Patents

Literature

38results about How to "Reduce thermal deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

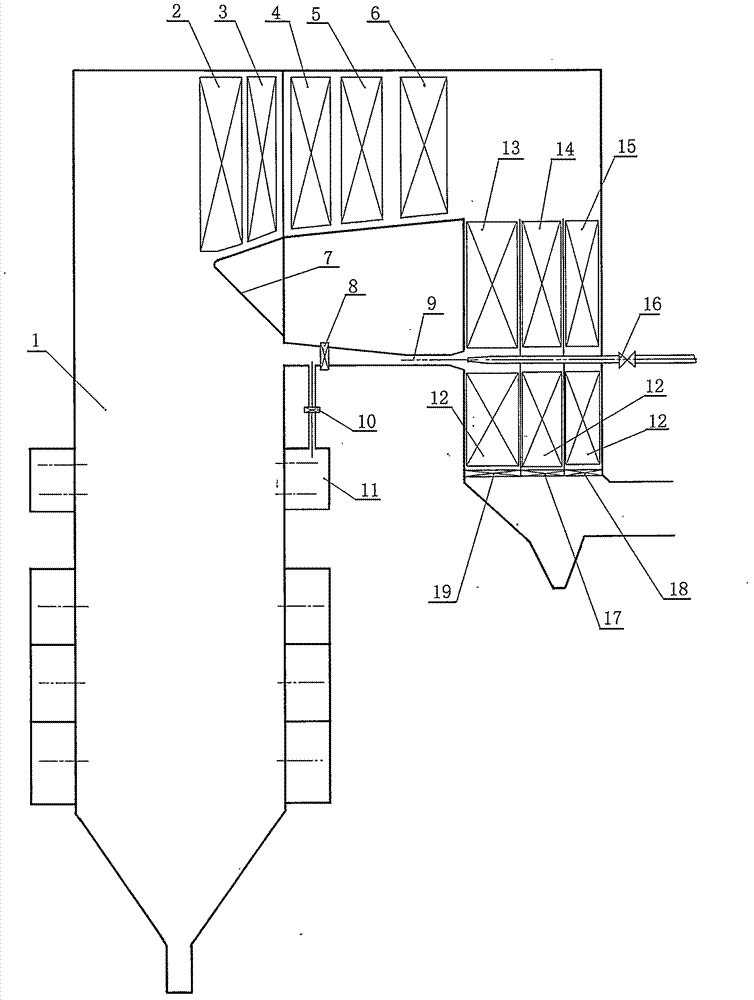

Circulating fluidized bed boiler

ActiveCN101818894AImprove securityImprove stabilityFluidized bed combustionApparatus for fluidised bed combustionFluidized bedPower equipment

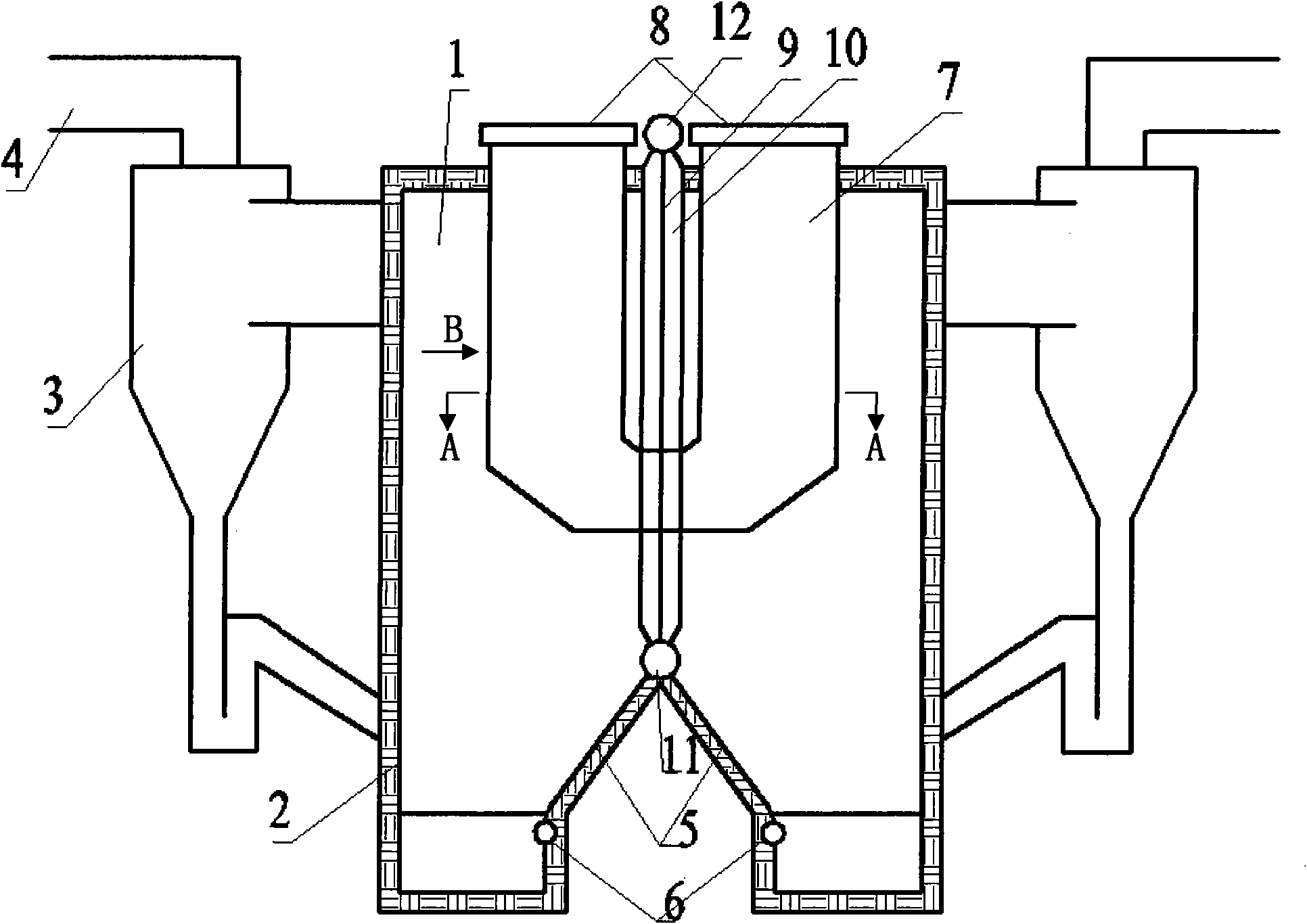

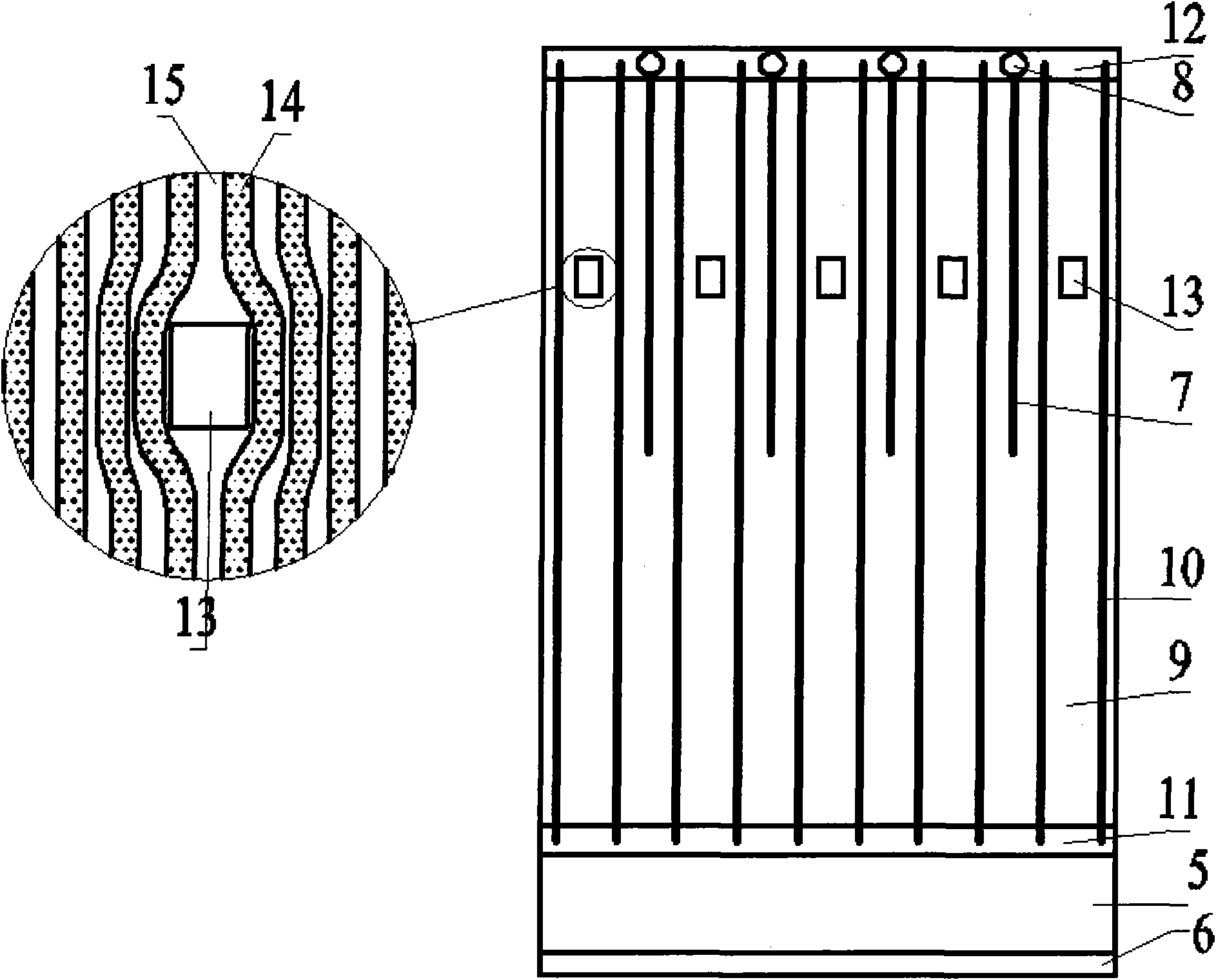

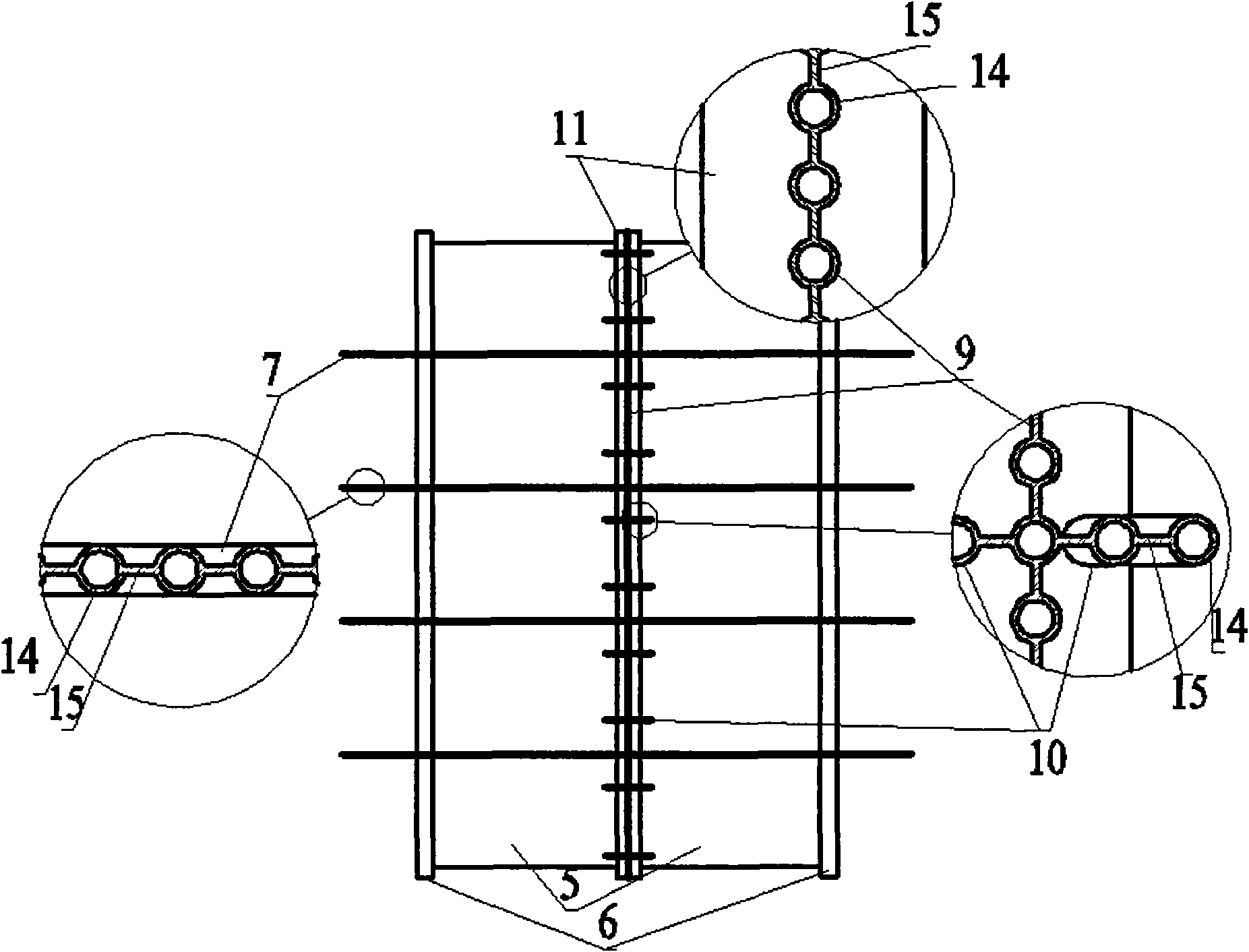

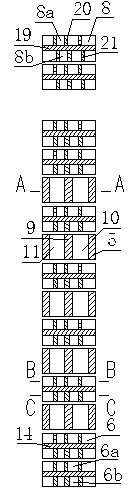

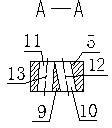

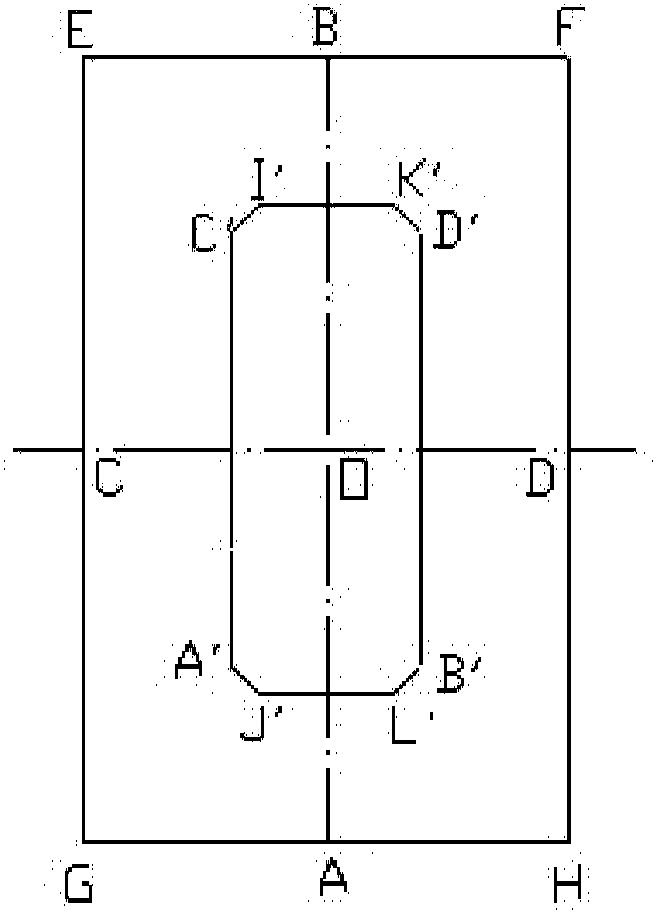

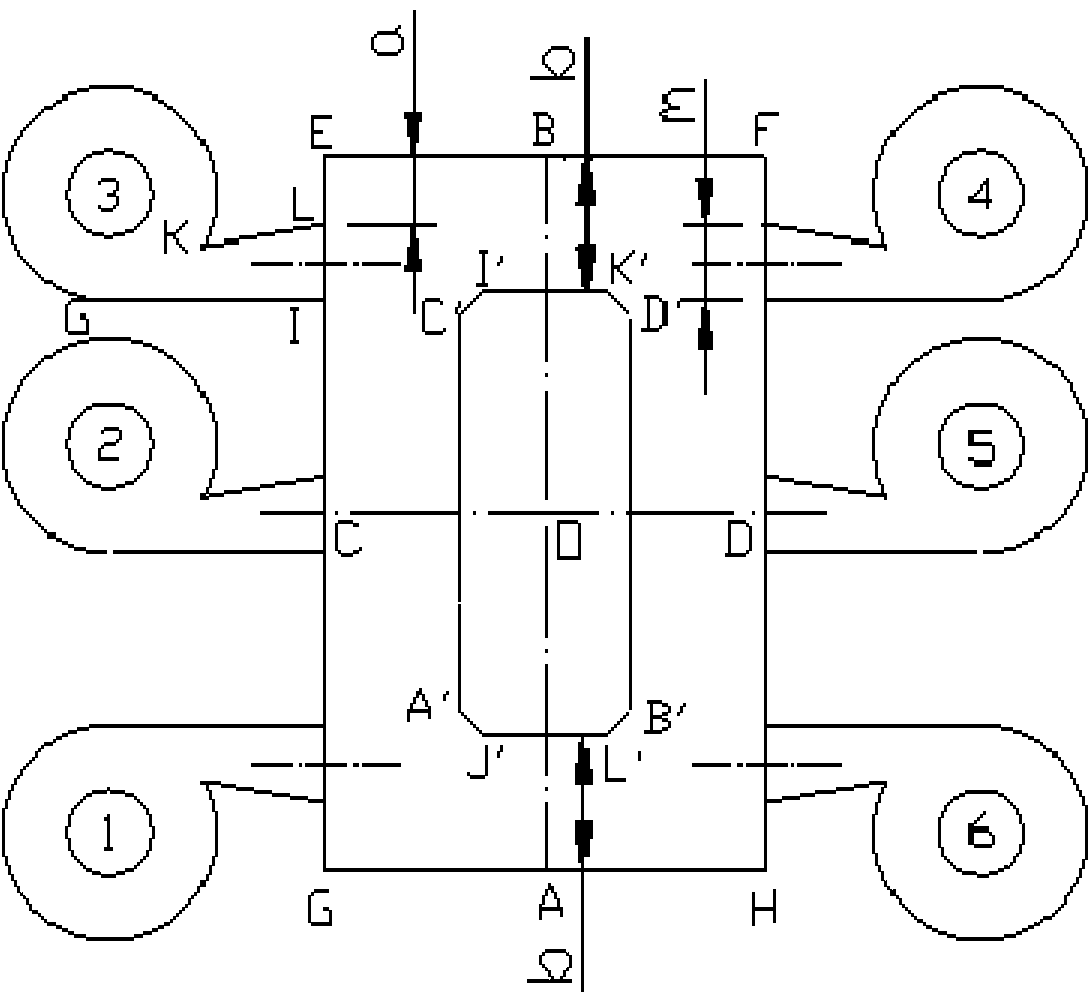

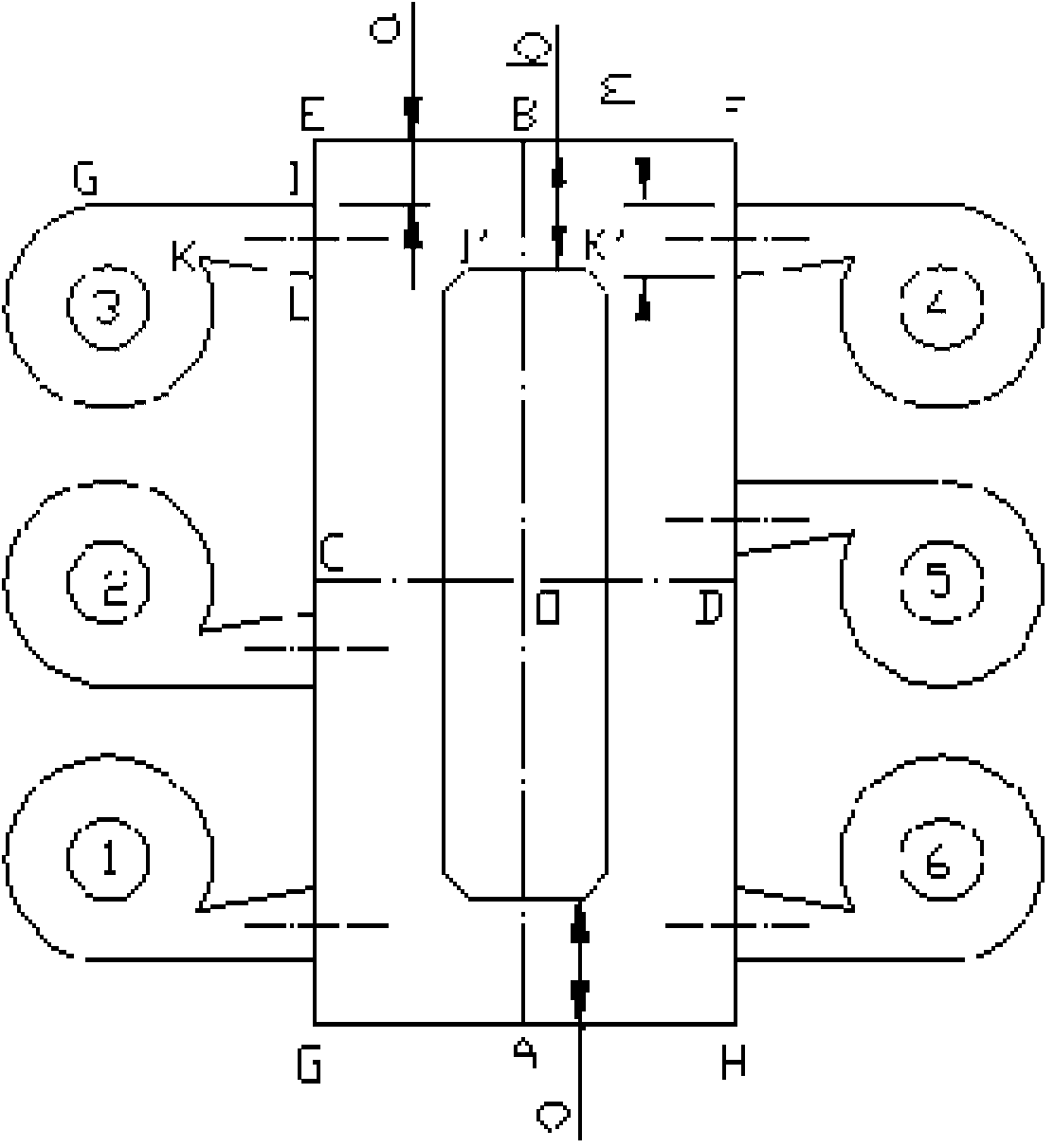

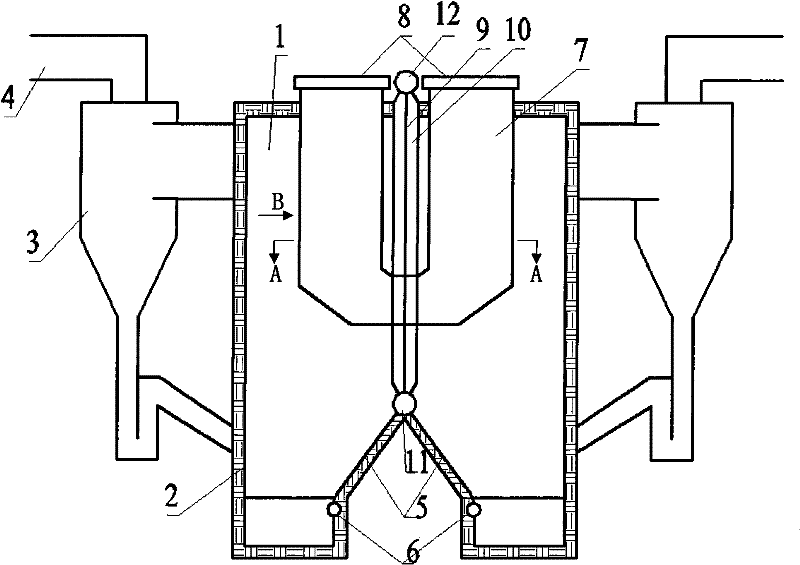

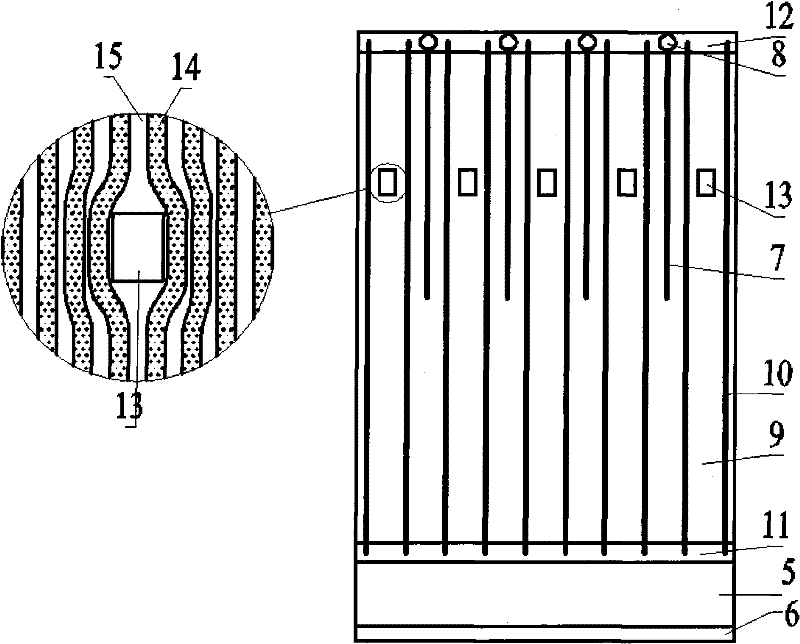

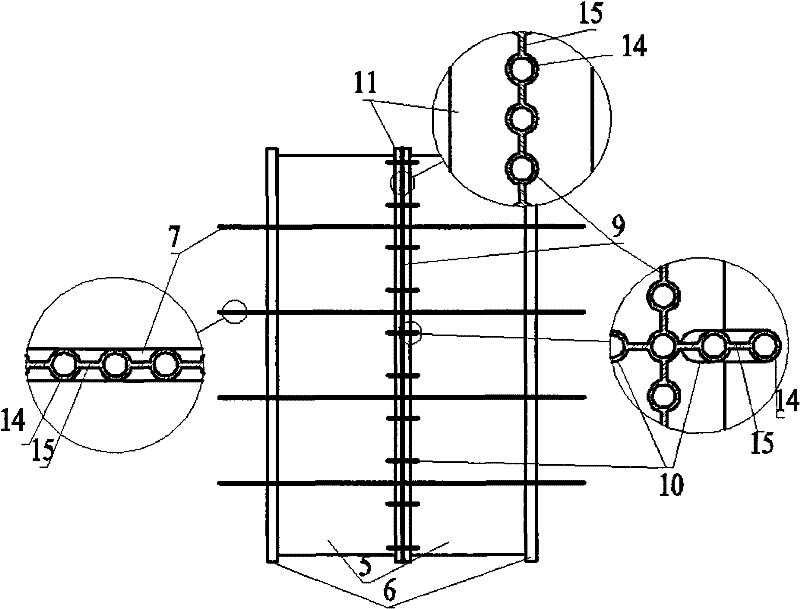

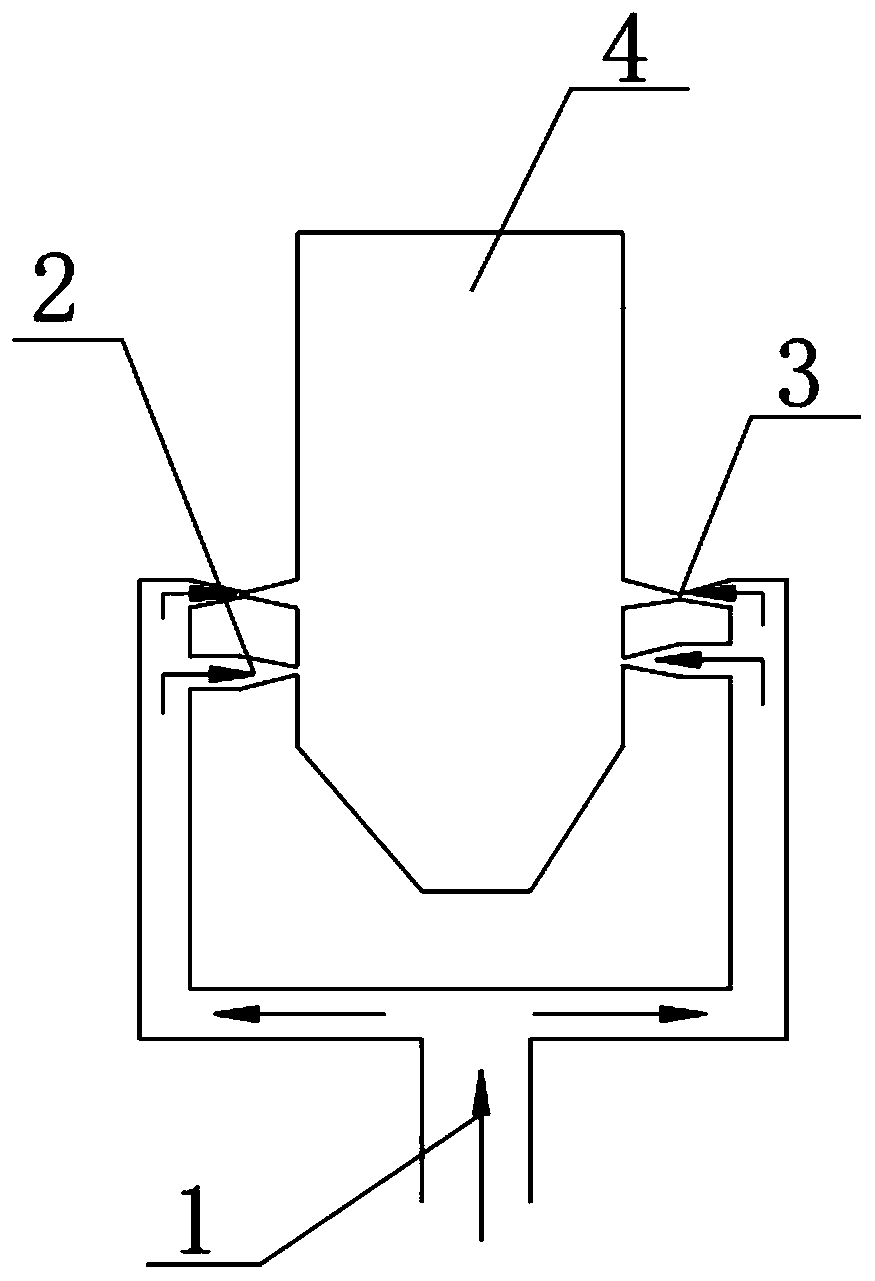

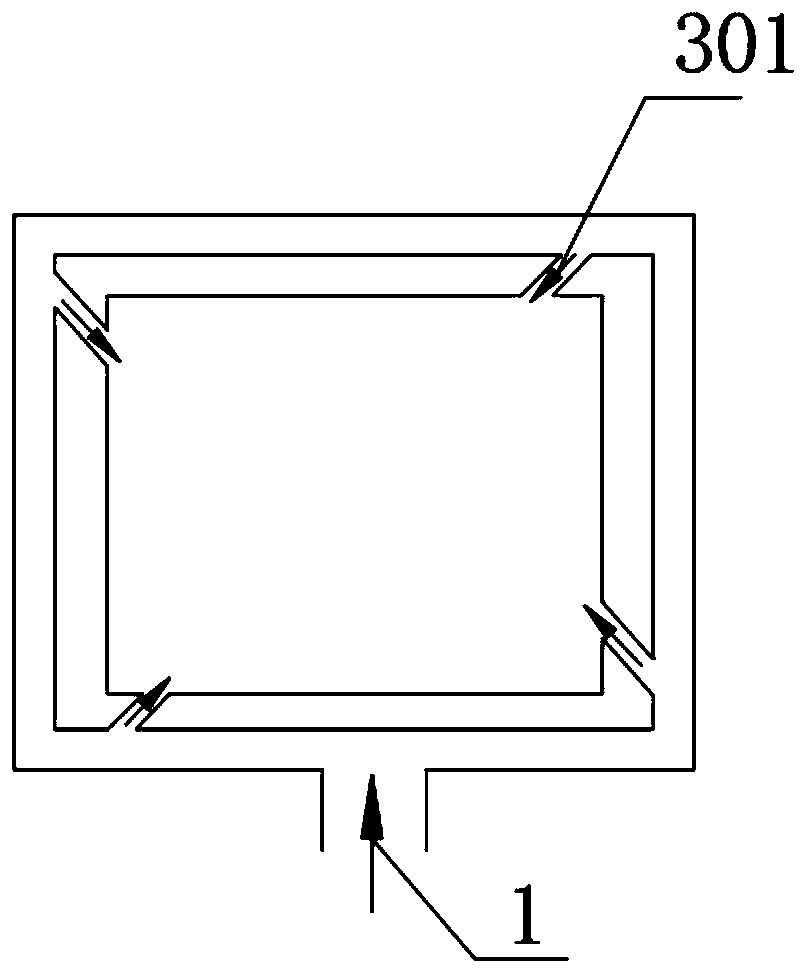

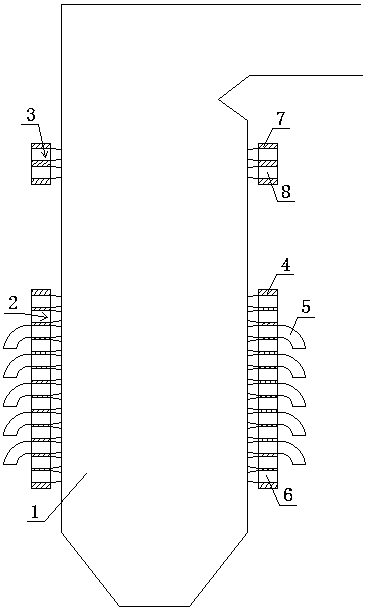

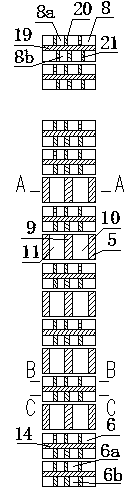

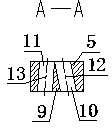

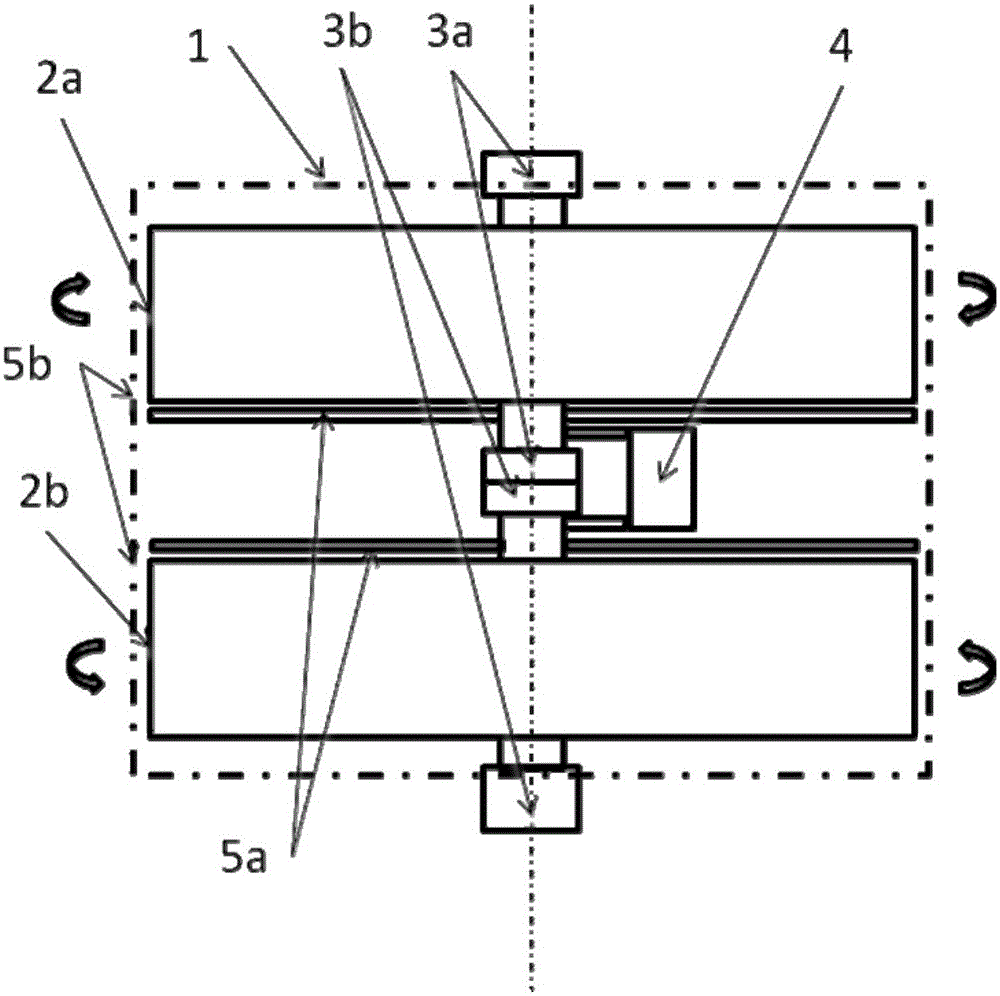

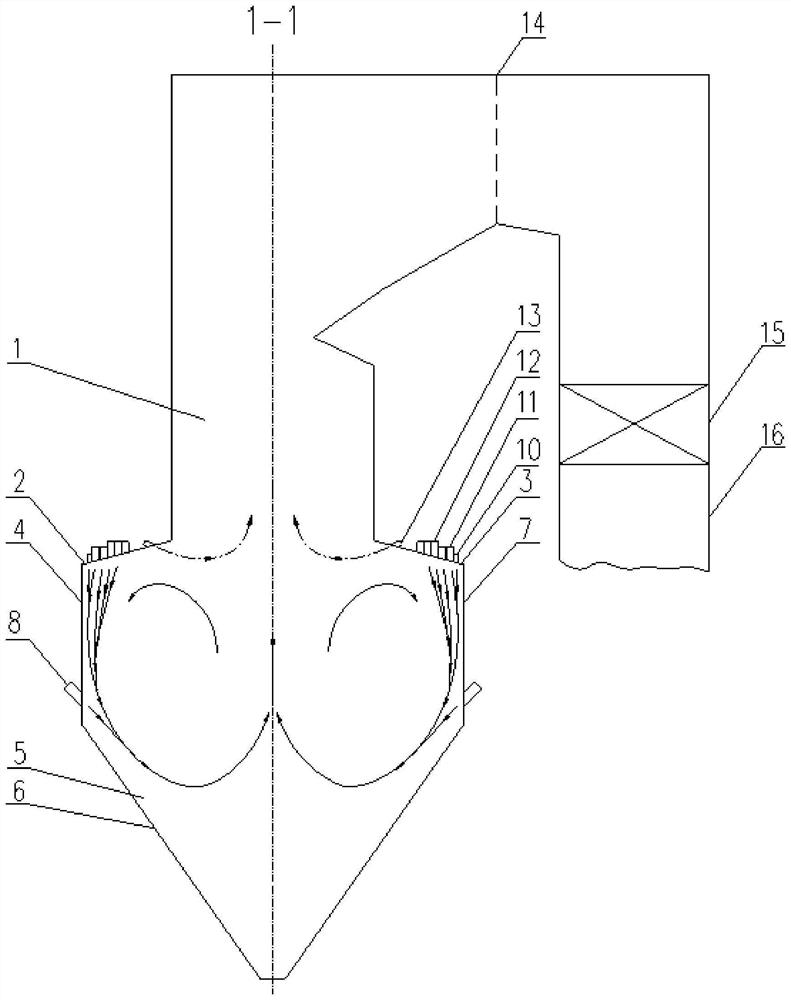

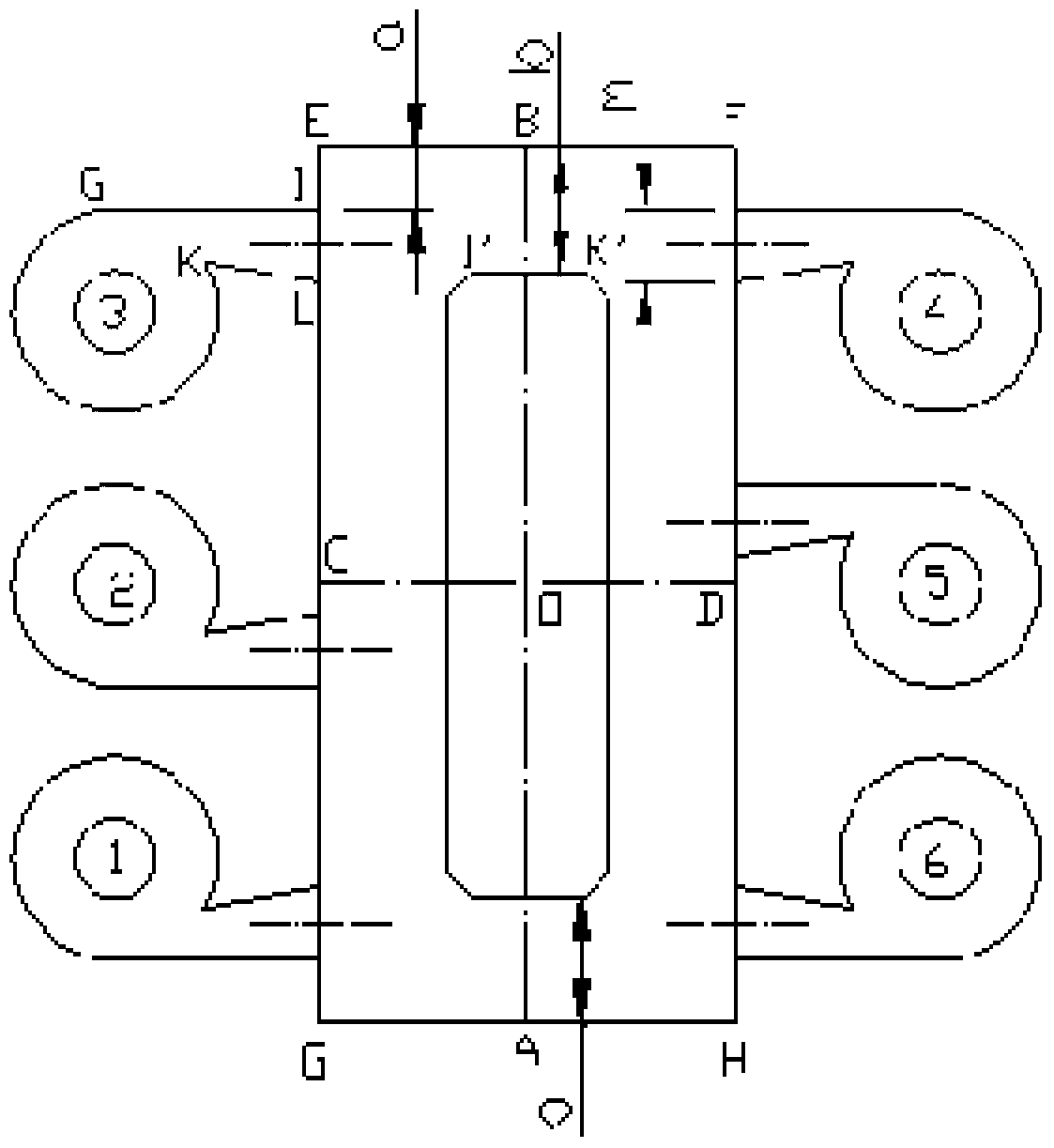

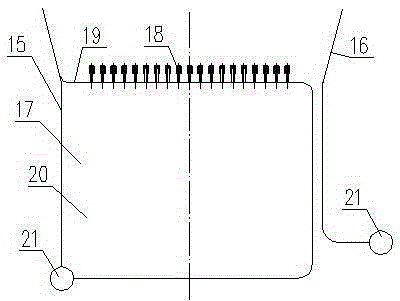

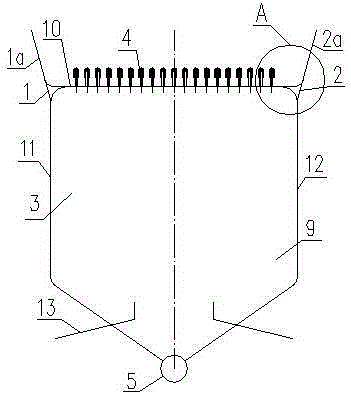

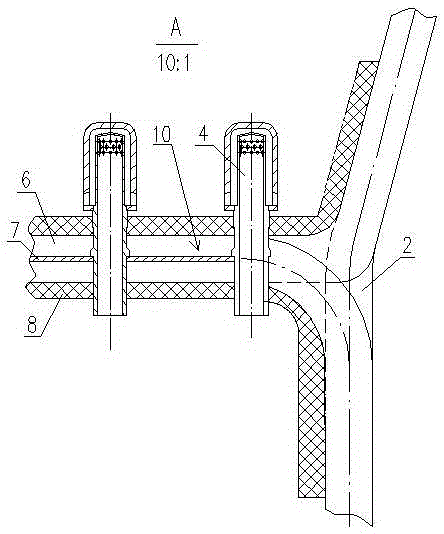

The invention discloses a circulating fluidized bed boiler, which belongs to the technical field of thermal power equipment. The circulating fluidized bed boiler consists of an v-shaped hearth, separators, tail flues, a water cooled wall, a middle membrane-type wall, a ribbed plate membrane-type wall, a U-shaped wall and headers, wherein the separators and the tail flues are symmetrically distributed on two sides of the hearth; the middle membrane-type wall divides the hearth into two completely symmetric parts to prevent a bed from titling; the upper part of the middle membrane-type wall is provided with a vent hole to maintain the pressure balance of the hearth; and the airflows in the U-shaped wall flow alternately to reduce the heat difference in the hearth. The circulating fluidized bed boiler avoids the bed tilting phenomenon in the v-shaped hearth of the circulating fluidized bed boiler, has the characteristics of uniform temperature distribution in the hearth and high safety and is a better circulating fluidized bed boiler which is particularly adaptable to the development trend of large circulating fluidized bed boilers.

Owner:TAIYUAN BOILER GROUP +1

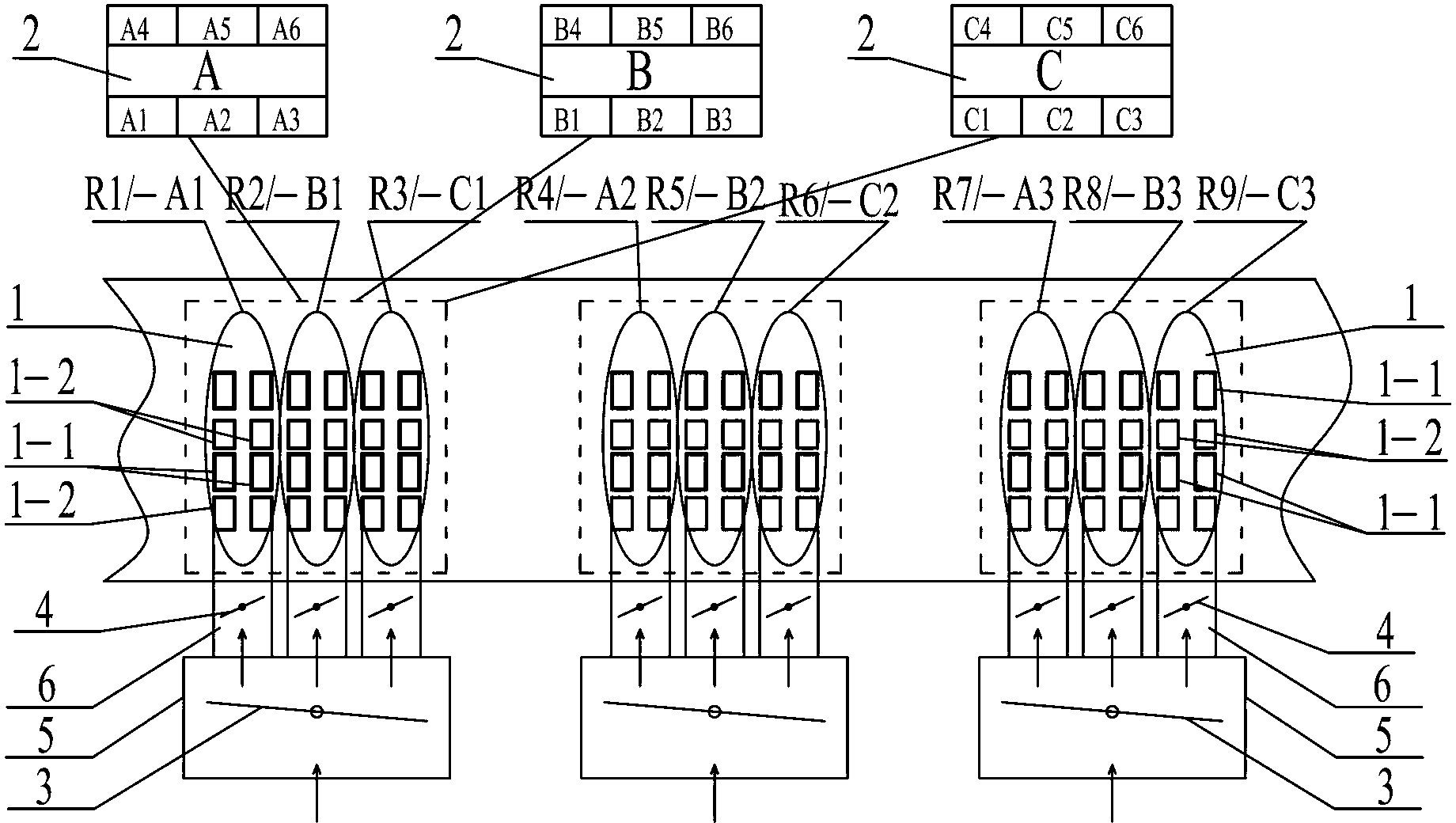

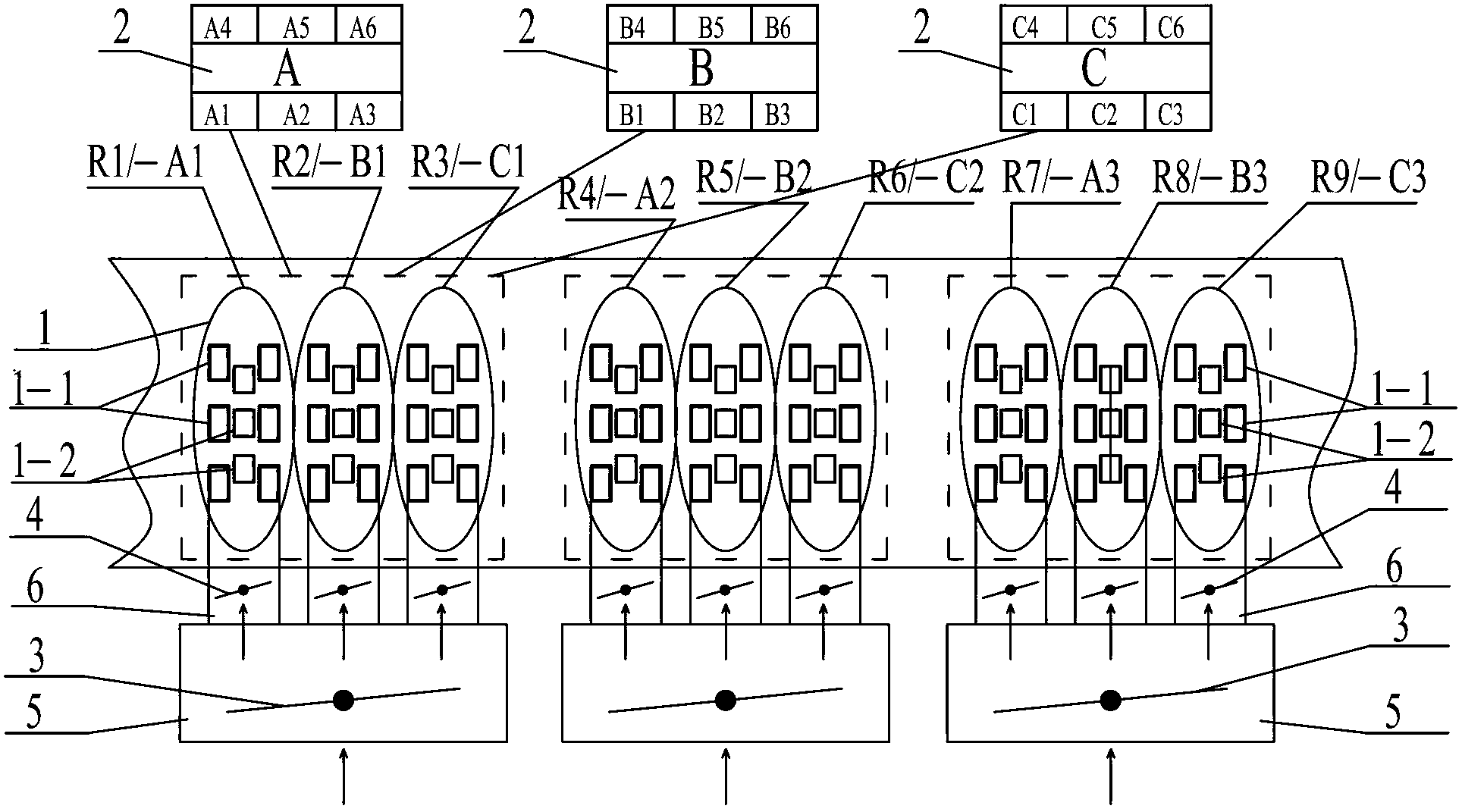

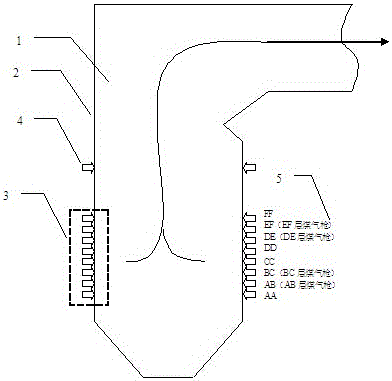

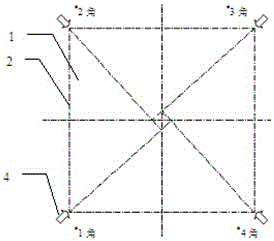

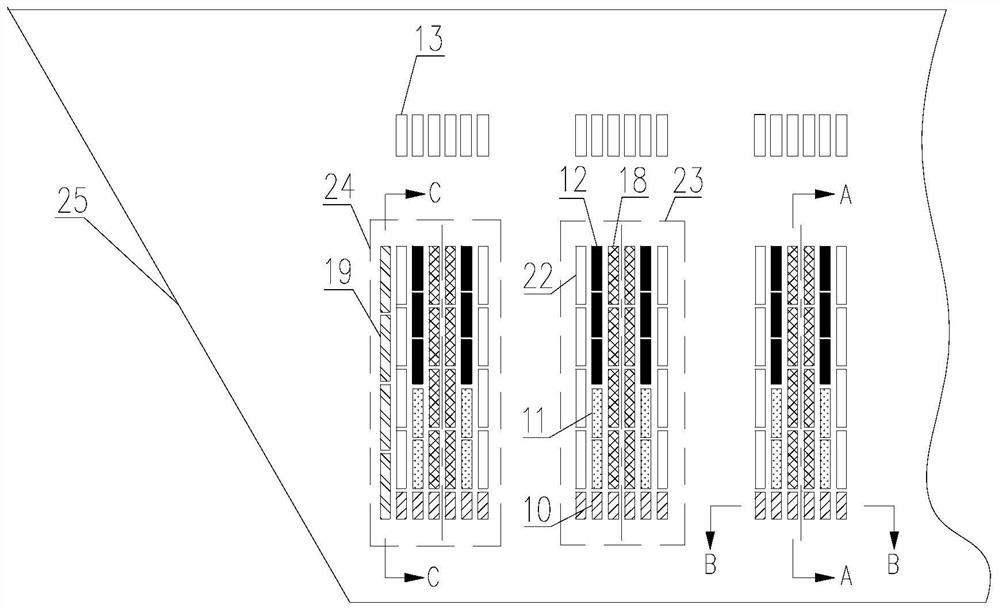

Multi-stage stratified combustion system and method for primary air and secondary air of boiler

ActiveCN103216821ARigid enoughWell mixedCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemSpray nozzle

The invention discloses a multi-stage stratified combustion system and a multi-stage stratified combustion method for primary air and secondary air of a boiler. The multi-stage stratified combustion system comprises combustors and air after-combustion devices, which are arranged on the four corners of a furnace chamber; each combustor comprises a secondary air box, at least one primary air tube and at least one primary secondary air spray nozzle; each air after-combustion device comprises an after-combustion air box and at least one after-combustion air spray nozzle; the secondary air boxes and the after-combustion air boxes are connected with a main air duct by the respective air tubes; the primary air tube spray nozzle is divided into a thick primary air spray nozzle and a thin primary air spray nozzle; the primary secondary air spray nozzle is divided into a secondary direct-blowing air spray nozzle and a secondary deviation-blowing air spray nozzle; the after-combustion air spray nozzle is divided into an after-combustion direct-blowing air spray nozzle and an after-combustion deviation-blowing air spray nozzle; and an effect of covering powder by air is formed during the combustion process by virtue of the multi-stage stratification of the primary air and the secondary air. The multi-stage stratified combustion method and the multi-stage stratified combustion method for the primary air and the secondary air of the boiler not only can be used for ensuring the ultralow emission of NOx and improving the combustion efficiency of the pulverized coal, but also can be used for preventing the agglomeration and the high-temperature corrosion of the water-cooling wall and reducing the thermal deviation of the heating area at the outlet of the furnace chamber.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

Eastern-Junggar-coal fired double-reheat steam power plant boiler

InactiveCN104075309ASave huge investmentClear thermostat logicSteam superheatersSteam boilersEngineeringSupersonic speed

The invention discloses an eastern-Junggar-coal fired double-reheat steam power plant boiler, and relates to a double-reheat steam power plant boiler which can be used by a thermal power station for a long time, and is safe, economical, and completely eastern-Junggar-coal fired. A tail flue is divided into a front flue, a middle flue and a rear flue by division walls, and the three flues all adopt structural supports; an ejector primary hot wind regulation baffle opens when the boiler is at middle or lower load, and the opening of the ejector primary hot wind regulation baffle is controlled to enable double reheat steam temperature to be kept at a rated value in the range of 40% to 100% BMCR; sequence and quantity of temperature-regulation air-flue ejectors along the width direction of the boiler are changed, so that thermal deviations of high-temperature heating surfaces along the width direction of the boiler can be compensated and reduced; a strong directional supersonic steam flow soot blower system is arranged on the ceiling, DCS controls continuous soot blowing time and interval time of each supersonic steam flow nozzle set, and thereby the thermal deviation of each high-temperature heating surface can be further compensated; the low thermal deviations effectively relieve the growing process of an oxide skin on the inner side of each high-temperature heating surface, so that operational reliability is significantly improved.

Owner:章礼道

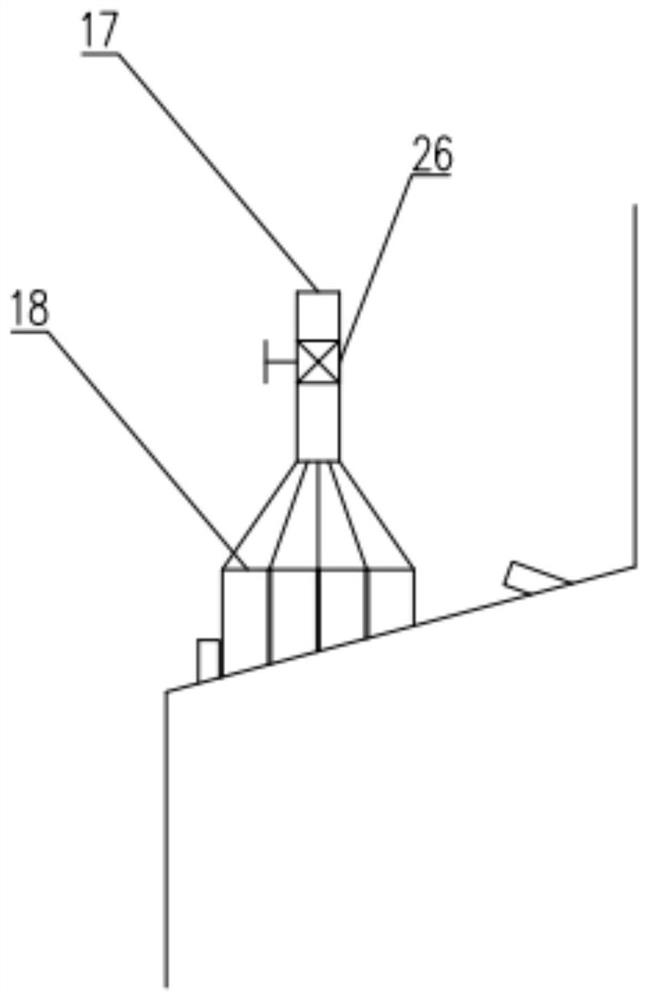

W flame boiler combustion optimizing device

ActiveCN102705816AHarm reductionReduce shockCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The invention relates to a W flame boiler combustion device relating to a boiler combustion device, belonging to the technical field of boiler combustion and aiming at solving the problems of large thermal deviation, water cooled wall overtemperature and nonuniform thermal load of a W flame boiler equipped with the traditional boiler combustion device. The W flame boiler combustion optimizing device comprises the W flame boiler, Y coal mills, a plurality of air chamber and a plurality of air chamber baffle plates, wherein the W flame boiler is provided with M combustor groups; each combustor is provided with a plurality of primary air nozzles and a plurality of secondary air nozzles; the M combustor groups are uniformly distributed on a furnace arch; an air inlet of each combustor group is provided with a secondary air bellow, and each secondary air bellow is internally provided with an air bellow baffle plate; the number of the plurality of air chamber baffle plates is consistent to that of the air chamber, and the air chambers baffle plates are arranged on the air chambers; and three combustors of each combustor group are respectively supplied with coal dust by different coal mills. The invention is suitable for optimizing the combustion of the W flame boiler.

Owner:HARBIN INST OF TECH

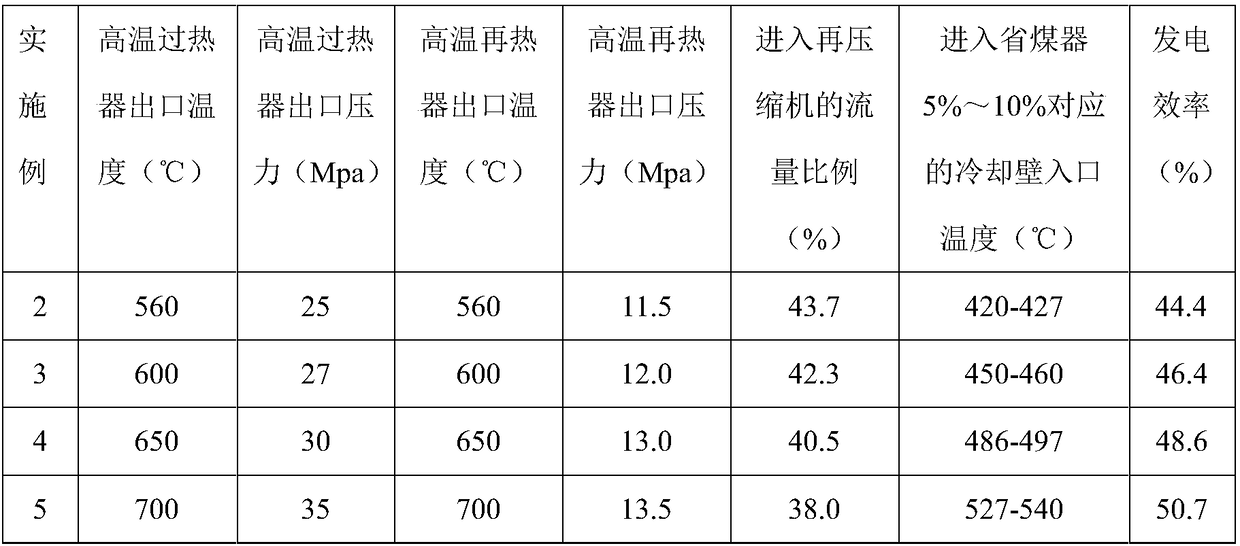

Parameter optimization ultra-supercritical secondary reheating power station boiler

ActiveCN104763997AClear main steam/primary reheat steam/secondary reheat steam temperature adjustment logicReduce energy consumptionSteam boilersSolid removalPower stationLow load

The invention claims a parameter optimization ultra-supercritical secondary reheating power station boiler and relates to an ultra-supercritical secondary reheating power station boiler which is efficient, safe and low in emission and low in cost and is matched with a parameter optimization ultra-supercritical secondary reheating turboset for a fire coal thermal power station. The main steam inlet parameter optimization at the boiler side is 35.7MPa at 590 DEG C; the primary reheating steam parameter optimization is 8.9MPa at 623 DEG C; the secondary reheating steam parameter optimization is 1.52MPa at 538 DEG C; the water giving temperature optimization is 303 DEG C; a tail smoke channel is divided into a front smoke channel, a middle smoke channel and a rear smoke channel through division walls; the ejector heat primary air damper is arranged in the boiler and is started at low load; the opening degree of the ejector heat primary air damper is controlled and the using number is controlled for maintaining the primary reheating temperature at rated value in the range of 40% to 100% BMCR; the adding times and the using number of the temperature adjusting wind-smoke ejector along the furnace width direction are changed for compensating and reducing heat deviation along the furnace width direction for the heating surface.

Owner:章礼道

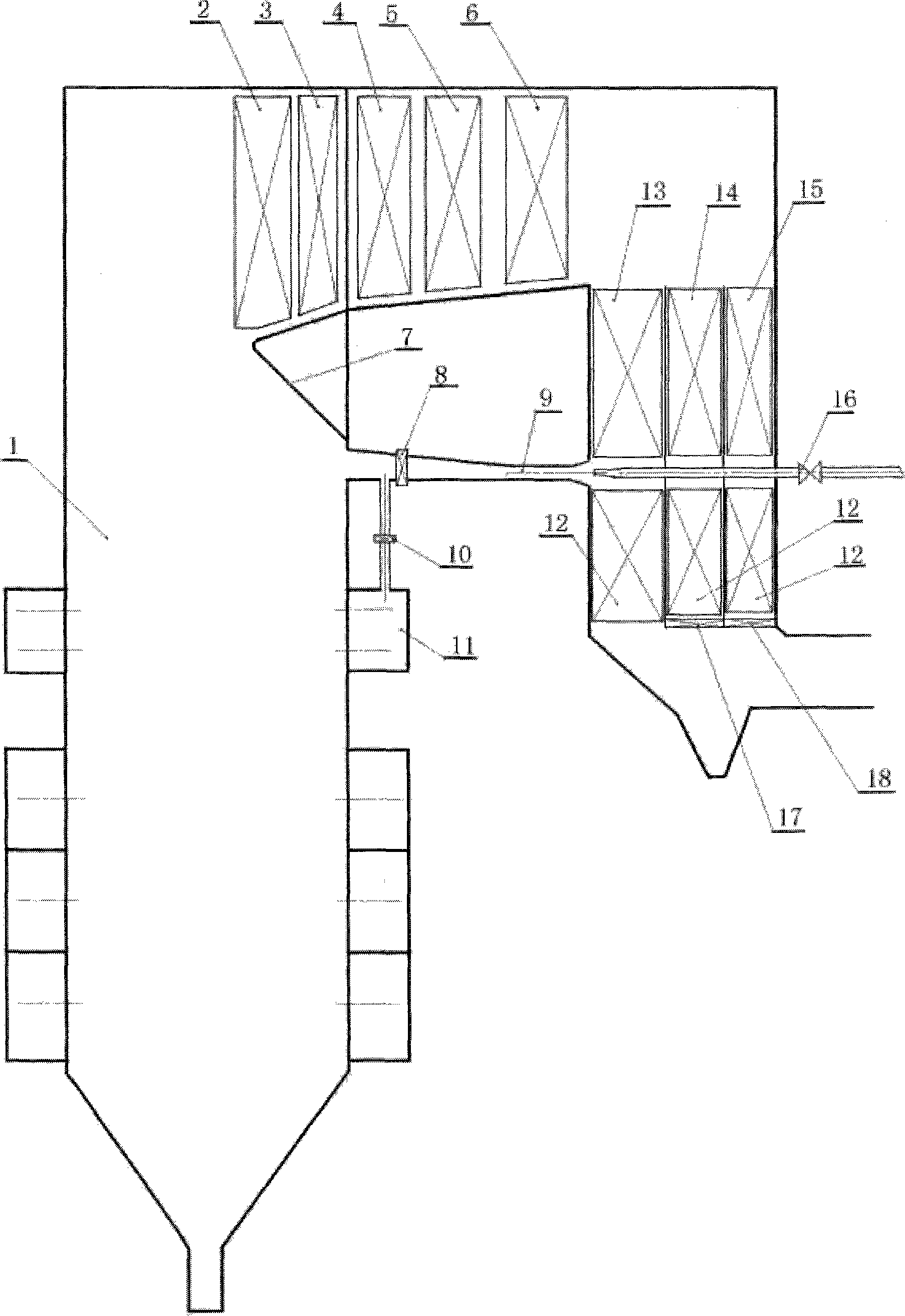

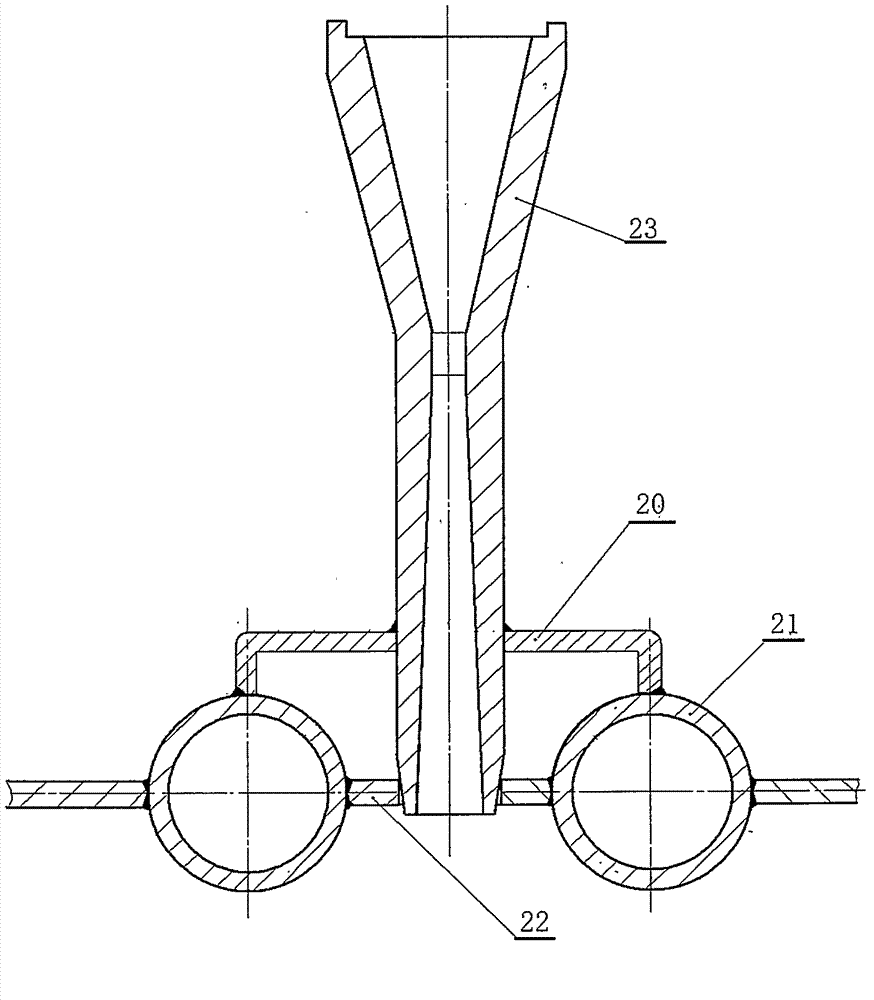

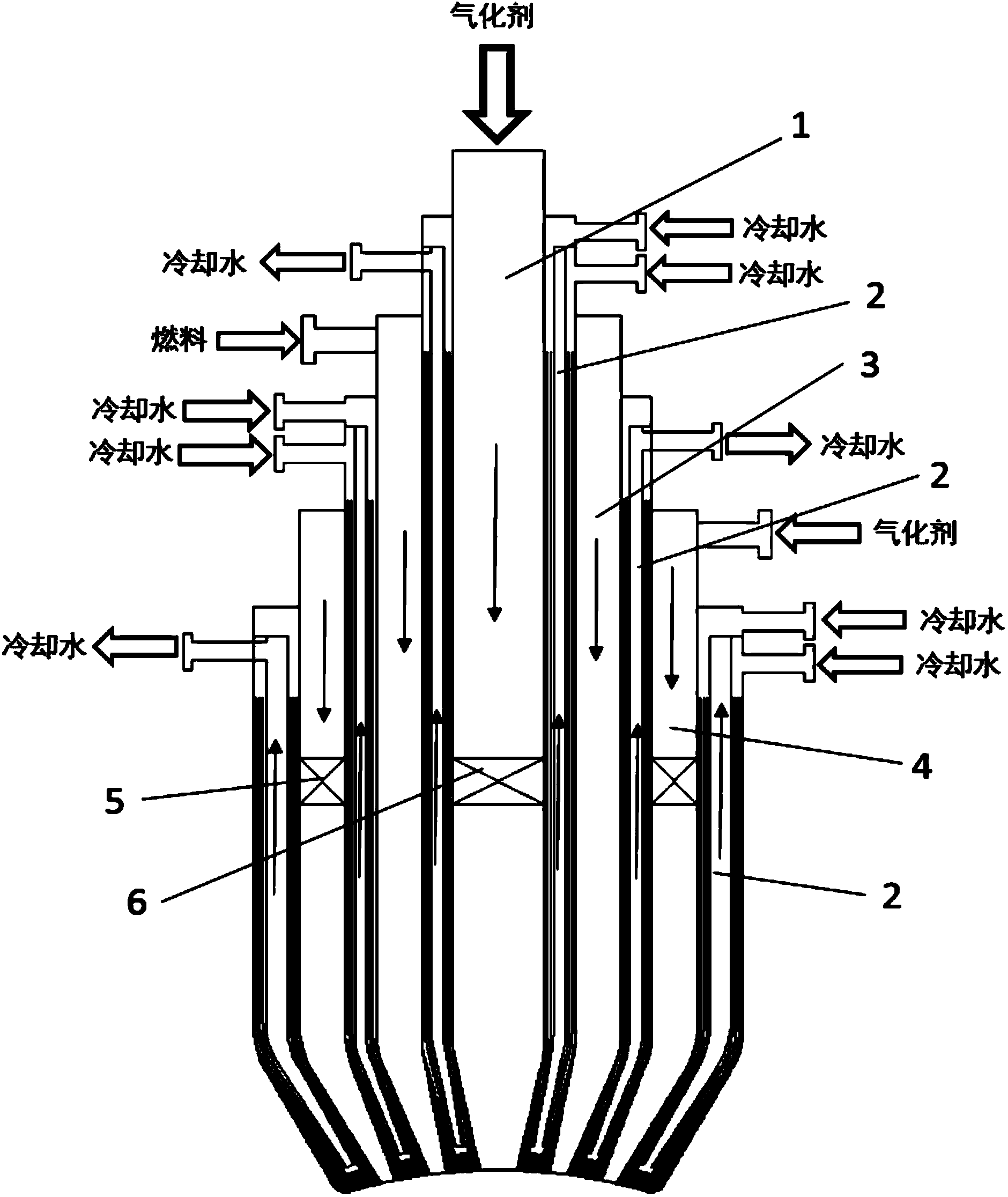

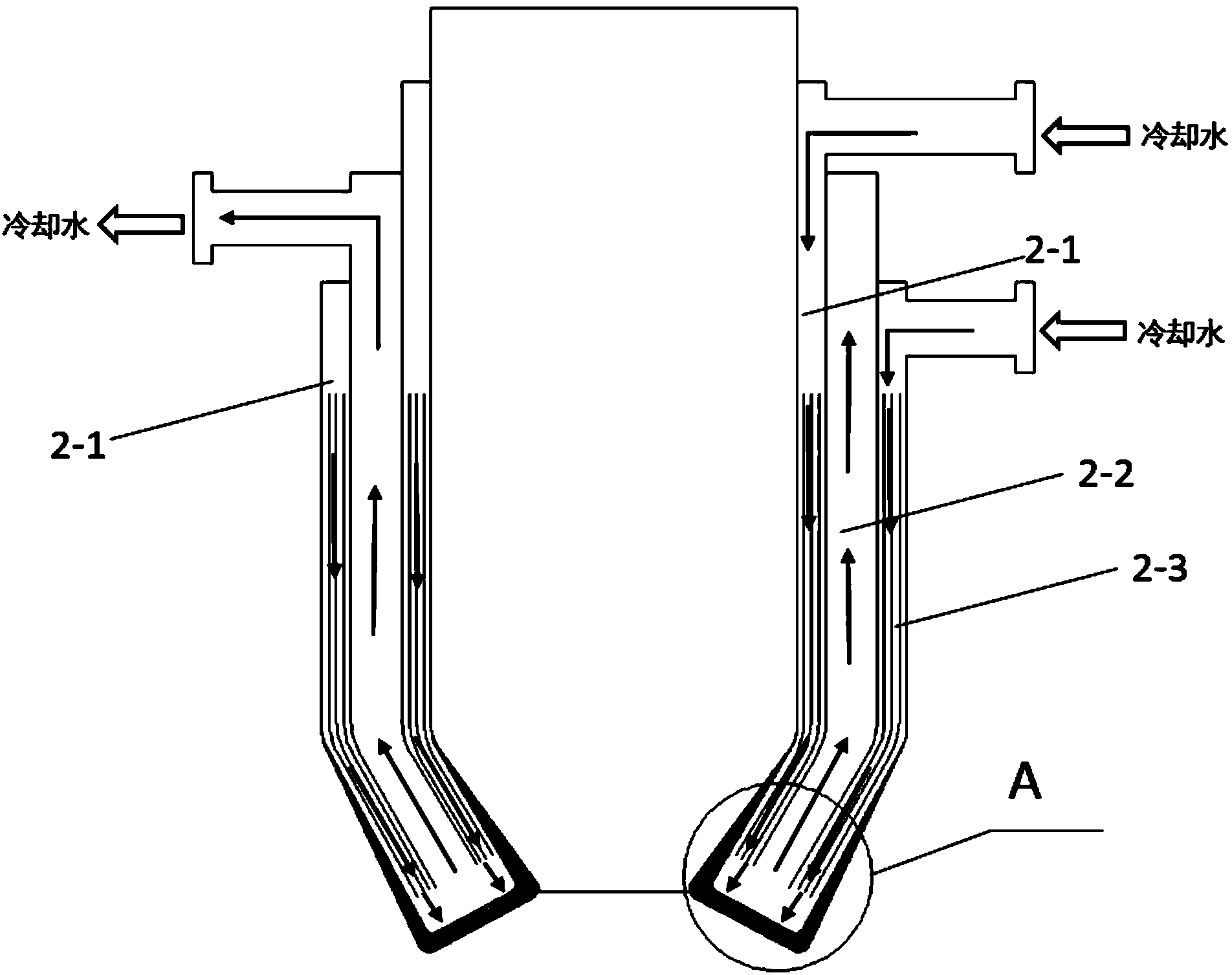

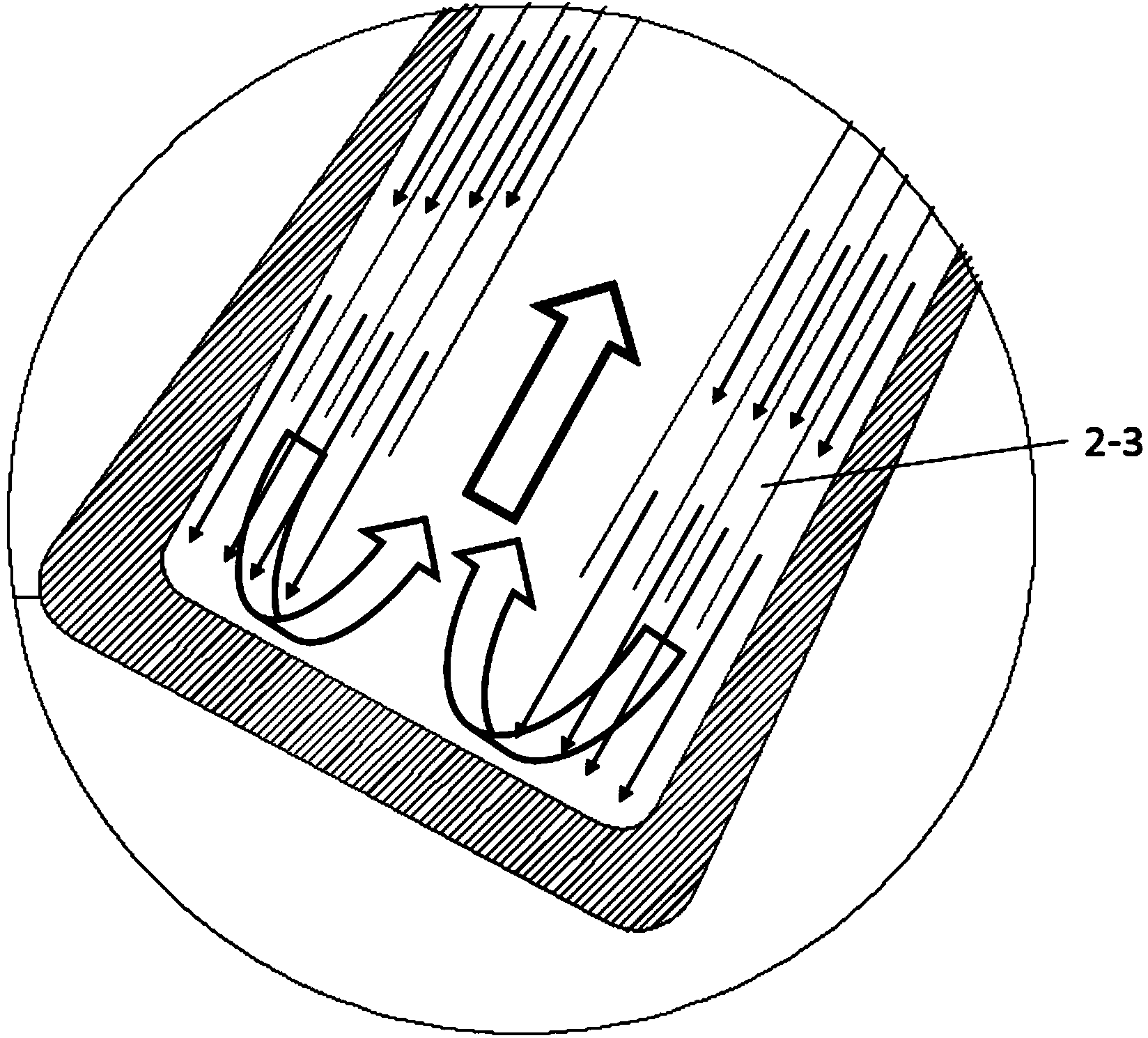

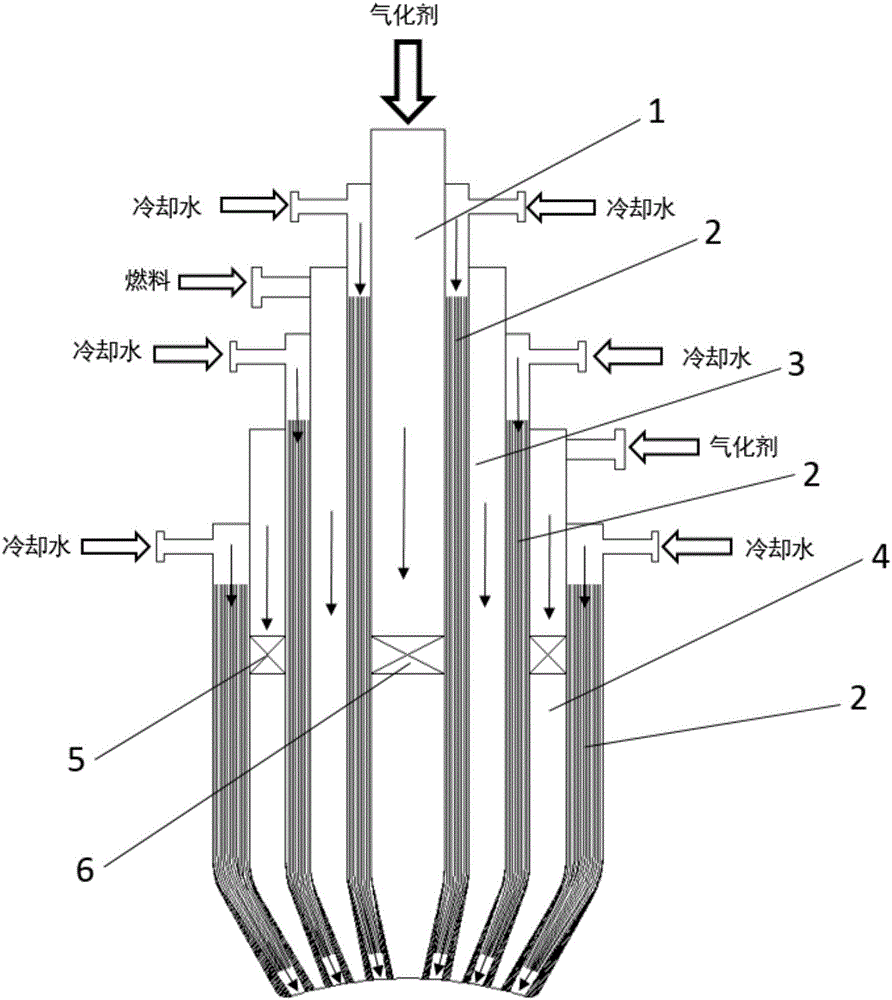

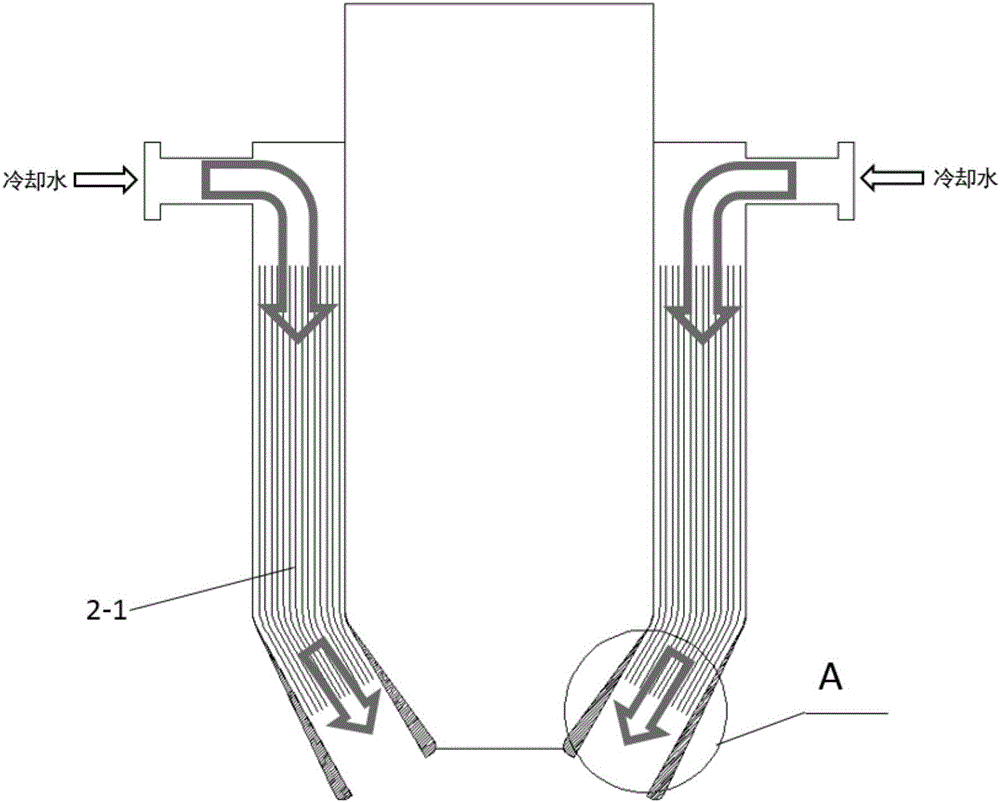

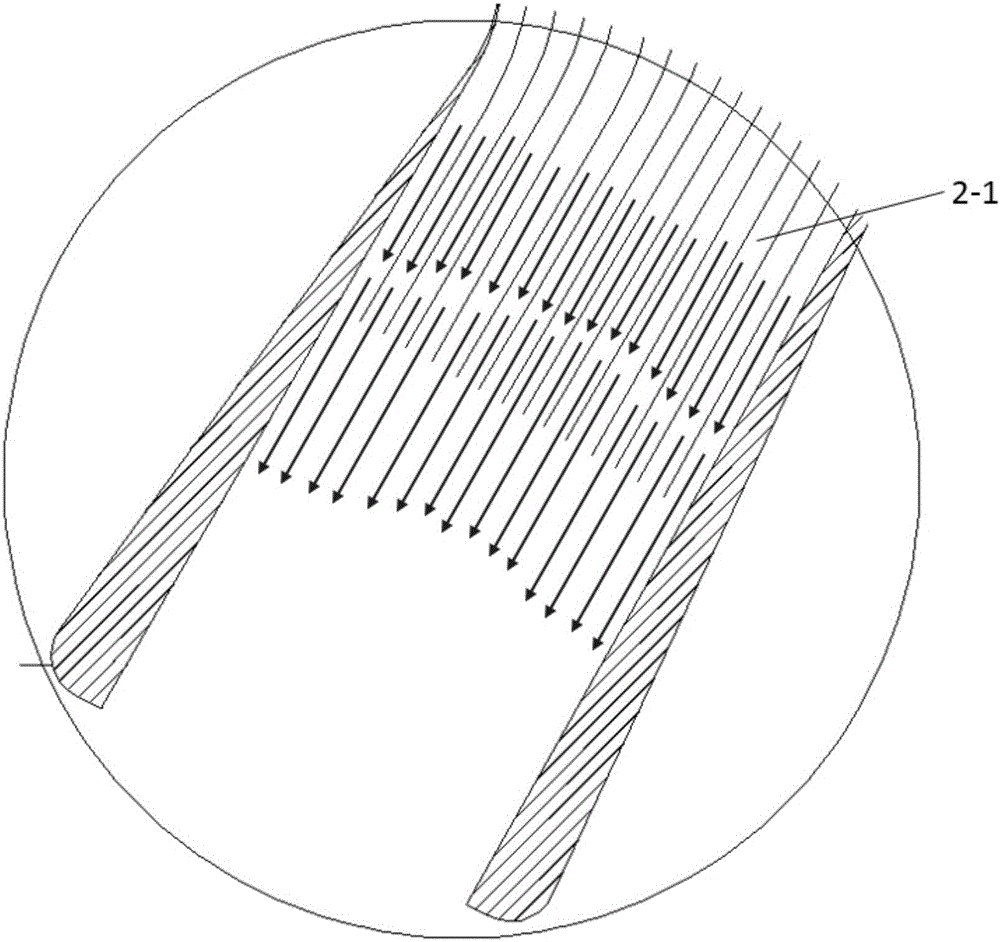

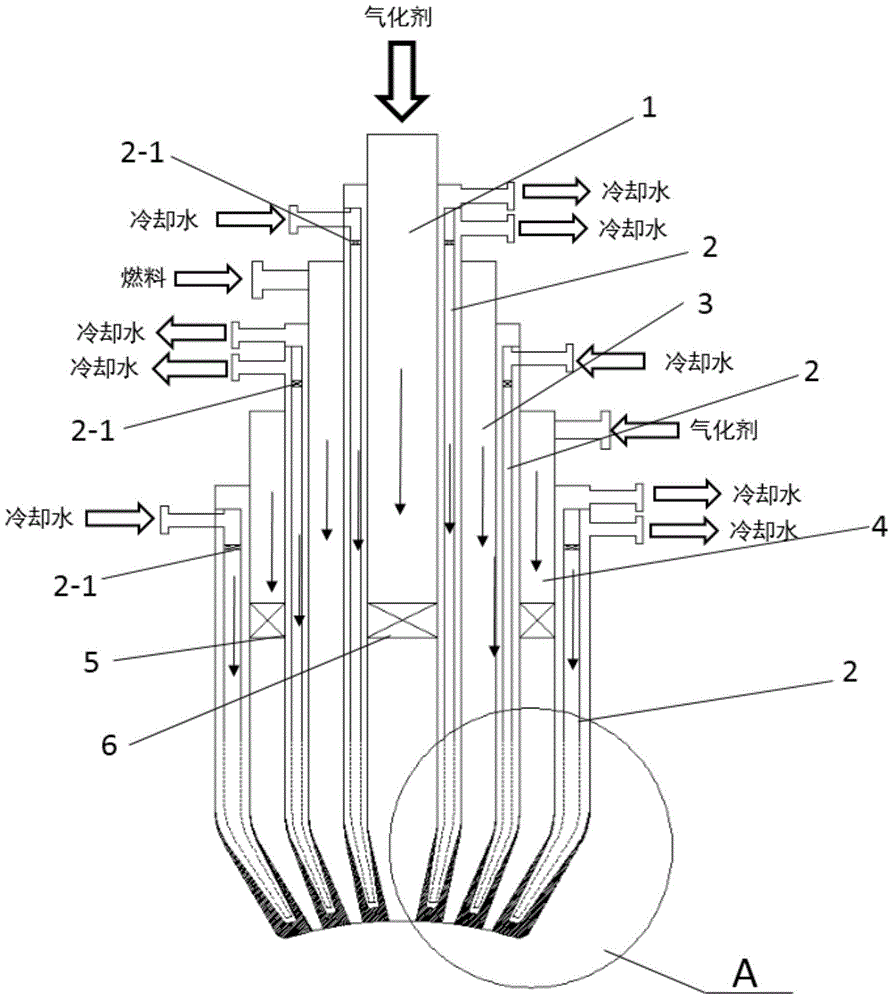

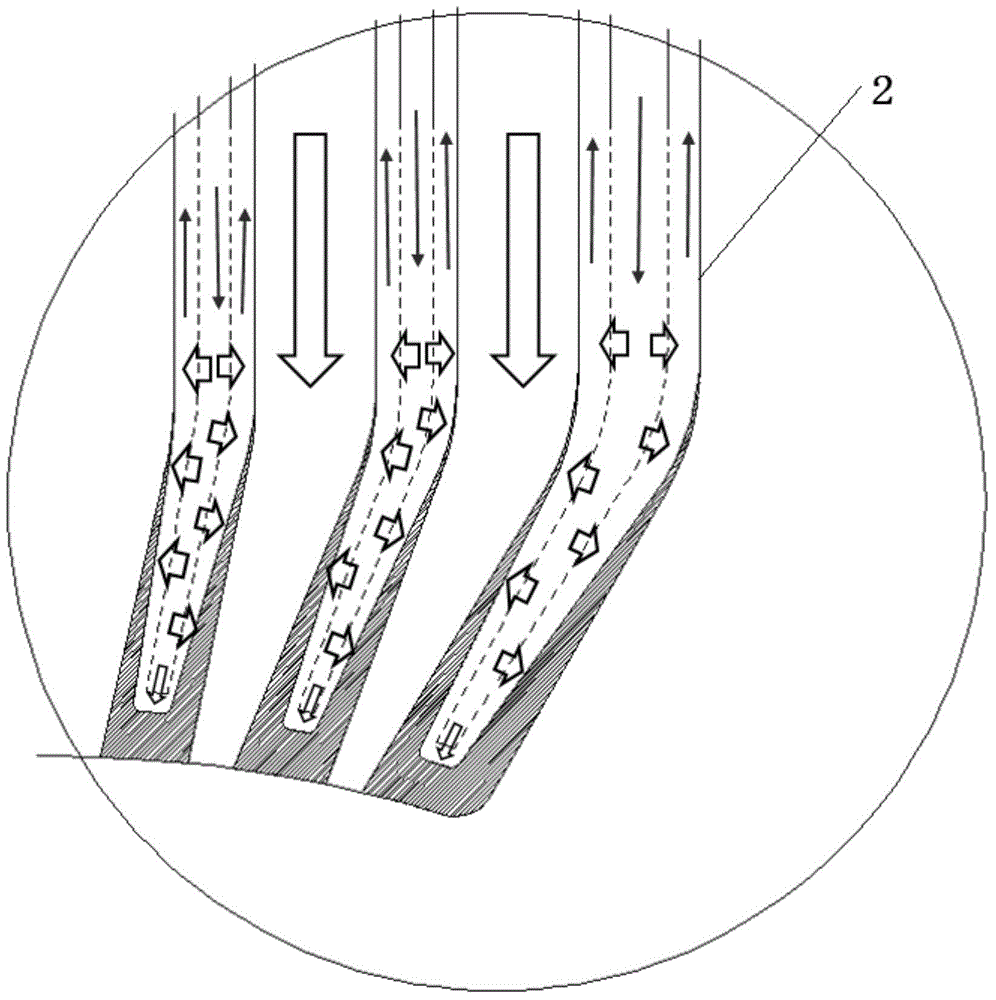

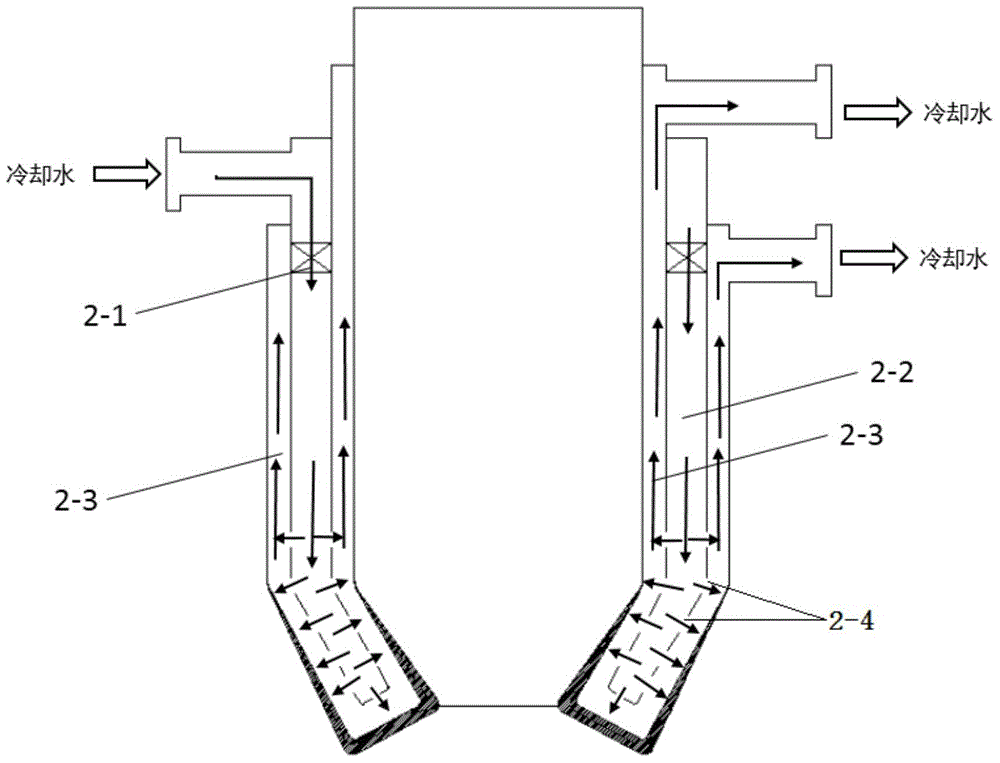

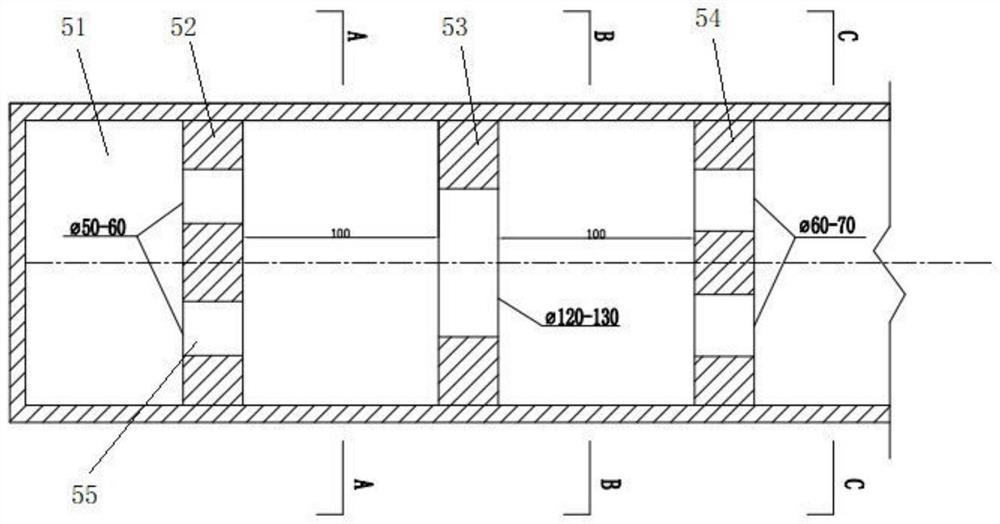

Novel micro-channel circularly cooling gasification process nozzle

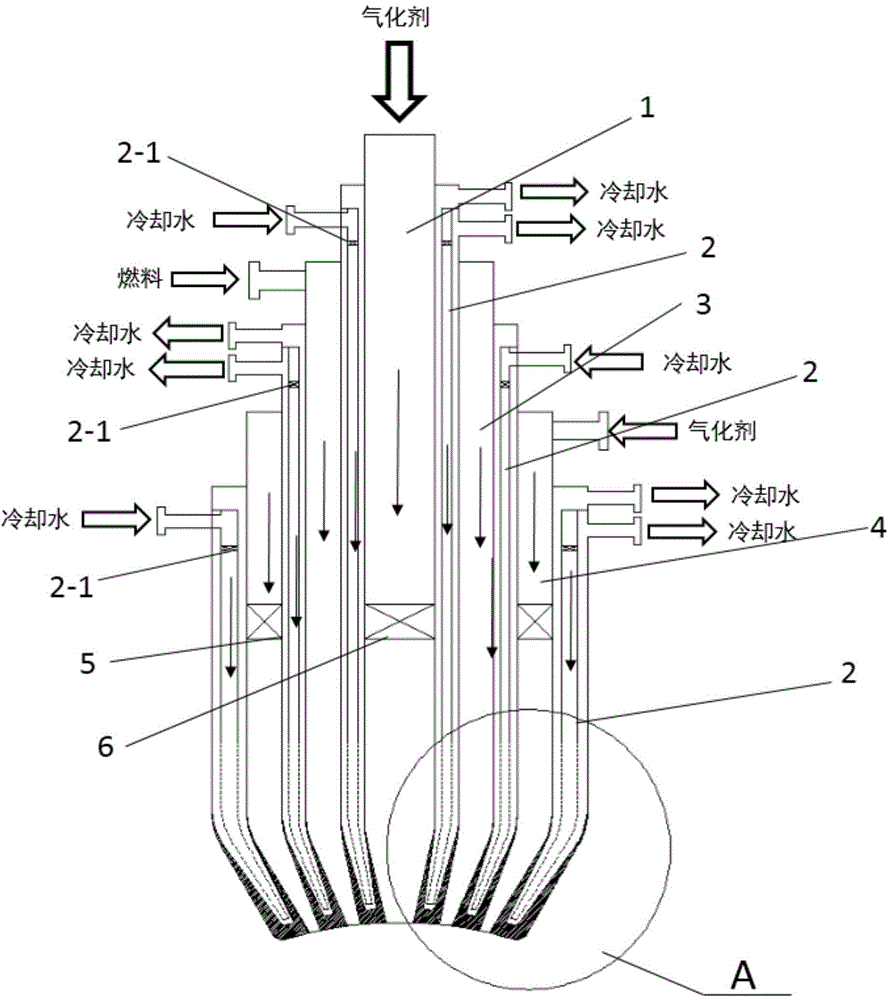

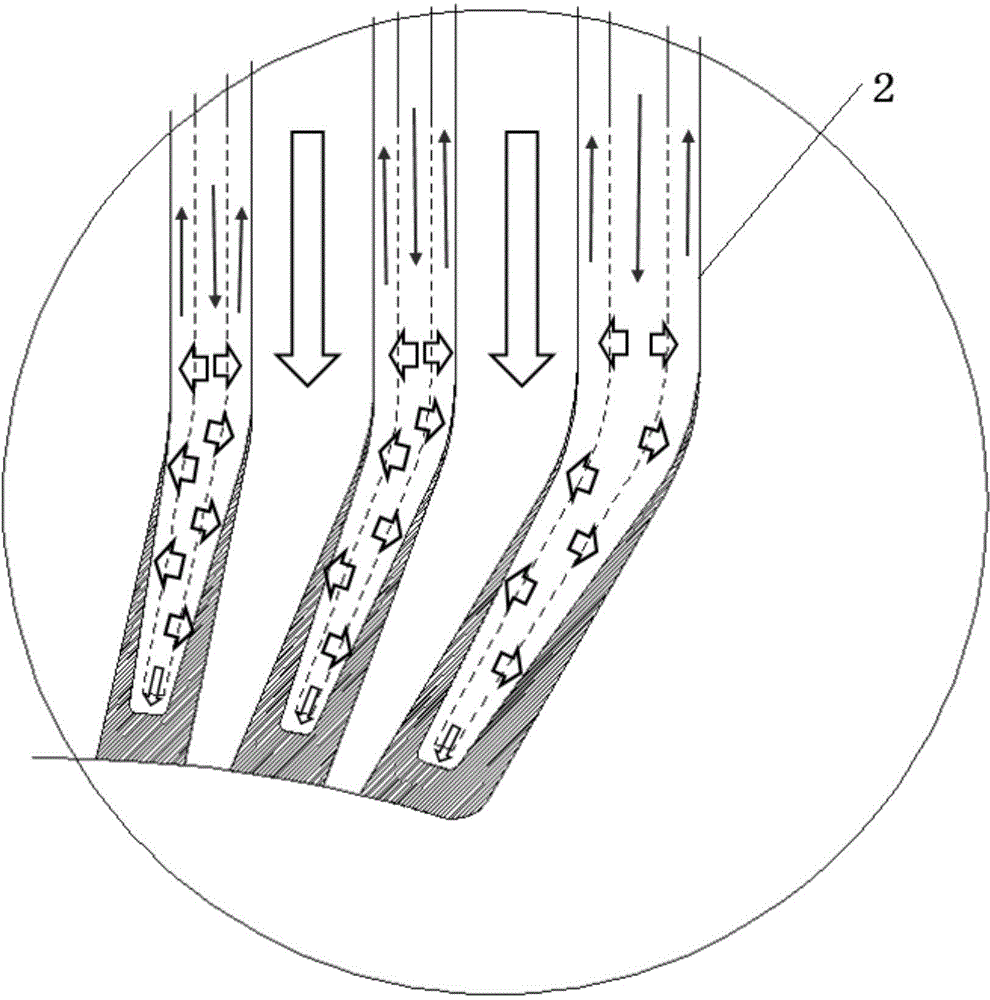

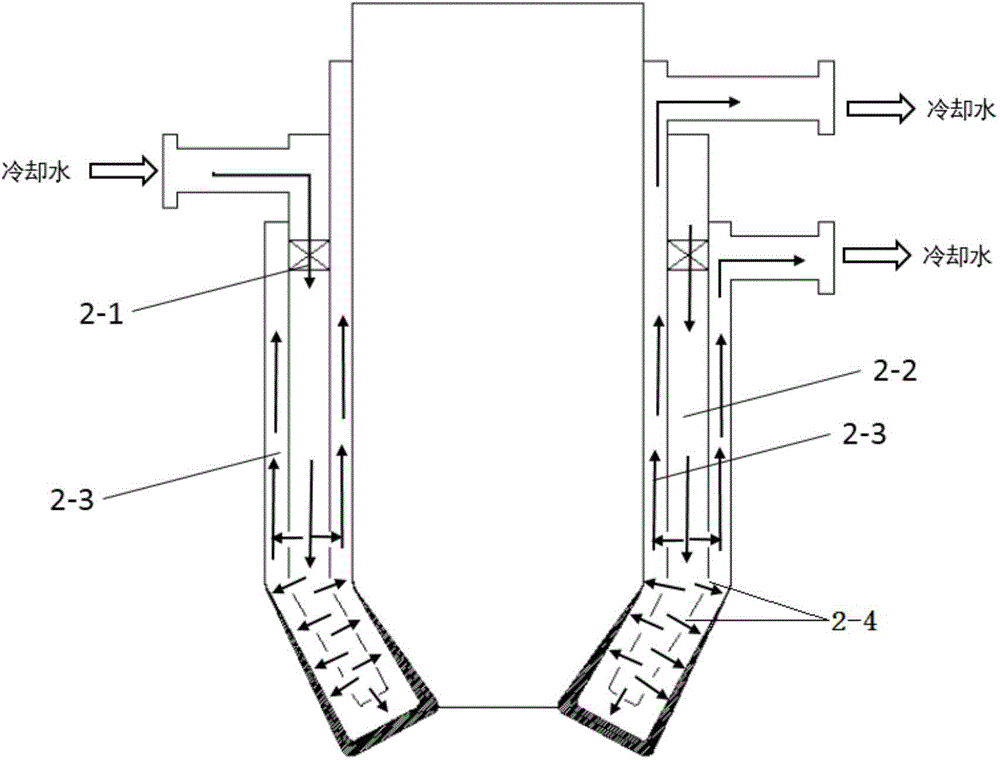

ActiveCN103881760AGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationWater channelWater flow

The invention provides a novel micro-channel circularly cooling gasification process nozzle. The nozzle comprises a center gasifying agent channel, a fuel channel, an outer gasifying agent channel and cooling water channels which are distributed between the center gasifying agent channel and the fuel channel, between the fuel channel and the outer gasifying agent channel and outside the gasifying agent channel, wherein the fuel channel and the outer gasifying agent are coaxial with and sequentially sleeved on the center gasifying agent channel; the water intake channels of the cooling water channels are composed of a plurality of micro-channels; the flowing speed of high-pressure cooling water increases in the micro-channels, and the center gasifying agent channel, the fuel channel, the outer gasifying agent channel and metal wall surfaces of the cooling water channels are efficiently cooled in heat conduction and forced-convection heat transfer modes; cooling water is sprayed from the micro-channel outlets in a high-speed jet manner, and the bottom metal wall surfaces of the cooling water channels are effectively cooled in a forced impact jet convection heat transfer manner, and then the cooling water flows back to the water outlets of the cooling water channels from a return channel. The novel micro-channel circularly cooling gasification process nozzle can be used for overcoming the defect of the gasified nozzle technology in the prior artthe nozzle is poor in cooling effect and has a short service life.

Owner:XI AN JIAOTONG UNIV

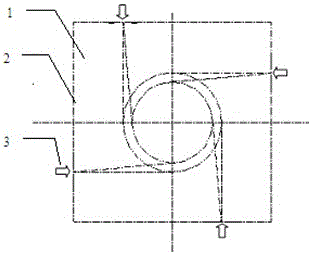

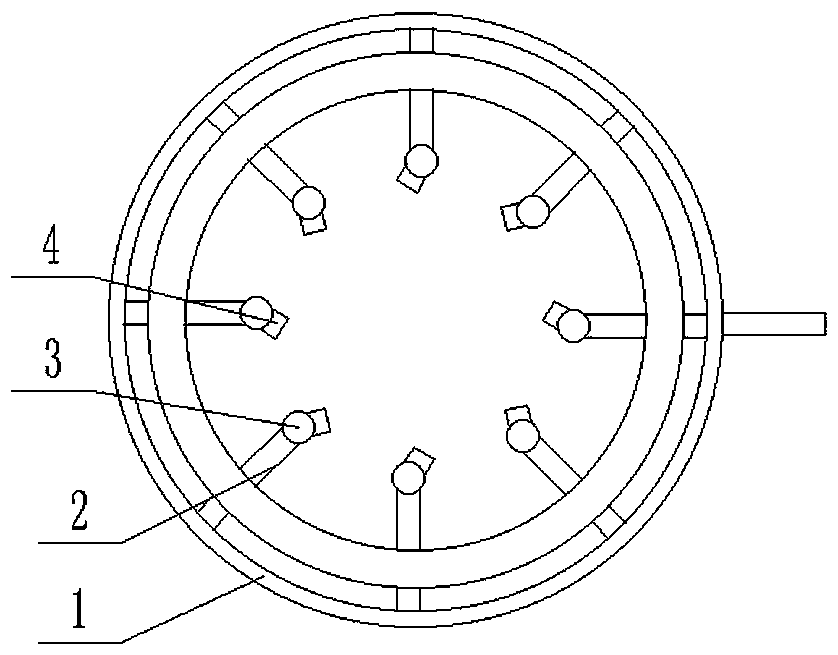

Circulating fluidized-bed boiler with multiple separators and annular hearth

ActiveCN106196025AUniform distribution of gas-solid flowImprove separation efficiencyFluidized bed combustionApparatus for fluidised bed combustionCycloneFluidized bed

A circulating fluidized-bed boiler with an annular hearth comprises the hearth and two sets of cyclone separators. The cyclone separators are correspondingly arranged on the outer sides of the two side walls. Each set of cyclone separators is provided with three cyclone separators, and all the cyclone separators are the same in cylinder structure and size. In the plane crossing all the hearth smoke outlet center points, the hearth smoke outlet center points of the two separators on the outmost side in one set of separators and the hearth smoke outlet center holes of the two separators on the outermost side in the other set of separators are symmetric about the intersecting point of the hearth center face perpendicular to the first side wall and the hearth center face perpendicular to the second side wall; and the hearth smoke outlet center points of the two separators on the outmost side in each set of cyclone separators are axially symmetric about the hearth center line formed by the intersecting line of the hearth center face perpendicular to the first side wall and the plane. The position relation of the two cyclone separators on the outmost side in each set of cyclone separators meets the conditions that when b is smaller than or equal to 2m, a is larger than or equal to b / 3 and smaller than b-0.3m; and when b is larger than 2m, a is larger than or equal to m / 2 and smaller than b-0.3m.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

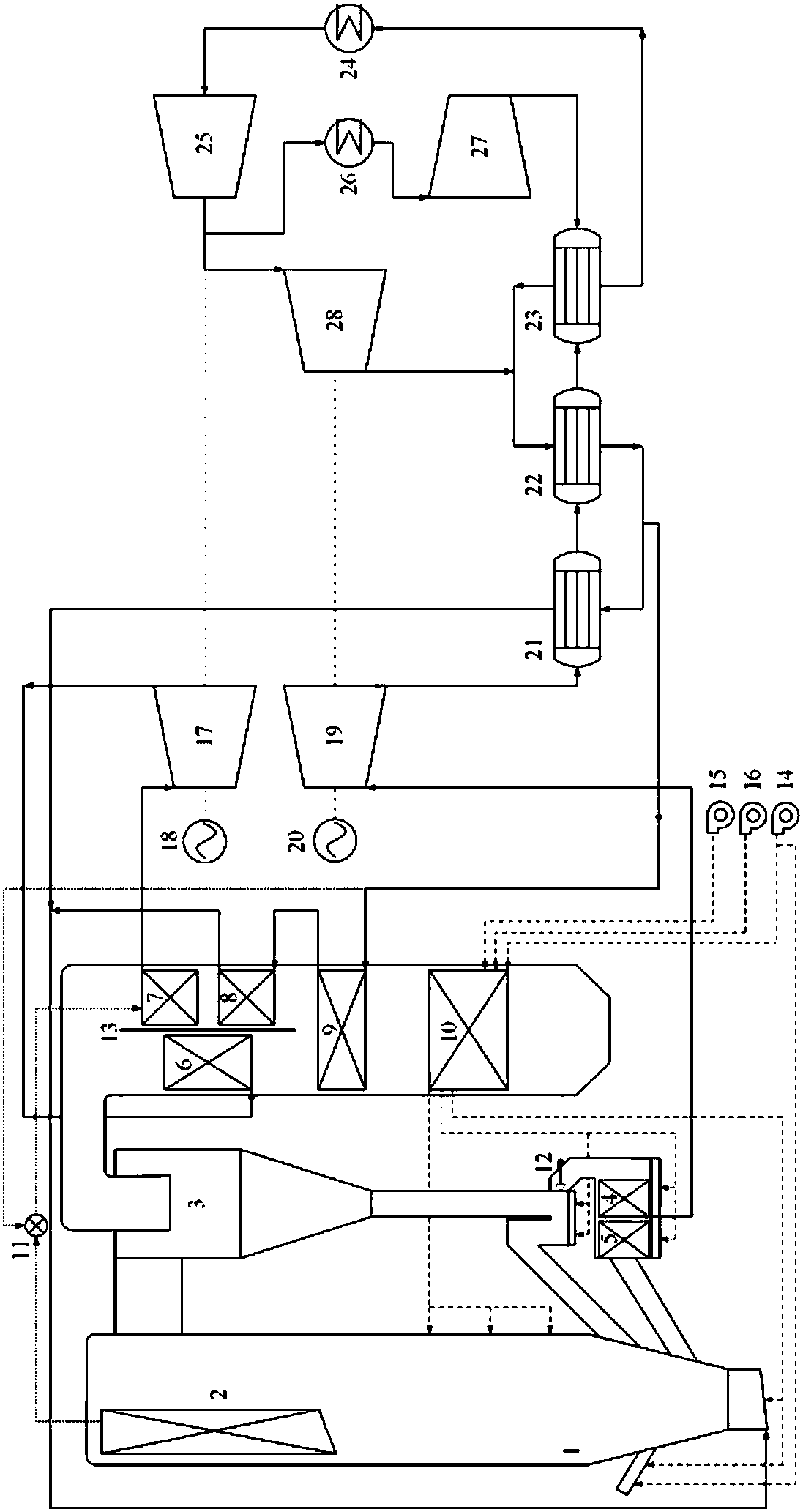

Supercritical carbon dioxide coal-fired circulating fluidized bed boiler, power generation system and power generation method

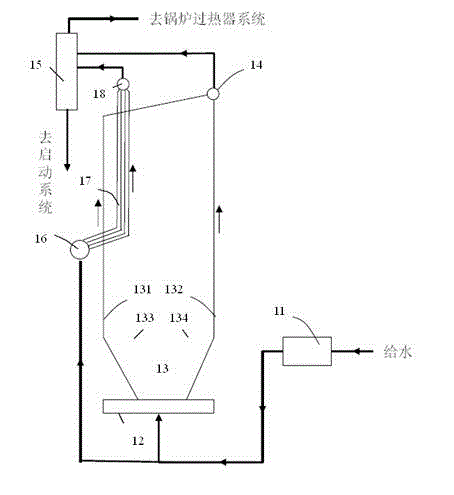

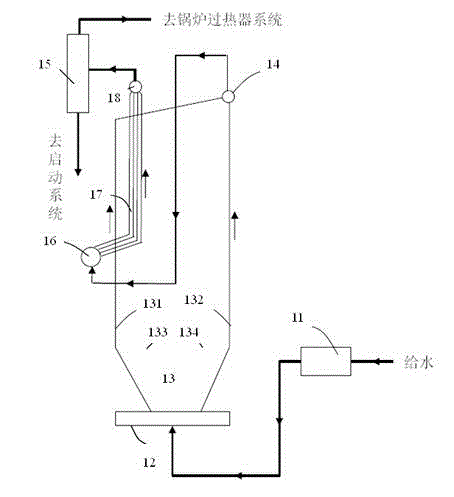

ActiveCN108180470AReduce thermal deviationGuaranteed uptimeFluidized bed combustionSteam engine plantsAir preheaterSuperheater

The invention discloses a supercritical carbon dioxide coal-fired circulating fluidized bed boiler, a power generation system and a power generation method. The supercritical carbon dioxide coal-firedcirculating fluidized bed boiler comprises a hearth, a separator, a tail flue and an externally-arranged type heat exchanger located in a material back section of the separator. A cooling wall and anintermediate-temperature overheater are arranged in the hearth. A high-temperature reheater and a low-temperature overheater are arranged in the externally-arranged type heat exchanger, wherein the low-temperature overheater communicates with the cooling wall and the intermediate-temperature overheater. A low-temperature reheater, a high-temperature overheater, an upper-level economizer, a lower-level economizer and an air preheater are arranged in the tail flue, wherein the high-temperature overheater communicates with the intermediate-temperature overheater, the low-temperature reheater communicates with the high-temperature reheater. The working medium of the boiler is supercritical carbon dioxide. By the adoption of the supercritical carbon dioxide coal-fired circulating fluidized bedboiler, the wall temperature of the cooing wall can be effectively controlled, it is guaranteed that the boiler safely and reliably operates, and the heat efficiency is high; a power generator set tends to be miniature, a higher load response speed is obtained, the deep peak load regulation adaptability is high, the advantages of coal resources are taken into full play, the energy utilization rate is improved, and energy safety is guaranteed.

Owner:SOUTHEAST UNIV

Novel jet impingement cooling gasification technology burner

ActiveCN103937553AGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationJet flowInlet channel

The invention discloses a novel jet impingement cooling gasification technology burner. The novel jet impingement cooling gasification technology burner comprises a central gasifying agent channel, fuel channels, outer gasifying agent channels, and cooling water channels; the central gasifying agent channel is coaxially sieved by the fuel channels and the outer gasifying agent channels successively; the cooling water channels are arranged between the central gasifying agent channel and the fuel channels, between the fuel channels and the outer gasifying agent channels, and on the outsides of the outer gasifying agent channels; the cooling water channels are composed of water inlet channels and water return channels; cooling water uniform distribution devices are arranged in the water inlet channels; the water inlet channels and the water return channels are communicated via a plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels; high pressure cooling water is delivered into the water inlet channels, and then the walls of the water return channels are impinged by the high pressure cooling water through the plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels in a jet flow manner, so that high efficient cooling of the walls of the water return channels is realized; and then the high pressure cooling water is delivered to water outlets of the cooling water channels via the water return channels. The novel jet impingement cooling gasification technology burner is capable of solving problems of existing gasification technology burners that cooling effect is poor, and service life is relatively short.

Owner:XI AN JIAOTONG UNIV

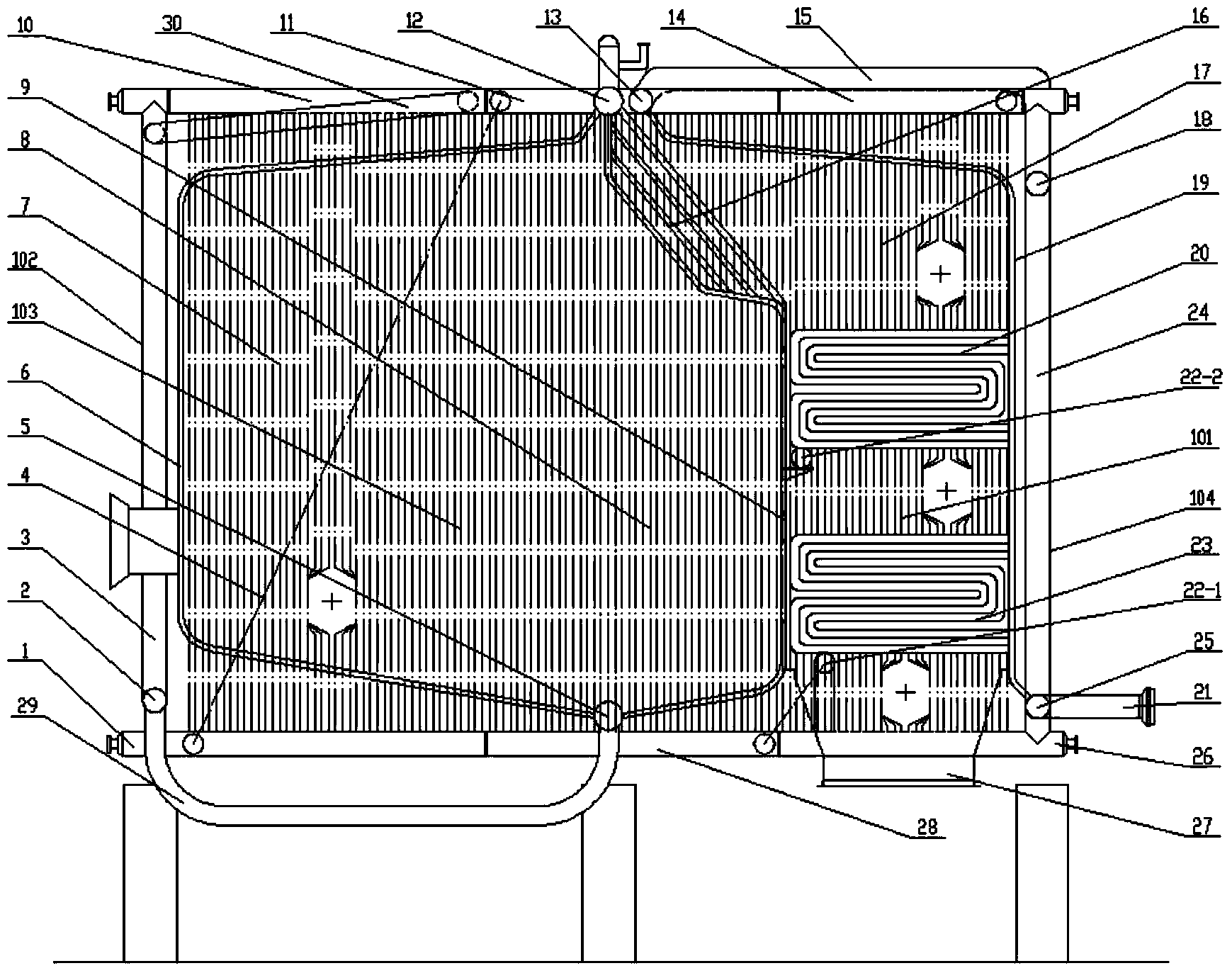

Water circulation structure of fuel gas corner tube hot-water boiler

The invention provides a water circulation structure of a fuel gas corner tube hot-water boiler. Rising flow is completely forced by a heat-absorbing face and possible tube burst accidents caused by hydraulic working condition deterioration such as subcooled boiling, stagnating and backflow are avoided. A boiler body is of a frame-type self-supporting structure composed of large-diameter steel tubes arranged on the four corners, an upper collecting box, a lower collecting box, a longitudinal collecting box and a transverse collecting box; the water circulation structure is composed of a water cooling wall of a front wall of a furnace hearth, a water cooling wall of a rear wall of the furnace hearth, a membrane-type water cooling wall heat-absorbing face of a side wall I, a membrane-type water cooling wall heat-absorbing face of a side wall II, a membrane-type water cooling wall heat-absorbing face of a side wall III, a conversion shaft membrane-type water cooling wall heat-absorbing face, a flag-type heat-absorbing face, a collection box and connection pipes between the water cooling wall of the front wall of the furnace hearth, the water cooling wall of the rear wall of the furnace hearth, the membrane-type water cooling wall heat-absorbing face of the side wall I, the membrane-type water cooling wall heat-absorbing face of the side wall II, the membrane-type water cooling wall heat-absorbing face of the side wall III, the conversion shaft membrane-type water cooling wall heat-absorbing face, the flag-type heat-absorbing face and the collection box. The flag-type heat-absorbing face which does not penetrate through the walls is directly welded to the densely-arranged membrane-type water cooling wall of the rear wall, so that the transverse pitches of tube bundles are reduced and reasonable smoke flow speed is guaranteed; two side walls are divided into three levels of heat-absorbing faces according to different heat loads, so that heat deviation and flow deviation in the water tubes are greatly reduced. The boiler body is composed of the full-membrane-type water cooling walls, the conversion tube bundles do not penetrate through the walls, the air-tightness is good, the air leakage amount is small, the burning efficiency is high, and the water circulation structure can safely and efficiently operate for a long time under various loads.

Owner:XI AN JIAOTONG UNIV

Natural gas condensing boiler system and method thereof for catalytic oxidation of fuel-rich combustion

InactiveCN109028580AFully absorbedEfficient emissionsAir heatersSustainable buildingsCombustion chamberCombustor

The invention discloses a natural gas condensing boiler system and a method thereof for catalytic oxidation of fuel-rich combustion. A combustor is successively connected with a fuel-rich combustion chamber, a second return flue pipe and a third return flue pipe to form three flue gas return paths. An excess air coefficient maintained in the fuel-rich combustion chamber is less than 1. 0, an unburnt gas catalytic oxidation device is arranged on the third return flue pipe, and flue gas passes through the three flue gas return paths and is connected with a chimney by passing through an energy saver and a condenser successively. According to the natural gas condensing boiler system, rapid combustion in a reducing atmosphere is achieved, and almost no NO<x> is generated by low-temperature oxidation in the unburnt gas catalytic oxidation device, thus the NO<x> emission level can be strictly controlled, and environmental pollution is reduced; according to the natural gas condensing boiler system and the method thereof for catalytic oxidation of fuel-rich combustion, NO<x> emission can be effectively decreased, meanwhile, the alteration cost is saved, and the heat is recycled; and the system has a wide application range, and is suitable for various heating condensing boilers.

Owner:XI AN JIAOTONG UNIV

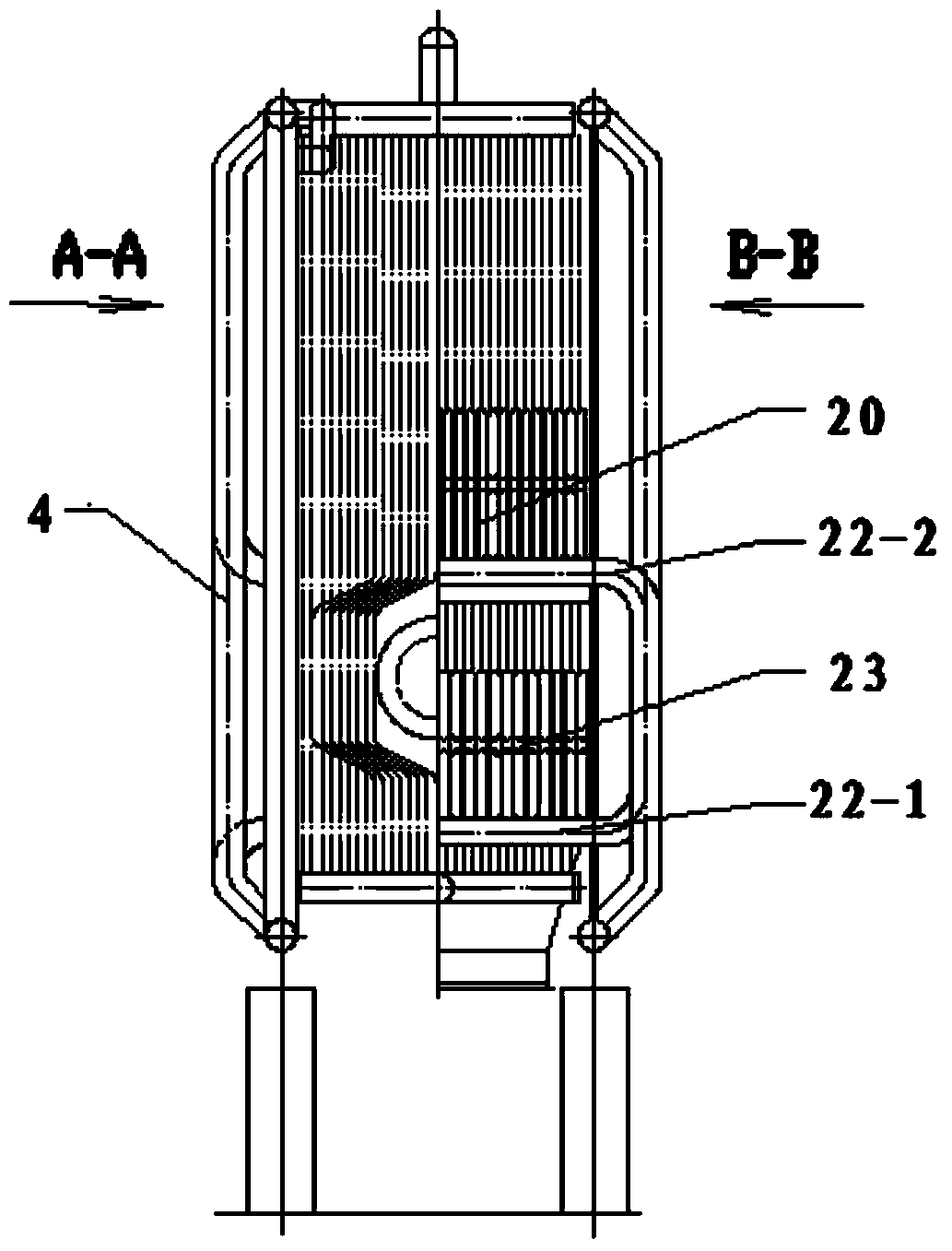

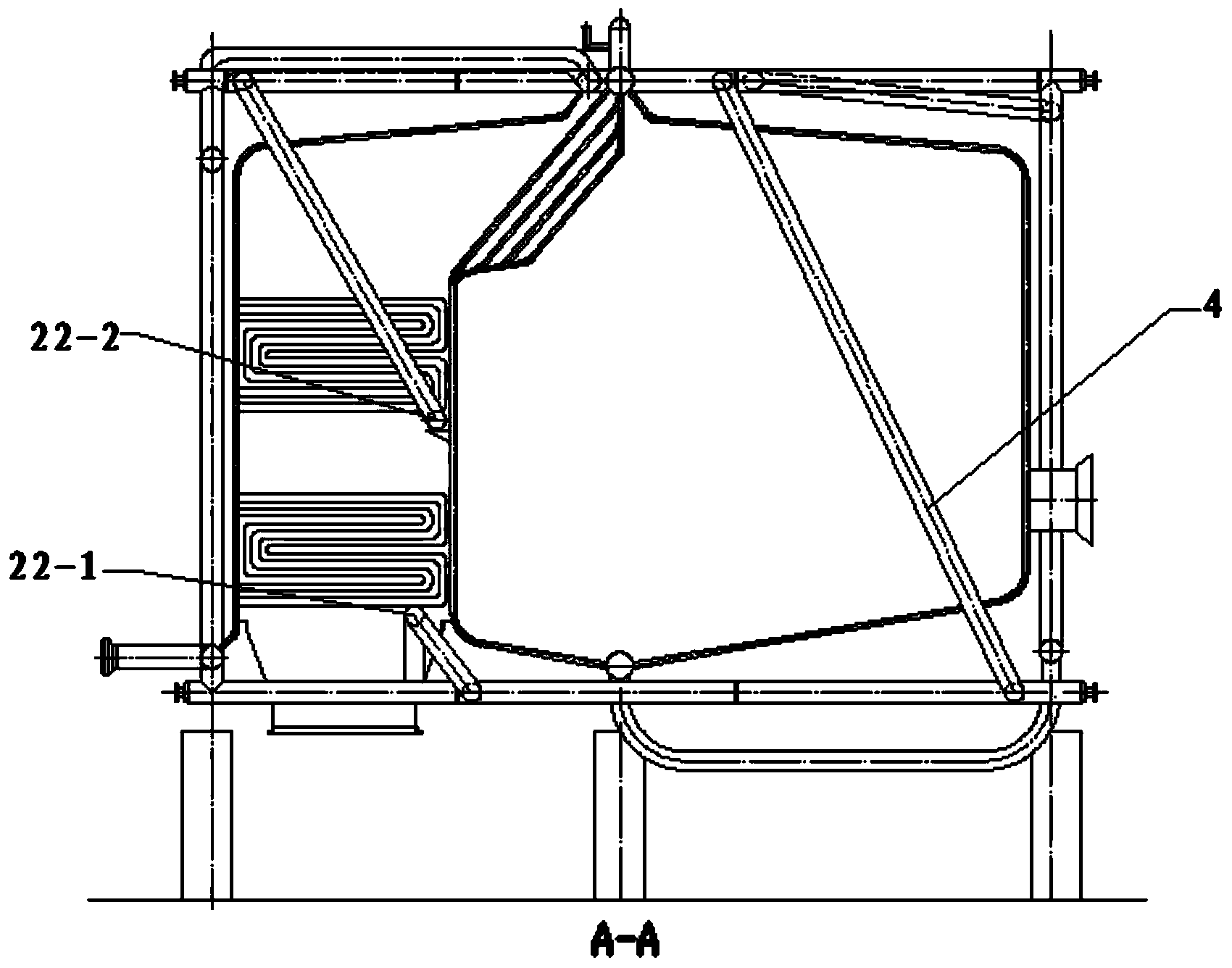

Supercritical circulating fluidized bed boiler with double-return evaporating heating surface

The invention relates to a supercritical circulating fluidized bed boiler with a double-return evaporating heating surface, which is characterized by comprising a descending section water-cooled screen inlet collection box connected with a hearth water-cooled wall outlet collection box, a descending section water-cooled screen connected with the descending section water-cooled screen inlet collection box, a water-cooled screen connecting collection box connected with the descending section water-cooled screen, an ascending section water-cooled screen connected with the water-cooled screen connecting collection box, and an ascending section water-cooled screen outlet collection box connected with the ascending section water-cooled screen, wherein the descending section water-cooled screen and the ascending section water-cooled screen adopt a double-return arrangement mode. The double-return arrangement mode is adopted, the hearth outlet collection box and the descending section water-cooled screen inlet collection box are arranged on the top of a hearth, the connecting length of pipelines is reduced, smaller hearth water-cooled wall heating area can be required, and the height of the hearth can be reduced.

Owner:SHANGHAI BOILER WORKS

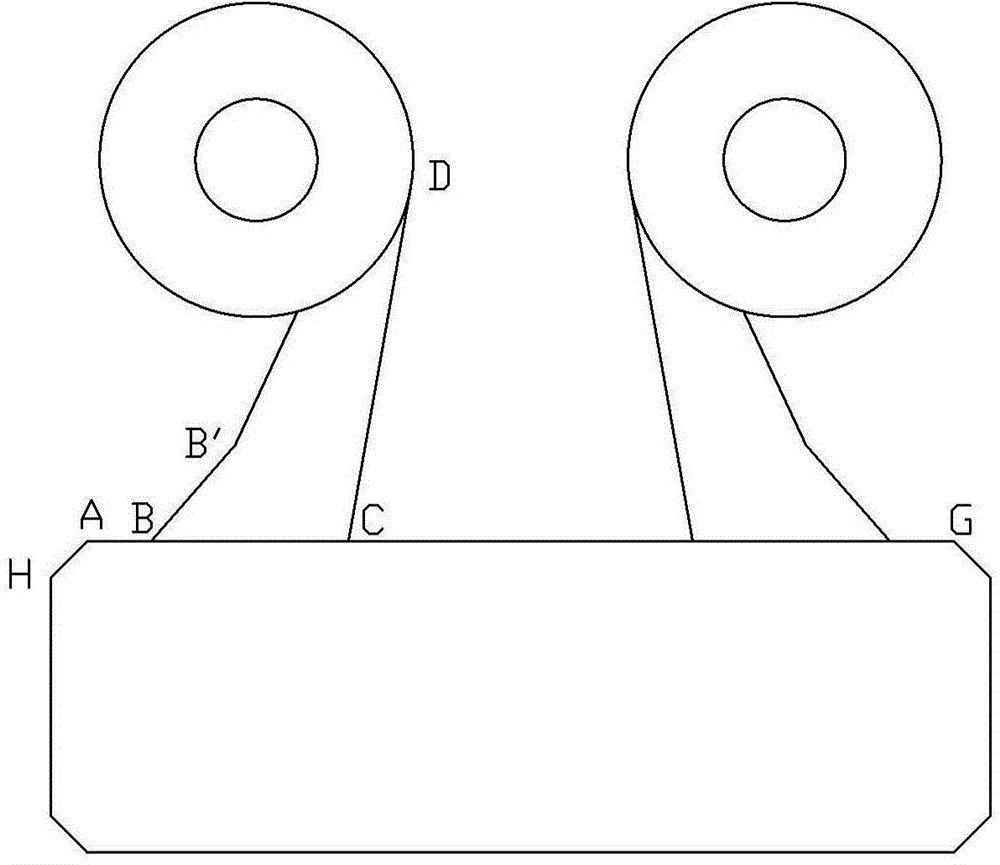

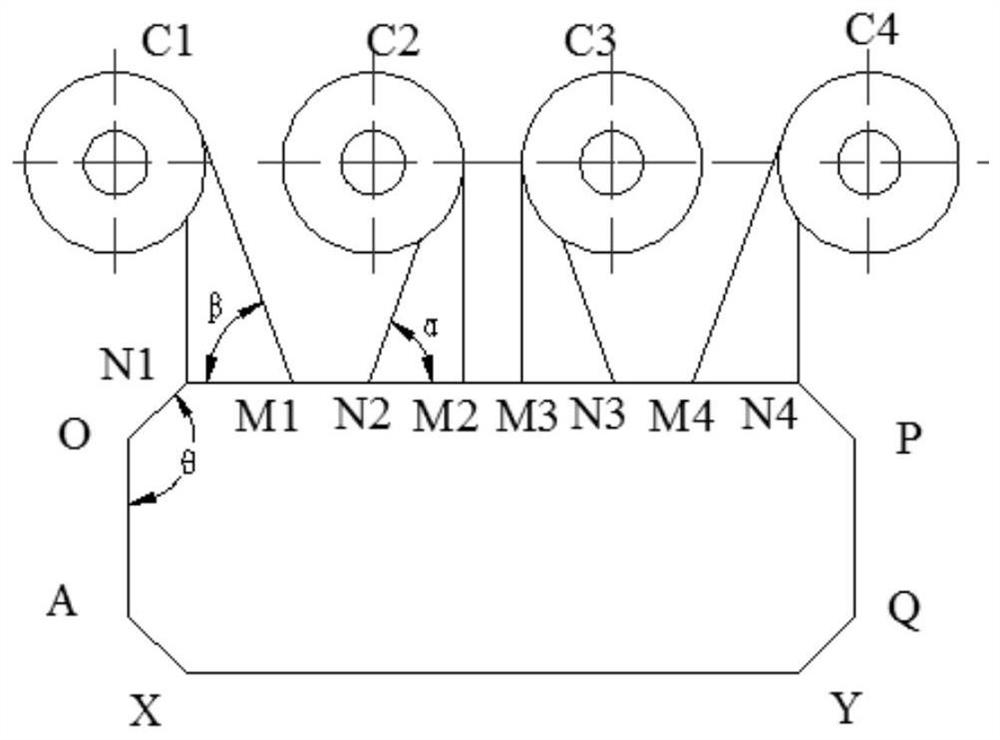

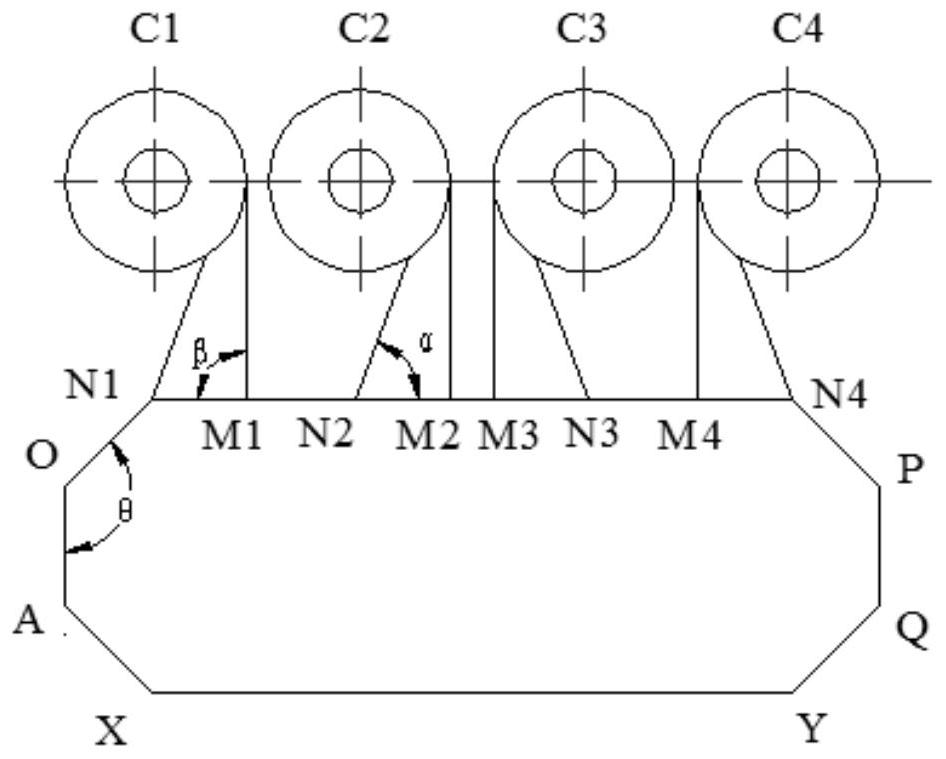

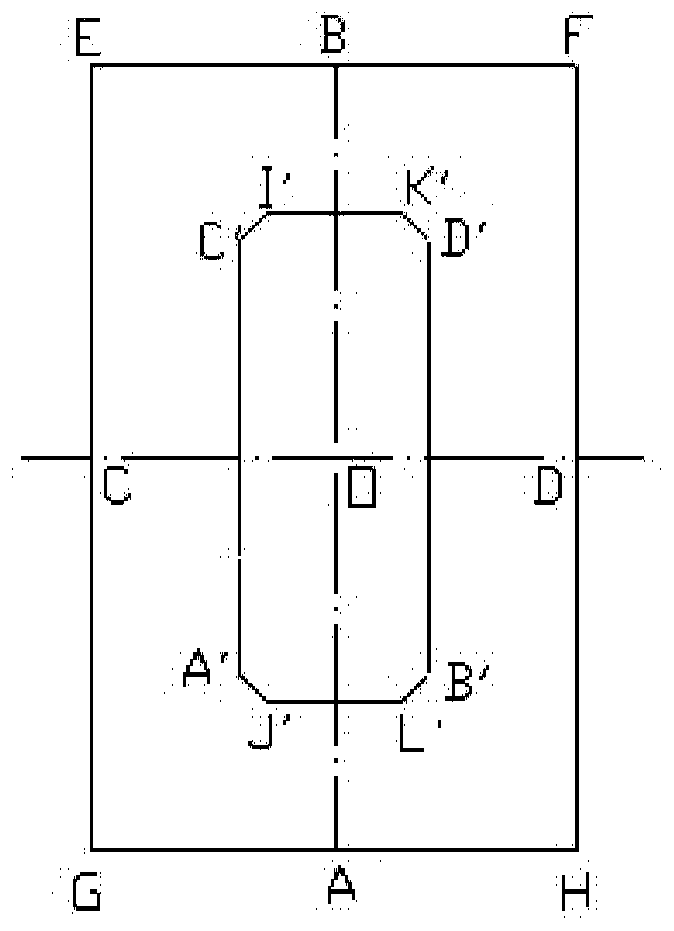

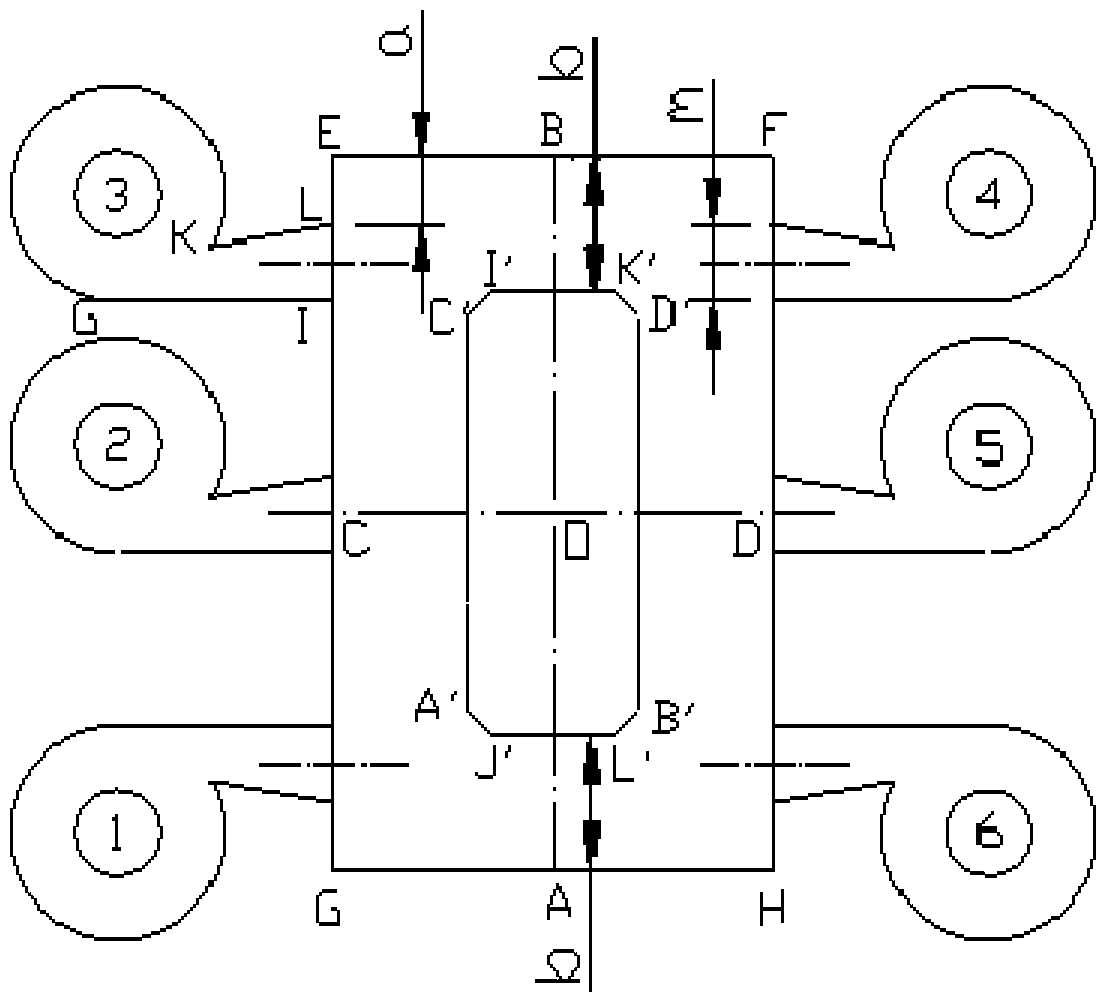

Octagonal hearth circulating fluidized bed boiler with multiple separators

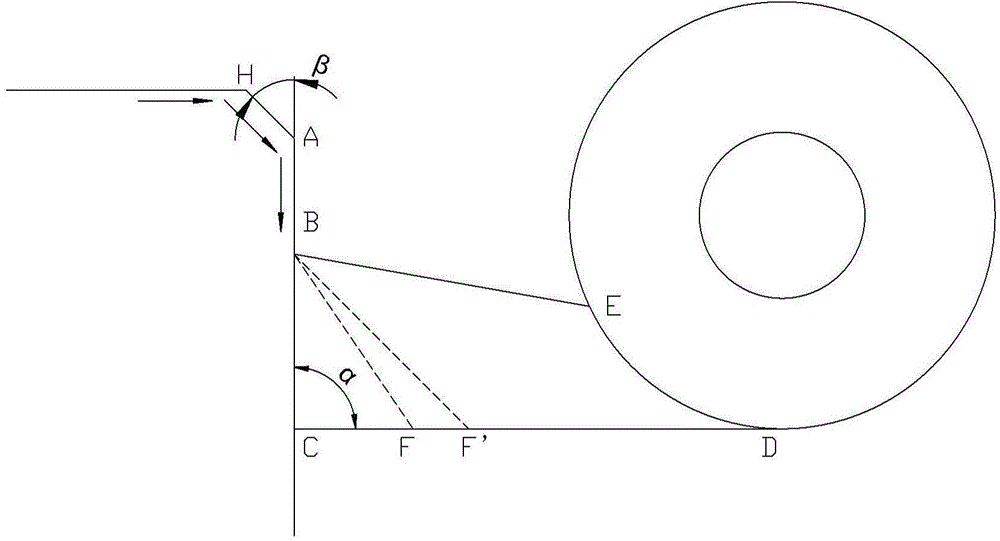

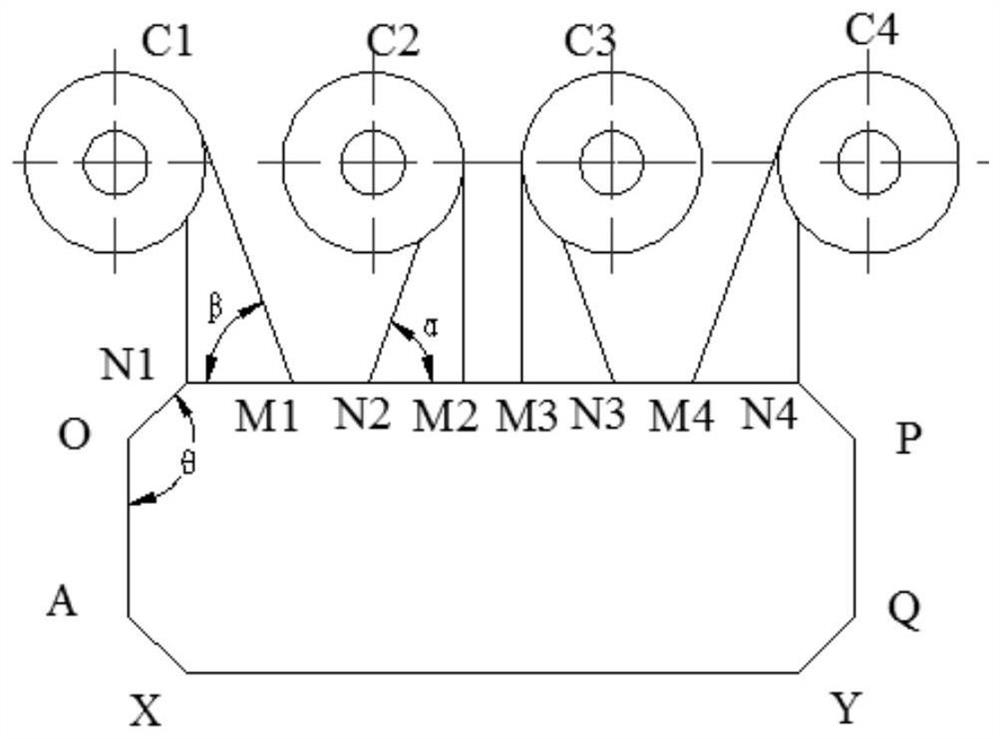

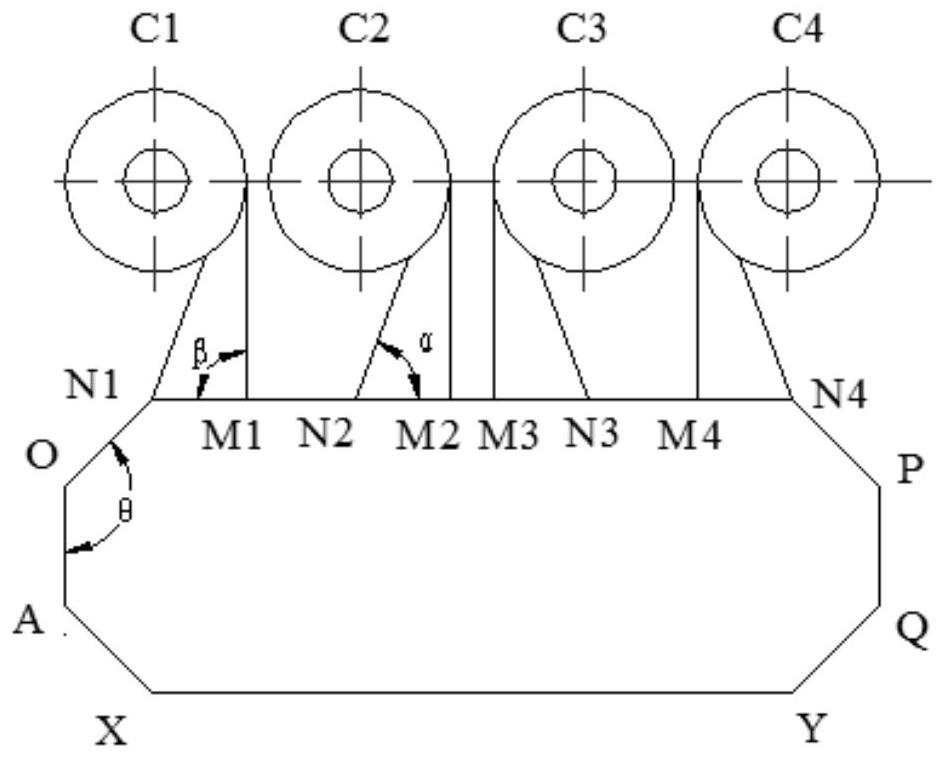

ActiveCN106196026AUniform distribution of gas-solid flowImprove separation efficiencyFluidized bed combustionApparatus for fluidised bed combustionEngineeringFlue

The invention provides an octagonal circulating fluidized bed boiler with multiple separators. The octagonal circulating fluidized bed boiler comprises a hearth, the first cyclone separator and the second cyclone separator, wherein the cross section of the hearth is octagonal; the hearth is composed of a front wall, a back wall, a left side wall, a right side wall and four membrane walls, and an angle beta is formed between each side wall and the corresponding membrane wall on the cross section; the cross section of the hearth is provided with a hearth front and back wall center line and a hearth left and right side wall center line and is axisymmetrical with respect to the two center lines; the first cyclone separator and the second cyclone separator are arranged on the back wall of the hearth; the tube structure and the size of the first cyclone separator are the same as those of the second cyclone separator; the inlet flue duct cross section of the first cyclone separator and the inlet flue duct cross section of the second cyclone separator are symmetrical with respect to the hearth front and back wall center line; in the tangential edges and the bevel edges of the inlet flue duct cross sections of the first cyclone separator and the second cyclone separator, the tangential edges are closer to the hearth front and back wall center line; the angle formed between the inner wall of the tangential edge of the inlet flue duct cross section of each cyclone separator and the back wall of the hearth is 90-110 degrees; and in addition, the position of an inlet flue duct of the first cyclone separator and the position of an inlet flue duct of the second cyclone separator both meet the following formula that AB=BC-(0.1-0.5)CD*cot beta.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A Gasification Process Burner with Narrow Channel Jet Cooling

ActiveCN103881758BGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationCooling effectHigh pressure

The invention relates to a novel gasifying process nozzle with a function of spray cooling through narrow channels. The nozzle comprises a central gasifying agent channel, a fuel channel and an external gasifying agent channel which are coaxially and sequentially sleeved outside the central gasifying agent channel, and cooling water channels which are arranged between the central gasifying agent channel and the fuel channel, between the fuel channel of the external gasifying agent channel and outside the external gasifying agent channel, wherein each cooling water channel consists of a plurality of narrow channels. High pressure cooling water is increased in the narrow channels at a flow rate to enhance the cooling effect on the central gasifying agent channel, the fuel channel, the external gasifying agent channel and the metal wall of the water cooling channel by way of heat conduction and forced-convection heat transfer. High pressure cooling water is sprayed from the outlets of the narrow channels in form of high speed impact jet to spray and cool the outlets of the nozzle so as to effectively cool the outlets of the nozzle by way of forced-convection heat transfer and phase-change heat transfer. The nozzle provided by the invention overcomes the defect that a nozzle in the gasifying nozzle technology in the prior art is poor in cooling effect and short in service life.

Owner:XI AN JIAOTONG UNIV

Circulating fluidized bed boiler

ActiveCN101818894BImprove securityImprove stabilityFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

The invention discloses a circulating fluidized bed boiler, which belongs to the technical field of thermal power equipment. The circulating fluidized bed boiler consists of an v-shaped hearth, separators, tail flues, a water cooled wall, a middle membrane-type wall, a ribbed plate membrane-type wall, a U-shaped wall and headers, wherein the separators and the tail flues are symmetrically distributed on two sides of the hearth; the middle membrane-type wall divides the hearth into two completely symmetric parts to prevent a bed from titling; the upper part of the middle membrane-type wall is provided with a vent hole to maintain the pressure balance of the hearth; and the airflows in the U-shaped wall flow alternately to reduce the heat difference in the hearth. The circulating fluidized bed boiler avoids the bed tilting phenomenon in the v-shaped hearth of the circulating fluidized bed boiler, has the characteristics of uniform temperature distribution in the hearth and high safety and is a better circulating fluidized bed boiler which is particularly adaptable to the development trend of large circulating fluidized bed boilers.

Owner:TAIYUAN BOILER GROUP +1

Biomass circulating fluidized bed boiler

PendingCN111237746AGuaranteed to burnReduce thermal deviationFluidized bed combustionApparatus for fluidised bed combustionNitrogen oxidesBiomass

The invention relates to a biomass circulating fluidized bed boiler. The biomass circulating fluidized bed boiler comprises a hearth with a rectangular section and is characterized in that a water wall is arranged on the outer side wall of the hearth, and the water wall is arranged on the side wall of the hearth in a covering mode; an air supply air channel is fixedly installed on the hearth, theair supply air channel communicates with the interior of the hearth, and the air supply air channel comprises a primary air supply air channel and a second air supply air channel; and the second air supply air channel comprises a secondary air mother pipe, a first-stage air channel with an annular structure and a second-stage air channel with an annular structure, the first-stage air channel and the second-stage air channel are arranged on the side wall of the hearth in a covering mode, the first-stage air channel is located below the second-stage air channel, wherein the first-stage air channel and the second-stage air channel communicate with the secondary air mother pipe. According to the biomass circulating fluidized bed boiler, by additionally arranged the first-stage air channel andthe second-stage air channel, generation of nitrogen oxides during biomass burning is reduced, sufficient burning is promoted to reduce the accumulation of ashes, and a fly ash phenomenon is prevented.

Owner:山东永能节能环保服务股份有限公司

Multi-stage stratified combustion system and method for primary air and secondary air of boiler

ActiveCN103216821BRigid enoughWell mixedCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemThermodynamics

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

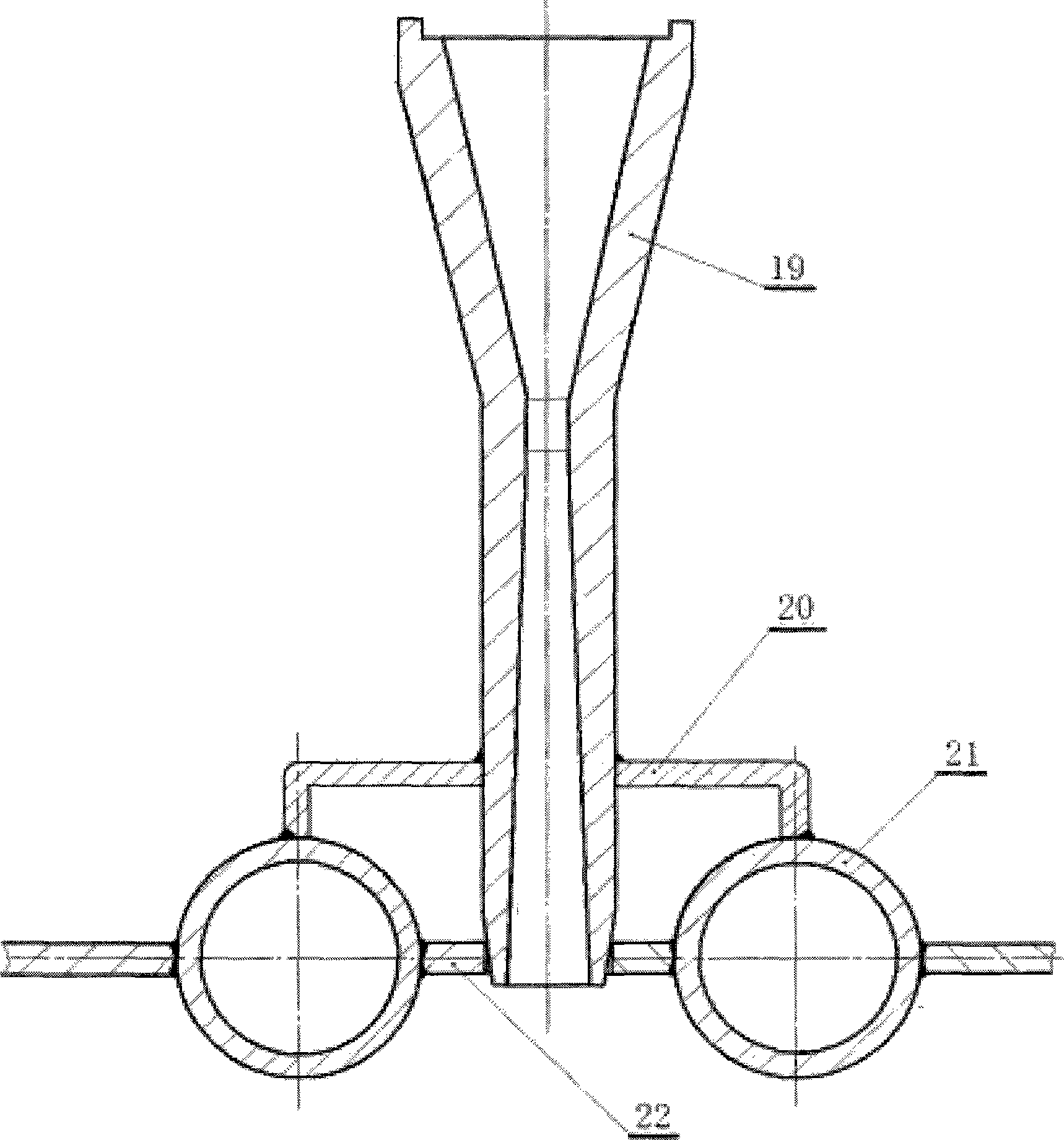

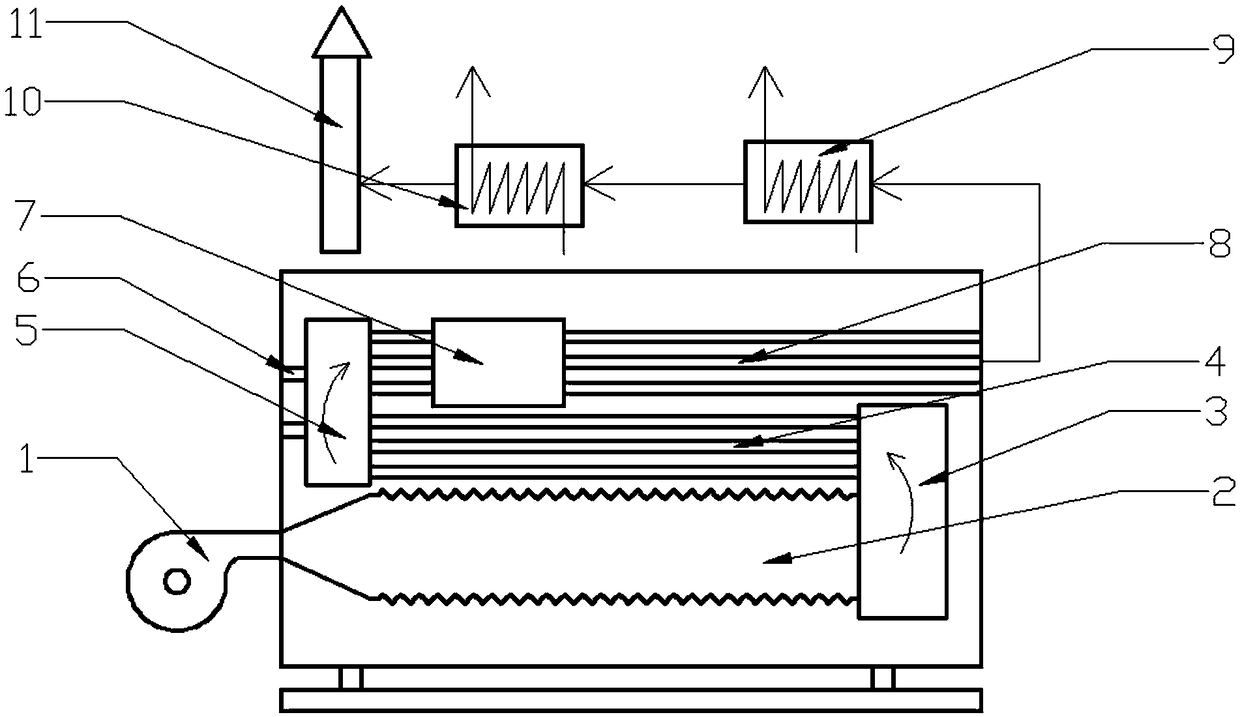

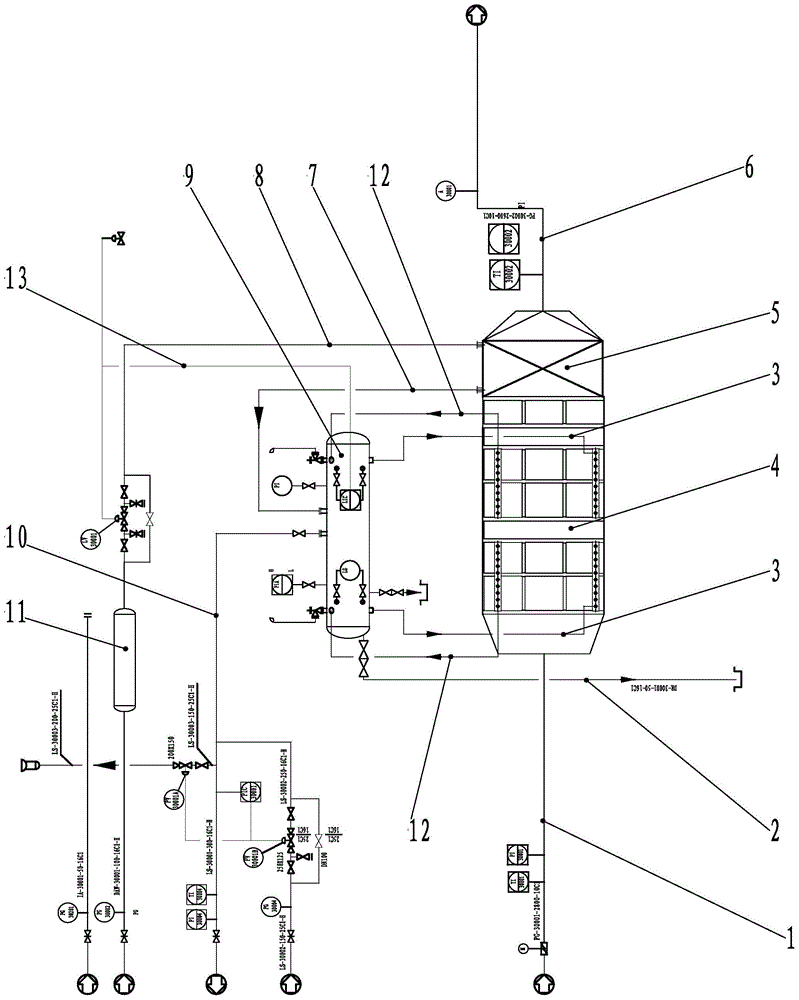

System for recovering waste heat of flue gas of coke oven

InactiveCN104061561AReduce thermal deviationImprove securityEnergy inputSteam boilersEngineeringSteam drum

The invention discloses a system for recovering waste heat of flue gas of a coke oven. The system comprises a waste heat boiler, a flue gas flowing line and a water heating circulation line, wherein the waste heat boiler comprises a boiler evaporator, a preheater and a boiler drum; the boiler evaporator and the preheater are arranged side by side; the boiler drum is arranged at the top part of the boiler evaporator; the flue gas flowing line consists of a flue gas inlet pipe and an exhaust pipe; the flue gas inlet pipe is connected with the boiler evaporator end of the waste heat boiler; the exhaust pipe is connected with the preheater end of the waste heat boiler; the water heating circulation line consists of a water inlet pipe, a preheating water pipe, down pipes, ascending pipes and a steam delivery pipe; the water inlet pipe and the preheating water pipe are communicated with the preheater and the boiler drum; the down pipes and the ascending pipes are communicated with the boiler evaporator and the boiler drum. According to the system, the high-temperature waste heat of the flue gas of the coke oven is fully utilized, and the waste heat boiler is introduced to recover the waste heat to generate steam; when the system is used for chemical production, not only is the energy saved but also pollution is reduced.

Owner:陕西龙门煤化工有限责任公司 +1

Method for arranging four separators of circulating fluidized bed boiler in parallel

PendingCN112413574AReduce non-uniformitySimple structureFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

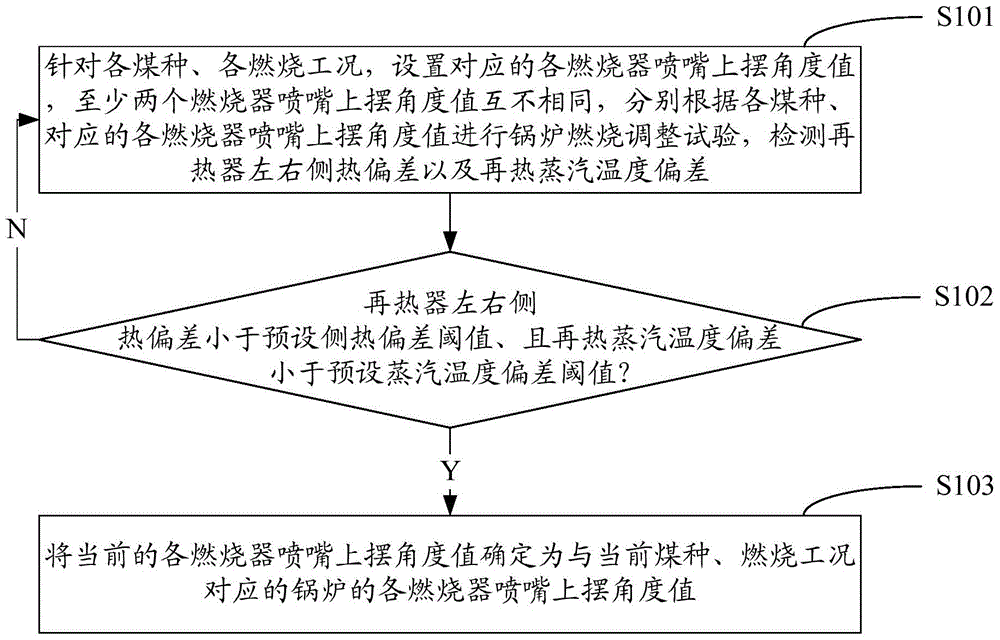

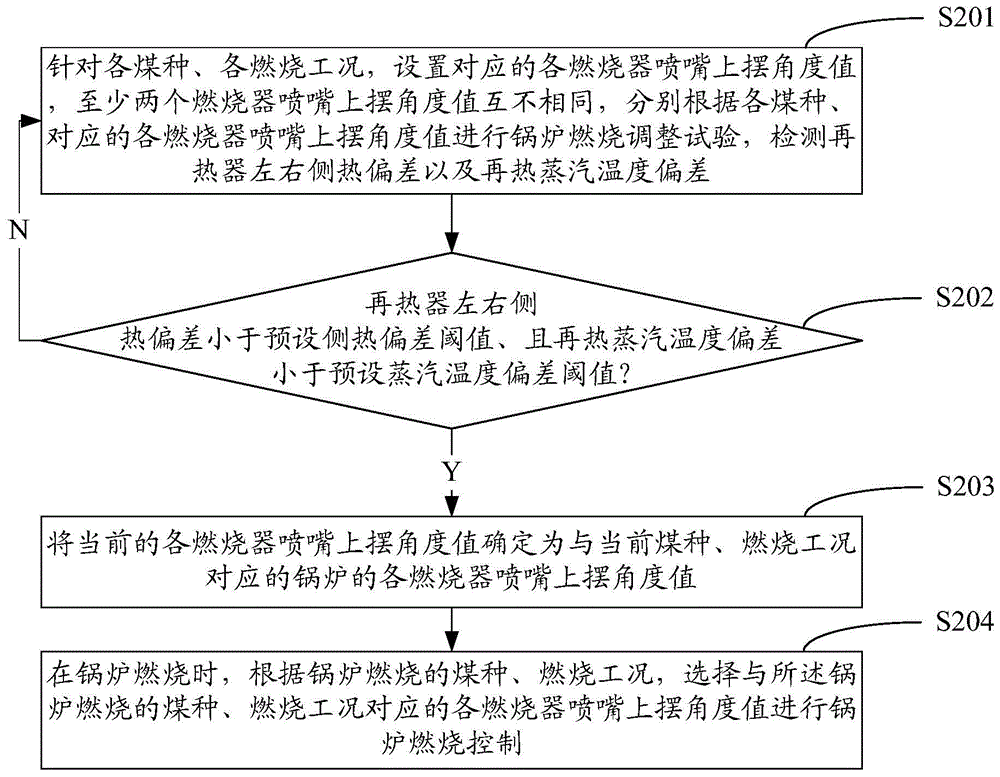

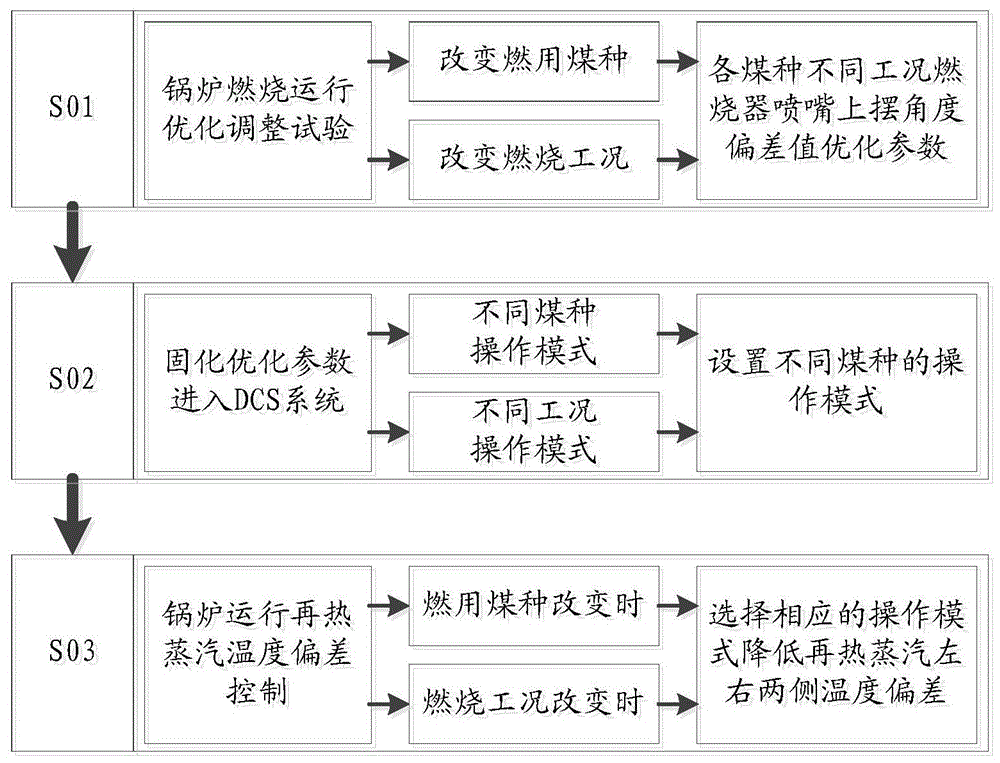

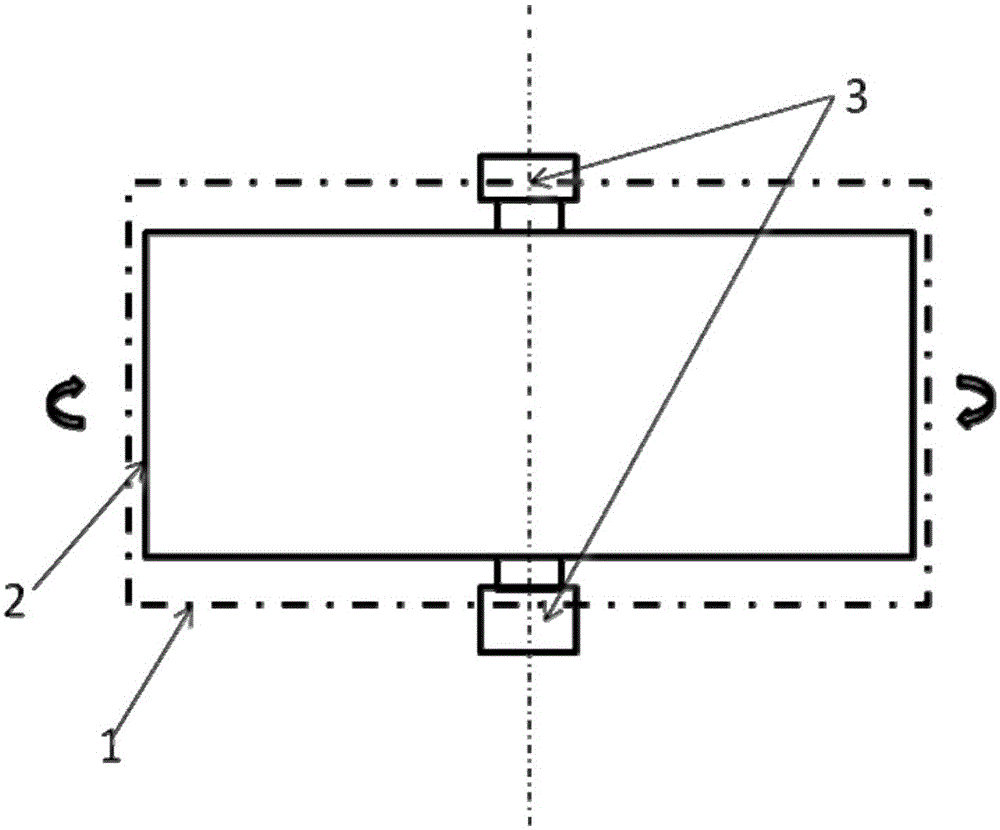

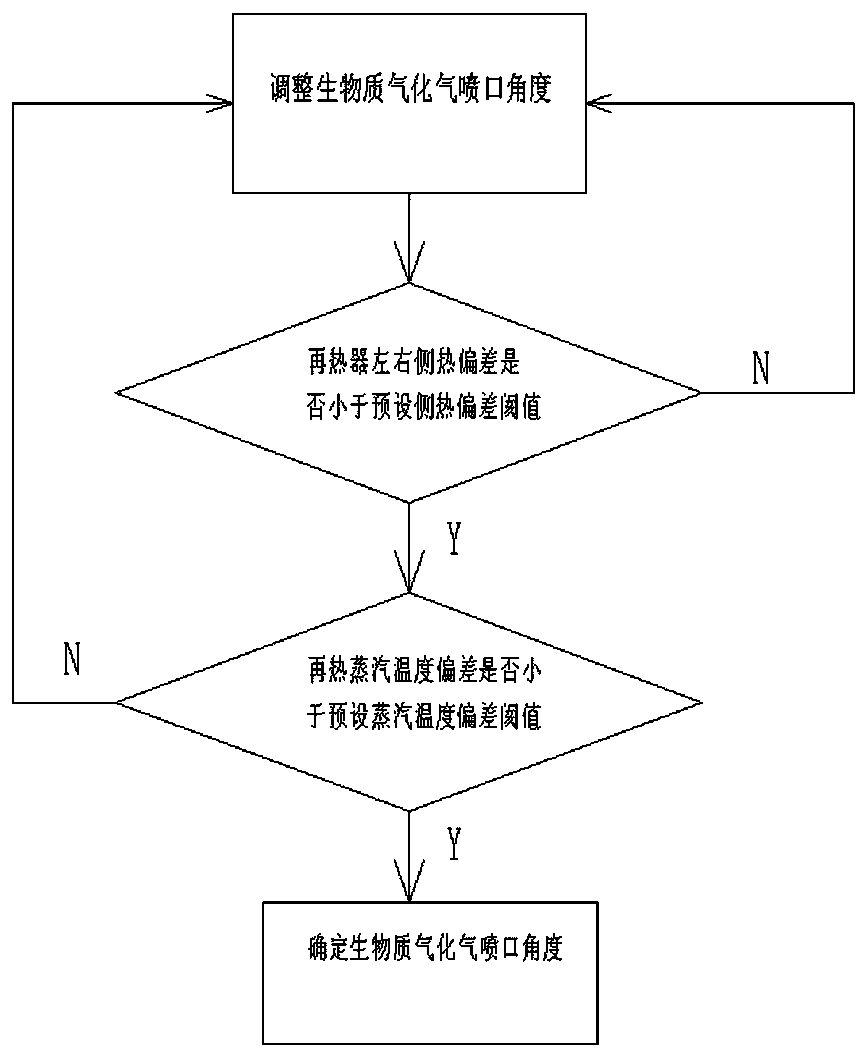

Determination method and combustion control method of upward swing angle value of burner nozzle of pulverized coal boiler

InactiveCN104214794BReduce thermal deviationReduce the temperatureCombustion regulationCombustorSpray nozzle

A pulverized-coal boiler burner nozzle up-swing angle value determination method and a pulverized-coal boiler combustion control method, the determination method includes: for each coal type and each combustion condition, respectively setting the corresponding burner nozzle up-swing angle value, At least two burner nozzle up-swing angle values are different from each other, and the boiler combustion adjustment test is carried out according to each coal type and the corresponding burner nozzle up-swing angle value, and the thermal deviation between the left and right sides of the reheater and the reheat steam temperature are detected Deviation; determine whether the heat deviation on the left and right sides of the reheater and the reheat steam temperature deviation are less than the preset side heat deviation threshold and the preset steam temperature deviation threshold respectively; if not, return to set the corresponding up-swing angle value of each burner nozzle; if , determine the current upward swing angle value of each burner nozzle as the upward swing angle value of each burner nozzle of the boiler corresponding to the current coal type and combustion working condition. The invention makes there be deviation values among the up-swing angle values, thereby improving the operation efficiency, economy and boiler operation safety of the unit.

Owner:ZHUHAI POWER STATION OF GUANGDONG YUDEAN GRP

Rotary air preheater with hierarchical reverse rotation

InactiveCN105020736AReduce biasReduce thermal deviationCombustion processIndirect carbon-dioxide mitigationFlueBoiler efficiency

The invention provides a rotary air preheater with hierarchical reverse rotation, relating to equipment of heating cold air by using low temperature hot gas. The rotary air preheater comprises a shell, at least two stages of rotors, a bearing, a gas channel and an air channel. The multiple stages of rotors are arranged in series. A reverse transmission device is arranged between the rotation shafts of two adjacent stages of rotors, the rotation directions of two adjacent stages of rotors are opposite, radial sealing pieces are arranged at the junctions of adjacent channels between the two adjacent stages of rotors, and circumferential sealing pieces are arranged at rotor and shell gaps between the two adjacent stages of rotors. Through different rotation directions of front and back stages of rotors, a rotor hot storage piece which is cooled by air is alternatively heated by two side gas in an air preheater channel, the deviation of boiler flue gas discharge temperature is reduced, thus the early entering of a part of gas in the air preheater channel into a dew point area is avoided, the problems of cold end heat storage piece condensation, dust touch, corrosion, clogging and the like are reduced, the boiler gas discharge temperature is reduced, and the boiler efficiency is improved.

Owner:TSINGHUA UNIV +2

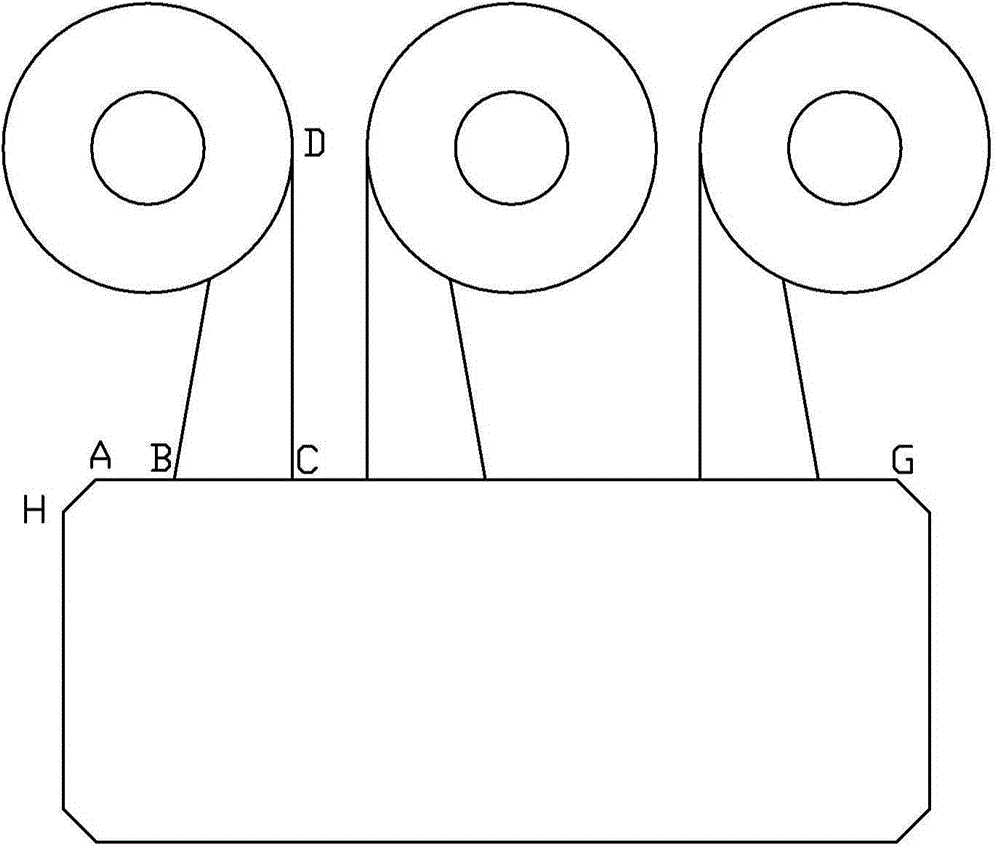

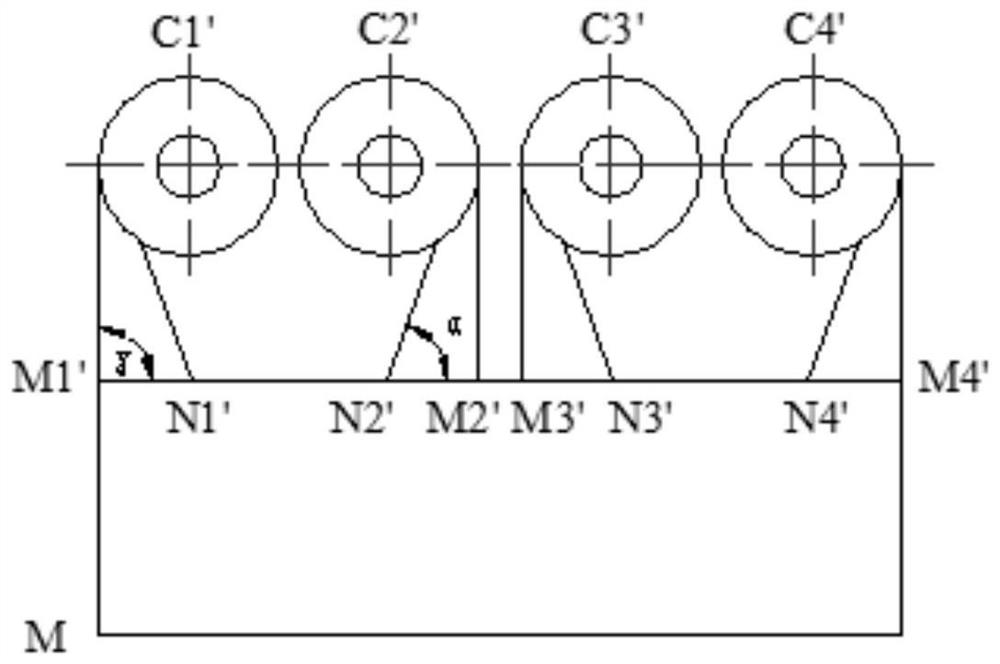

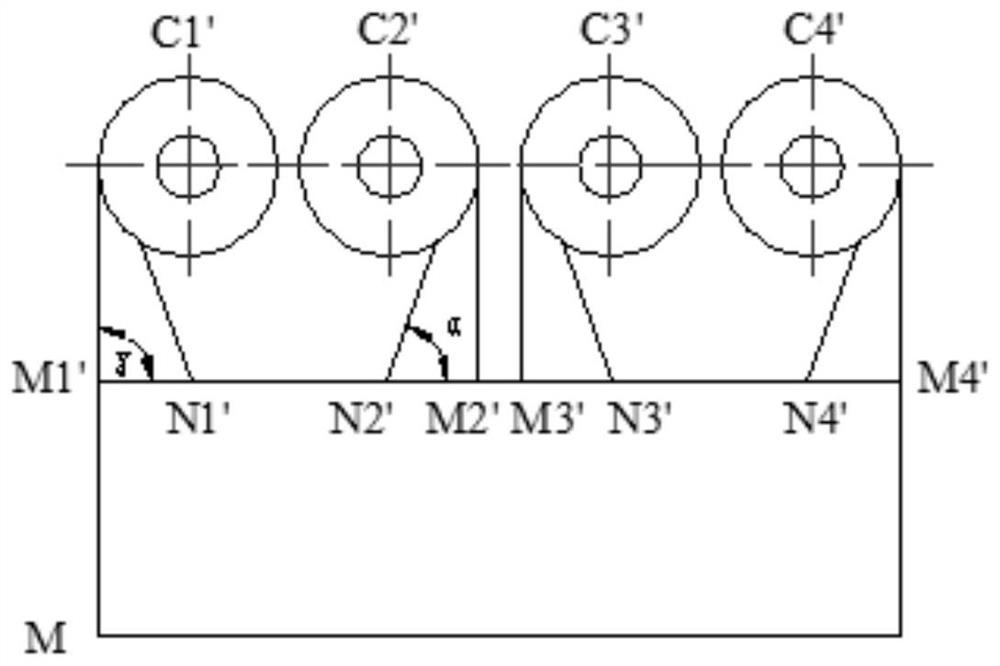

Circulating fluidized bed boiler with four separators arranged in parallel and arrangement method thereof

PendingCN111911918AReduce non-uniformitySimple structureFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

The invention discloses a circulating fluidized bed boiler with four separators arranged in parallel. The circulating fluidized bed boiler comprises a hearth and four cyclone separators. The hearth comprises a front wall, a rear wall, a left side wall and a right side wall. The cross section of the hearth is symmetrical about the hearth front-rear wall center line and the hearth left-right side wall center line. Each of the four cyclone separators is composed of an inlet flue and a barrel. The four cyclone separators are arranged on the rear wall of the hearth in parallel. The lengths of intersecting lines of the inlet flues of the four cyclone separators and the rear wall of the hearth are equal. The invention further discloses an arrangement method of the separators in the circulating fluidized bed boiler. The circulating fluidized bed boiler with the four separators arranged in parallel and the arrangement method thereof have the beneficial effects that through the four cyclone separators being arranged on the single side of the boiler in parallel, a hearth of a conventional large circulating fluidized bed boiler is simplified into four circulating loops, the system structure and running operation are simplified, and the uniformity of the circulating loops is improved. Due to the arrangement of the inlet flue of each cyclone separator, the flow distribution of smoke and particles is more uniform, and the consistency of the performance of each cyclone separator is ensured.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A new gasification process burner with jet impingement cooling

ActiveCN103937553BGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationJet flowInlet channel

The invention discloses a novel jet impingement cooling gasification technology burner. The novel jet impingement cooling gasification technology burner comprises a central gasifying agent channel, fuel channels, outer gasifying agent channels, and cooling water channels; the central gasifying agent channel is coaxially sieved by the fuel channels and the outer gasifying agent channels successively; the cooling water channels are arranged between the central gasifying agent channel and the fuel channels, between the fuel channels and the outer gasifying agent channels, and on the outsides of the outer gasifying agent channels; the cooling water channels are composed of water inlet channels and water return channels; cooling water uniform distribution devices are arranged in the water inlet channels; the water inlet channels and the water return channels are communicated via a plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels; high pressure cooling water is delivered into the water inlet channels, and then the walls of the water return channels are impinged by the high pressure cooling water through the plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels in a jet flow manner, so that high efficient cooling of the walls of the water return channels is realized; and then the high pressure cooling water is delivered to water outlets of the cooling water channels via the water return channels. The novel jet impingement cooling gasification technology burner is capable of solving problems of existing gasification technology burners that cooling effect is poor, and service life is relatively short.

Owner:XI AN JIAOTONG UNIV

Combustion adjustment method of a supercritical boiler mixed with coke oven gas

ActiveCN104713064BReduce air volumeReduce smoke temperature deviationAir supply regulationSteam generationSupercritical steam generatorCombustion

The invention discloses a combustion adjustment method for a supercritical boiler capable of performing blending combustion of coke oven gas. The device comprises a supercritical boiler capable of performing blending combustion of coke oven gas. The combustion adjustment method comprises the following steps: adopting nonlinear normal pagoda type air door air distribution openings by virtue of an eight-layer secondary air door, sequentially reducing the air door opening upwards, allowing the air door opening of a burnout air door at a diagonal part to be smaller than the air door opening at another diagonal part, and feeding two layers of secondary air at least by virtue of a gas gun by adopting a normal pagoda type air distribution mode. The normal pagoda type air door distribution opening of the secondary air door and different air door openings at two diagonal parts of the burnout air door are adopted, and multilayer air is fed by virtue of the gas gun, so that the fume temperature deviation at the hearth outlet can be effectively reduced, and the detonation accidents of the boiler are reduced. Moreover, according to stable combustion in a fuel enriched area on the middle lower part of the hearth and feeding of the gas gun, the NOx generation amount is greatly reduced, the boiler operates in a high-efficiency economic performance area, the comprehensive operating cost is reduced, and the adjustment method is simple.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

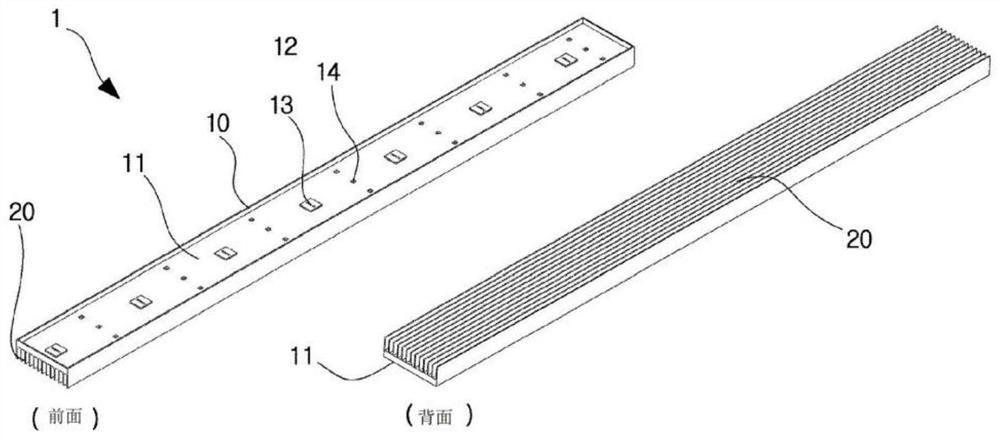

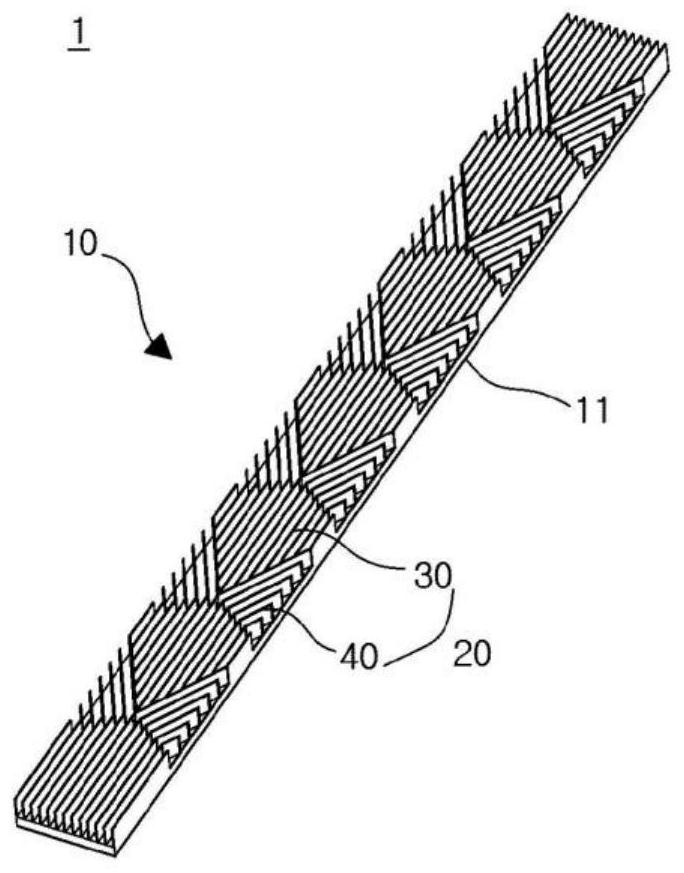

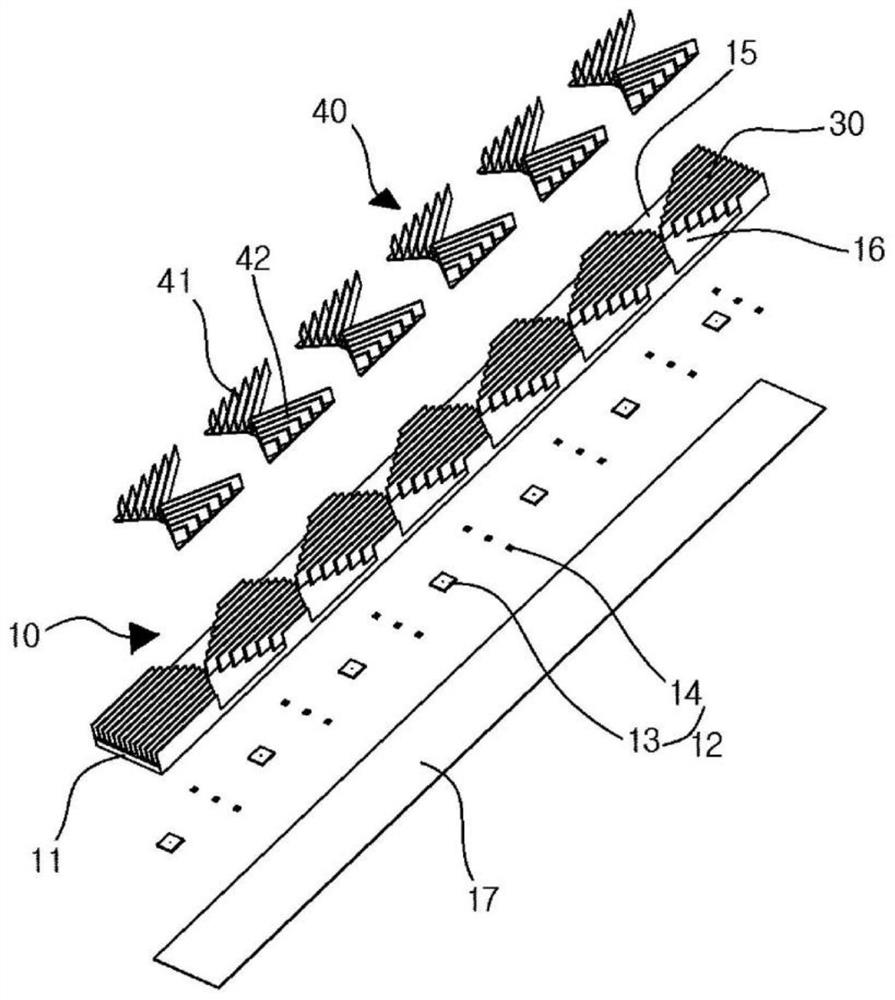

Heat-radiating mechanism for antenna device

PendingCN112602232AReduce thermal deviationImprove cooling effectAntenna equipments with additional functionsDe-icing/drying-out arrangementsMechanical engineeringPhysics

The present invention relates to a heat-radiating mechanism for an antenna device. Particularly, the heat-radiating mechanism comprises multiple communication elements for generating predetermined heat during electrically operating; a heat-radiating combined case having one surface on which the multiple communication elements are placed and the other surface on which multiple heat-radiating ribs are integrally formed; and an antenna board on which the multiple communication elements placed on the one surface of the heat-radiating combined case are mounted, wherein the multiple heat-radiating ribs are formed such that an ascending air current formed by heat relatively radiated from a lower portion of the heat-radiating combined case is discharged slantly upward and toward the left and rightof the width direction of the heat-radiating combined case in a relative upper portion thereof. Therefore, the heat-radiating mechanism provides an advantage of improving a heat-radiating performanceof the antenna device.

Owner:KMW INC

W flame boiler adopting circulating flue gas type slit-type direct-flow pulverized coal burners

ActiveCN113324242AEmission reductionAdjustable air volumeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSlag

The invention discloses a W flame boiler adopting circulating flue gas type slit-type direct-flow pulverized coal burners, and relates to the technical field of boiler combustion. The W flame boiler solves the problems that an existing W flame boiler is high in NOx emission concentration, poor in combustion stability, high in fly ash combustible matter content, overtemperature of a water cooling wall of a lower hearth, large in wall temperature deviation and slag bonding. According to the W flame boiler, the plurality of direct-flow pulverized coal burners are symmetrically arranged on a front arch and a rear arch with the center line of a hearth as the center, thin pulverized coal airflow nozzles are arranged on the sides close to the water cooling walls, main circulating flue gas nozzles are arranged on the sides, close to the center lines of the direct-flow pulverized coal burners, of thick pulverized coal airflow nozzles and the thin pulverized coal airflow nozzles, secondary air nozzles are arranged on the sides, away from the center lines of the direct-flow pulverized coal burners, of the thick pulverized coal airflow nozzles and the thin pulverized coal airflow nozzles, and outer circulating flue gas nozzles are arranged on the sides, close to the water cooling walls in the width direction of the hearth. The W flame boiler is used for reducing NOx emission of a hearth outlet, enhancing stable combustion and burnout of pulverized coal, reducing overtemperature and thermal deviation of the water cooling walls of the front wall and the rear wall of the lower hearth, and preventing slag bonding of the water cooling walls.

Owner:HARBIN INST OF TECH

Rapid production method of bow-shaped water tube boiler

InactiveCN107906510APrevent precipitationInhibition of precipitated N conversionCombustion using gaseous and pulverulent fuelGaseous fuel feeder/distributionEngineeringOperation safety

The invention discloses a rapid production method of a bow-shaped water tube boiler. The rapid production method of the bow-shaped water tube boiler comprises the following steps that angles of biomass gasification gas nozzles are determined, aiming at all fuel, all combustion working conditions, the corresponding upward-swing angle values of the biomass gasification gas nozzles are set, the upward-swing angle values of at least two biomass gasification gas nozzles are different of each other, a boiler combustion adjusting test is conducted according to all the fuels and the corresponding upward-swing angle values of all the biomass gasification gas nozzles, and the thermal deviation of the left side and the right side of a reheater and the temperature deviation of reheat steam are detected. According to the rapid production method of the bow-shaped water tube boiler, the thermal deviation of the left side and the right side of the reheater of the pulverized coal boiler and the temperature deviation of the steam of the reheater can be effectively reduced, the average temperature of the reheat steam is improved, the operation efficiency and economy of a unit are improved, meanwhile,local metal over-temperature of the reheater is prevented, the frequency of boiler tube bursting is reduced, and the operation safety of the boiler is improved.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

Annular furnace circulating fluidized bed boiler with multiple separators

ActiveCN106196025BUniform distribution of gas-solid flowImprove separation efficiencyFluidized bed combustionApparatus for fluidised bed combustionCycloneFlue gas

A circulating fluidized bed boiler with an annular furnace, comprising: a furnace; two sets of cyclone separators, respectively arranged on the outside of two side walls, each set of cyclone separators has three cyclone separators, the cylinder structure of each cyclone separator and The dimensions are all the same, where: in the plane across the center points of all furnace flue gas outlets, the center points of the furnace flue gas outlets of the two outermost separators of one set of separators are the same as the outermost two separators of the other set of separators The center point of the furnace flue gas outlet of the two separators is symmetrical about the intersection point of the furnace center plane perpendicular to the first side wall and the furnace center plane perpendicular to the second side wall; the outermost two of each set of cyclone separators The center point of the furnace flue gas outlet of each separator is axisymmetric to the furnace center line formed by the intersection line between the furnace center plane perpendicular to the first side wall and the plane; and the two outermost cyclone separators of each set of cyclone separators The positional relationship of the location satisfies: when b≤2m, b / 3≤a<b-0.3m; when b>2m, m / 2≤a<b-0.3m.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

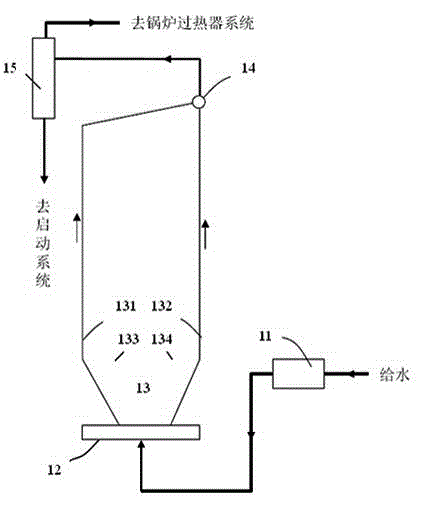

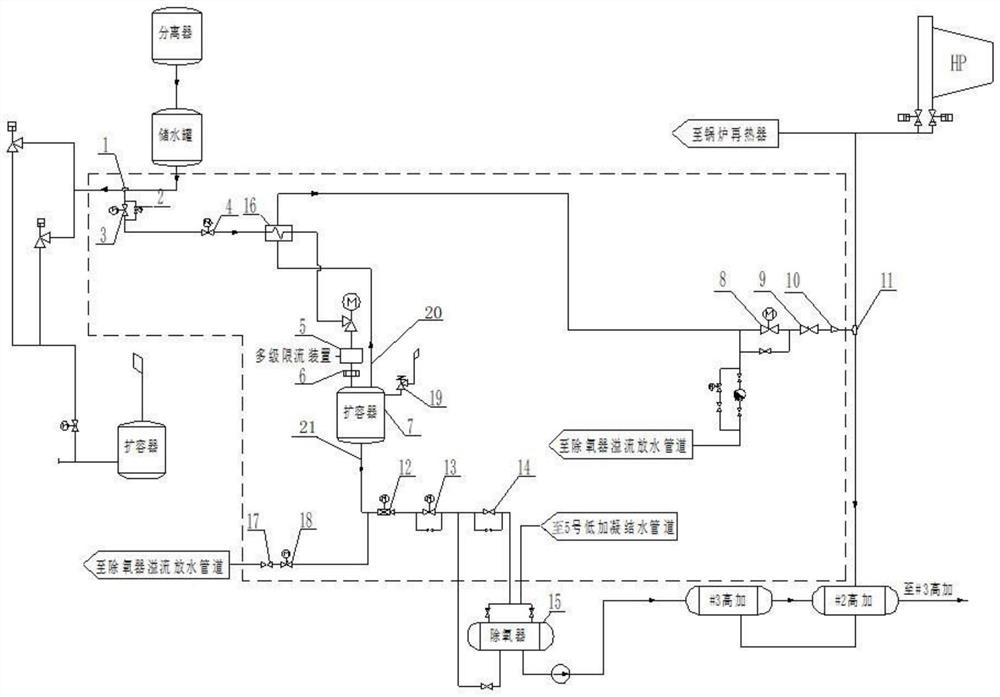

Deep peak regulation dry and wet state switching system for supercritical boiler

InactiveCN114321871AAchieve continuous operationImprove the ability of deep peak shavingLiquid degasificationBoiler cleaning apparatusSupercritical steam generatorThermodynamics

The invention discloses a deep peak regulation dry and wet state switching system for a supercritical boiler, which comprises a multi-stage flow limiting device and a flash tank, after the supercritical boiler is switched to a wet state, high-temperature saturated water flows through the multi-stage flow limiting device through a pipeline for pressure reduction, and then enters the flash tank; expansion steam generated after expansion evaporation in the flash tank is divided into two paths, namely a first pipeline and a second pipeline, and the expansion steam in the first pipeline is drained to a steam inlet pipeline of a second high-pressure heater through a pipeline so as to replace part of extracted steam of the second high-pressure heater to heat feed water. The method is suitable for the supercritical boiler without a boiler water circulating pump to be converted from a dry state to a wet state for operation, and full recovery of working media and heat after the supercritical boiler is converted into the wet state for operation and continuous operation after deep peak regulation is converted into the wet state are achieved.

Owner:GUODIAN SCI & TECH RES INST

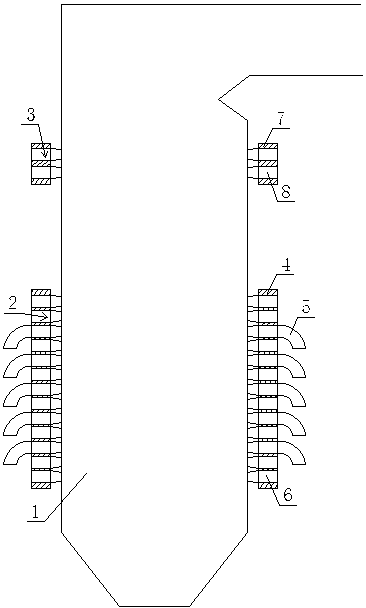

An air distribution device for a circulating fluidized bed boiler

ActiveCN103335305BReduce thermal deviationFluidized bed combustionApparatus for fluidised bed combustionWear resistantFluidized bed

The invention discloses an air distribution device of a circulating fluidized bed boiler. The air distribution device comprises a front water wall panel, a back water wall panel, a left side wall and a right side wall, a plurality of wind cowl devices and a lower header. The front water wall panel comprises a curved front upper panel part, a horizontal panel part, a back middle panel part, and an inclined back lower panel part; the back water wall panel comprises a curved back upper panel part, a horizontal panel part, a front middle panel part, and an inclined front lower panel part. The pipes of the horizontal panel parts of the front and the back water panels are staggered with each, and are coated with fire-resistant and wear-resistant layers; the front middle panel part and the back middle panel part, and the inclined front lower panel part and the inclined back lower panel part are symmetrically arranged respectively, and are coated with the fire-resistant and wear-resistant layers; the ends of the inclined front and the inclined back lower panel part are both connected with the lower header; the plurality of wind cowl devices are arranged on a air distribution plate. The air distribution device is capable of decreasing thermal deviation and hydrodynamic deviation of the front and the back water wall panels, and providing technical support for a development of circulating fluidized bed boilers with high-capacity and high parameters.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com