Combined hood for engineering machinery

A combined technology for engineering machinery, applied in the cooling combination arrangement of power units, superstructure, superstructure sub-assembly, etc., can solve problems that easily affect the performance of the heat dissipation system, and achieve difficult backflow, good sound insulation performance, Effect of reducing the amount of noise radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

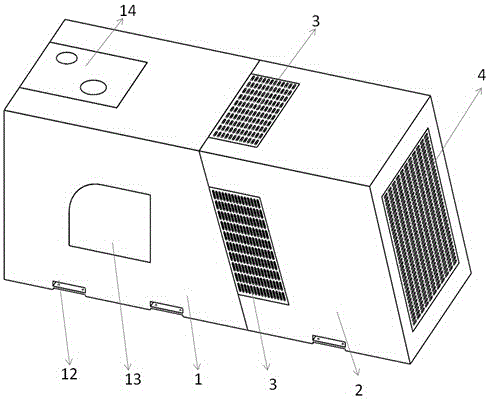

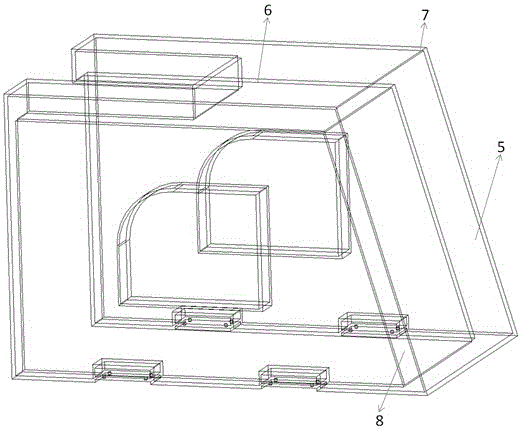

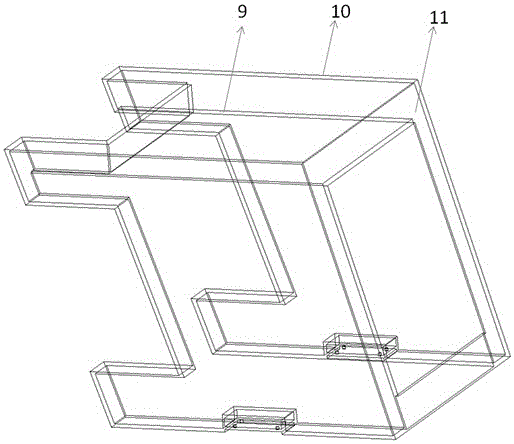

[0019] Such as Figure 1 to Figure 3 As shown, a combined hood for construction machinery of the present invention includes an engine compartment cover 1 and a heat dissipation compartment cover 2 . An air intake grid 3 and an exhaust grid 4 are arranged on the heat dissipation cabin cover 2 . The heat dissipation cabin cover 2 is fixedly connected to the afterbody of the engine compartment cover 1 . The heat dissipation compartment cover 2 and the engine compartment cover 1 are separated by the tail end plate 5 of the engine compartment cover 1 . The engine compartment cover 1 includes an engine compartment inner cover 6 and an engine compartment outer cover 7 located outside the engine compartment inner cover 6 . The engine compartment inner cover 6 and the engine compartment outer cover 7 are fixedly connected, and a first airtight cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com