High-temperature combustion-supporting device and special combustion device for inverse combustion type biomass fuel

A biomass fuel and combustion device technology, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of black smoke, unsuitable use of biomass fuel, dust pollution, etc., to reduce investment and be beneficial to environmental protection , the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

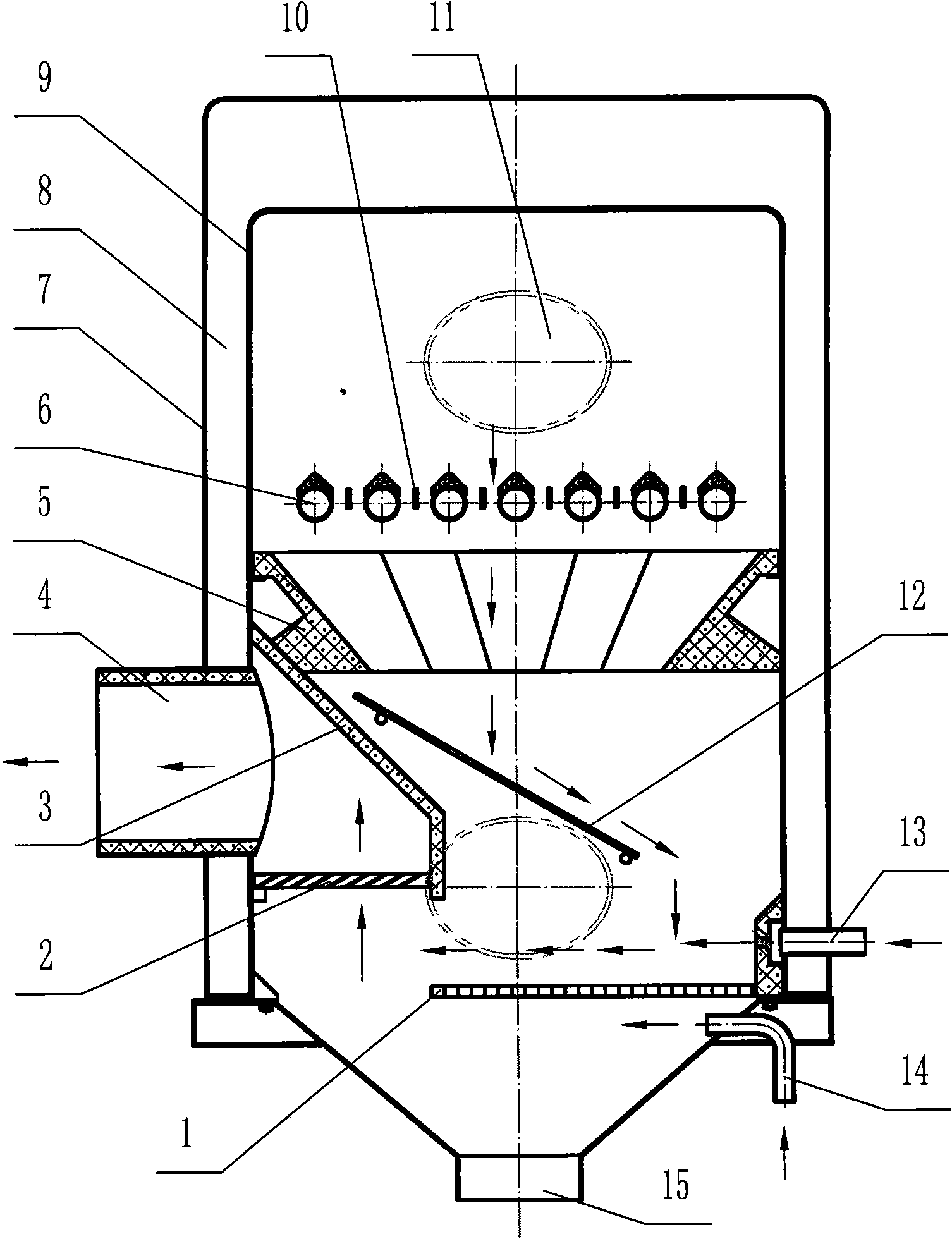

[0037] Embodiment one: see figure 1 ,Image 6- Figure 8 , Figure 11-Figure 15 , in the figure, a water jacket 8 and an outer shell 7 are provided on the surrounding surface and the top surface of the inner shell 9 of the special combustion device for backfired biomass fuel, and the upper part of the chamber surrounded by the inner shell 7 is the furnace, and the lower part is the ash In the slag chamber, the upper grate 6 and the lower grate 1 are arranged in the furnace, and the body wall of the inner shell 9, the water jacket 8 and the body wall of the outer shell 7 are respectively provided with a feeding port 11 and a high-temperature flue gas outlet 4. The port 11 is set on the upper part of the surrounding surface of the inner shell 9; the lower part of the ash chamber is provided with an ash discharge port 15, and the furnace between the upper grate 6 and the lower grate 1 is respectively provided with a high-temperature burner 5 and a hanging grate 12 , the inner sh...

Embodiment 2

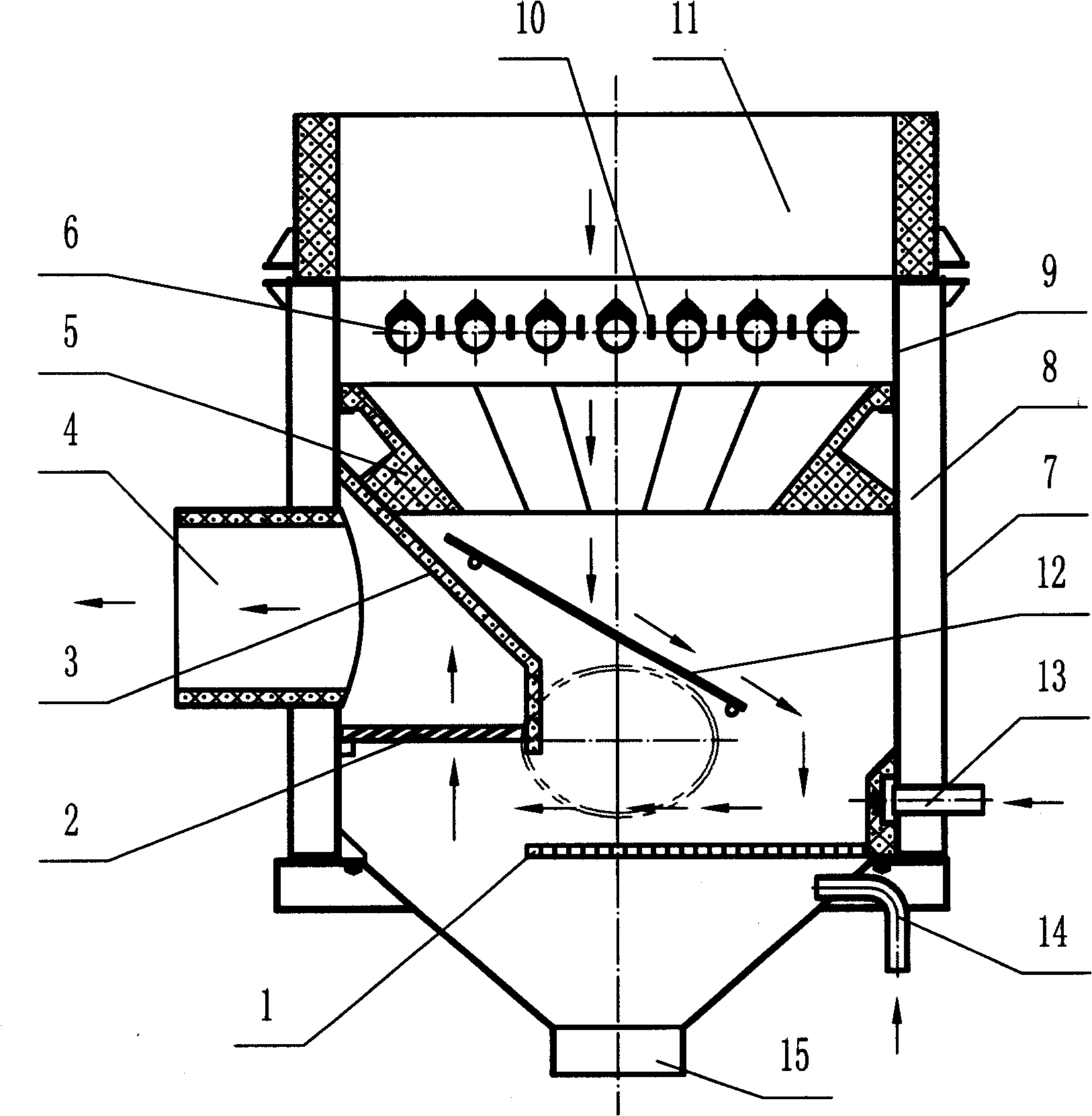

[0043] Embodiment two: see figure 2 , the number in the figure is the same as that of Embodiment 1, and the representative meaning is the same, and the same parts will not be repeated. The difference is that a water jacket 8 and an outer shell 9 are arranged on the surrounding surface of the inner shell 9, and the feed inlet 11 is arranged on On top, open feed.

Embodiment 3

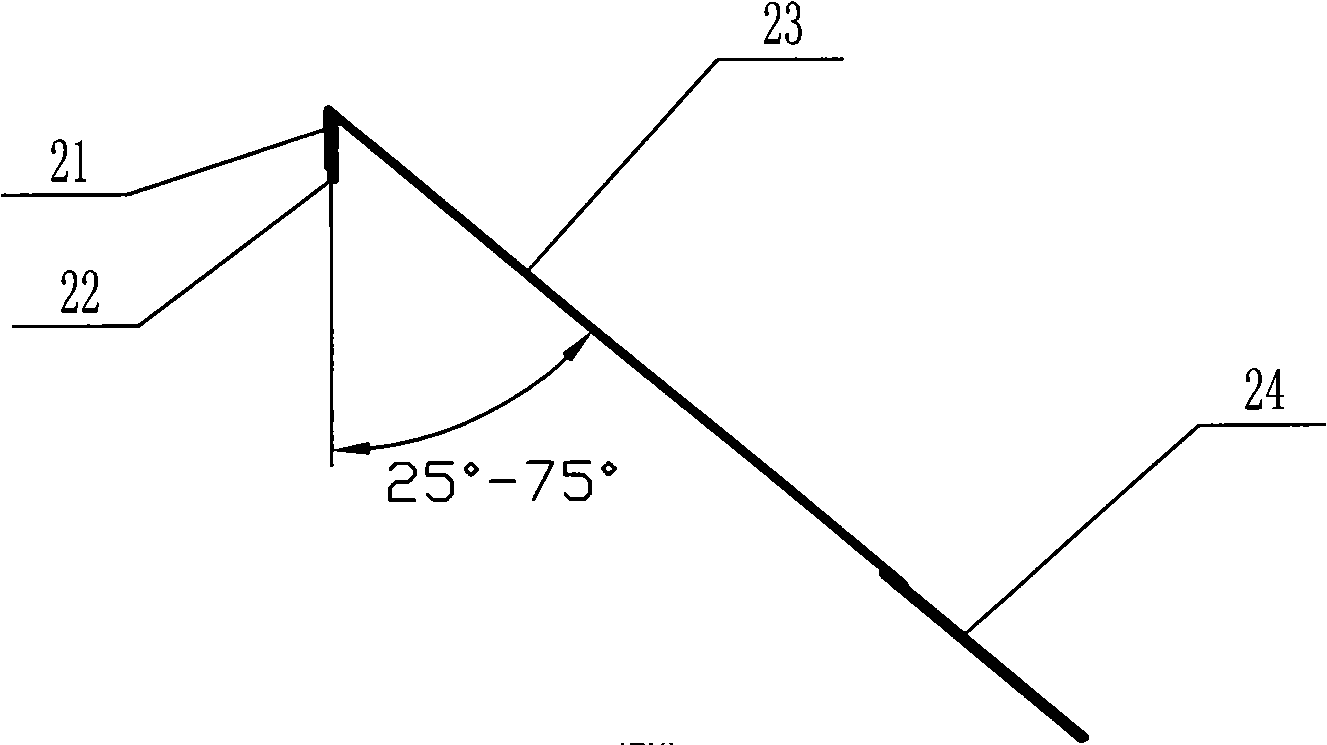

[0044] Embodiment three: see image 3 with Figure 4 , the numbers in the figure are the same as those in Embodiment 1, and the representative meanings are the same, and the same parts will not be repeated. The difference is that the lower end of the expanded steel mesh 23 for hanging the fire grate 12 is provided with a linear leg 24, and the leg 24 is connected to the The side walls of the inner case 9 are in contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com