Trisegment composite initiator for synthesizing super high molecular weight polyacrylamide

A composite initiator and polyacrylamide technology, applied in the field of three-stage composite initiators, can solve the problems of high decomposition temperature of the initiator, too fast reaction, low reactivity of the initiator, etc., and achieve smooth polymerization reaction curve and polymerization reaction speed. Smooth, good product dissolving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

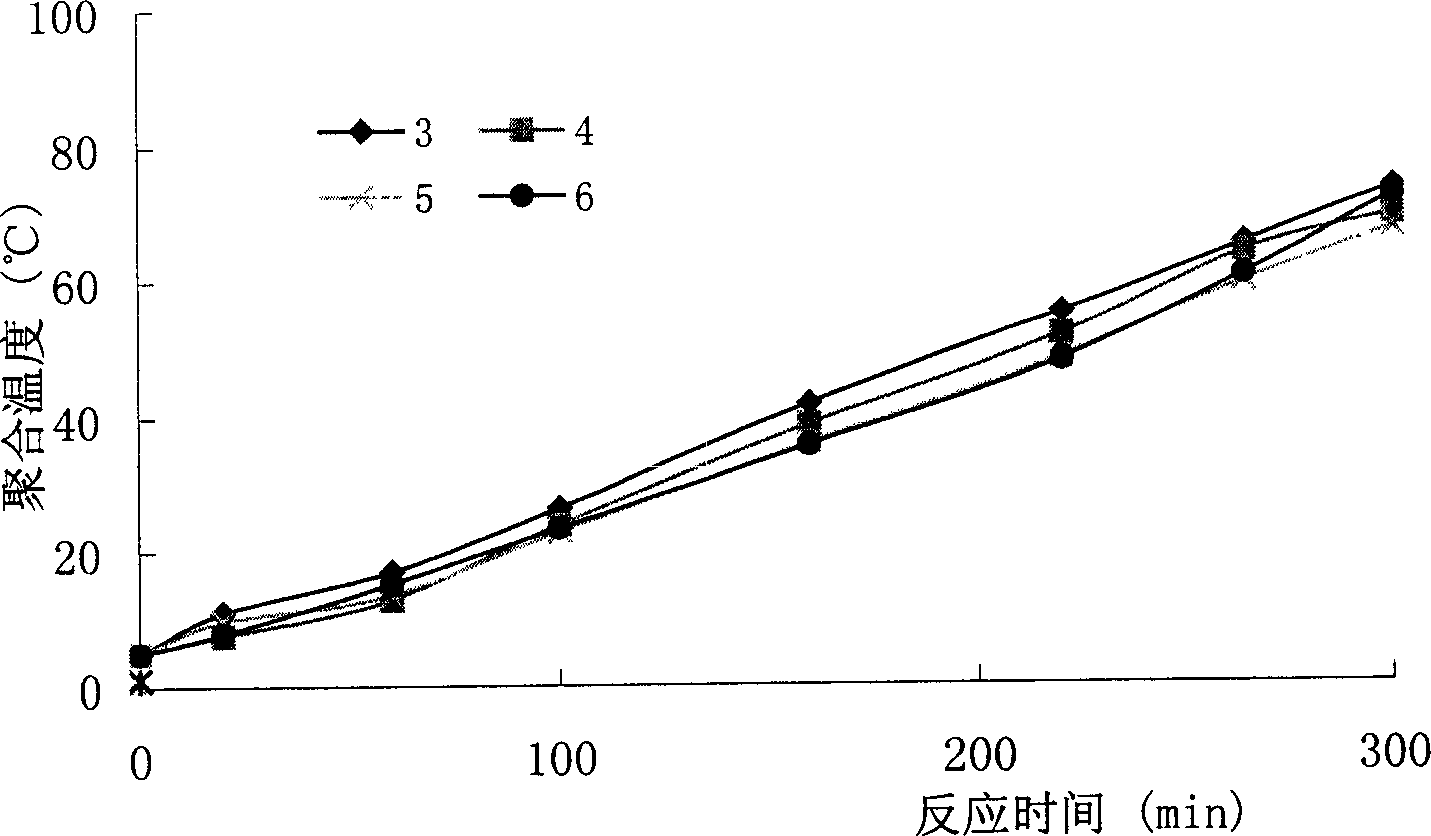

[0040] In the laboratory, the method of acrylamide aqueous solution polymerization is carried out under adiabatic conditions. The scale of laboratory synthesis is carried out step by step according to 1200g / pot, 10kg / pot, 20kg / pot, and 50kg / pot.

[0041] 1. Instrument

[0042] Dewar bottles, small polymerization kettles, latex tubes, temperature recorders, constant temperature water baths, analytical balances, nitrogen and nitrogen ventilation devices, porous ceramics, stirrers, glass instruments, ovens, colloid mills, fluidized bed dryers, etc.

[0043] 2. Chemical reagents

[0044] Acrylamide AM (industrial grade); Potassium persulfate, analytical grade; Sodium sulfite, analytical grade; Sodium hydroxide, chemically pure; Phthaloyl peroxide, analytical grade; N, N-xylidine, analytical grade; Tetraethyl Diamine, analytical grade; N,N-dimethyl-p-toluidine (DMT), analytical grade; urea oxide, analytical grade; deionized water, impedance ≥ 18.2MΩ, etc.;

[0045] 3. Experiment...

Embodiment 2

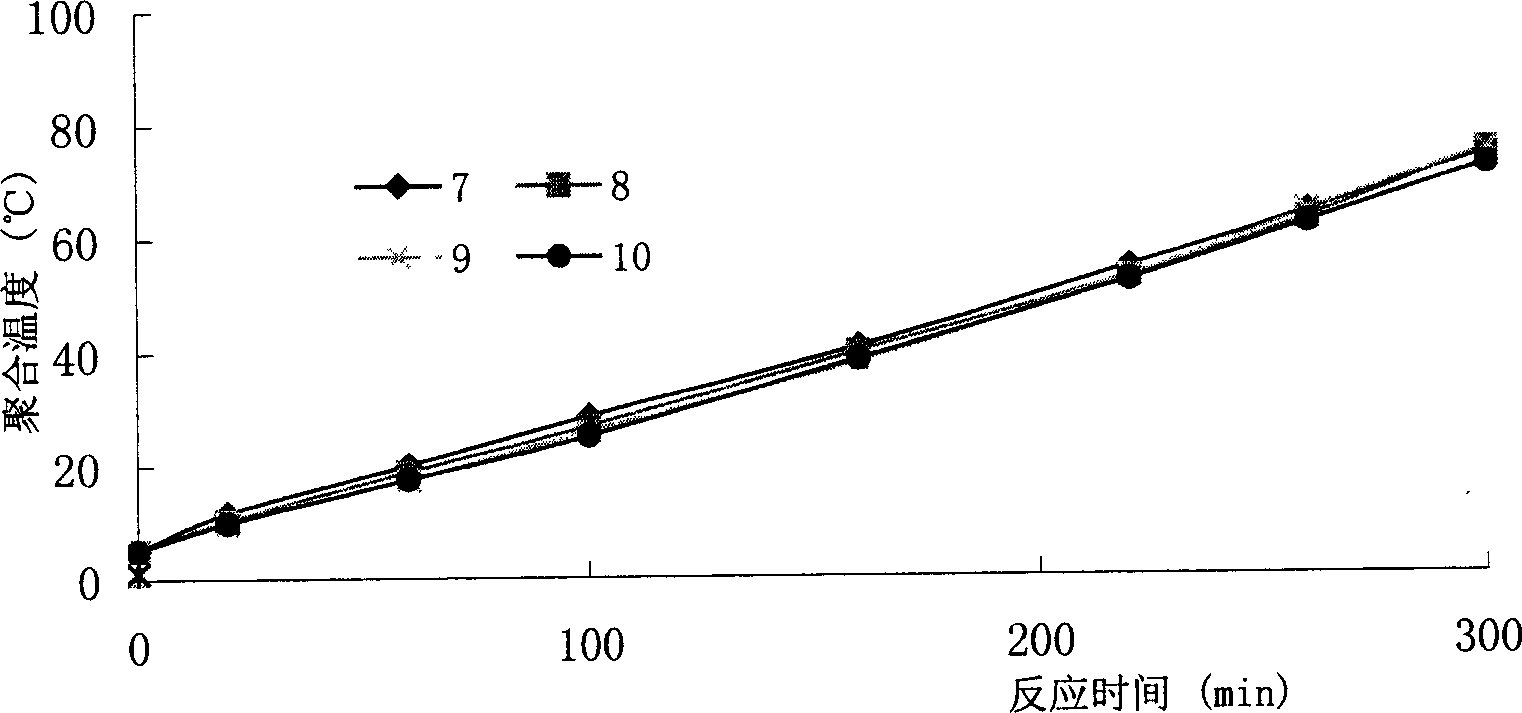

[0053] Industrial production, adopting adiabatic tank reactor, hydrolysis process after polymerization, and the synthesis scale is 8 tons / kettle.

[0054] 1. Equipment

[0055] Dissolving tank (10 tons), polymerization kettle (10 tons), pre-grinding machine, temperature recorder, hydrolysis machine, granulator, nitrogen and nitrogen ventilation device, fluidized bed dryer, etc.

[0056] 2. Chemical reagents

[0057] Acrylamide AM (technical grade); Ethylene glycol dimethacrylate (technical grade); Potassium persulfate, analytical grade; Sodium sulfite, analytical grade; Sodium hydroxide, chemically pure; Disodium ethylenediamine tetrahexanoate, analytical Pure; Phthaloyl peroxide, analytical grade; N,N-xylidine, analytical grade; Tetraethyldiamine, analytical grade; N,N-dimethyl-p-toluidine (DMT), analytical grade; Oxygenated urea, analytical grade; deionized water, impedance ≥ 18.2MΩ, etc.;

[0058] 3. Experimental steps

[0059] (1) Prepare an aqueous solution of 26% acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com