Processing, conveying and cooling equipment for gypsum production line

A cooling equipment and production line technology, applied in lighting and heating equipment, conveyors, refrigerators, etc., can solve the problems of difficult to achieve rapid cooling of gypsum, low cooling speed, waste of raw materials, etc., to reduce the loss of raw materials and increase cooling Time, the effect of good quick cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

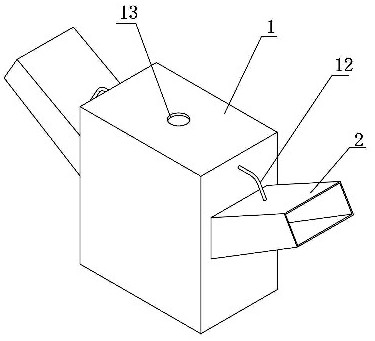

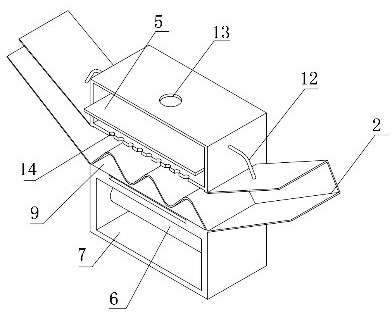

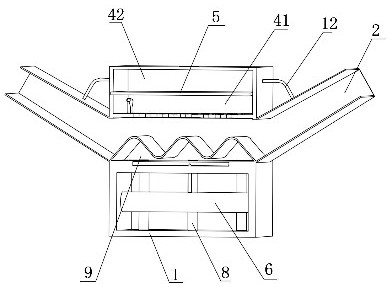

[0022] refer to Figure 1-3 , a processing and conveying cooling equipment for a gypsum production line, comprising a cooling box 1 and a conveying bucket 2, the conveying bucket 2 is provided with a conveyor belt for gypsum transportation, the conveying bucket 2 is sealed and runs through the two side walls of the cooling box 1, and the conveying bucket 2 The part located in the cooling box 1 adopts a wave-shaped structure, which increases the path of the conveying bucket 2 during transportation, thereby prolonging the time for the gypsum to stay in the cooling box 1. The part of the conveying bucket 2 located outside the cooling box 1 adopts a middle low , a funnel-shaped structure with high sides, the conveying bucket 2 is located on the upper wall of the cooling box 1, and a cooling port 3 is opened through it, and the part of the cooling box 1 above the cooling port 3 is provided with a processing space, and the cooling box 1 is located on the conveying bucket 2 The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com