Pressure reducing air inlet high compression ratio internal-combustion engines

A high compression ratio, internal combustion engine technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as damage to spark plug insulators, increased fuel consumption, engine overheating, etc. Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

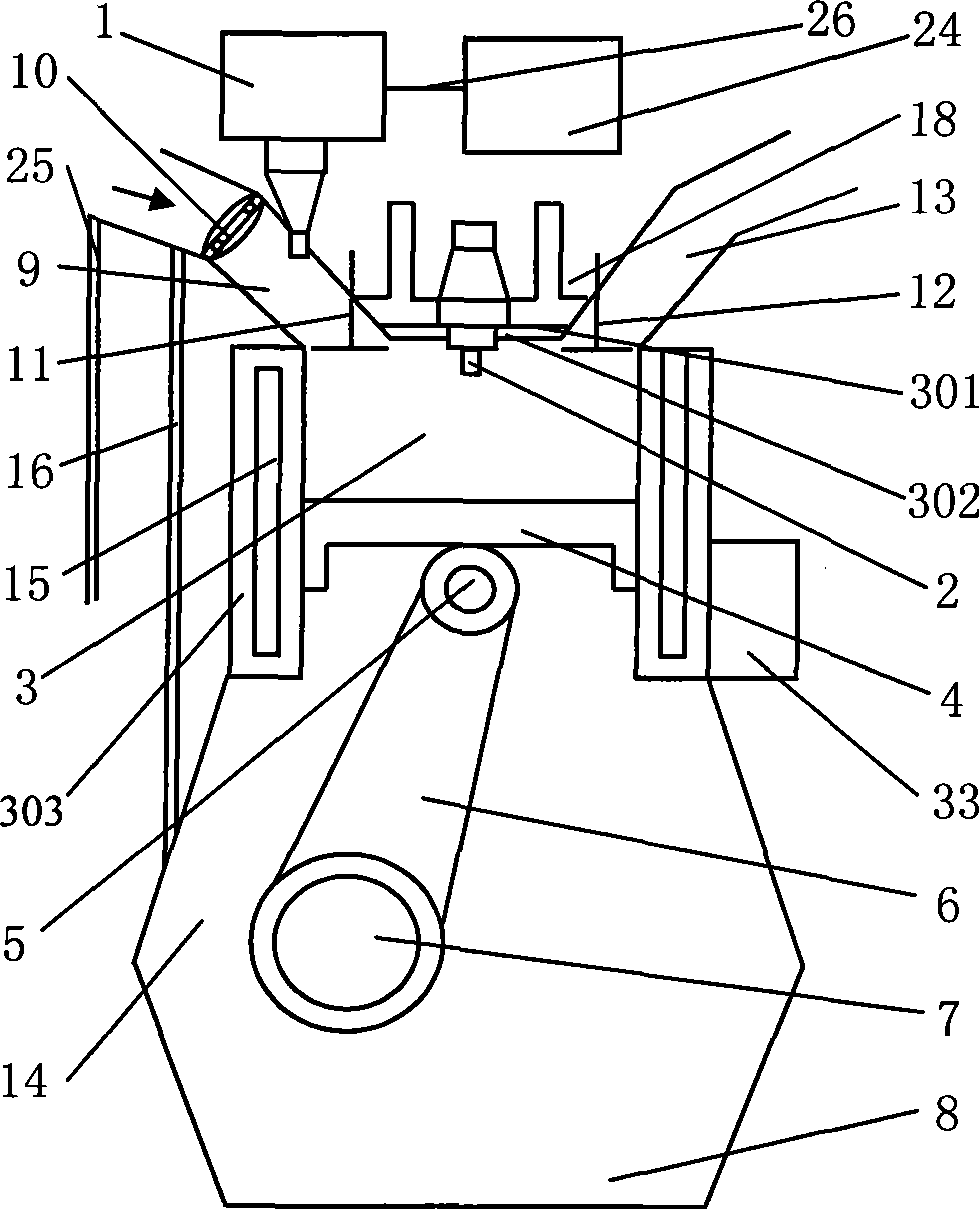

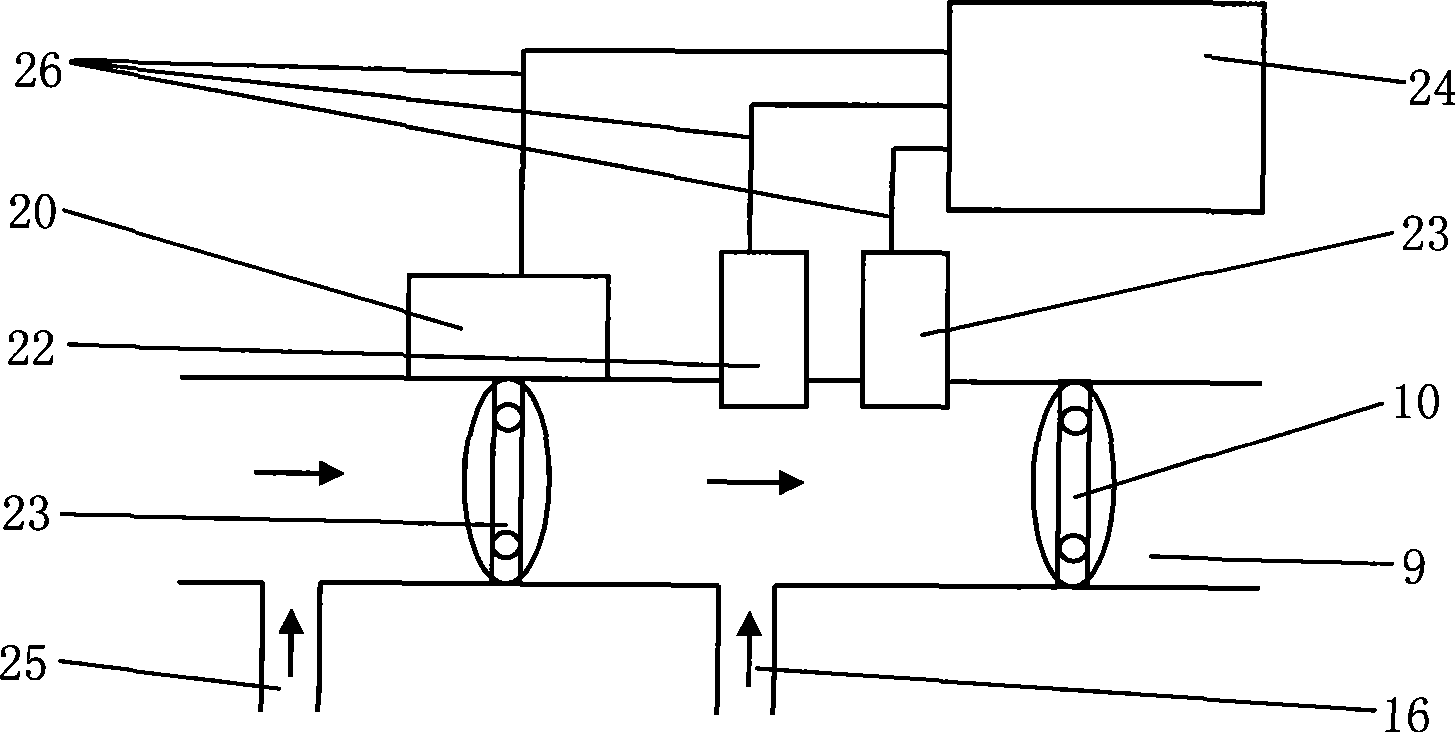

[0022] see figure 2 , image 3 . A decompression intake air high compression ratio internal combustion engine, comprising a fuel injection system 1, a spark plug 2, a cylinder 3, a piston 4, a piston pin 5, a connecting rod 6, a crankshaft 7, an oil pan 8, an intake manifold 9, and a throttle valve 10. Intake valve 11, exhaust valve 12, exhaust pipe 13 and crankcase 14, cylinder head 301 is arranged on the top of cylinder 3, oil pan 18 is arranged on cylinder head 301, cylinder block 303 is around cylinder 3, the The internal combustion engine also includes an intake pressure reducing valve 20 and its valve driver 21, a pressure sensor 22 and a flow sensor 23. The intake pressure reducing valve 20 is arranged on the intake manifold 9 and is located at the end of the throttle valve 10 in the intake direction. The upstream position, and the intake pressure reducing valve 20 is located between the crankcase suction passage 16 and the exhaust gas recirculation passage 25; the v...

no. 2 example

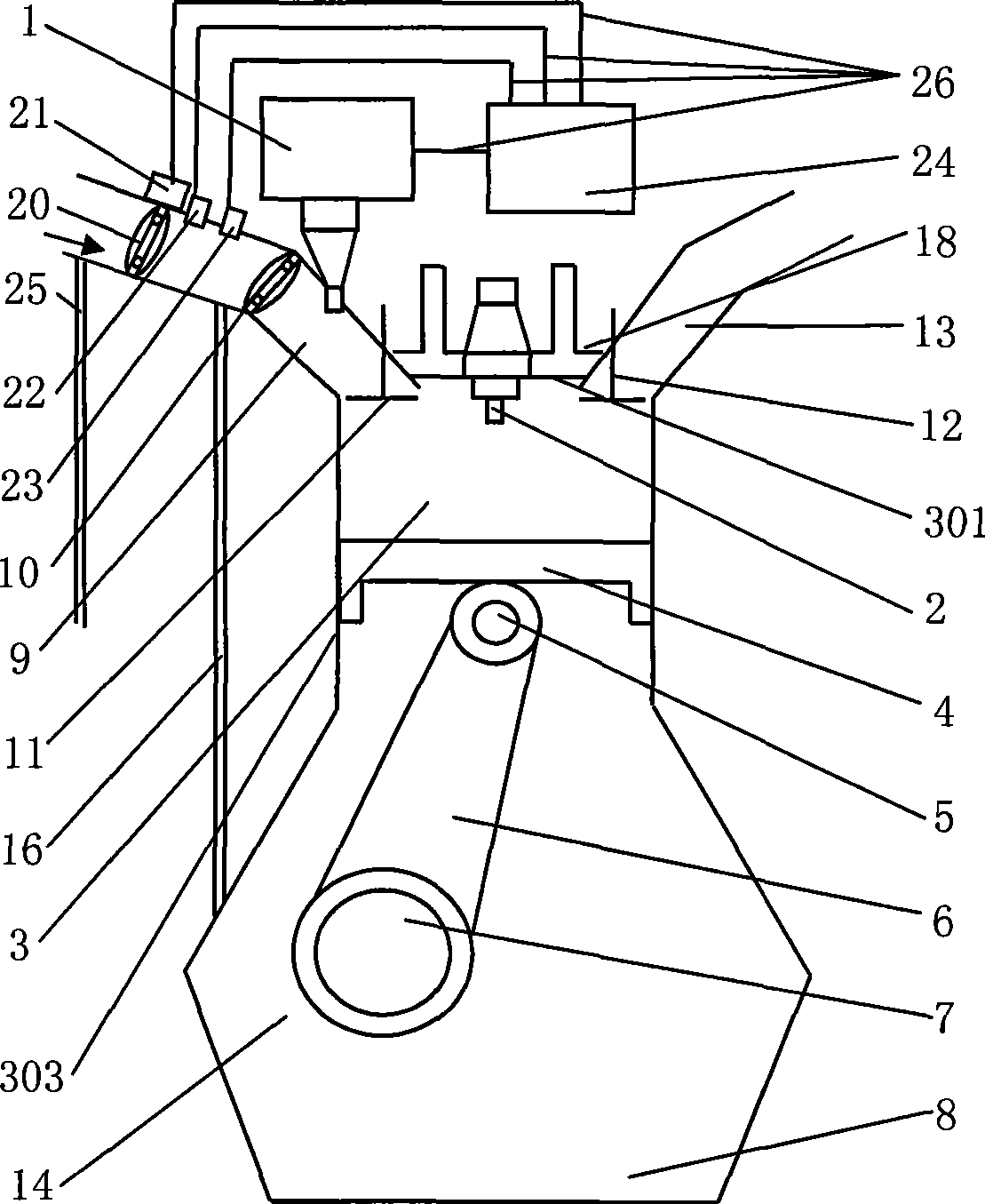

[0026] see Figure 4. A decompression intake high compression ratio internal combustion engine, comprising a fuel injection system 1, a spark plug 2, a cylinder 3, a piston 4, a piston pin 5, a connecting rod 6, a crankshaft 7, an oil pan 8, an intake manifold 10, an intake Door 11, exhaust valve 12, exhaust pipe 13 and crankcase 14, cylinder head 301 is arranged on the top of cylinder 3, and oil pan 18 is arranged on cylinder head 301, and this internal combustion engine also includes an intake pressure reducing valve 20 and its valve Driver 21 , pressure sensor 22 and flow sensor 23 . The intake decompression valve 20 is arranged on the intake manifold 9 and is located upstream of the throttle valve 10 in the intake direction, and the intake decompression valve 20 is located between the crankcase extraction passage 16 and the exhaust gas recirculation passage 25 The position between; the valve driver 21 is arranged on the outside of the intake manifold 9 near the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com