Operation method of two-stage-throttling intermediate complete cooling type refrigeration system and two-stage-throttling intermediate complete cooling type refrigeration system

A technology of secondary throttling and refrigeration system, applied in the field of two-stage compression refrigeration system and refrigeration system, can solve the problems of compressor shock, reduced defrosting efficiency, slow defrosting speed, etc., to improve service life, flexible and convenient to use , The effect of high defrosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

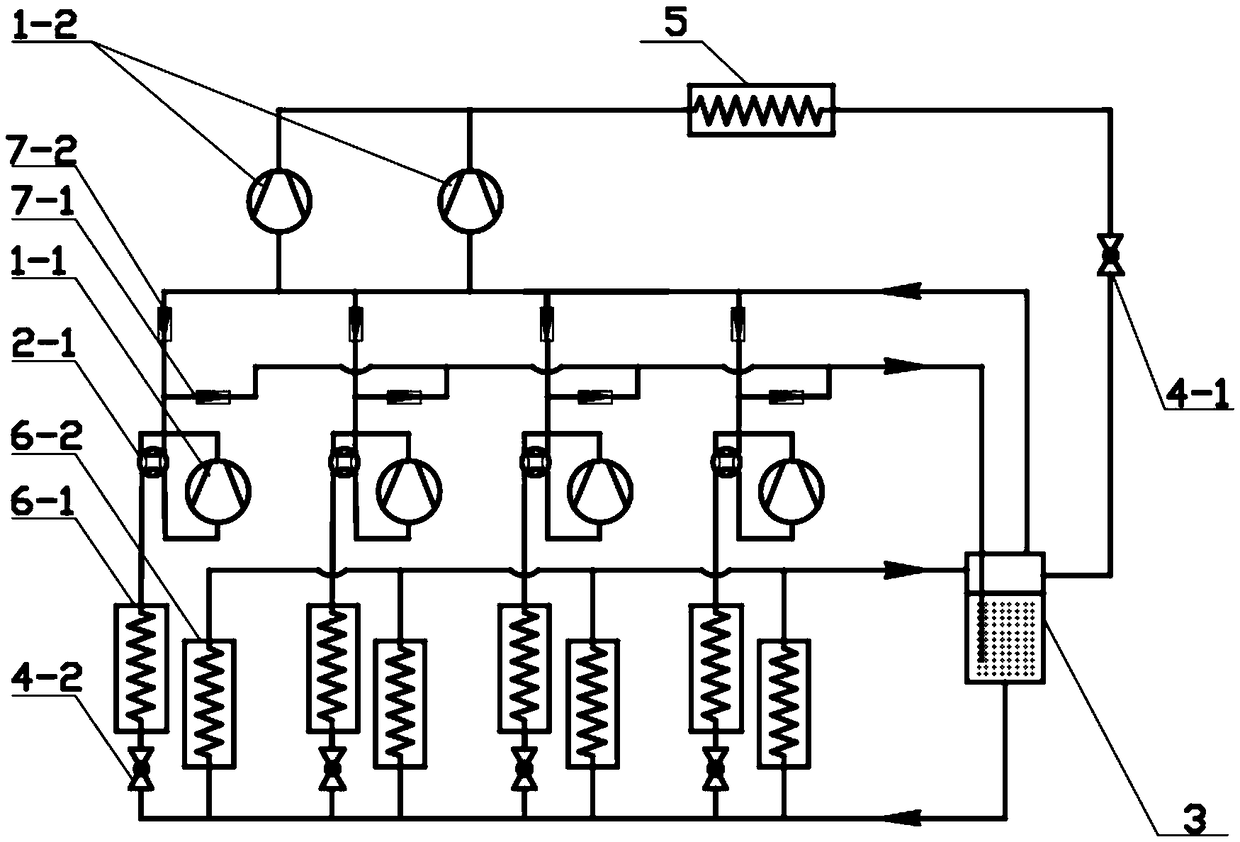

Embodiment 1

[0039] The schematic diagram of the structure of the full-liquid secondary throttling intermediate completely cooled refrigeration system for hot gas defrosting of the present invention is as follows: figure 1 As shown, it includes a high-pressure stage compressor group, a condenser 5, a first throttle valve 4-1, an intercooler 3 and multiple groups of low-pressure stage units. In this embodiment, the high-pressure stage compressor group includes one or more high-pressure stage compressors 1-2. When multiple high-pressure stage compressors 1-2 are used, the The suction port is connected in parallel as the suction end of the high pressure stage compressor group, and the exhaust port of each of the high pressure stage compressors 1-2 is connected in parallel as the discharge end of the high pressure stage compressor group. The low-pressure stage unit can be used for a refrigeration cycle or a defrosting cycle, and each of the low-pressure stage units includes a low-pressure stag...

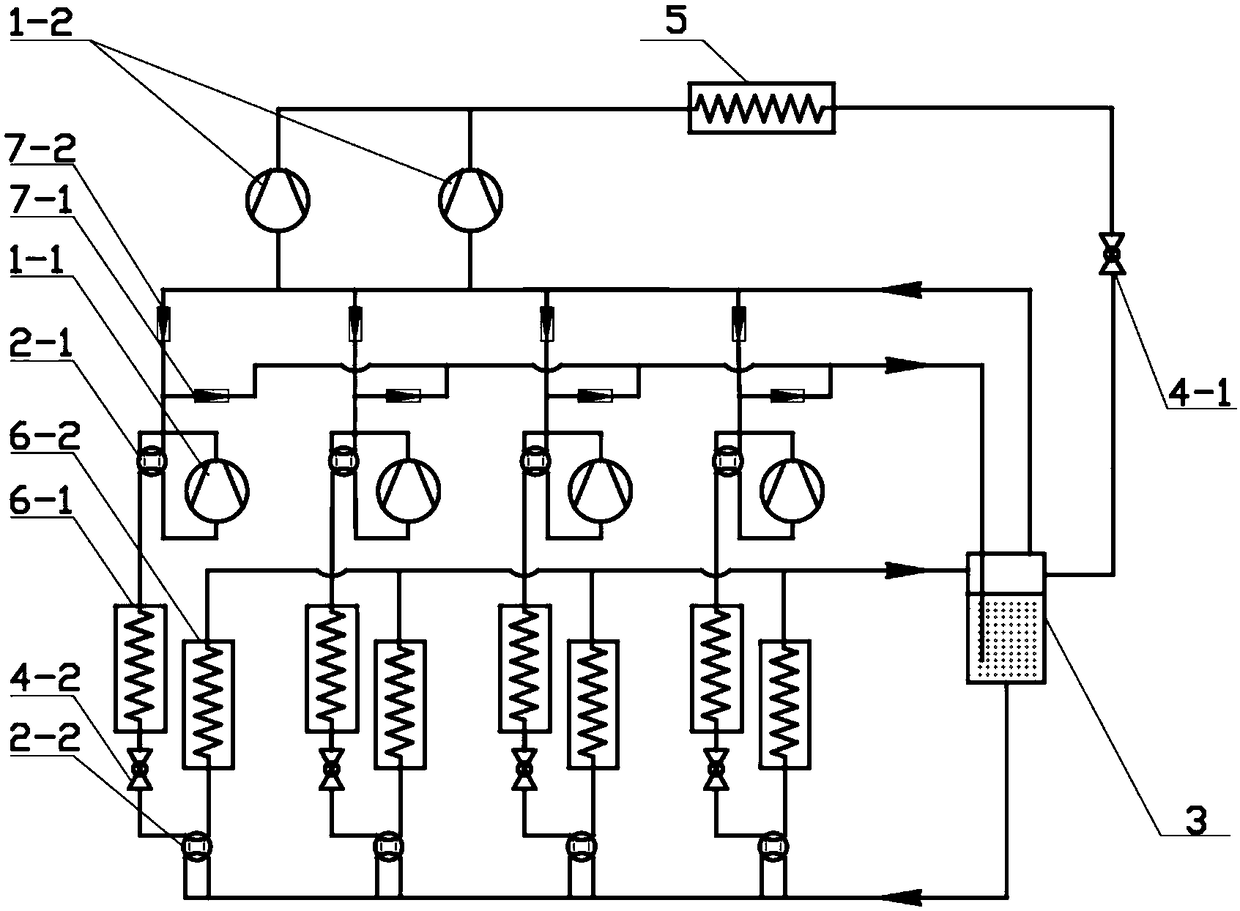

Embodiment 2

[0043] The schematic diagram of the structure of the full-liquid secondary throttling intermediate completely cooled refrigeration system for hot gas defrosting of the present invention is as follows: figure 2 As shown, it includes a high-pressure stage compressor group, a condenser 5, a first throttle valve 4-1, an intercooler 3 and multiple groups of low-pressure stage units. In this embodiment, the high-pressure stage compressor group includes one or more high-pressure stage compressors 1-2. When multiple high-pressure stage compressors 1-2 are used, the The suction port is connected in parallel as the suction end of the high pressure stage compressor group, and the exhaust port of each of the high pressure stage compressors 1-2 is connected in parallel as the discharge end of the high pressure stage compressor group. The low-pressure stage units can be used in a refrigeration cycle or a defrosting cycle, and each of the low-pressure stage units includes a low-pressure sta...

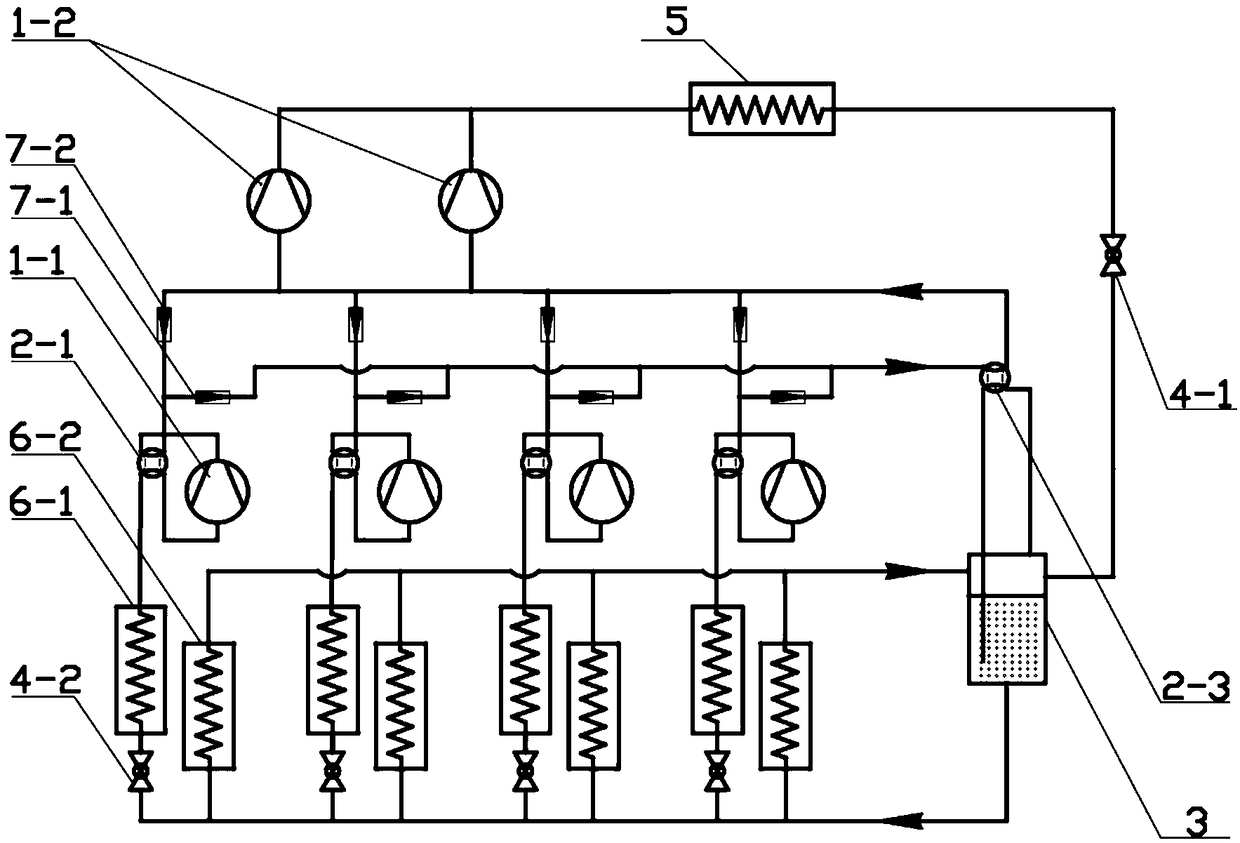

Embodiment 3

[0047] The structure principle diagram of the non-full liquid type secondary throttling intermediate complete cooling refrigeration system for high-temperature hot gas defrosting of the present invention is as follows: image 3 As shown, it includes a high-pressure stage compressor unit, a condenser 5, a first throttle valve 4-1, an intercooler 3, a third four-way reversing valve 2-3 and a plurality of low-pressure stage units. In this embodiment, the high-pressure stage compressor group includes one or more high-pressure stage compressors 1-2. When multiple high-pressure stage compressors 1-2 are used, the The suction port is connected in parallel as the suction end of the high pressure stage compressor group, and the exhaust port of each of the high pressure stage compressors 1-2 is connected in parallel as the discharge end of the high pressure stage compressor group. The low-pressure stage unit can be used in a refrigeration cycle or a defrosting cycle, and each low-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com