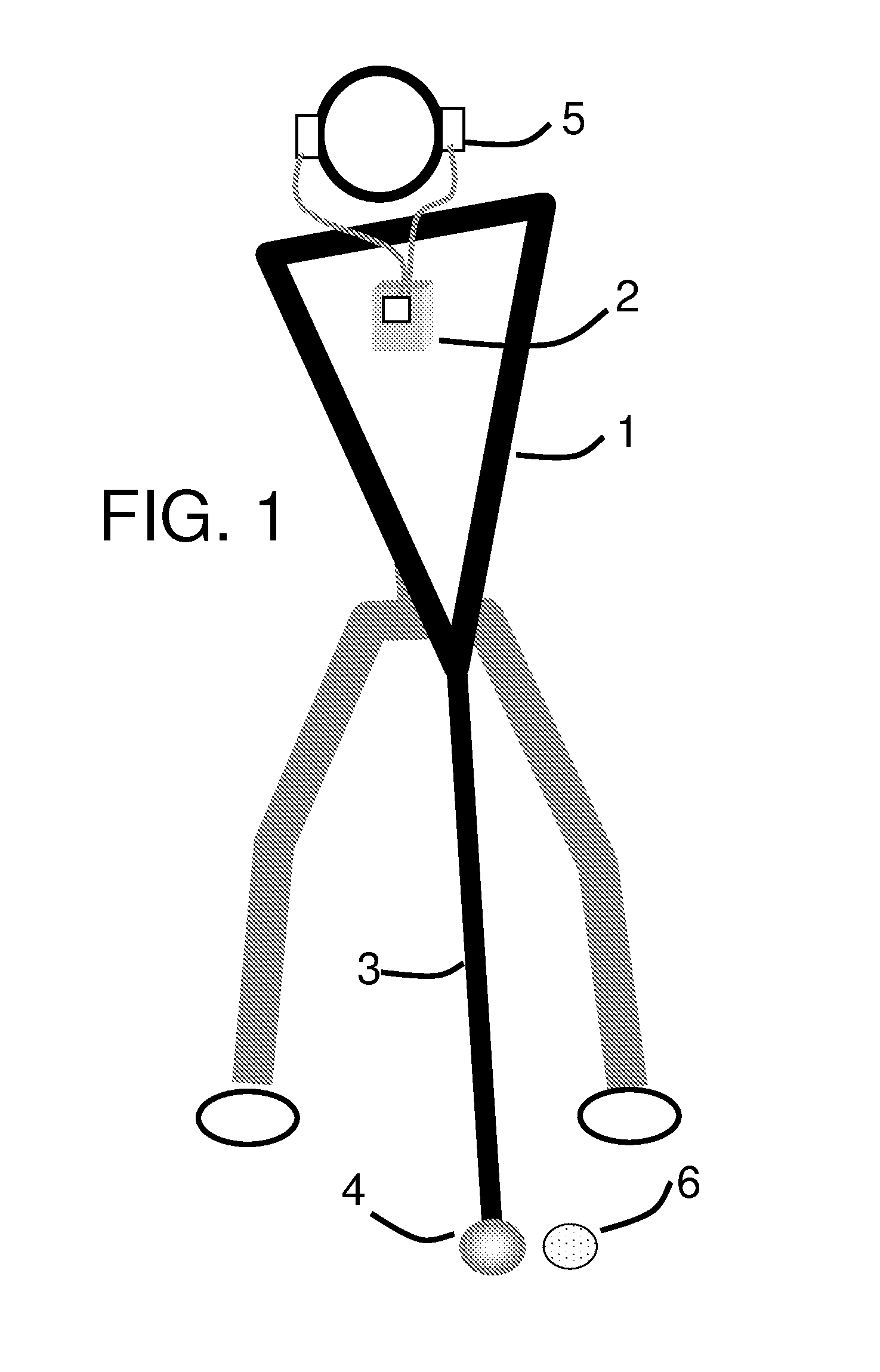

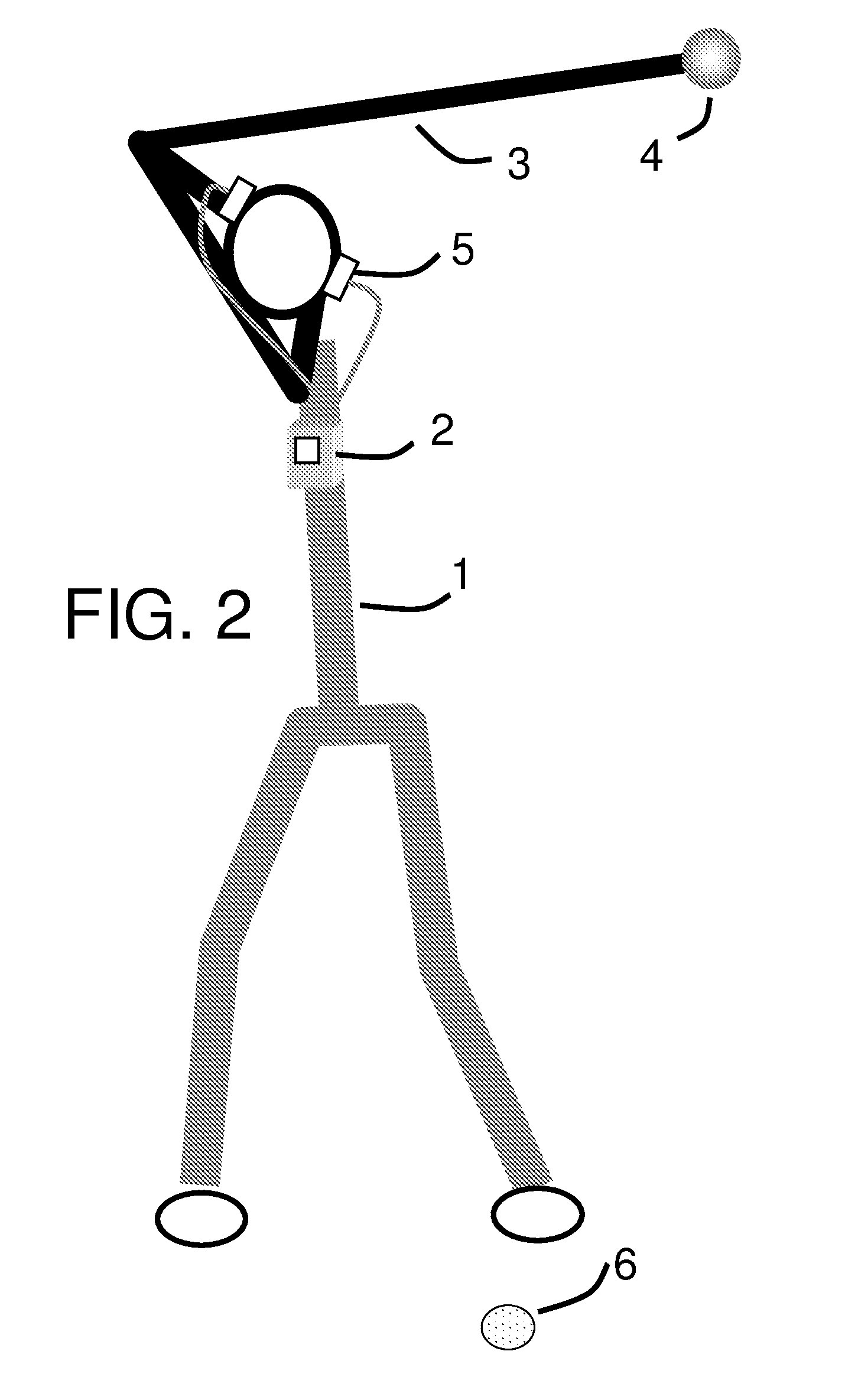

Core Tempo Golf Swing Training Tones

InactiveUS20110143866A1Simple and accurate methodEasy to useGolfing accessoriesSpecial data processing applicationsEngineeringGolf Ball

A computer program product and method for generating an audio file and a method of training a golfer using the audio file on how to make a golf swing with a golf club and strike a golf ball through synchronization of golf club movement with an audio analog model of a preferred tempo-consistent golf swing comprising a pre-shot training sequence, a continuous backswing audio signal that models the backswing velocity of a clubhead, a continuous downswing to impact audio signal that models the downswing velocity of the clubhead, an impact audio signal that provides an indication to the golfer of when the peak clubhead speed should occur, and a followthrough audio signal that models the velocity of the clubhead from impact to the finish of the followthrough. In addition, a process for generating an audio file and a method of training a golfer using the audio file on how to make a putting stroke with a putter is included.

Owner:MCCONNELL WILLIAM DEAN

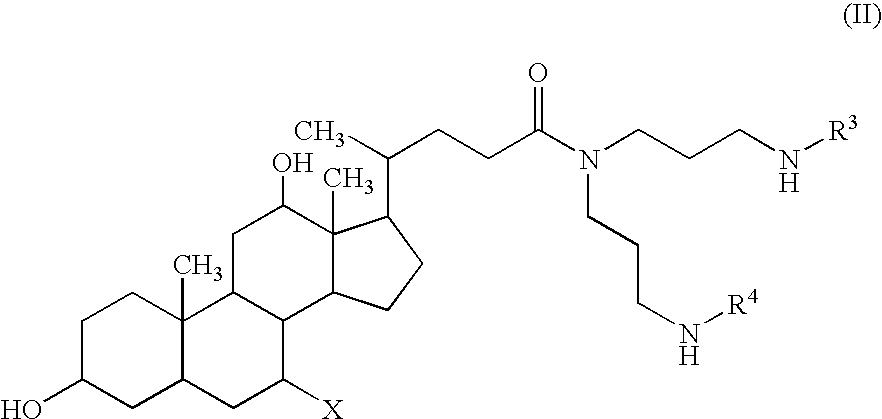

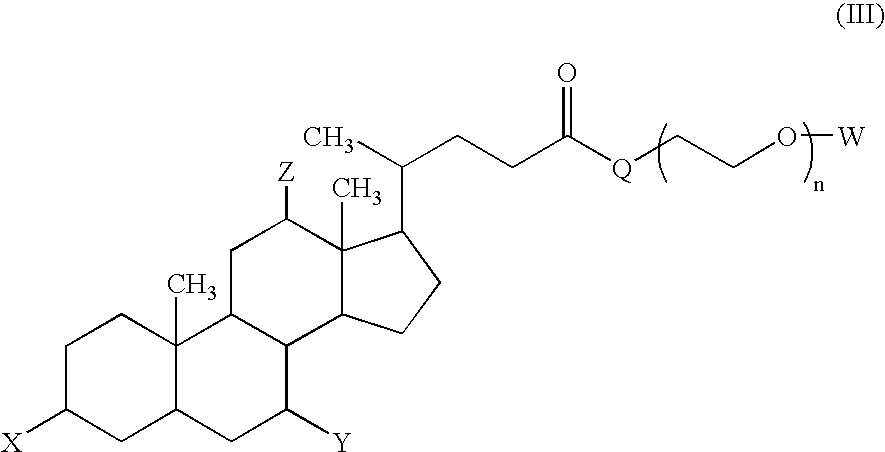

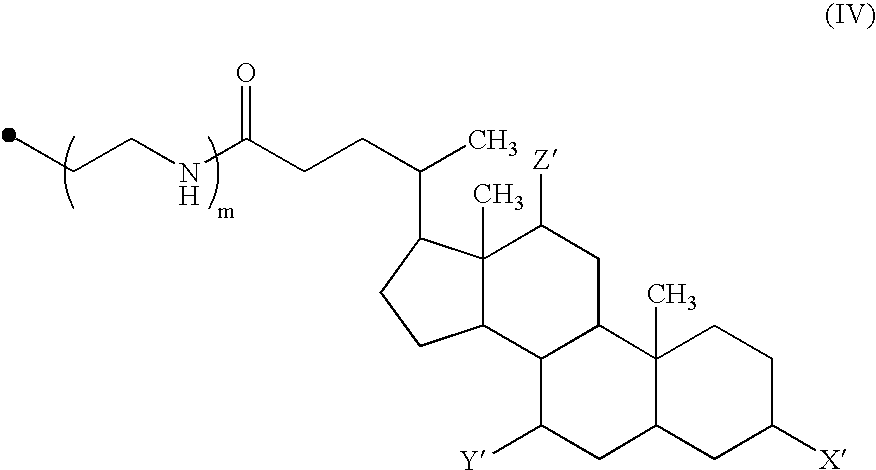

Method and reagent for measuring cholesterol in high-density lipoproteins

InactiveUS20050287619A1The process is simple and accurateSimple and accurate methodMicrobiological testing/measurementBiological material analysisBile acidHigh-density lipoprotein

A method for quantitatively determining cholesterol in high-density lipoprotein, which comprises: treating a sample with cholesterol esterase and cholesterol oxidase or cholesterol esterase, an oxidized coenzyme and cholesterol dehydrogenase in an aqueous medium comprising a bile acid derivative; and measuring the formed hydrogen peroxide or a reduced coenzyme; and a reagent used therefor.

Owner:KYOWA MEDEX CO LTD

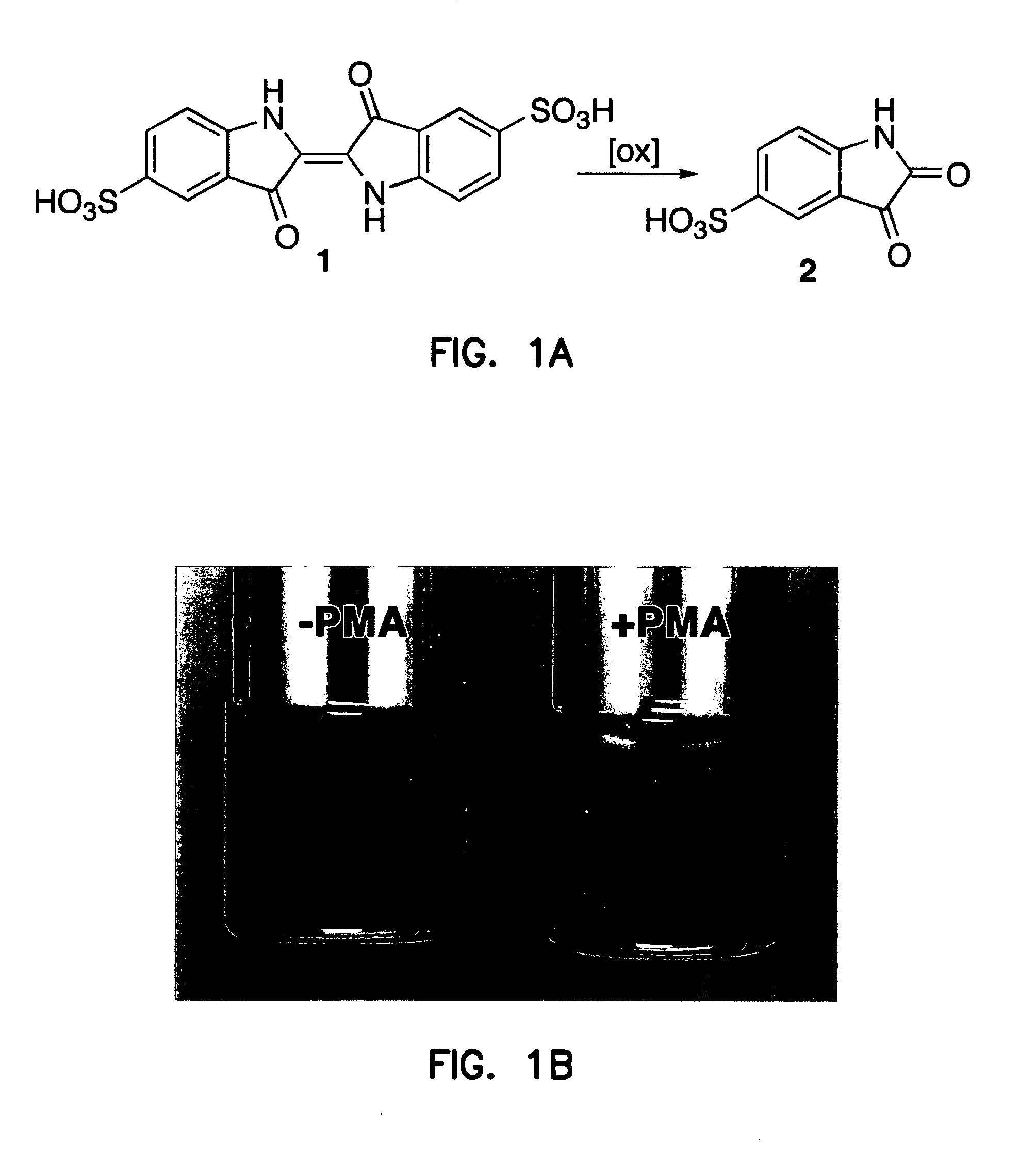

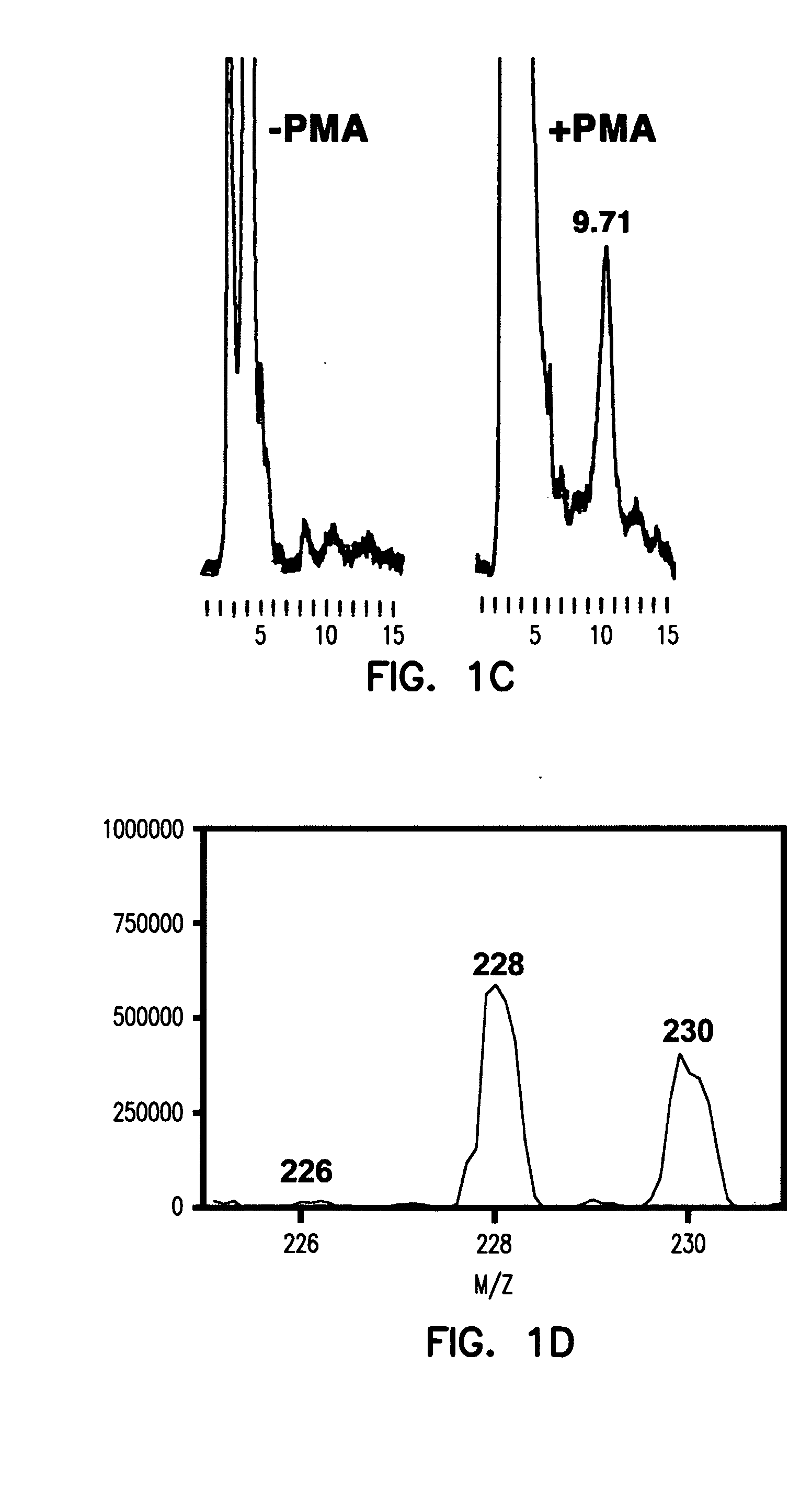

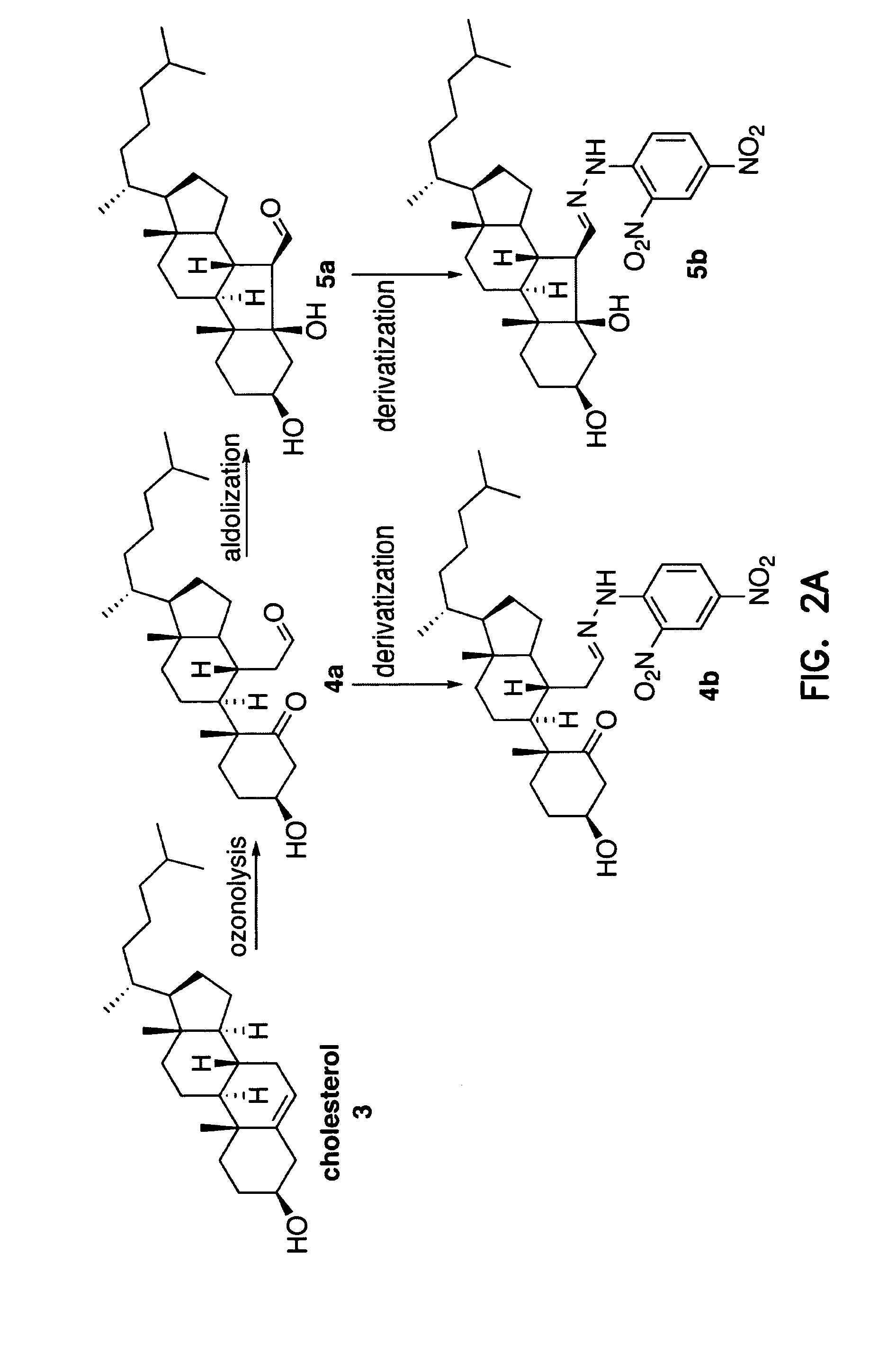

Detection of cholesterol ozonation products

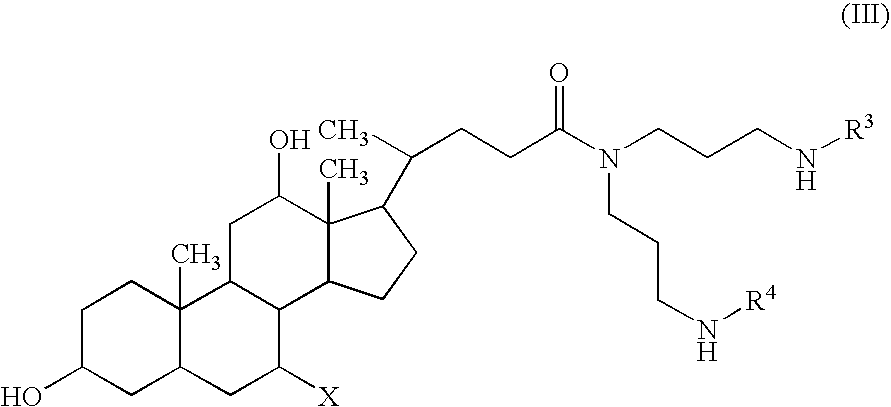

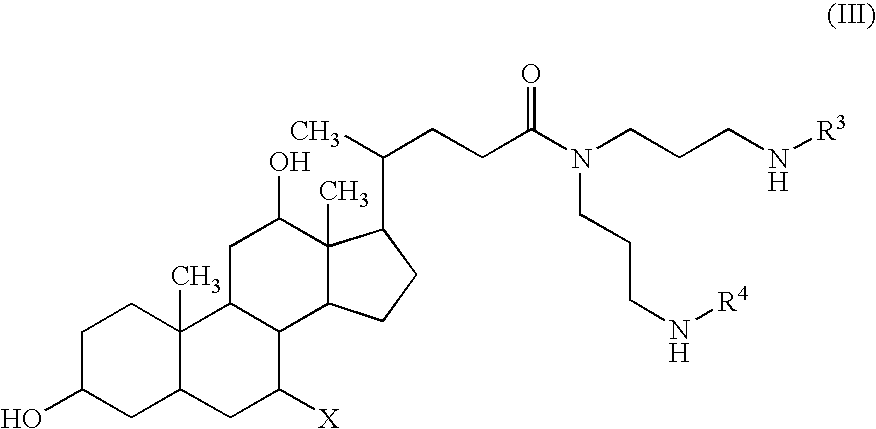

InactiveUS20050085556A1Simple and accurate methodBiocideOrganic compound preparationCholesterolBlood vessel

The invention relates to detection of cholesterol ozonation products that are generated by atherosclerotic plaque material, and to methods of detecting vascular conditions that relate to the accumulation and oxidation of cholesterol.

Owner:THE SCRIPPS RES INST

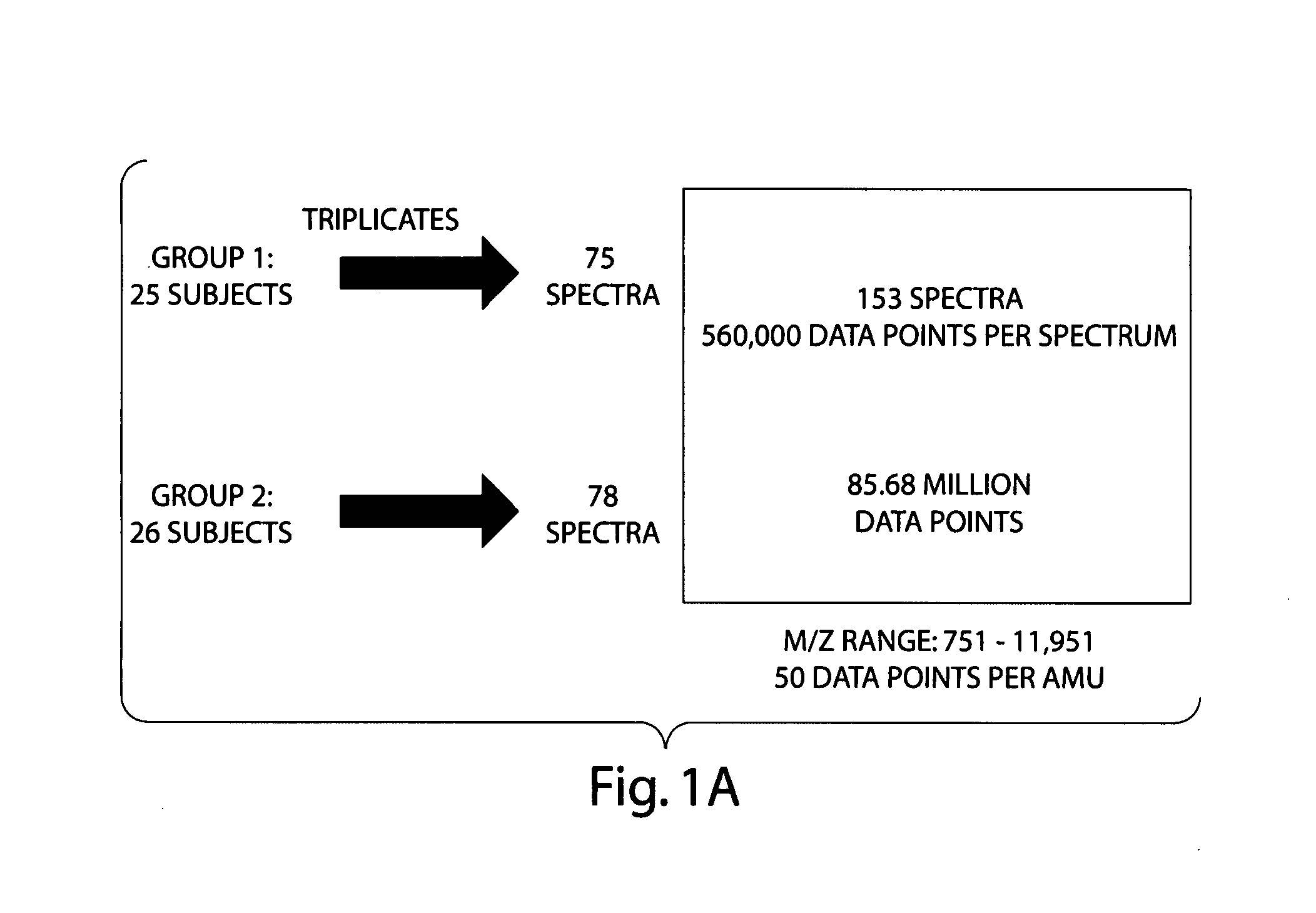

Method for Diagnosing a Person Having Sjogren's Syndrome

InactiveUS20070184511A1Simple and accurate methodMinimal processingMedical data miningMicrobiological testing/measurementSicca syndromePeptide

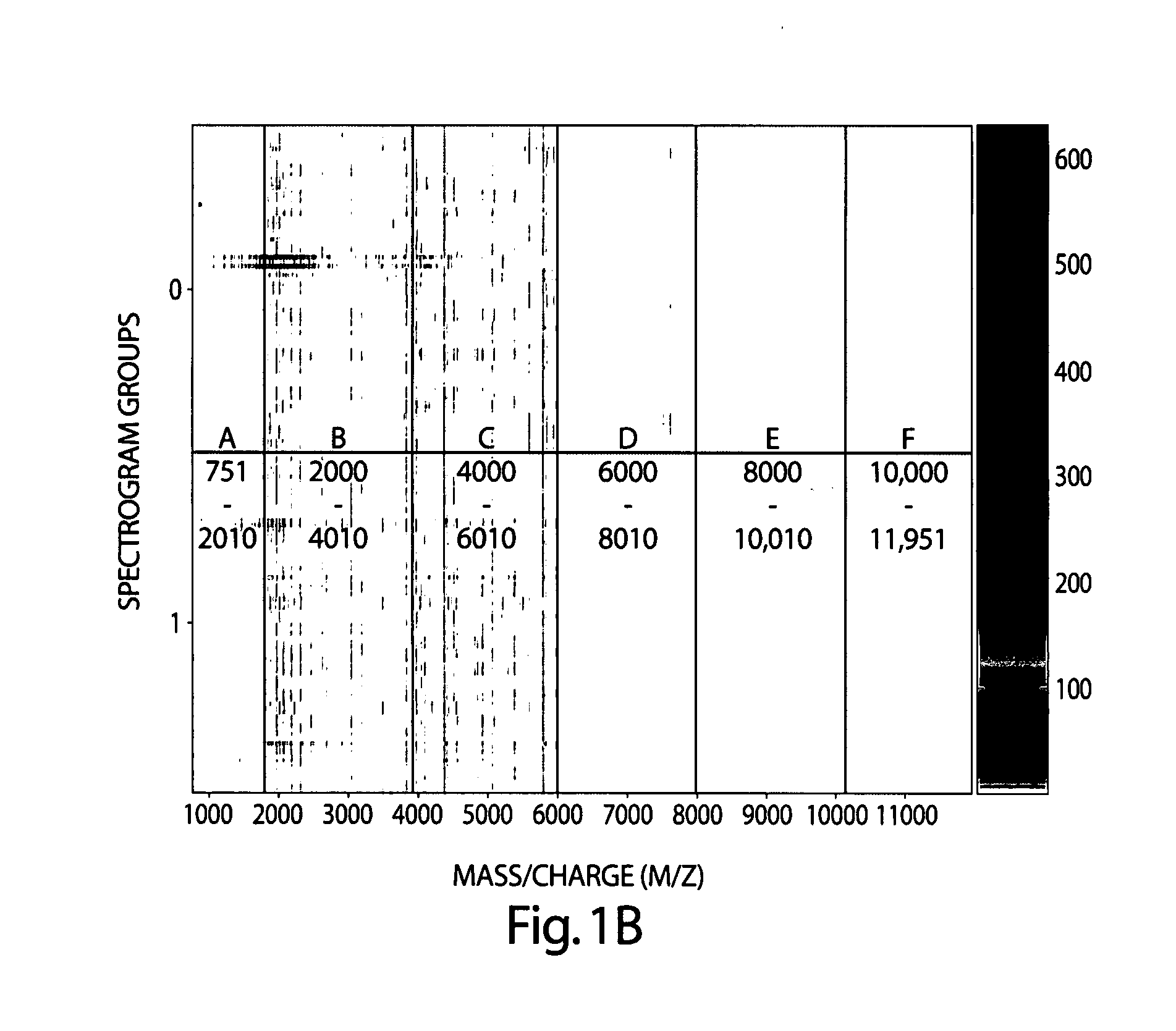

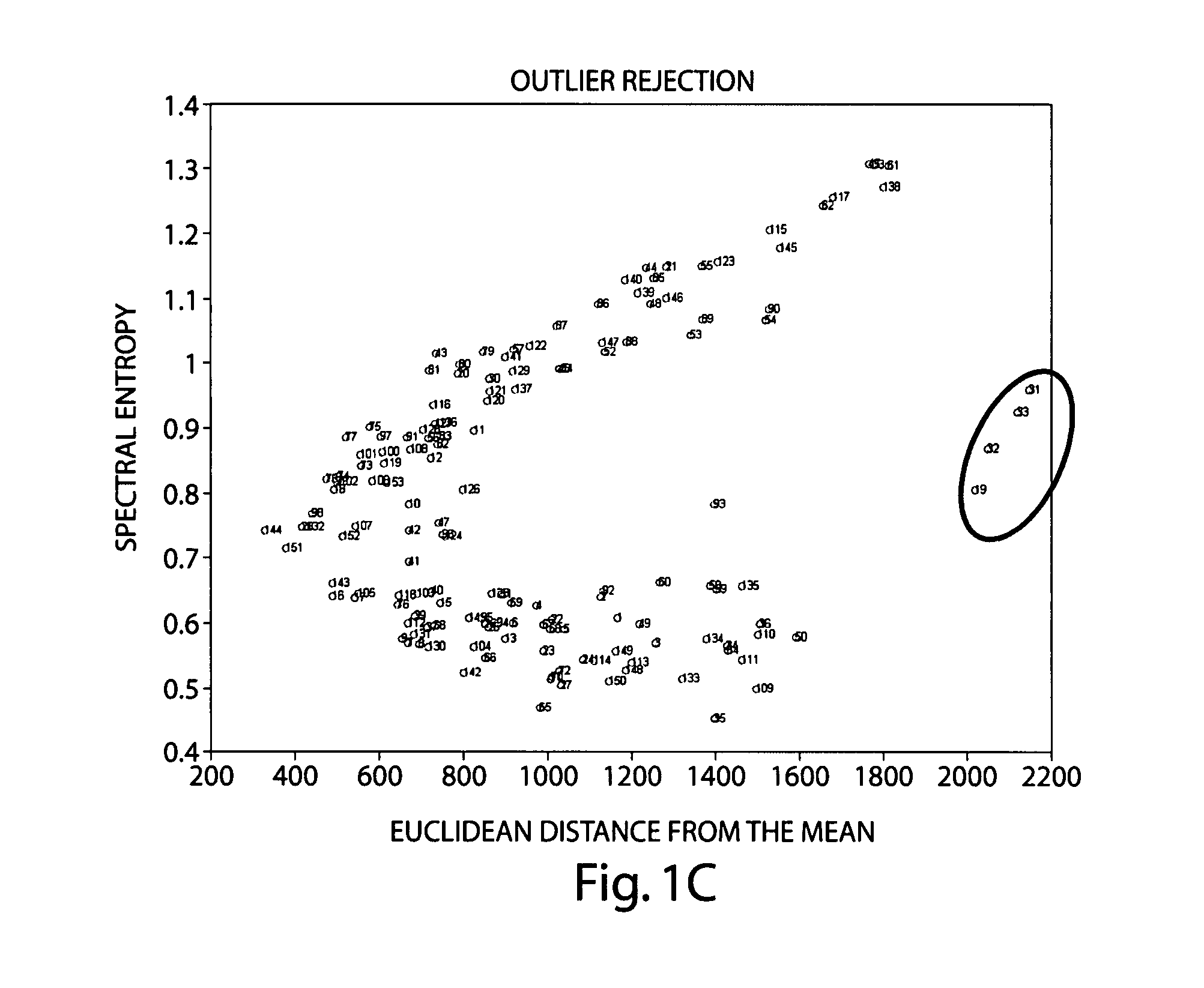

Described is a method for diagnosing a person having or being at risk of developing Sjögren's Syndrome and excluding patients with symptoms similar to Sjögren's Syndrome but with a different etiology, comprising the following steps: providing a sample of a body fluid or tissue from said person, said sample containing a mixture of unknown proteins, protein fragments or peptides; analyzing said samples with mass spectrometry to generate a m / z (mass to charge ratio) spectrogram for each sample; comparing whether the patient's sample contains m / z values that are characteristic of a Sjögren's Syndrome reference database derived from the analysis and cataloguing of multiple patient spectrograms; and determining whether said patient either has or does not have Sjögren's Syndrome on the basis of this comparative analysis.

Owner:SCHEPENS EYE RES INST THE +1

Method and reagent for measuring cholesterol in high density lipoproteins

ActiveUS20060014229A1The process is simple and accurateSimple and accurate methodMicrobiological testing/measurementBiological material analysisHigh densityPhenyl Ethers

A method for quantitatively determining cholesterol in high-density lipoprotein in a sample, which comprises: reacting a sample with i) cholesterol esterase and cholesterol oxidase or ii) cholesterol esterase, an oxidized coenzyme and cholesterol dehydrogenase in an aqueous medium comprising i) nonionic surfactant, polyanion and albumin or ii) a combination of a surfactant selected from the group consisting of polyoxyethylene alkylamine or polyoxyethylene alkenylamine and a surfactant selected from the group consisting of polyoxyethylene polycyclic phenyl ether sulfate and an anionic bile acid derivative, and measuring the formed hydrogen peroxide or a reduced coenzyme; and a reagent used therefor.

Owner:KYOWA MEDEX CO LTD

Method for quantitatively determining cholesterol in high density lipoprotein and reagents therefor

ActiveUS7851174B2Simple and accurate methodMicrobiological testing/measurementBiological material analysisPhenyl EthersAcid derivative

A method for quantitatively determining cholesterol in high-density lipoprotein in a sample, which comprises: reacting a sample with i) cholesterol esterase and cholesterol oxidase or ii) cholesterol esterase, an oxidized coenzyme and cholesterol dehydrogenase in an aqueous medium comprising i) nonionic surfactant, polyanion and albumin or ii) a combination of a surfactant selected from the group consisting of polyoxyethylene alkylamine or polyoxyethylene alkenylamine and a surfactant selected from the group consisting of polyoxyethylene polycyclic phenyl ether sulfate and an anionic bile acid derivative, and measuring the formed hydrogen peroxide or a reduced coenzyme; and a reagent used therefor.

Owner:KYOWA MEDEX CO LTD

System and method for wind turbine sensor calibration

ActiveUS9909570B2Accurate and reliableSimple and easily verifiablePump componentsWind motor controlEngineeringRelative motion

A system and method for the verification and calibration of wind turbine sensor systems is provided. The system comprises an optical capture device provided on a wind turbine which is arranged to record the position of at least one light source provided at the wind turbine during operation of the wind turbine. The motion of the light source relative to the optical capture device can provide an indication of relative motion of a portion of the wind turbine during operation, which can then be used as an input to a calibration and / or a verification system for a sensor system of the wind turbine.

Owner:LM WP PATENT HLDG

Cleaning method for laser device cooling box and detection method for detecting cleanness of cleaning method

InactiveCN105521973AThe method is convenient and accurateImprove cleanlinessHollow article cleaningCleaning using liquidsWater circulationTransmittance

The invention discloses a cleaning method for a laser device cooling box and a detection method for detecting the cleanness of the cleaning method, and aims to provide a cleaning method which is convenient, precise, high in cleanness and capable of rapidly cleaning a cooling box of a complicated structure and a detection method which is simple, convenient, accurate and capable of quantificationally and precisely judging the washing cleanness. The cleaning method disclosed by the invention comprises the following steps: respectively connecting an inlet pipeline and an outlet pipeline of a water pump with a water inlet and a water outlet of a cooling water circulation loop of a cooling system of the laser device cooling box; filling pure glycol washing liquid into the laser device cooling box; subsequently putting the laser device cooling box full of the glycol washing liquid into an ultrasonic washer of which the temperature is regulated to 80 DEG C; starting the ultrasonic washer and the water pump to make sure that the glycol in the laser device cooling box can flow circularly under the effect of the water pump; performing a transmittance test on a standard glycol sample and a glycol liquid sample by using a spectrophotometer; afterwards comparing the transmittance test results of the standard glycol sample and the glycol liquid sample, wherein the cleanness is considered to be good if the sample transmittance is 2% smaller than the standard glycol transmittance.

Owner:SOUTH WEST INST OF TECHN PHYSICS

Method for determining the glucose concentration by fluorescence polarization

InactiveUS20060216773A1Simple and accurate methodMicrobiological testing/measurementChemiluminescene/bioluminescenceFluorescenceConcentrations glucose

The invention generally relates to a method for in vivo glucose monitoring in which the glucose concentration is measured by means of fluorescence polarization by detecting the change in viscosity, caused by changes in the glucose concentration.

Owner:ROCHE DIABETES CARE INC

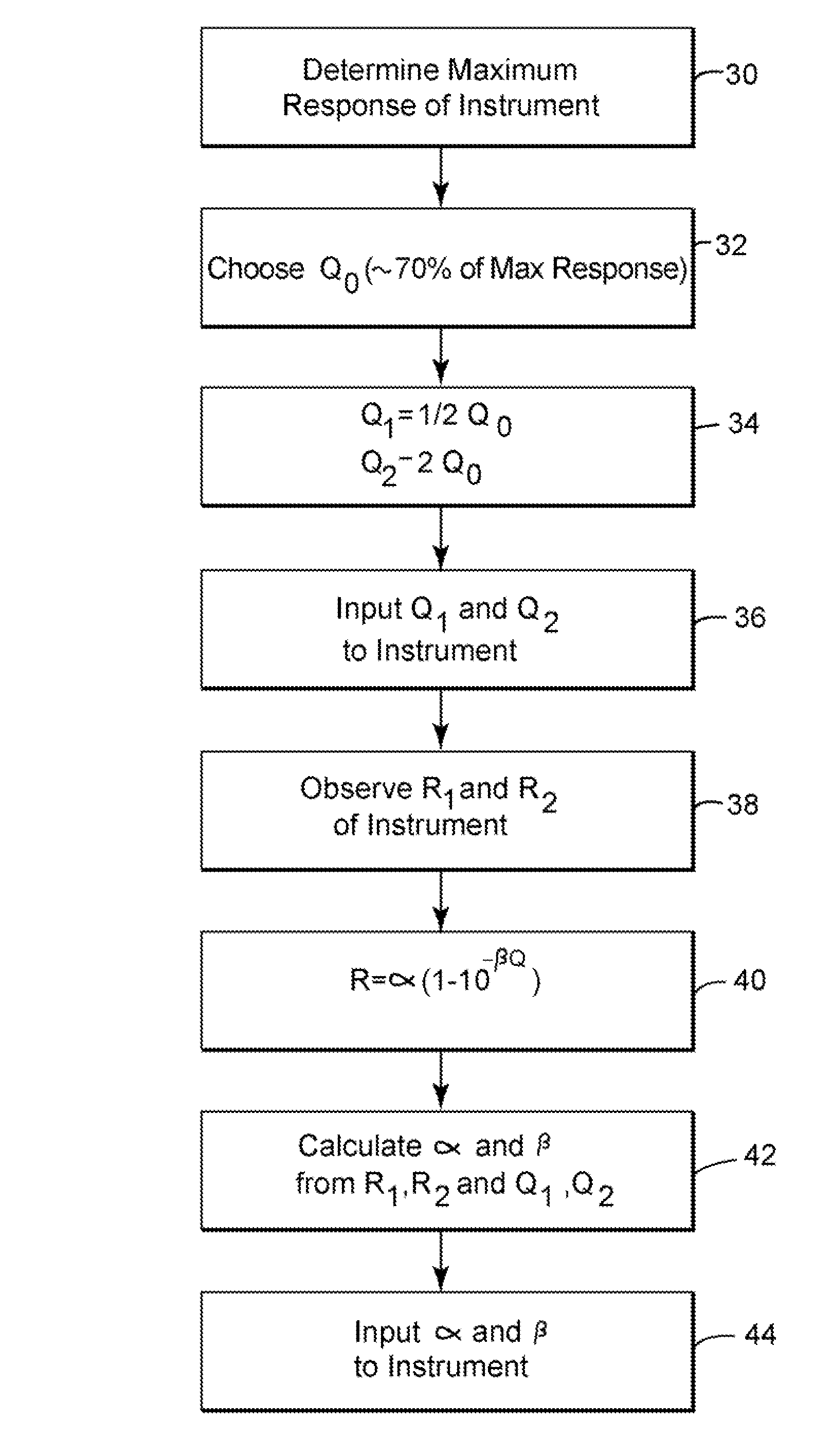

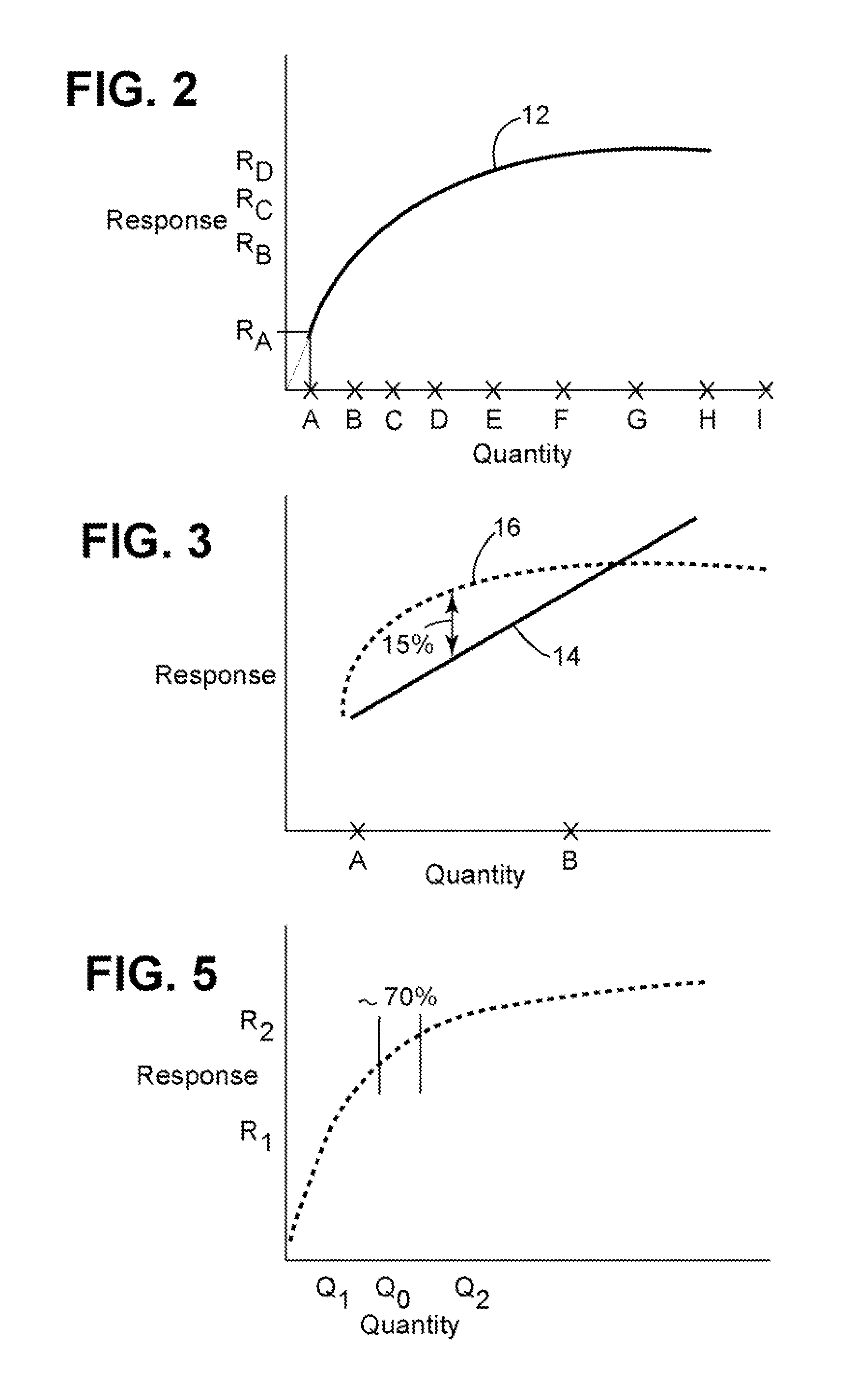

Ion trap mobility spectrometer calibration method and system

InactiveUS20080087818A1Accurate and yet simple calibration methodSimple methodStability-of-path spectrometersIsotope separationIon trap mass spectrometryAnalyte

An ion trap mobility spectrometer calibration system and method wherein the maximum response of the spectrometer is determined. A quantity Q0 is chosen representing a response which is a predetermined percentage of the maximum response. Input to the ion trap mobility spectrometer are at least two known quantities Q1 and Q2 of an analyte, which have a predetermined relationship with Q0. The responses corresponding to R1 and R2 of the ion trap mobility spectrometer are observed based on the respective inputs of quantities Q1 and Q2. R1, R2, and Q1 and Q2 are then used to calculate the calibration constants in an equation describing a curve where the response of the ion trap mobility spectrometer is a function of the quantity of the analyte input therein. The calculated calibration constants are input to thereafter determine, from the response, the quantity of a detected analyte based on the equation.

Owner:GENERAL ELECTRIC CO

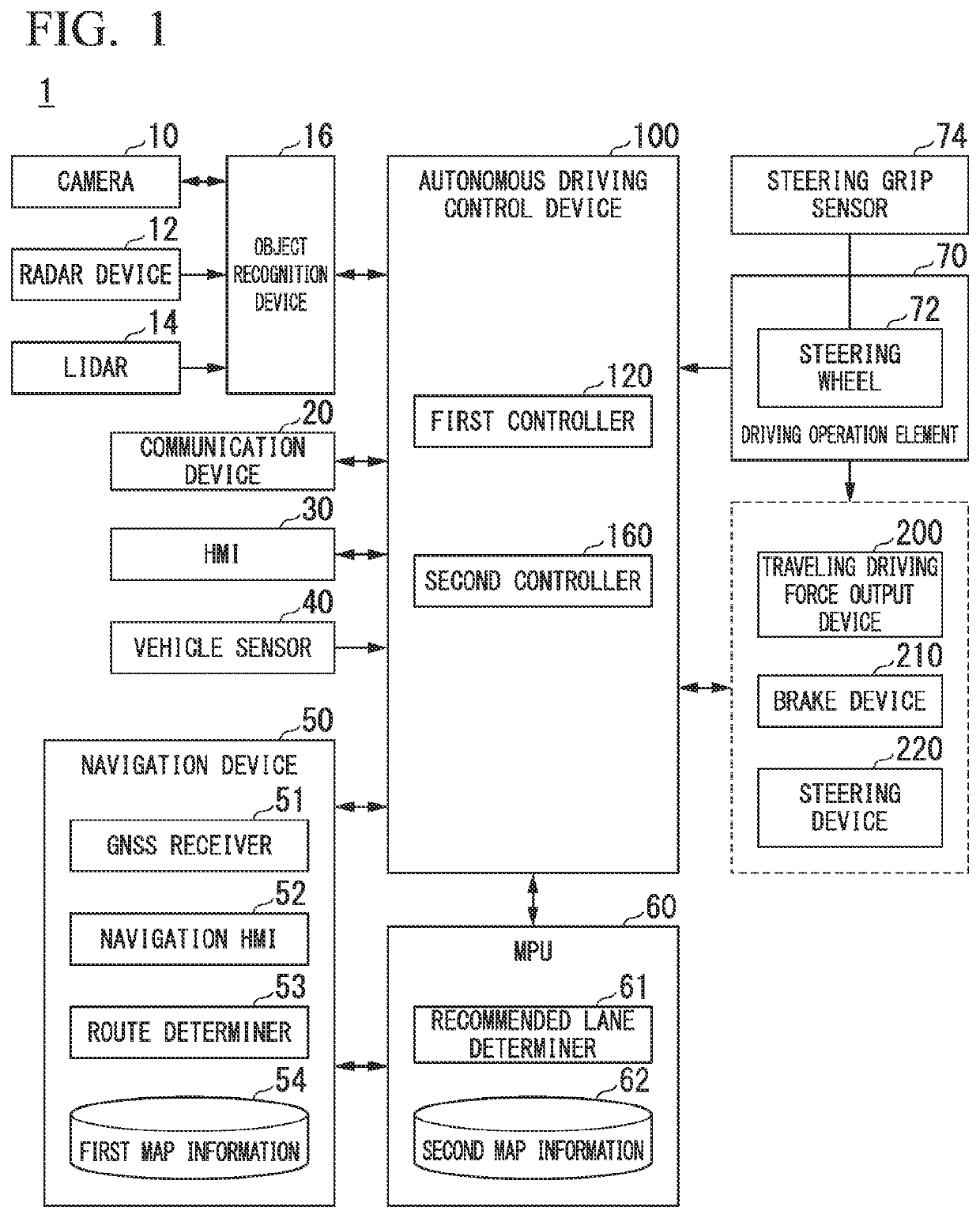

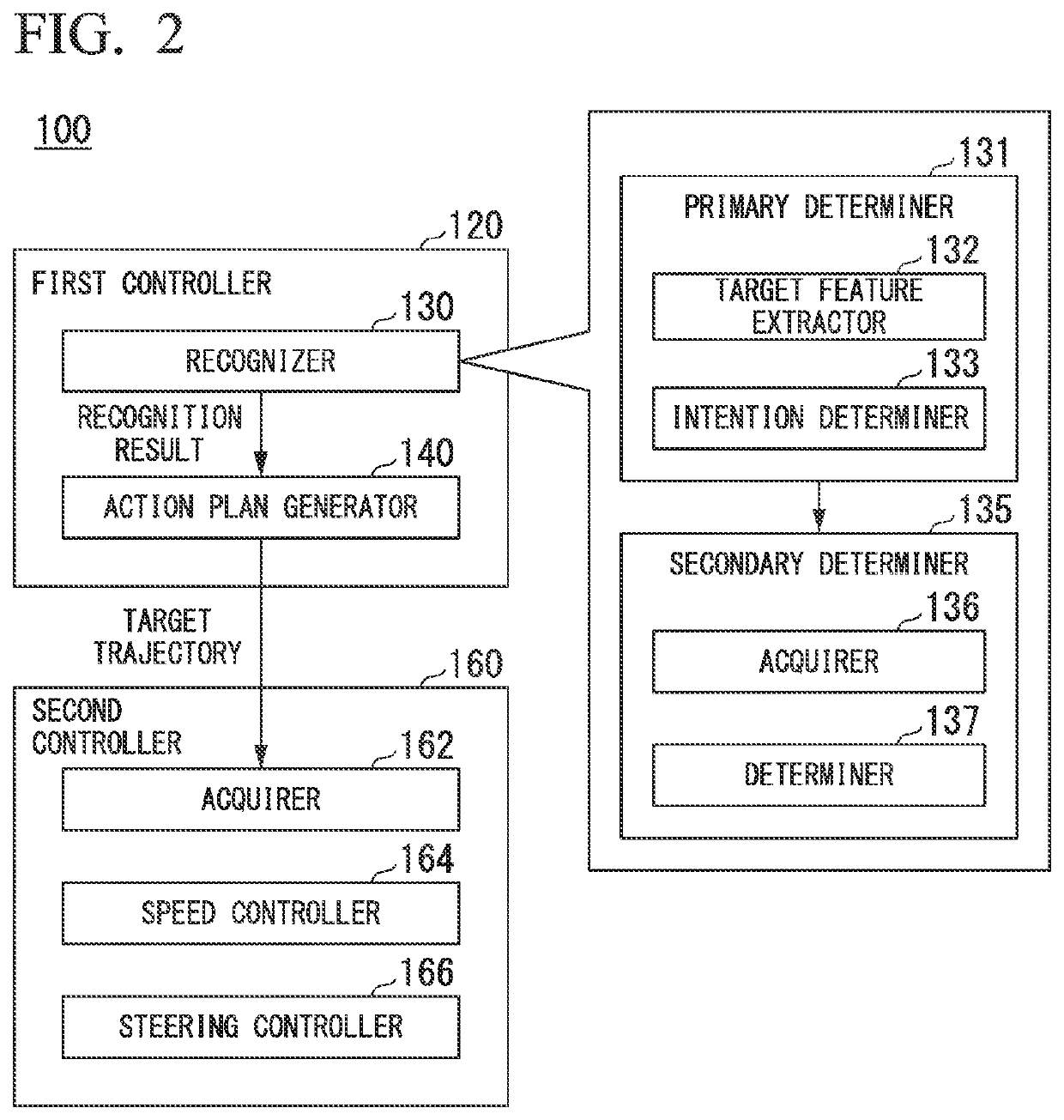

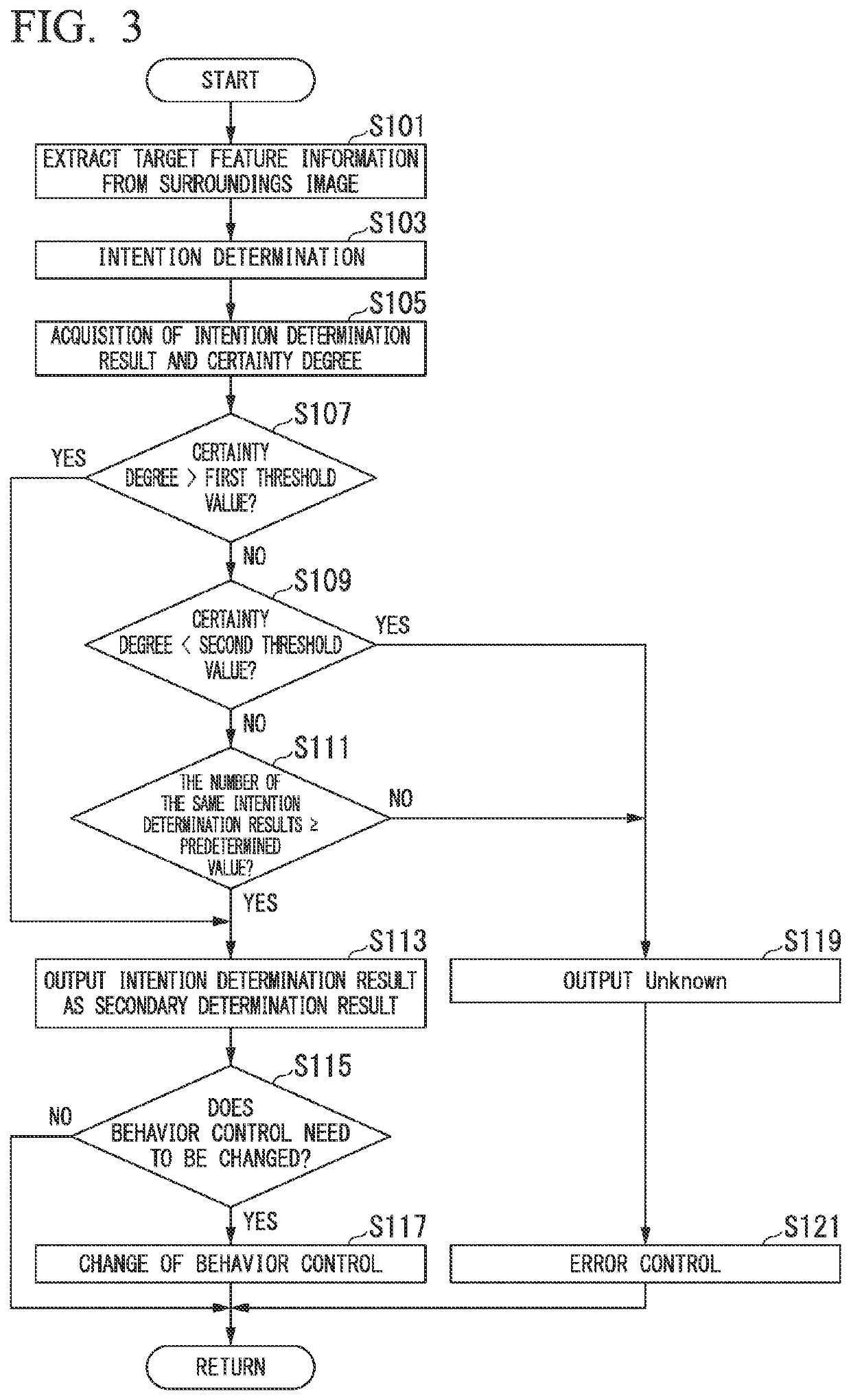

Determination device, vehicle control device, determination method, and storage medium

PendingUS20220266855A1Simple and accurate methodImprove accuracyScene recognitionSimulationThresholding

Owner:HONDA MOTOR CO LTD

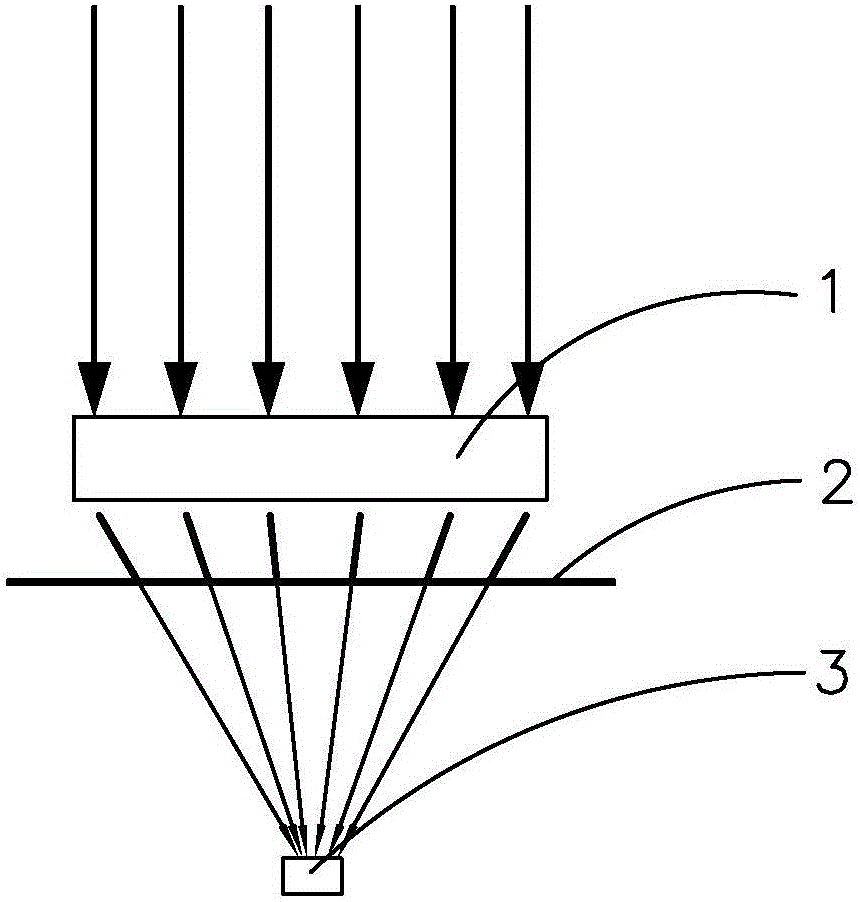

Heat-insulating property detection device and detection method

ActiveCN104990951AImprove purification effectEasy to compareMaterial thermal conductivityMaterial heat developmentThermal insulationMagnifying glass

The invention discloses a heat-insulating property detection device and a detection method. The detection device comprises a magnifying lens and a light source, wherein the magnifying lens is used for focusing the light rays generated by the light source. The magnifying lens focuses the light rays generated by the light source, a to-be-detected heat-insulating film is placed before or behind the magnifying lens, and the heat intensity difference is compared between the light rays passing through the heat-insulating film and the light rays not passing through the heat-insulating film, so as to judge the property of the heat-insulating film. The heat-insulating property detection method provided by the invention has the advantages of being visual, scientific, simple and accurate, is capable of effectively prompting the purification of thermal insulation industries, such as a heat-insulating film industry, and prompting the quality of products, and further, the heat-insulating property detection device provided by the invention is simple and convenient to operate.

Owner:青岛久越新材料科技有限公司

Method for detecting target cell

InactiveUS20120115130A1Easily and promptly detectEasily and promptly dataMicrobiological testing/measurementBiological particle analysisTest measurementQuantum mechanics

A target cell detection method includes performing a test measurement on a dispersion to obtain a measurement result 1, the test measurement being an optical or electromagnetic measurement, and the dispersion including labeled particles and target cells, the labeled particles being particles on each of which a substance that specifically binds to a specific molecule present on a surface of each of the target cells is immobilized, performing measurement that is identical with the test measurement on a dispersion that includes the target cells, but does not include the labeled particles to obtain a measurement result 2, and comparing the measurement result 1 with the measurement result 2.

Owner:JSR CORPORATIOON

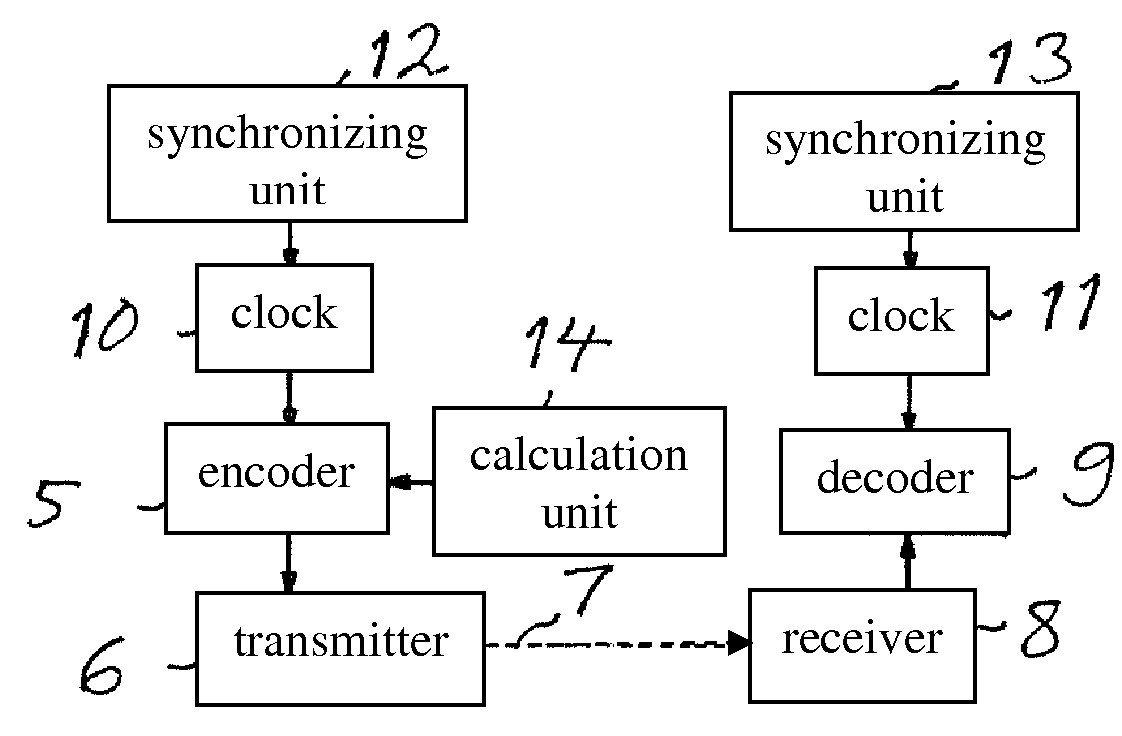

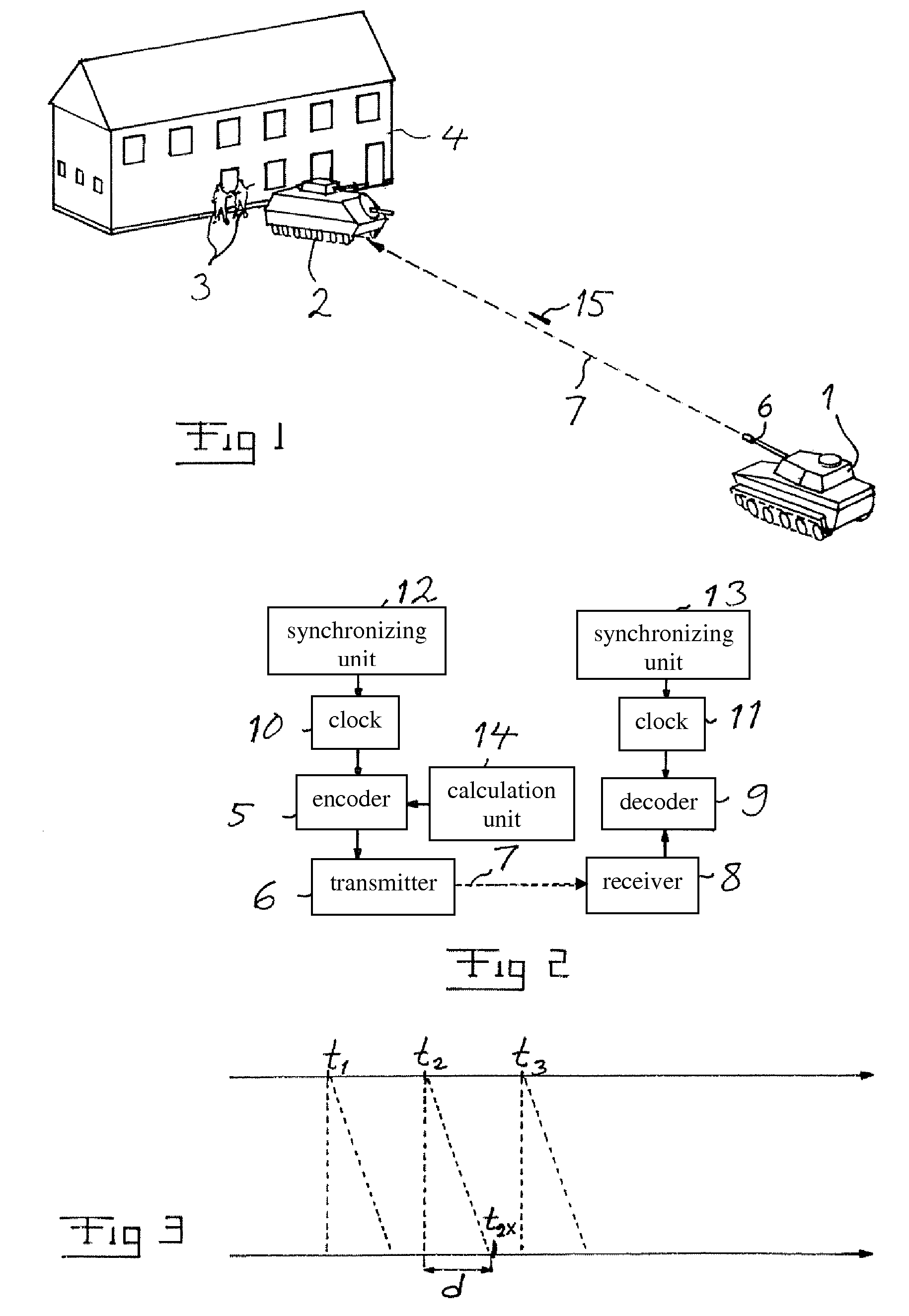

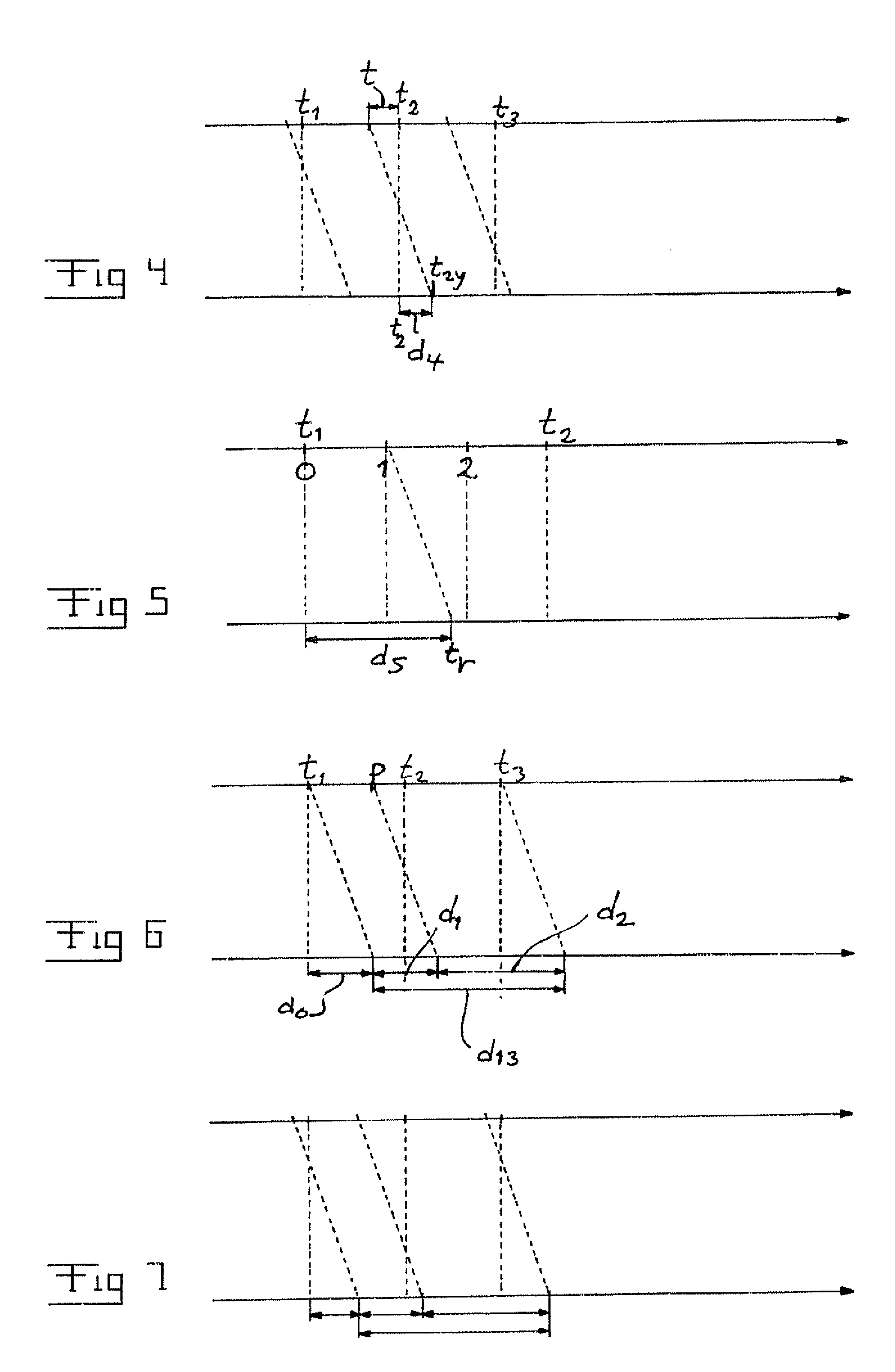

System and a method for transmission of information

ActiveUS7844183B2Simple and accurate methodReliable informationSynchronising transmission/receiving encryption devicesSynchronisation arrangementEngineeringInformation transfer

A system for transmission of information between at least two players in a training area comprises means on a first (1) of said players for encoding light pulses and means for transmitting information in the form of such coded light pulses towards at least one second (2-4) of said players, said second player having means for receiving said light pulses and means for decoding the information thereof. Each of said players is provided with a clock, and the system comprises means for keeping said clocks synchronized. The encoding means and the decoding means are adapted to utilize data of times of transmission and receipt of said light pulses for transmitting information from the first player to the second player.

Owner:SAAB AB

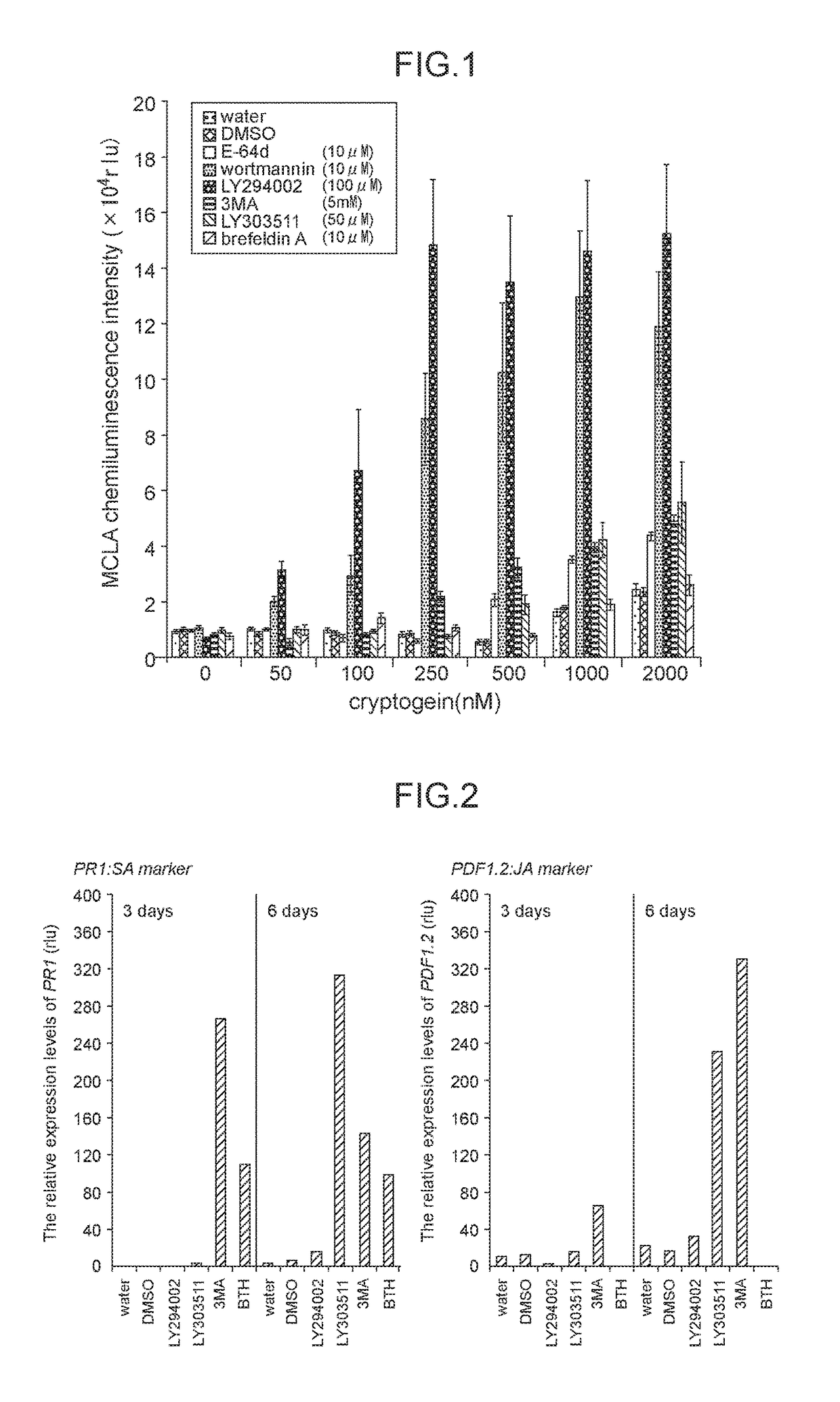

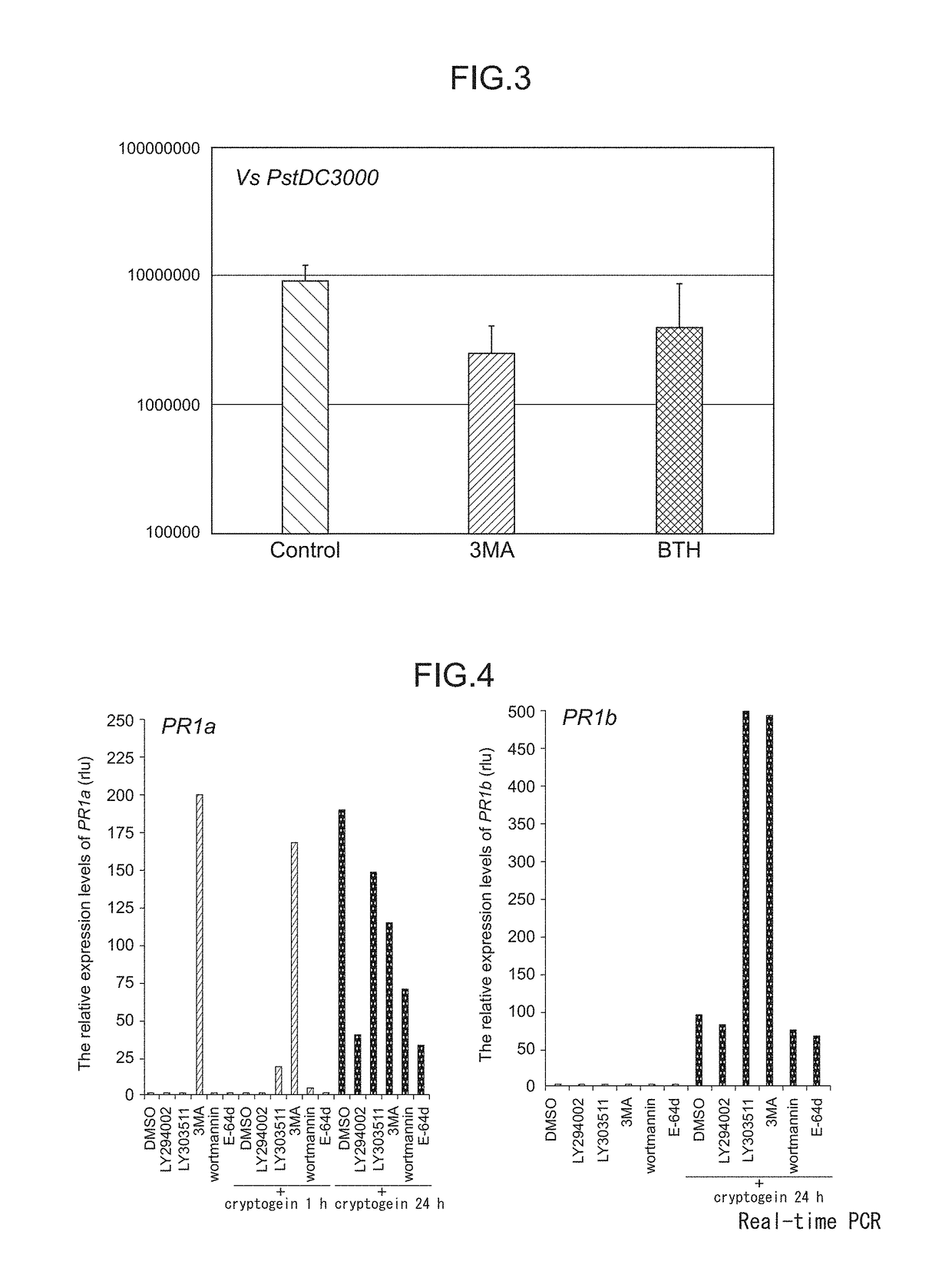

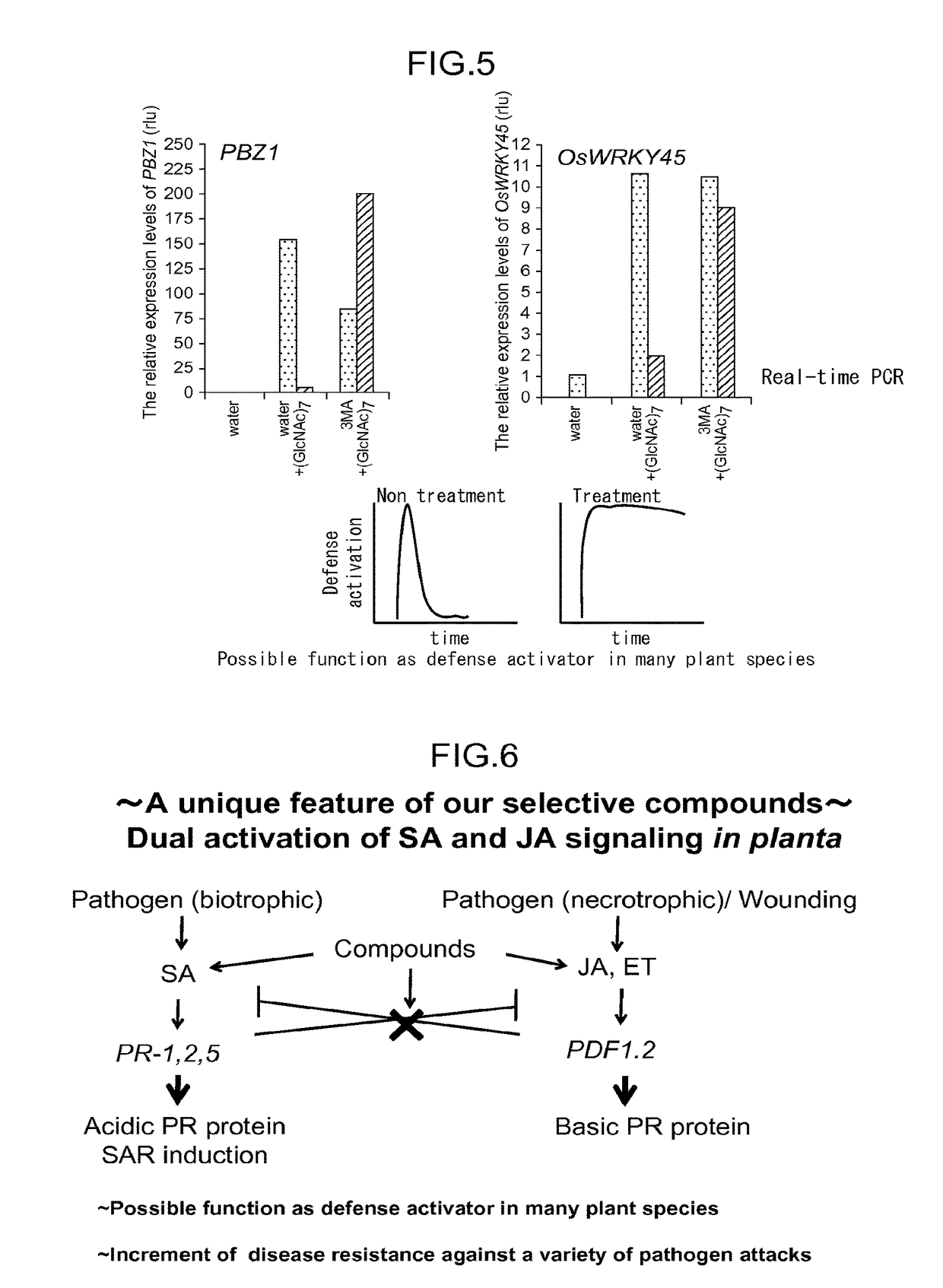

Method of screening for plant defense activators, plant defense activators, and method of enhancing immune response

ActiveUS9739767B2Enhance immune responseSimple and accurate methodBiocideMicrobiological testing/measurementPlant cellPlant Immunity

A method of screening for a plant defense activator, which enhances an immune response of a plant, from at least one candidate substance includes: contacting a plant cell in which a jasmonic acid-dependent defense pathway and a salicylic acid-dependent defense pathway of a plant defense system are capable of working independently from each other, with a candidate substance; contacting the plant cell with a trigger material that induces an immune response; and assaying the plant cell after contacting with the trigger material based on an index representing an immune response, to select a target substance that enhances an immune response of the plant. A method of enhancing an immune response of a plant includes use of a specific compound, and a plant immune response enhancer includes the specific compound.

Owner:TOKYO UNIVERSITY OF SCIENCE

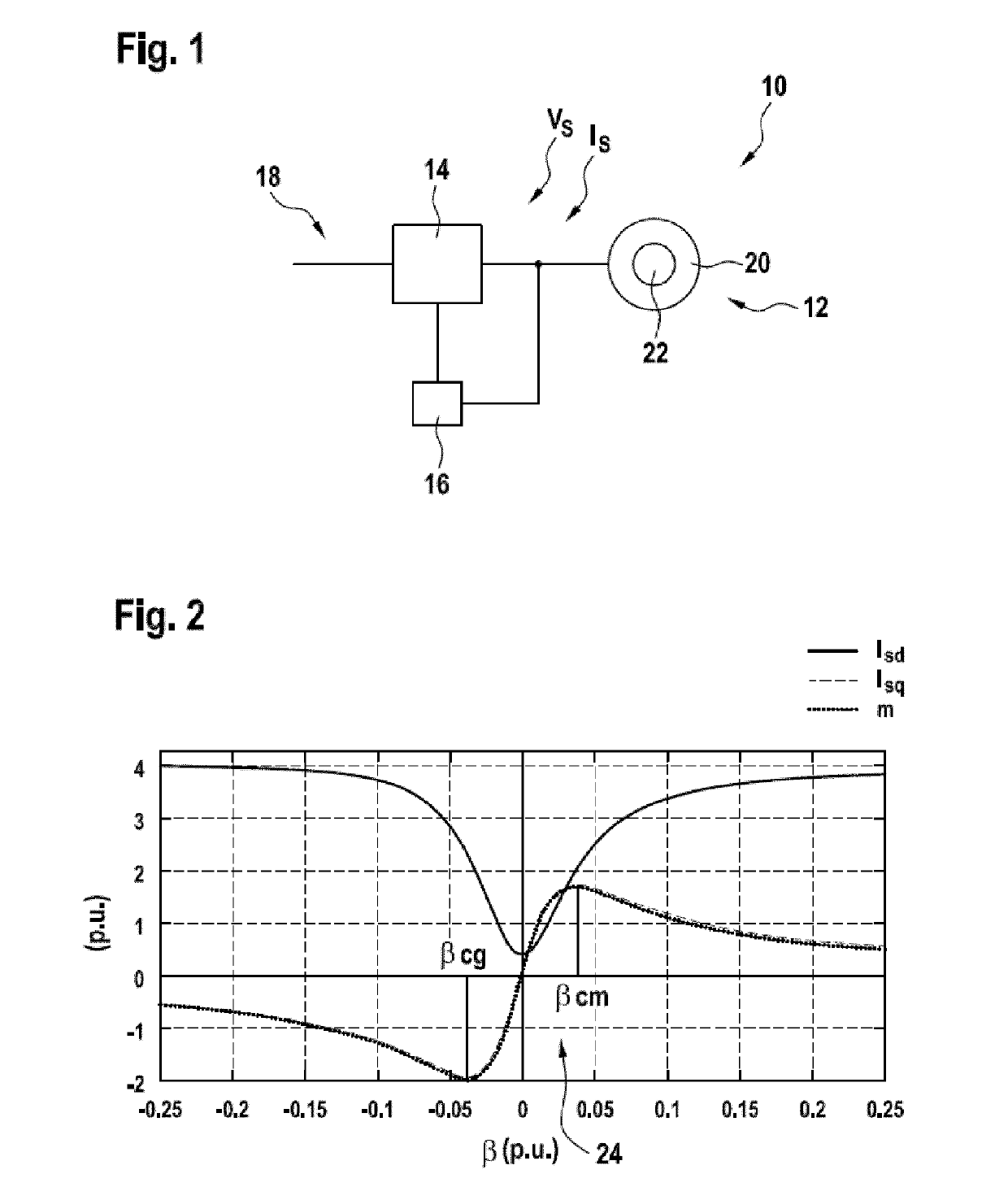

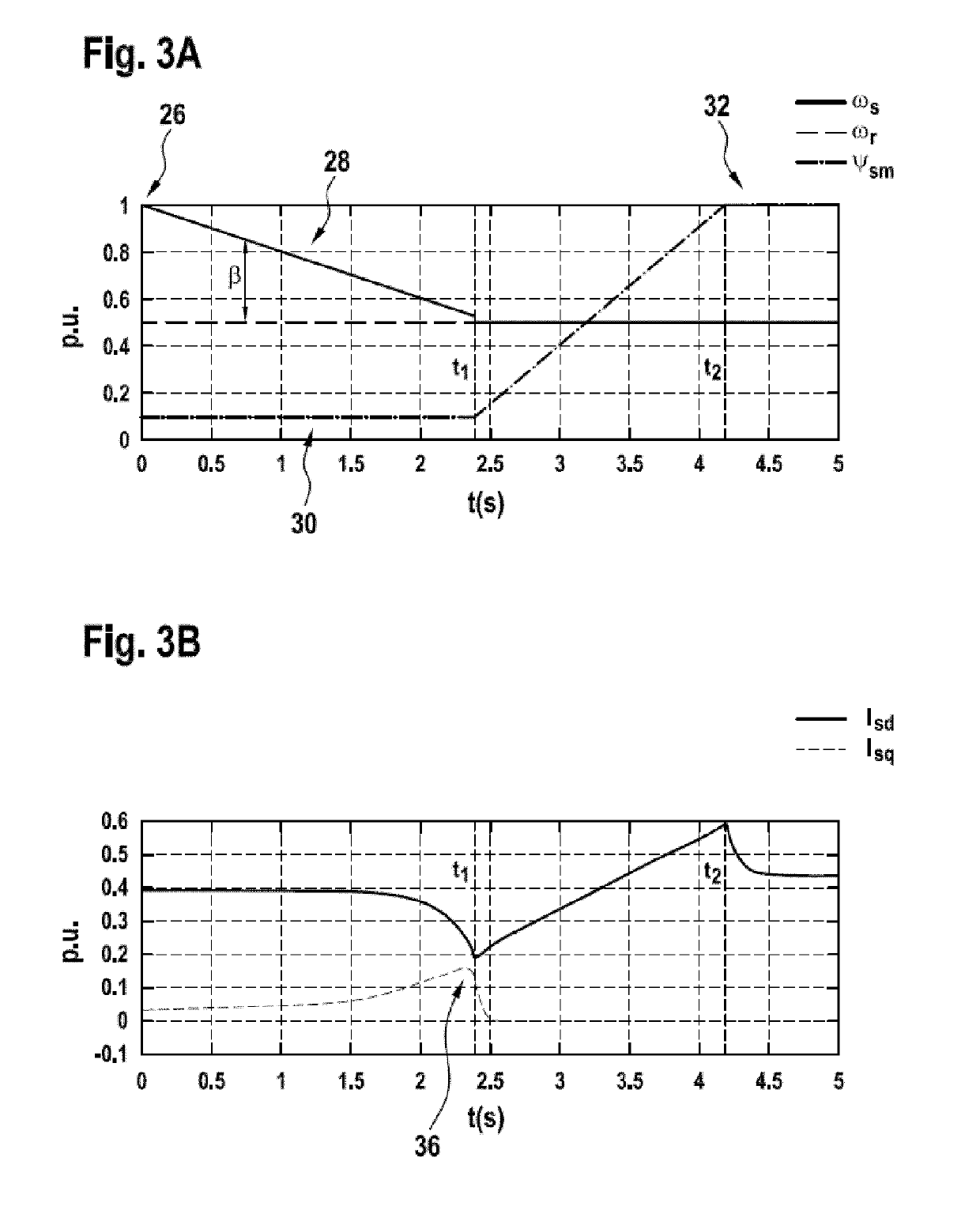

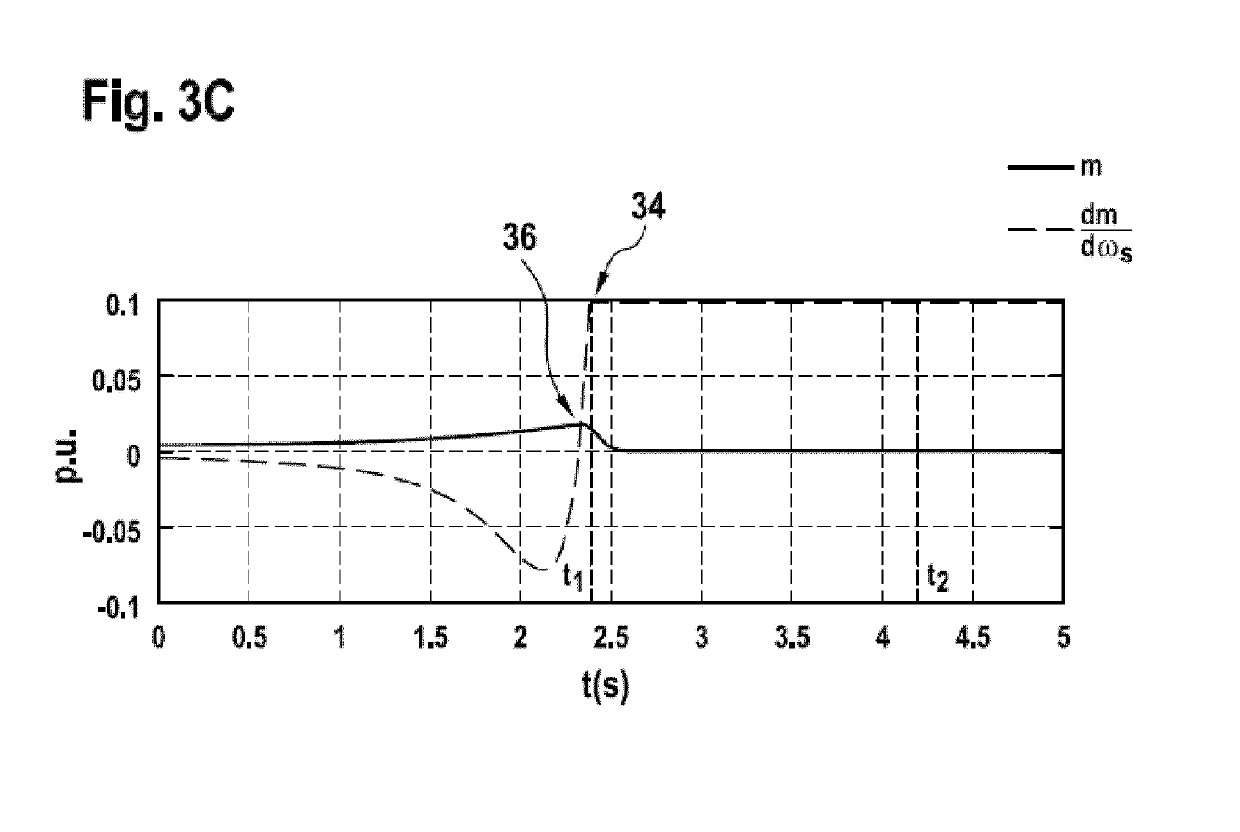

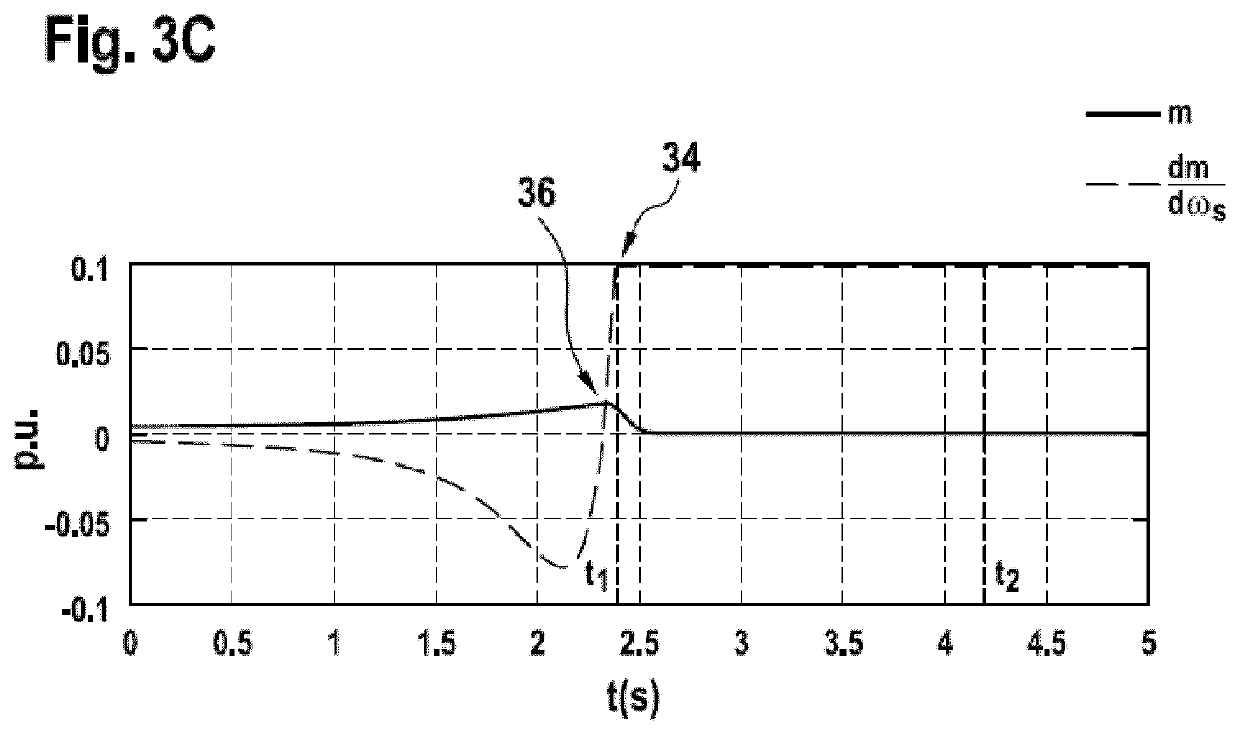

Starting an induction machine

ActiveUS20190140563A1Weaken energyWeakening rangeElectronic commutation motor controlSynchronous motors startersResidual fluxEngineering

A method for starting an induction machine without residual flux includes: scanning a state of the induction machine with different stator frequencies by controlling a supply voltage applied to the induction machine; determining whether a slip value, being a difference between a rotor frequency and a stator frequency, is within a slip interval; and, when it has been determined that the slip value is in the slip interval, regulating the slip value towards zero and magnetising the machine to the required level.

Owner:ABB (SCHWEIZ) AG

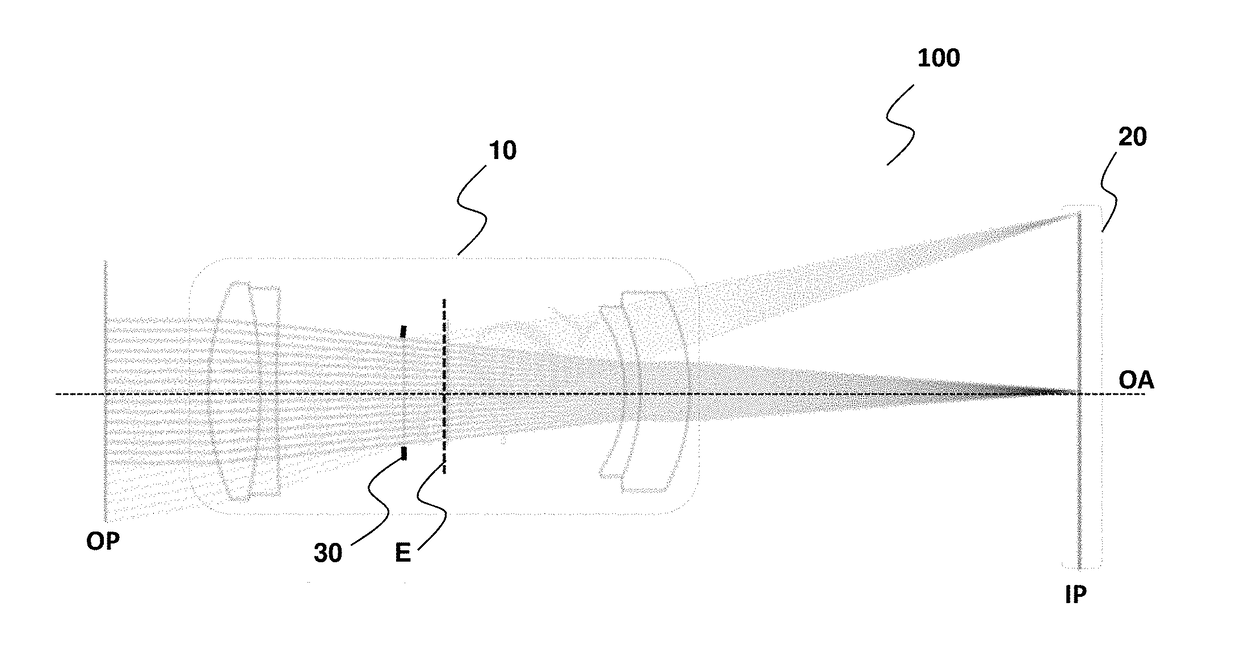

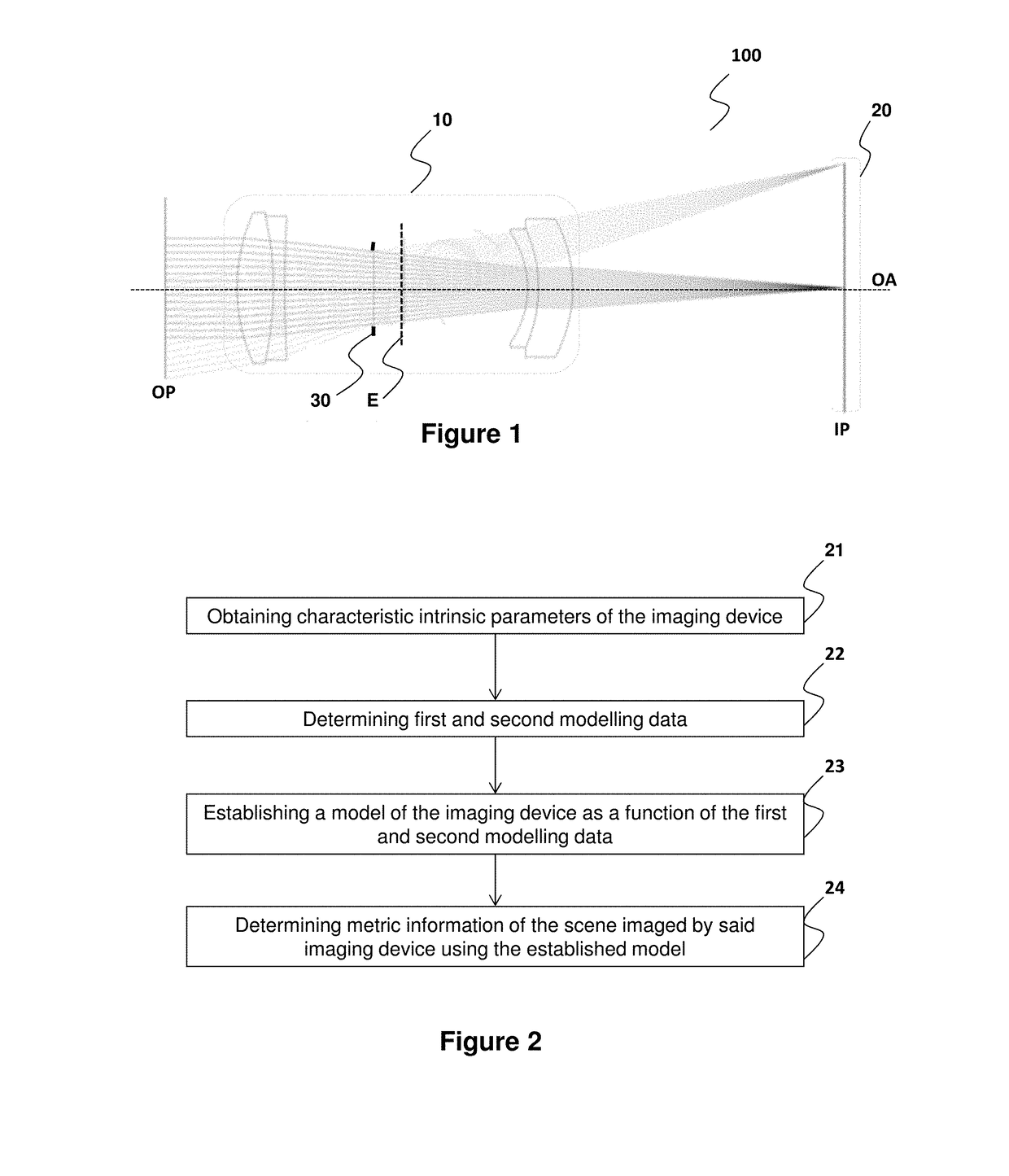

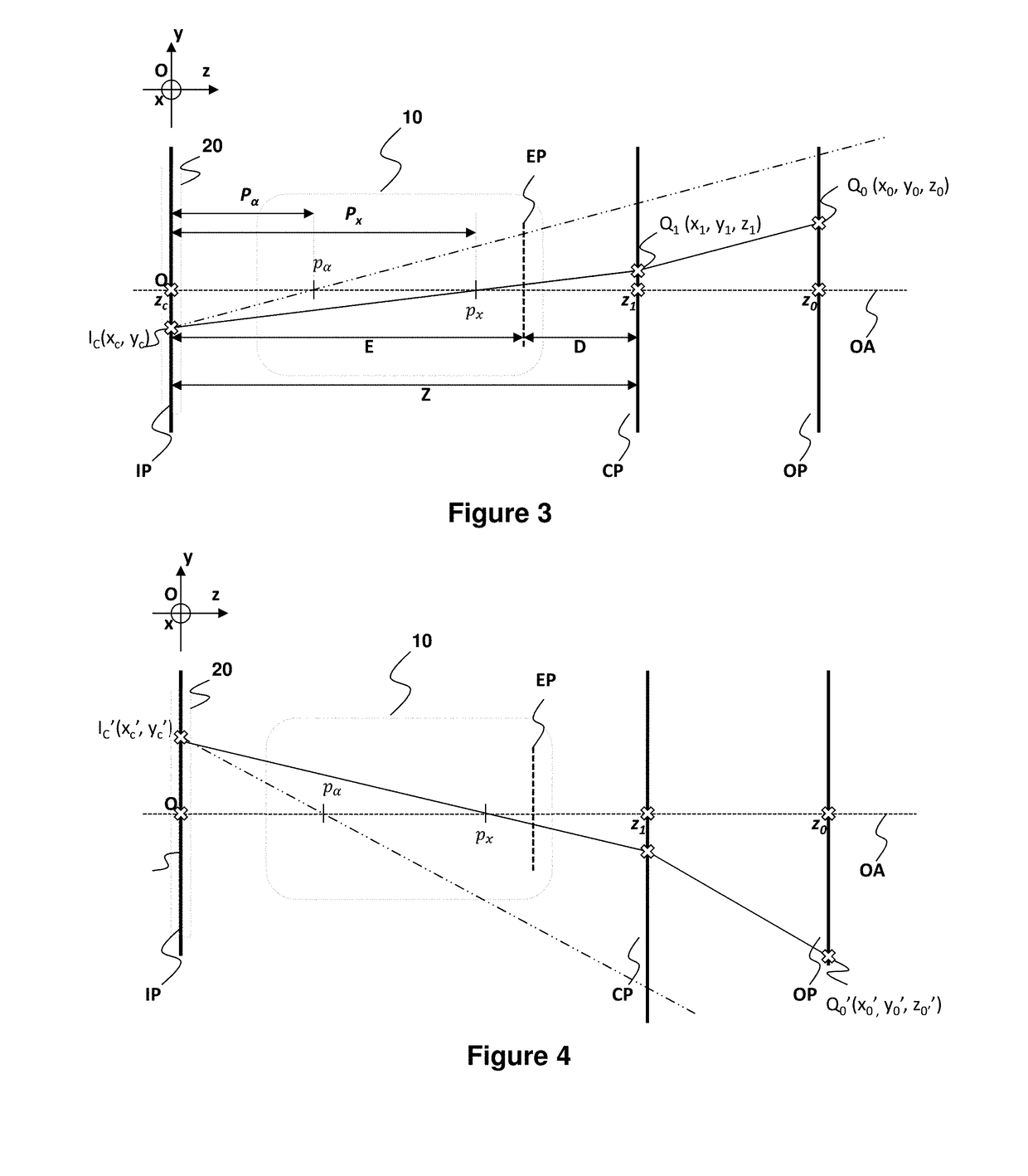

Method for modelling an image device, corresponding computer program product and computer-readable carrier medium

ActiveUS20180150975A1Simple and accurate methodSimple methodImage enhancementImage analysisMagnificationComputer science

A method for modelling an imaging device including an image sensor and an optical system is disclosed. The optical system has an aperture iris diaphragm defining an entrance pupil of the optical system. For a given configuration of the imaging device the method includes estimating a set of characteristic intrinsic parameters of the imaging device, in which a first intrinsic parameter is representative of a distance between the image plane and a sensor conjugated plane conjugated to the image sensor with respect to the optical system; a second intrinsic parameter is representative of a distance between the sensor conjugated plane and the entrance pupil and a third intrinsic parameter is representative of a magnification of the optical system; determining first and second modelling data respectively as a function of the first and third intrinsic parameters and second and third intrinsic parameters; and establishing a model of the imaging device as a function of the second and third modelling data.

Owner:INTERDIGITAL CE PATENT HLDG

Method for measuring HVAC efficiency

ActiveUS20150233599A1Improve efficiencyHeat transferMechanical apparatusSpace heating and ventilation safety systemsEngineeringDesign specification

Owner:ROCK LANCE

Starting an induction machine

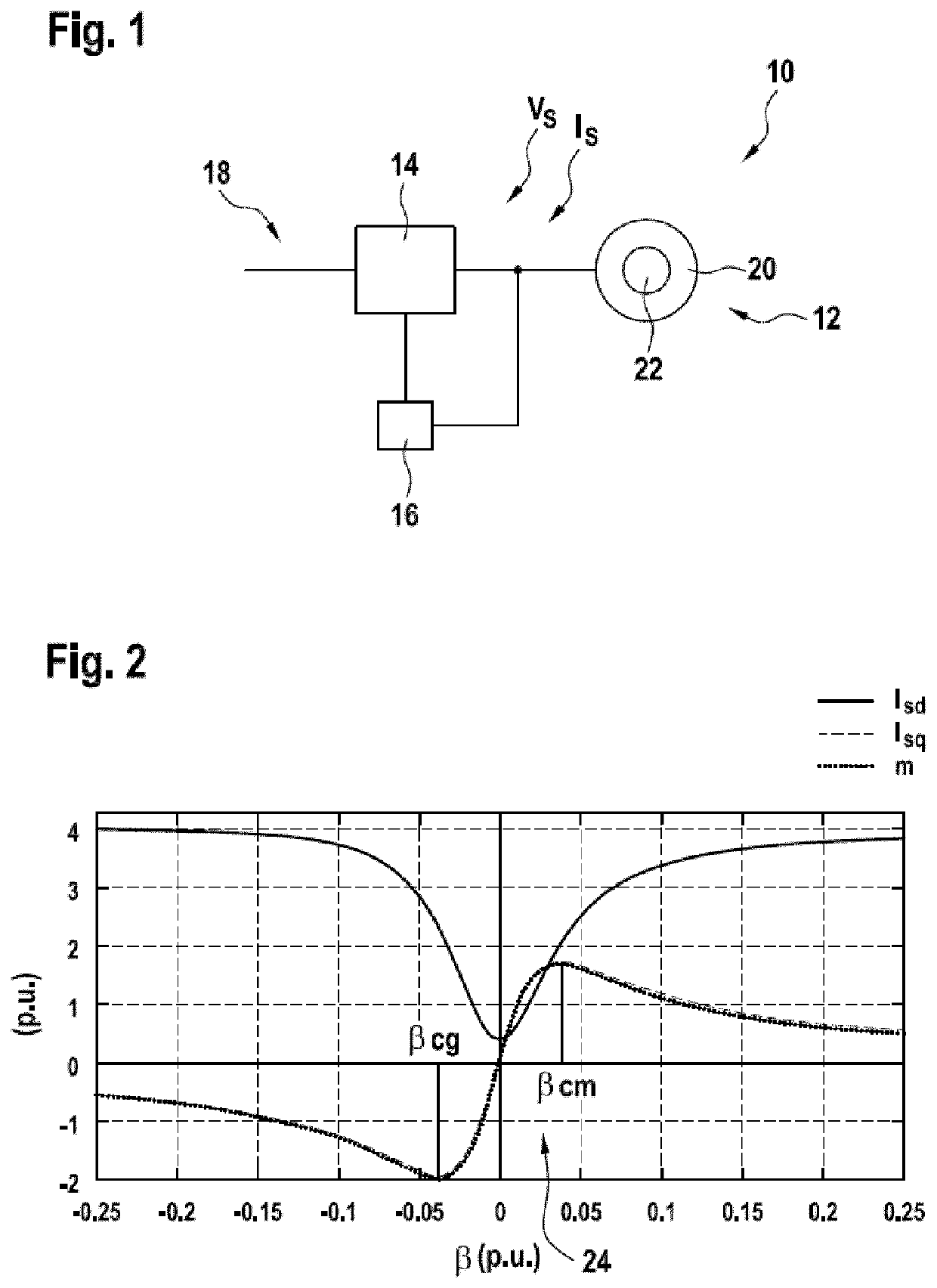

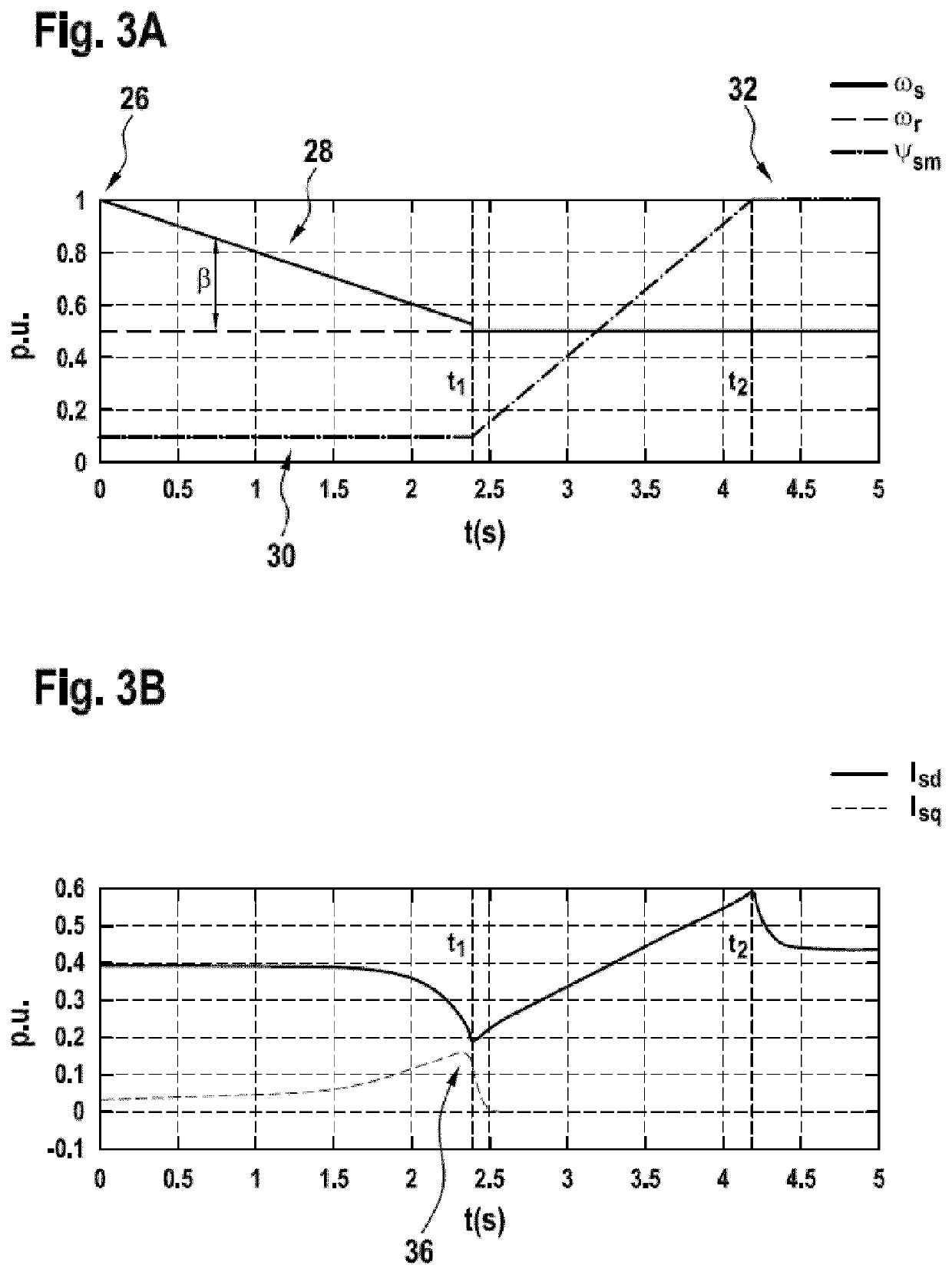

ActiveUS10819255B2Simple and accurate methodWeaken energyElectronic commutation motor controlSynchronous motors startersResidual fluxElectric machine

A method for starting an induction machine without residual flux includes: scanning a state of the induction machine with different stator frequencies by controlling a supply voltage applied to the induction machine; determining whether a slip value, being a difference between a rotor frequency and a stator frequency, is within a slip interval; and, when it has been determined that the slip value is in the slip interval, regulating the slip value towards zero and magnetising the machine to the required level.

Owner:ABB (SCHWEIZ) AG

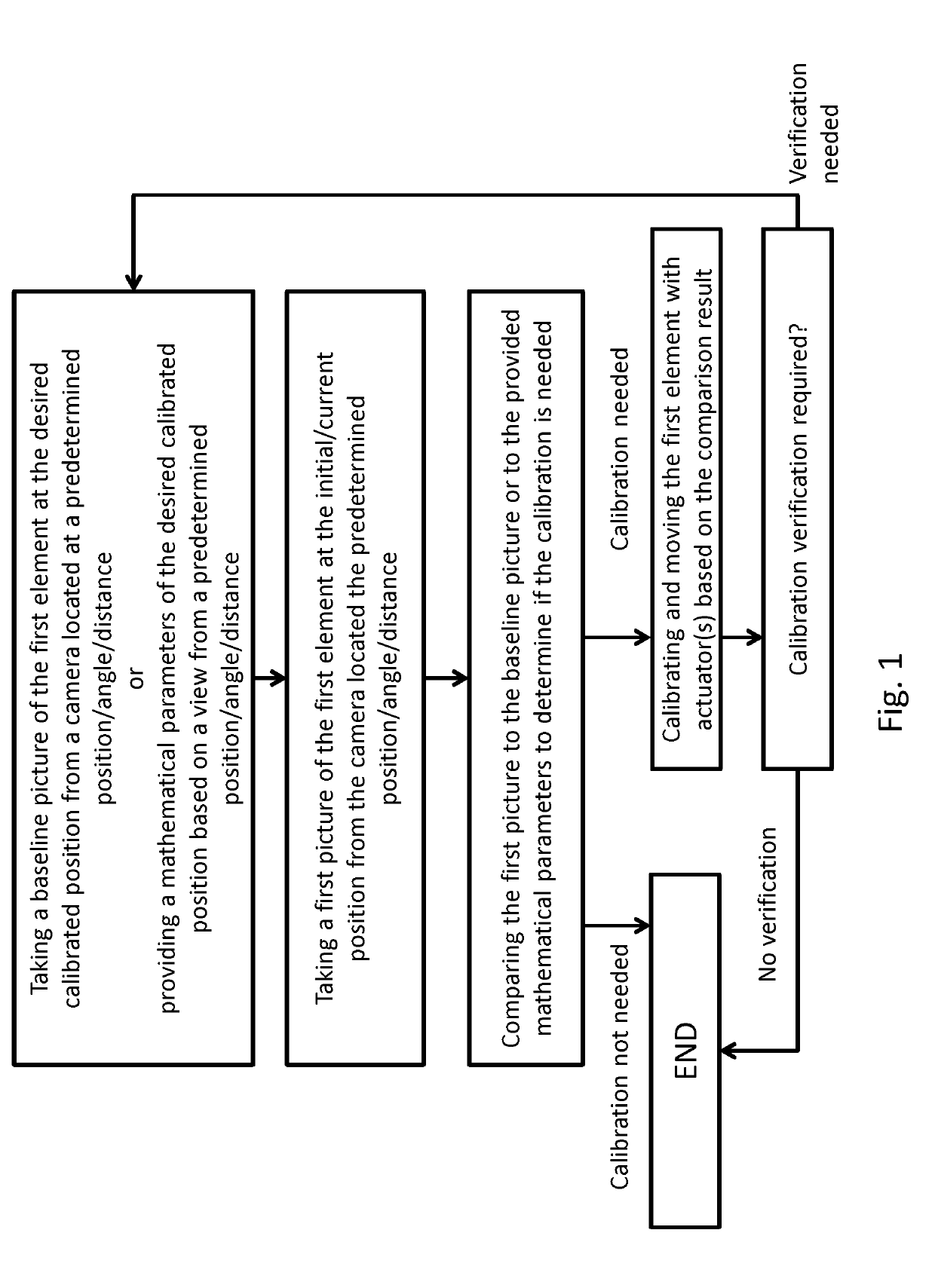

Calibration system with at least one camera and method thereof

ActiveUS20190197675A1Simpler and accurate calibrating methodThe process is simple and accurateImage enhancementImage analysisEngineeringActuator

A method for calibrating element in a semiconductor processing device with a camera is provided. The method for calibrating element in a semiconductor processing device with a camera includes taking a first picture of a first element by a camera; providing a first actuator to move the first element an increment along a first direction; taking a second picture of the first element by the camera; and comparing the first picture and the second picture to calibrate the first element. A system for calibrating element in a semiconductor processing device with a camera is also provided.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com