Hot-air stove

A technology of hot air generator and furnace body, which is applied in the direction of furnace grate, air heater, fluid heater, etc. It can solve the problems affecting product quality and grade, hot air is easy to mix with miscellaneous gas, and the ambient air has a large impact, so as to achieve product quality. Guaranteed, improved energy utilization, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

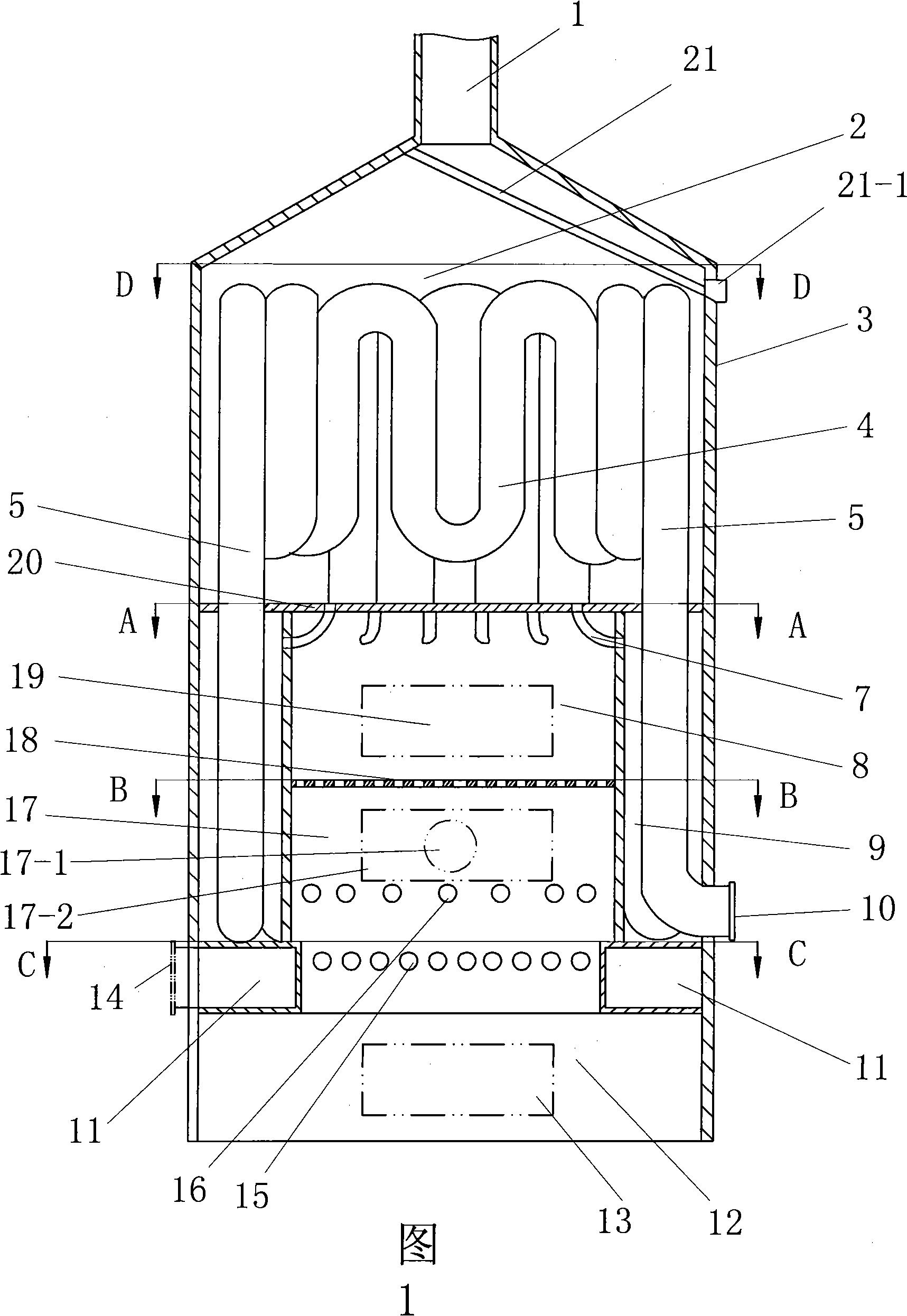

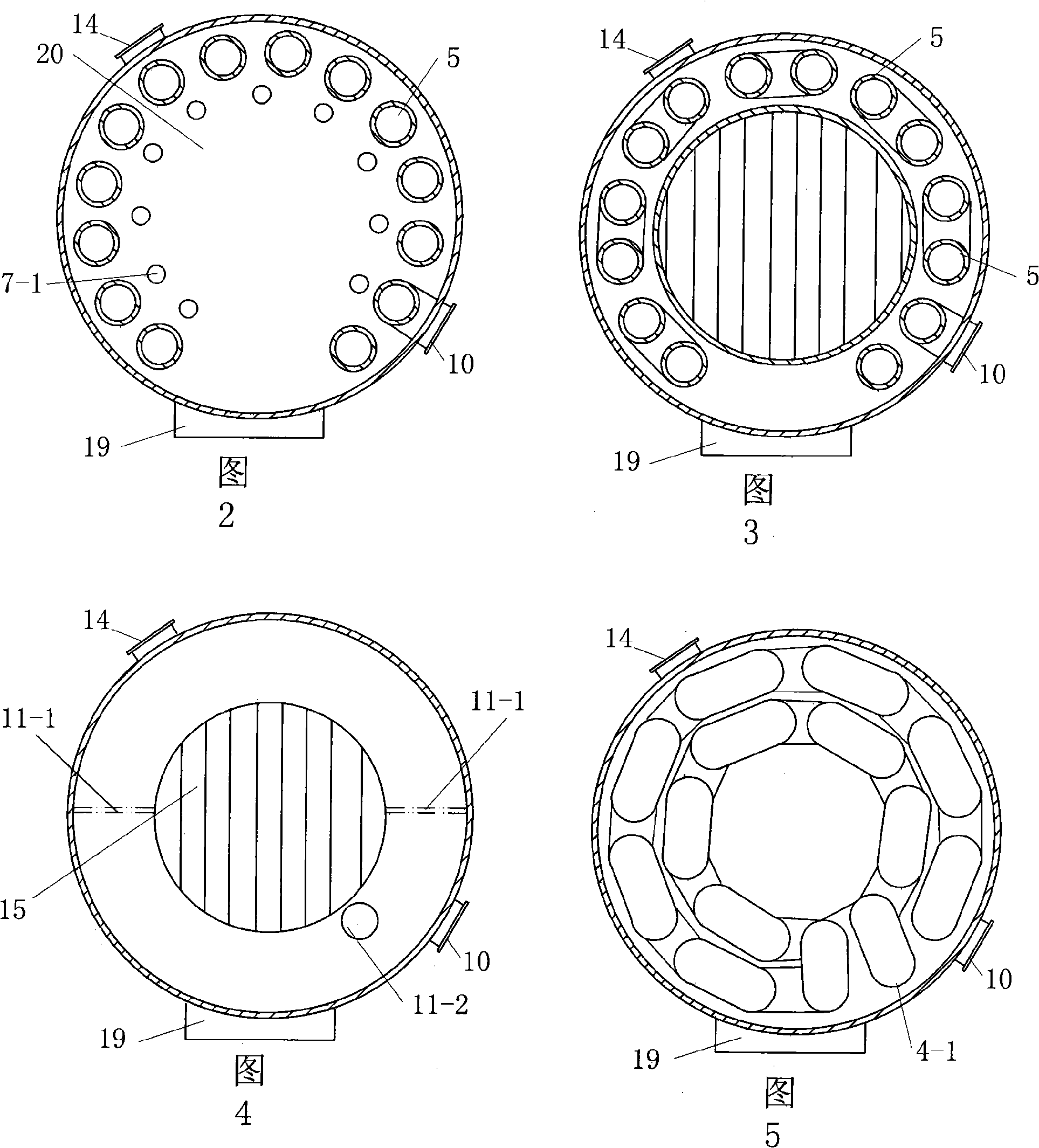

[0021] As shown in the figure, a hot blast furnace includes a furnace body 3 arranged vertically, a chimney 1 is arranged on the top of the furnace body, a combustion chamber 8 is arranged in the center of the furnace body, and heat-absorbing air ducts are arranged around and above the combustion chamber. The inlet 10 of the hot air pipe is located at the side of the furnace and communicates with the outside air; a horizontally arranged top plate 20 is also arranged in the middle of the body of furnace to separate the body of furnace into two parts, the top of the top plate is the heating chamber 2, and the bottom of the top plate is the said The combustion chamber, the lower side of the combustion chamber is provided with a secondary combustion chamber 17 (separated by a grate 18 between the described combustion chamber and the secondary combustion chamber below), and the surrounding walls of the combustion chamber and the secondary combustion chamber are fixed on An airtight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com