Copper-based resin prepreg production equipment for mobile communication circuit boards

A mobile communication, prepreg technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low yield rate of copper clad laminate production, uneven composition of prepreg, inclusion of air bubbles, etc., to avoid premature curing, reduce air bubble content, The effect of preventing excessive leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

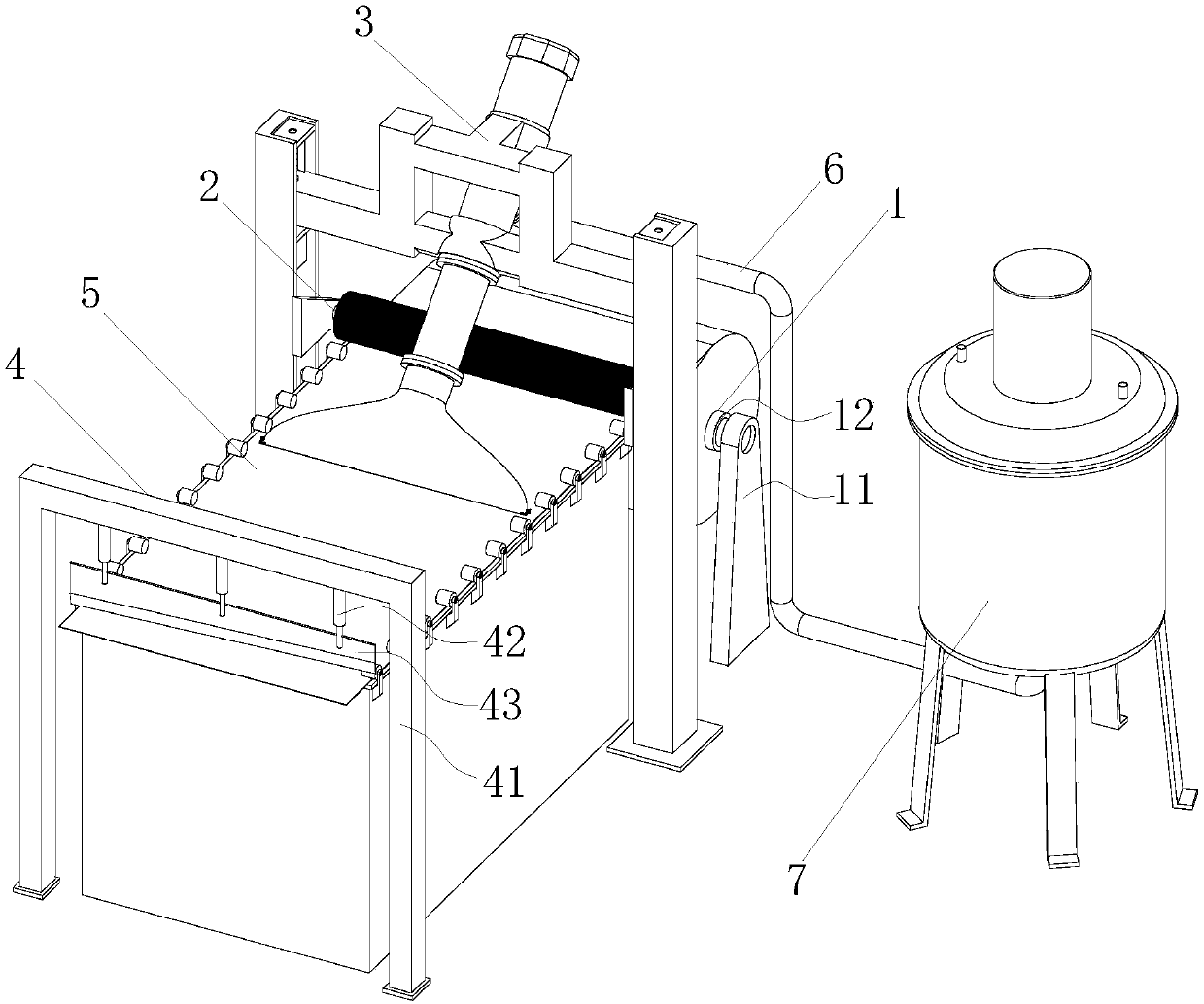

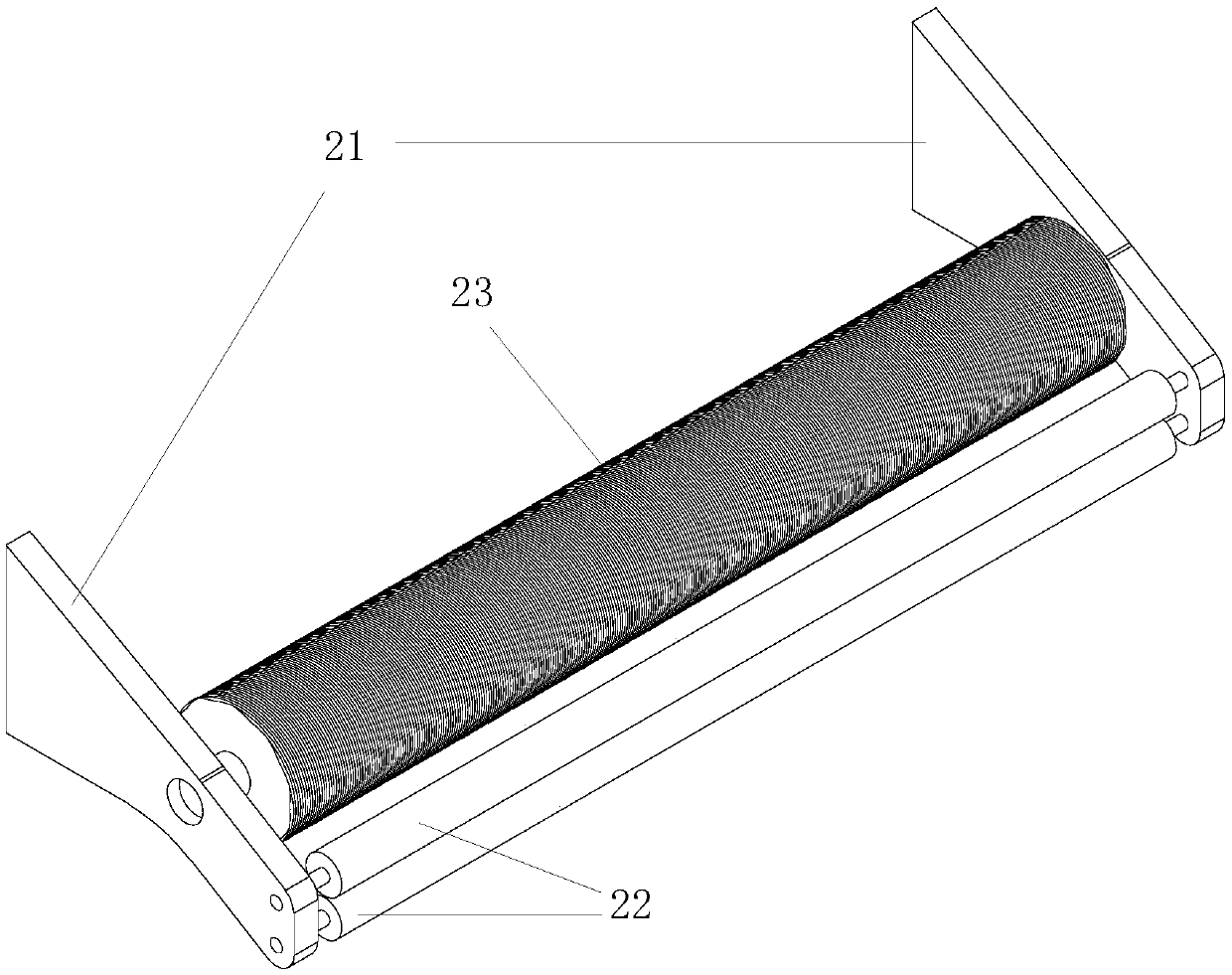

[0027] Such as Figure 1 to Figure 5 As shown, a copper-based resin prepreg production equipment for mobile communication circuit boards, including a copper foil reel 1, a polishing device 2, a coating device 3 and a cutting device 4 arranged in sequence from front to back, installed in the coating device 3 and the drying device 5 below the cutting device 4, and the glue supply device 7 connected to the coating device 3 through the delivery pipe 6.

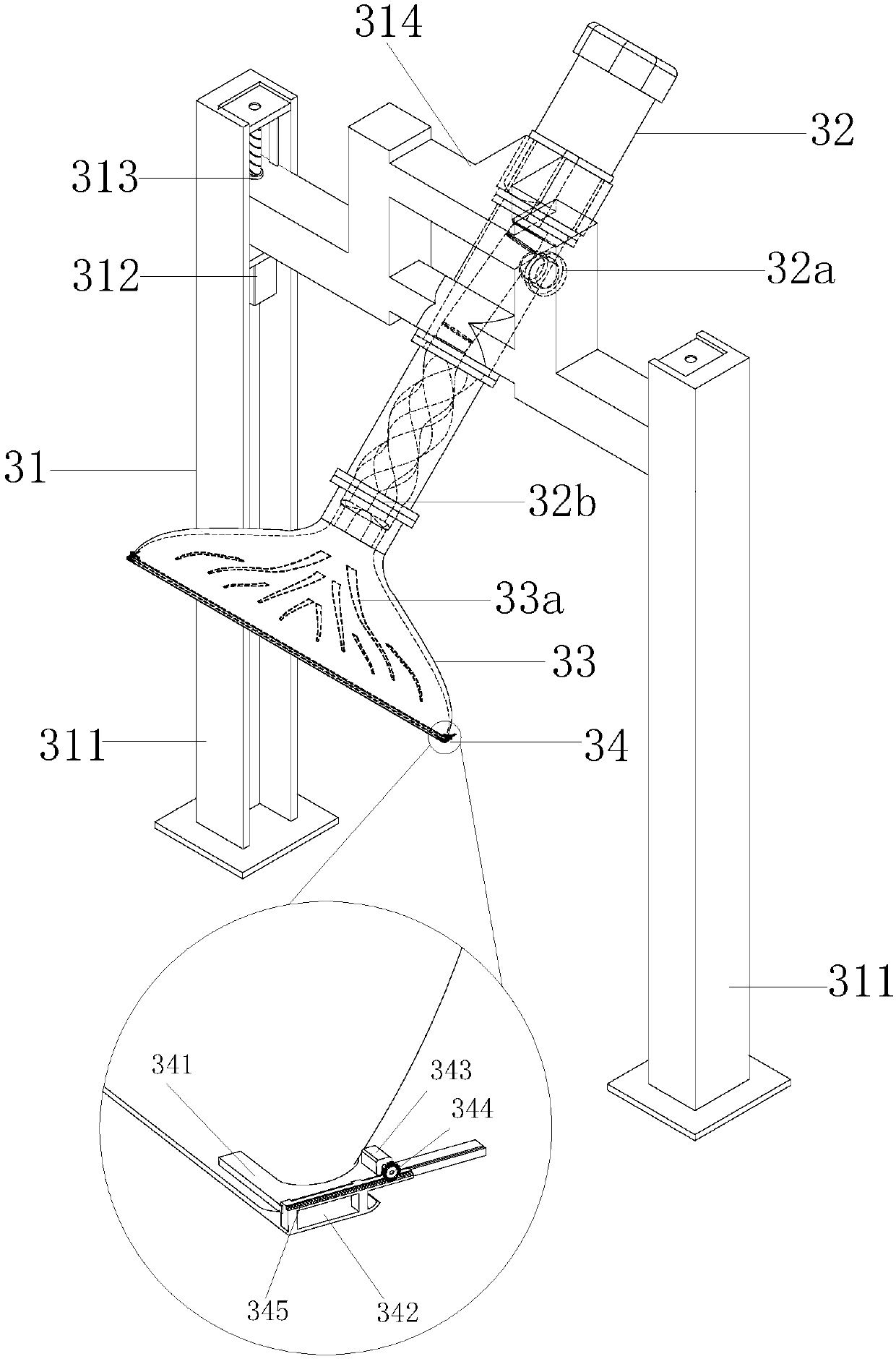

[0028] The coating device 3 includes a gantry 31, a single screw pump 32, an extrusion part 33 and a sealing device 34; the gantry 31 includes a column 311, a screw motor 312, a nut 313 and a pump bracket 314 on each of the left and right sides, A screw motor 312 is respectively installed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com