Supercritical circulating fluidized bed boiler with double-return evaporating heating surface

A technology of evaporating heating surfaces and circulating fluidized beds, which is applied in steam boilers, steam superheating, steam generation, etc., can solve the problems of increased cost, long pipelines, and high difficulty in system structure layout, so as to reduce boiler costs, reduce heating area, The effect of increasing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

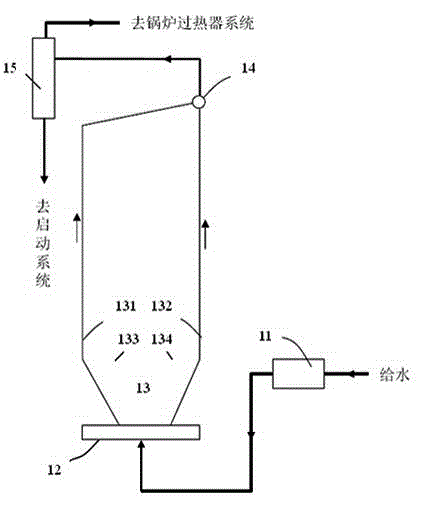

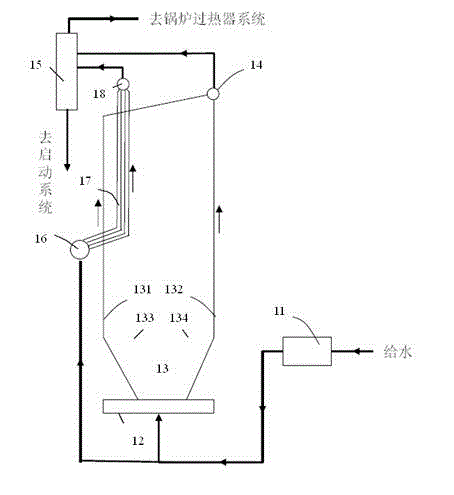

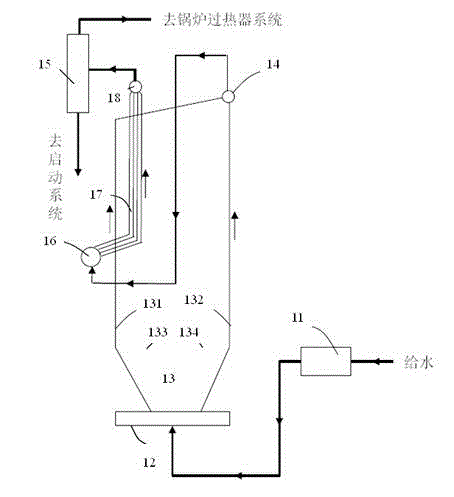

[0030] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0031] The present invention describes a supercritical circulating fluidized bed boiler with a double-pass evaporation heating surface, the structure of which is as follows Figure 4 As shown, the boiler includes an economizer 21, a furnace water-cooled wall inlet header 22, a furnace 23, a furnace water-cooled wall outlet header 24, a steam-water separator 25, a descending section water-cooled screen inlet header 26, a descending section water-cooled screen 27, The water cooling screen is connected to the header box, the water cooling screen 29 of the ascending section and the outlet header 30 of the water cooling screen of the ascending section.

[0032]The input port of the economizer 21 inputs working medium water through a pipeline, and its output port is connected with the inlet header 22 of the furnace water wall through a pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com