Feeding device for small biomass granular fuel boiler

A biomass pellet and feeding device technology, which is applied to fuel supply, furnace grate, combustion method, etc., can solve the problems of low ignition temperature of biomass pellet fuel, easy damage of rotating support, lubrication system, and large dust, so as to solve the problem of preventing The effect of coking, smooth combustion and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

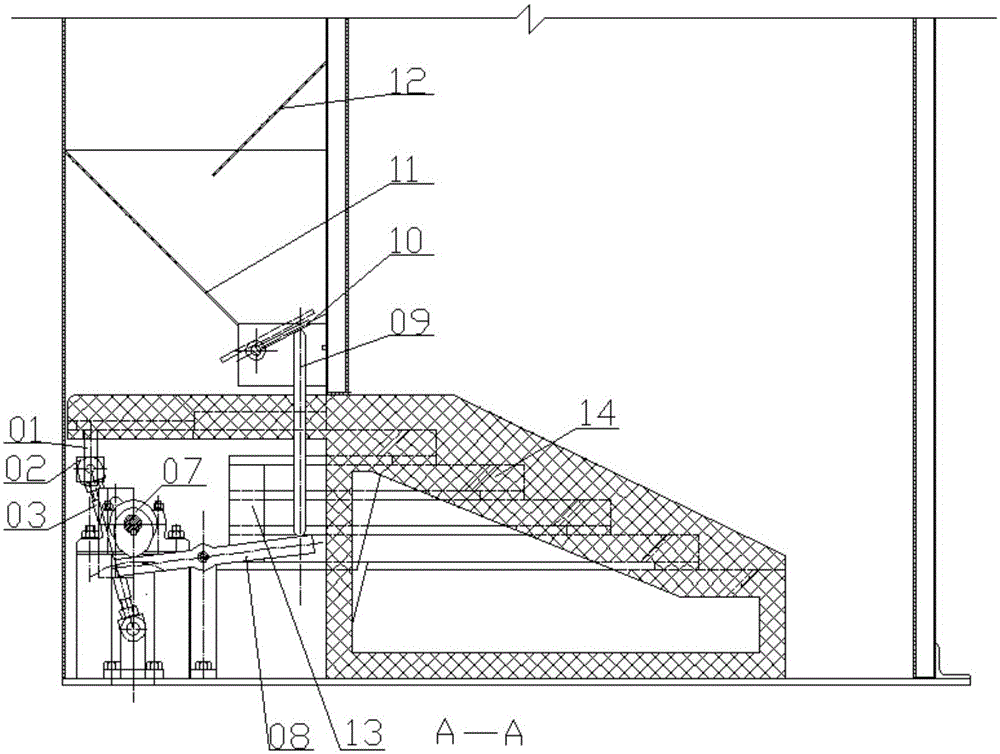

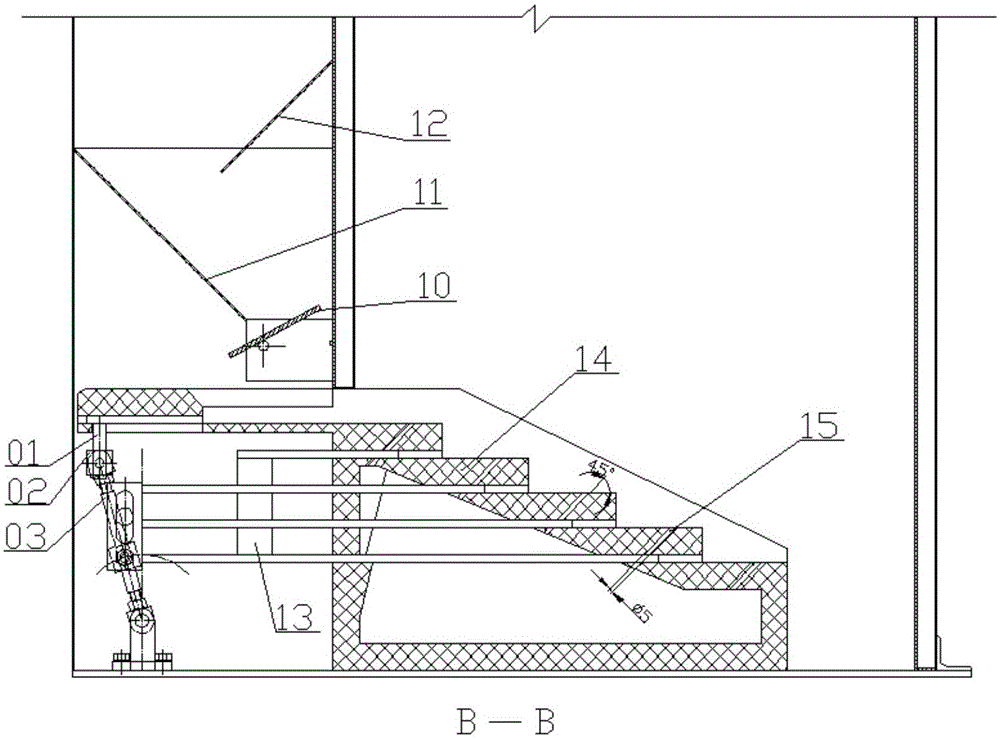

[0026]The present invention defines that one side of the rotating shaft of feeding turning plate 10 is the left side.

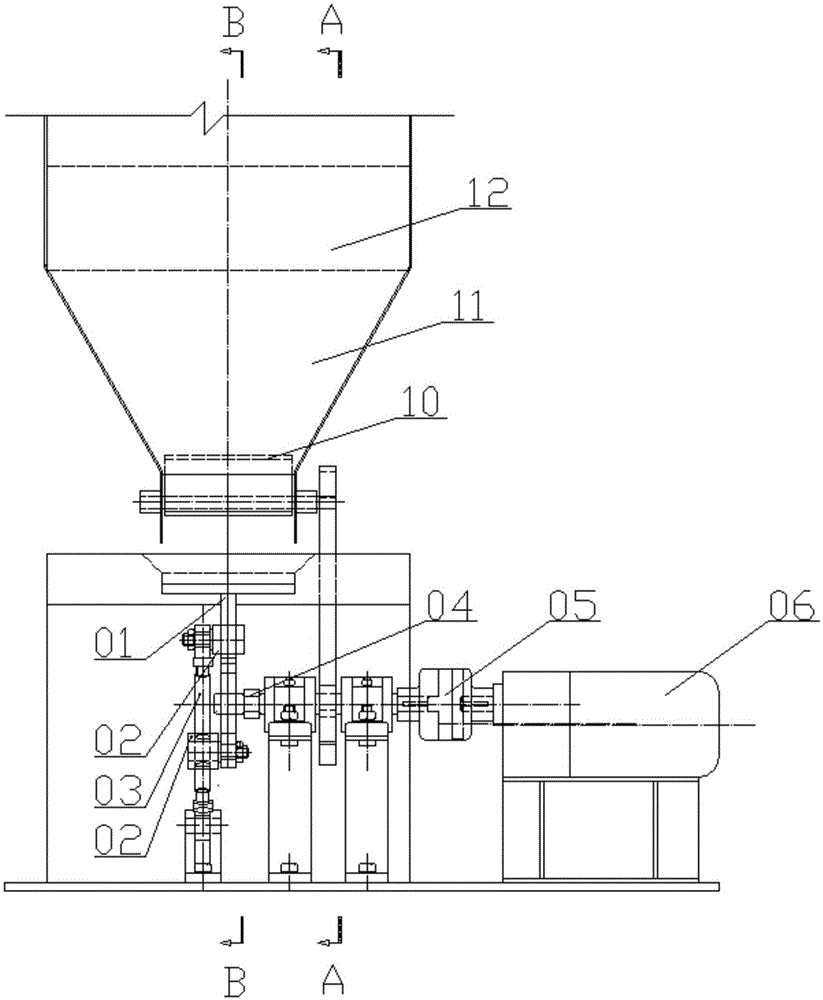

[0027] refer to figure 1 — image 3 , a small biomass particle fuel boiler feeding device, including a storage bin driven by an adjustable speed reduction motor 6 and moving in an orderly manner, a feeding mechanism, a pushing mechanism, a poking mechanism and a stepped firebed 14, wherein The feeding flap 10 in the feeding mechanism is arranged at the lower end of the storage bin, one side is hinged with the storage bin, and the other side is stuck on the edge protrusion of the storage bin; the pushing mechanism is set It is on the first step of the stepped fire bed and can slide on the first step; the feeding mechanism is hinged with the pushing mechanism; connection; the transmission parts of the feeding mechanism, the pushing mechanism and the fire poking mechanism are arranged outside the boiler body below the storage bin, and the described feeding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com