Method capable of improving gel strength of curdlan

A gelation and strength technology, which is applied in the application field of new microbial polysaccharide curdlan gum, can solve the problems of high-strength gel initial temperature and low gel strength, so as to achieve the improvement of gel strength and strengthening effect , improve the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) The microbial polysaccharide curdlan gum: hydrogen bonding force promoter: coagulant is mixed uniformly according to 1: 1: 6; the hydrogen bonding force promoter is potassium chloride, potassium phosphate, calcium chloride 1. One or more of borax, and the coagulation aid is one or more of ammonium nitrate, ammonium chloride, urea, diammonium hydrogen phosphate;

[0018] 2) The product compounded in 1) is dissolved in water with the mass of microbial polysaccharide curdlan gum and water: the volume absolute concentration is 2.0%;

[0019] 3) The resulting solution was gelled at 95°C for 10 minutes;

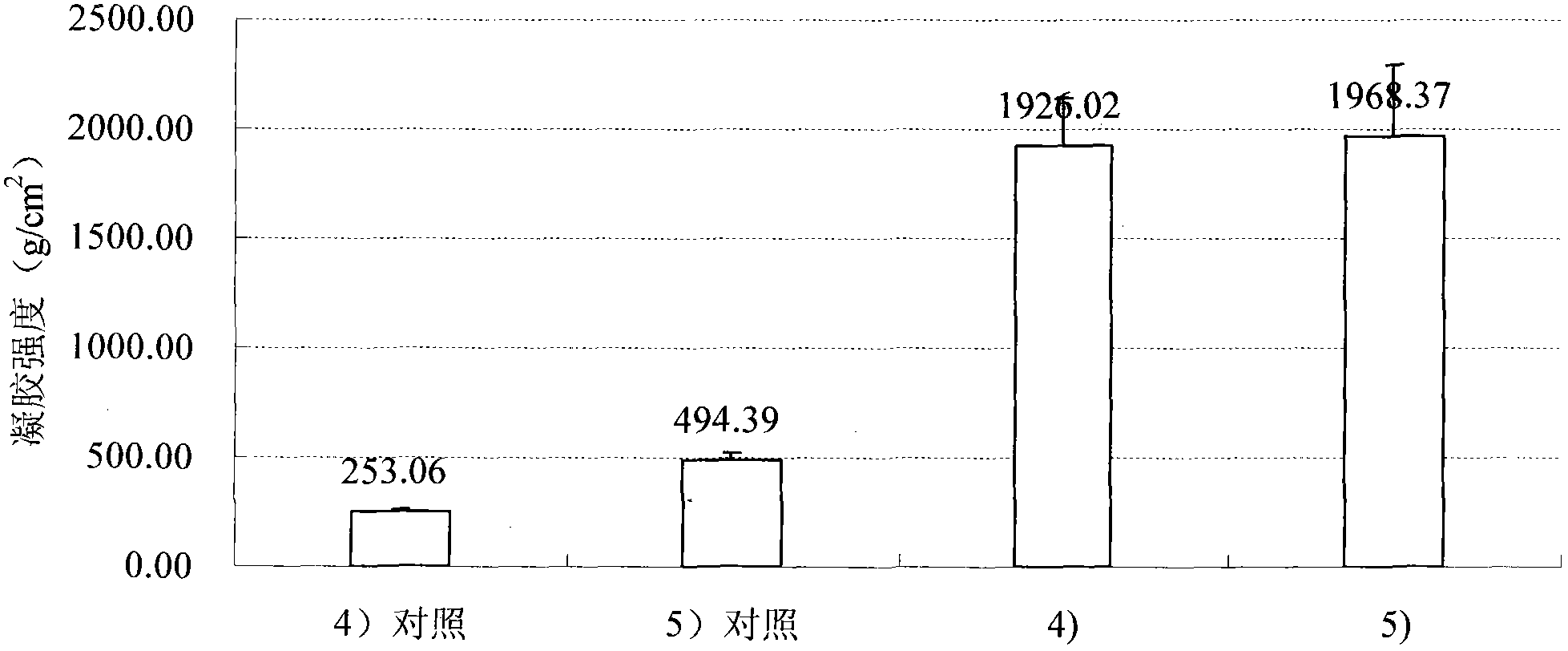

[0020] 4) directly measure its gel strength at high temperature;

[0021] 5) measure its gel strength after the gained gel is cooled;

[0022] The measurement results are attached figure 1 .

Embodiment 2

[0024] 1) The microbial polysaccharide curdlan gum: the hydrogen bonding force accelerator is compounded and mixed uniformly in a ratio of 1:1; the hydrogen bonding force accelerator is one of potassium chloride, potassium phosphate, calcium chloride, and borax or several;

[0025] 2) The product compounded in 1) is dissolved in water with the mass of microbial polysaccharide curdlan gum and water: the volume absolute concentration is 2.0%;

[0026] 3) The resulting solution was gelled at 95°C for 10 minutes;

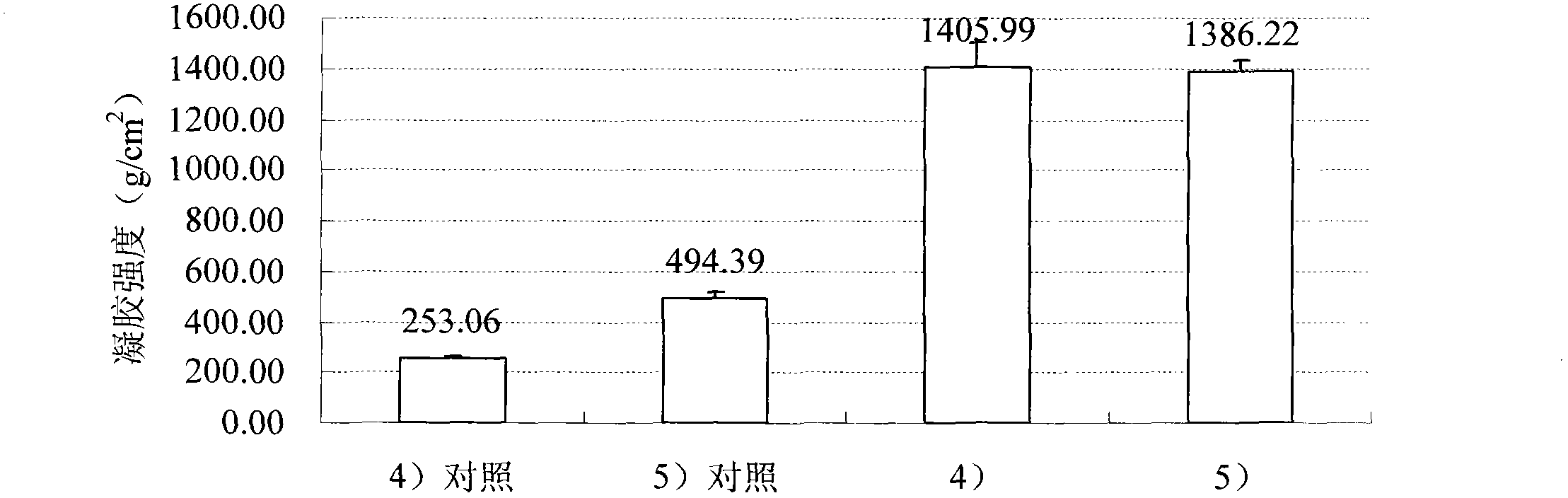

[0027] 4) directly measure its gel strength at high temperature;

[0028] 5) measure its gel strength after the gained gel is cooled;

[0029] The measurement results are attached figure 2 .

Embodiment 3

[0031] 1) The microbial polysaccharide curdlan gum: the coagulant aid is mixed uniformly at a ratio of 1:6; the coagulant aid is one or more of ammonium nitrate, ammonium chloride, urea, and diammonium hydrogen phosphate;

[0032] 2) The product compounded in 1) is dissolved in water with the mass of microbial polysaccharide curdlan gum and water: the volume absolute concentration is 2.0%;

[0033] 3) The resulting solution was gelled at 95°C for 10 minutes;

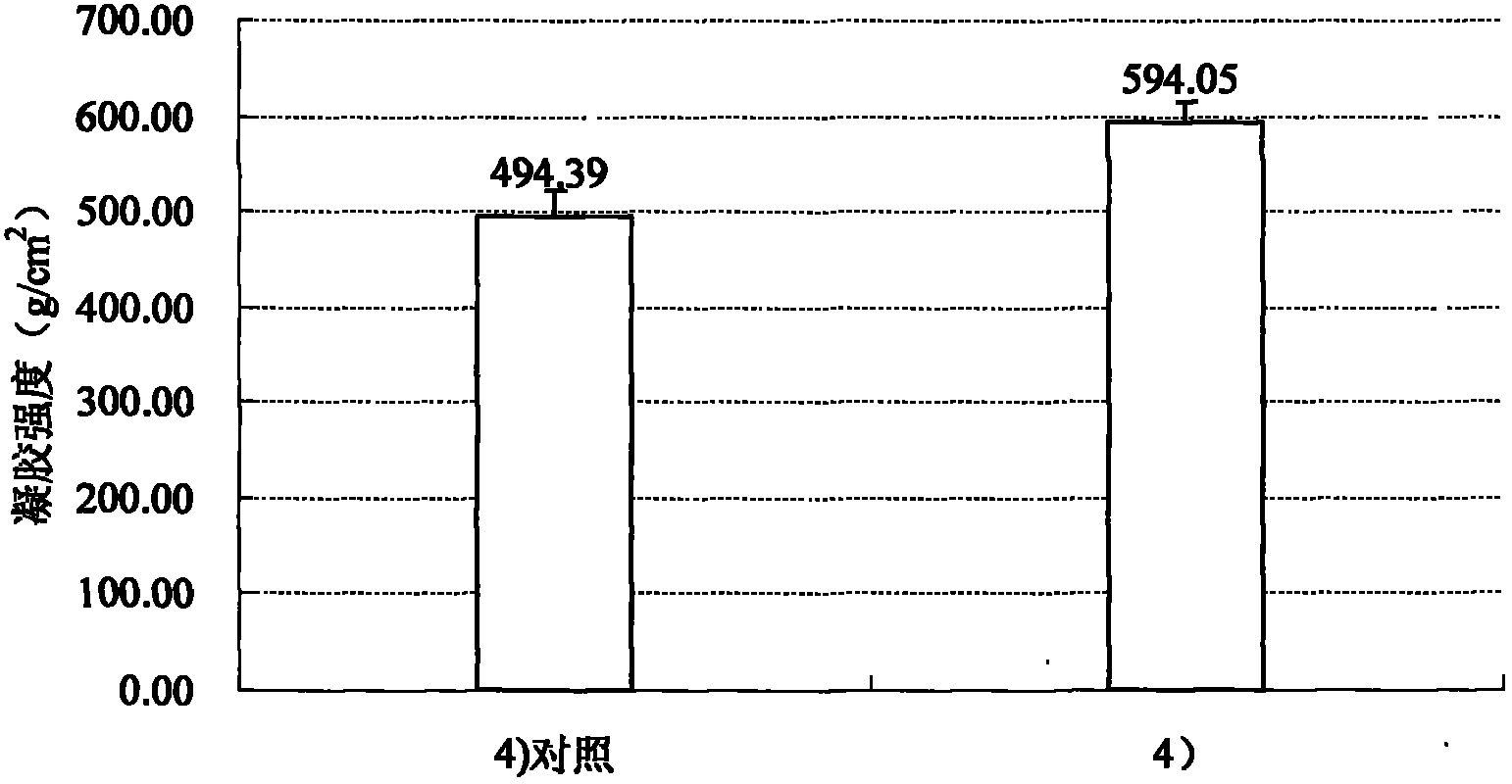

[0034] 4) measure its gel strength after the gained gel is cooled;

[0035] The measurement results are attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com