Fixed type water chiller capable of recycling waste heat

A waste heat recovery and recycling technology, applied in applications, household appliances, household refrigeration devices, etc., can solve problems such as affecting efficiency, large total volume, and long cooling time of cooling medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

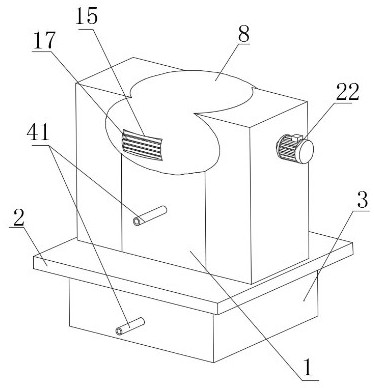

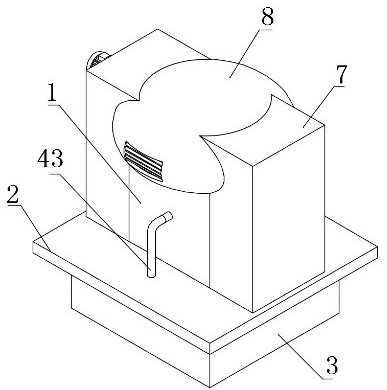

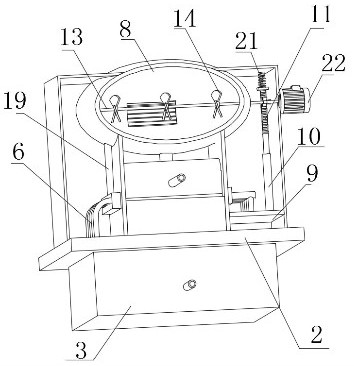

[0024] refer to Figure 1-2 , a fixed waste heat recovery and recycling ice water machine, including a machine shell 1 and a bottom plate 2, the bottom plate 2 is fixedly connected to the external ground by a plurality of bolts, the bottom of the bottom plate 2 is fixedly provided with a liquid tank 3, inside the machine shell 1 A refrigerator 4 is fixedly provided with a cooling liquid outlet pipe 41, a water inlet pipe 42, a water outlet pipe, and a cooling liquid inlet pipe 43 respectively in the refrigerator 4. The water outlet pipe is connected with a distribution box 5, and the other end of the distribution box 5 A plurality of return pipes 6 are arranged in communication, and the plurality of return pipes 6 penetrate the bottom plate 2 and communicate with the inside of the liquid tank 3 , and the return pipes 6 are connected with a waste heat utilization structure and a cooling recirculation structure.

[0025] refer to Figure 3-5 The waste heat utilization structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com