Two-stage supercharging vehicle-mounted air compressor

An air compressor and two-stage supercharging technology, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of reducing the service life of air compressors, inconsistent installation dimensions, and damage to piston rings, etc., to achieve Improved exhaust efficiency, reduced power consumption, and high exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

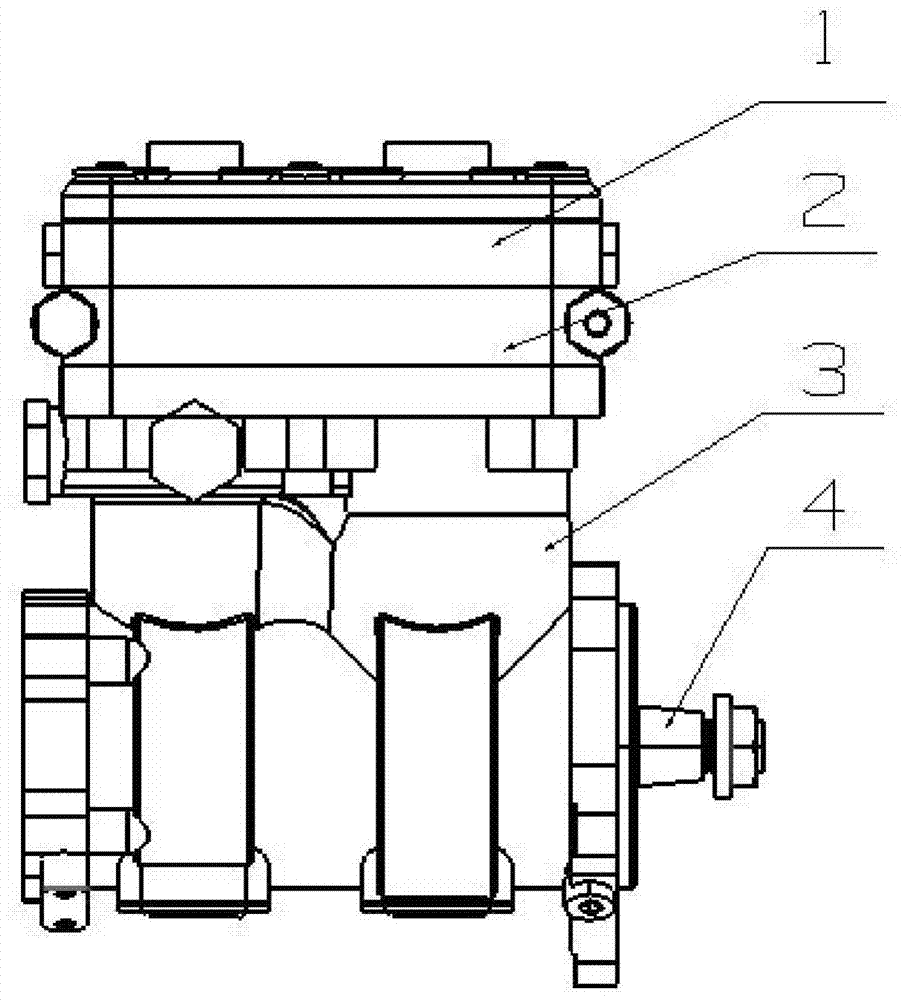

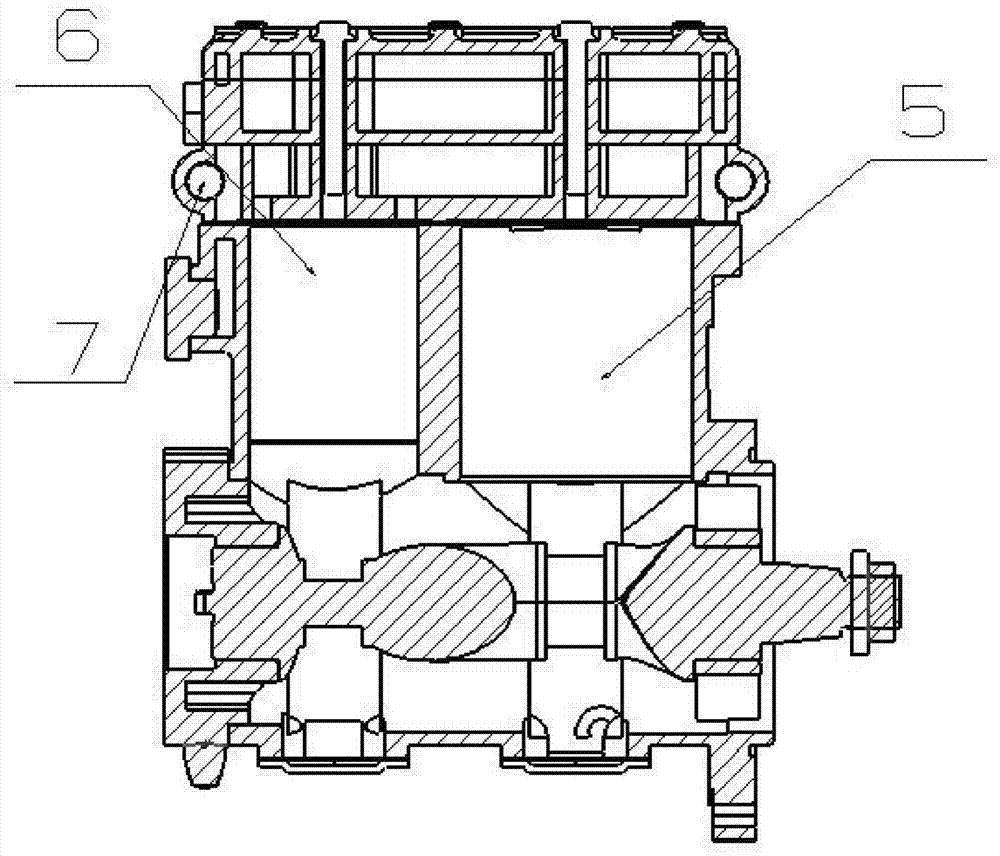

[0032] Such as figure 1 As shown, the present invention includes a cylinder head 1, the cylinder head 1 and the cylinder body 3 are connected through a valve plate assembly 2, a crankshaft 4 is arranged under the cylinder body 3, and a first-stage cylinder 5 and a second-stage cylinder are arranged side by side in the cylinder body 3 6. The valve plate assembly 2 is provided with an unloading mechanism 7 .

[0033] In this embodiment, during the working process, the compression process is equally distributed in the secondary compression process, that is, after the first stage 5 primary compression process is completed, the primary exhaust gas will be used as the intake air for the secondary compression, and will be used by the secondary compression process. The secondary cylinder 6 is repressurized by the secondary compression system and finally discharged to the air storage tank. Through the secondary pressurization inside the system, the demand for high exhaust pressure can...

Embodiment 2

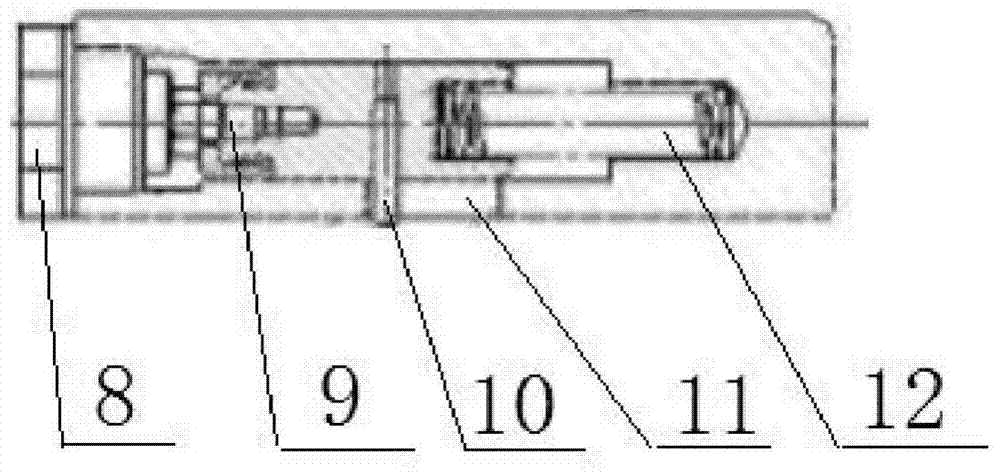

[0035] The difference from Embodiment 1 is that the unloading mechanism 7 includes an unloading hole 8, a plunger 9, a pin 10, a rack 11, a spring 12 and a gear 13, and the plunger 9 is fixedly connected to the rack 11 through the pin 10, One end of the plunger 9 is facing the unloading hole 8 , the other end is connected with the spring 12 , and the rack 11 is engaged with the gear 13 .

[0036] In this embodiment, the gear 13 is driven by the plunger 9 and the rack 11, and finally drives the movement of the unloading valve plate to realize the opening and closing of the unloading hole 8. By sealing the gear 13, the working chamber of the air compressor is completely isolated With the working chamber of the unloading plunger, this structure makes up for the defect that the working chamber of the air compressor in the original rack and ring gear structure is indirectly connected with the working chamber of the plunger, so that there is pressure gas at the tail of the plunger, w...

Embodiment 3

[0038] The difference from Embodiment 2 lies in that the cylinder head 1 is provided with a cooling system, and the gas compressed and discharged from the first-stage cylinder 5 enters the second-stage cylinder 6 after being cooled by the cooling system.

[0039] In this embodiment, after the first-stage compression process of the first-stage cylinder 5 is completed, the first-stage exhaust gas will be used as the intake air of the second-stage compression after being cooled between the stages, and will be repressurized by the second-stage cylinder 6 and the second-stage compression system. The temperature of the secondary exhaust can be lowered, ie the initial temperature of the final exhaust output is lowered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com