Preparation and energy recycling system of coal-bed gas hydrate

A technology of energy recovery and hydrate, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., and can solve the problem of high recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

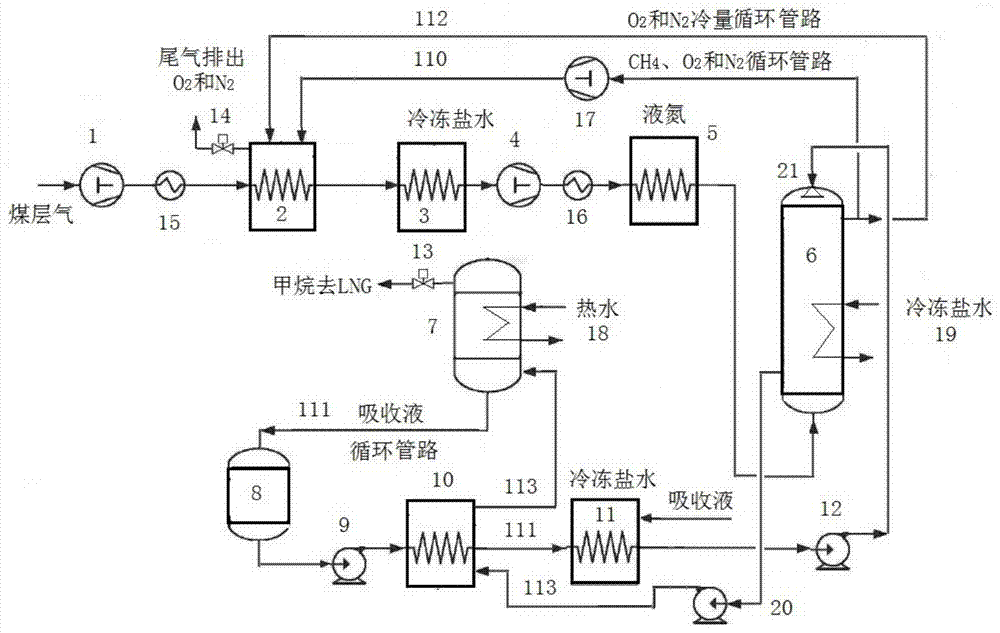

[0013] figure 1 It is a schematic flow diagram of the coalbed methane hydrate separation and capacity recovery system (example), in which 110 is the unabsorbed coalbed methane circulation pipeline, 1 is the gas pump, 2 is the heat exchanger, 3 is the refrigerant (frozen brine) cooler, 4 is Air pump, 5 is a refrigerant (liquid nitrogen) cooler, 6 is a hydrate reactor, 7 is a hydrate decomposer, 111 is an absorption liquid circulation pipeline, 8 is an absorption liquid storage tank (the absorption liquid contains 15-30 mass percent % tetrahydrofuran aqueous solution). 9 is the absorption liquid circulation pump, 10 is the heat exchanger, 11 is the refrigerant (frozen brine) cooler, 12 is the absorption liquid circulation pump, 112 is the tail gas cold recovery circulation pipeline, 13 is the methane (high concentration) gas discharge valve , 14 is the tail gas (including nitrogen, oxygen, etc.) discharge valve, 113 is the saturated absorption liquid recovery cooling capacity p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com