Multi-stage stratified combustion system and method for primary air and secondary air of boiler

A layered combustion and secondary air technology, applied in the direction of combustion method, use of multiple fuels, combustion types, etc., can solve the problems of high-temperature corrosion of water-cooled walls, increase the amount of desuperheating water, and large rotational momentum, etc., to prevent knots Slag and high temperature corrosion, improve combustion efficiency, reduce the effect of thermal deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

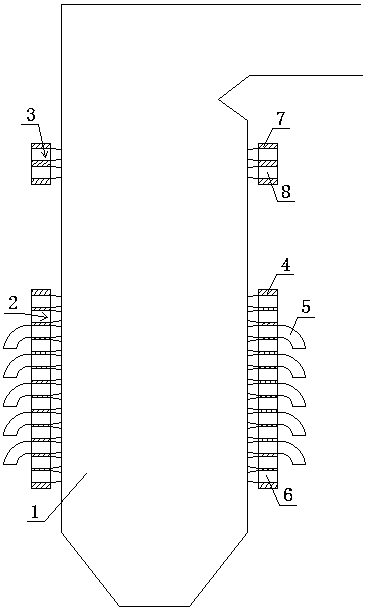

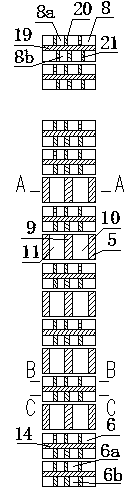

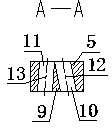

[0032] Such as Figure 1 to Figure 7 As shown, the boiler primary and secondary air multi-level layered combustion system includes four burners 2 arranged at the four corners of the lower part of the furnace 1, four exhaust air devices 3 arranged at the upper four corners of the furnace 1, the burners 2 and The overburning air device 3 is arranged in a tangential circle at four corners, and each burner 2 includes a secondary air box 4, five primary air ducts 5 vertically arranged in the secondary air box 4, and eight main secondary air nozzles 6, two Two main secondary air nozzles are arranged below the lowermost primary air duct, a main secondary air nozzle 6 is arranged between two adjacent primary air ducts 5, and two main secondary air nozzles 6 are located at the top. The two main secondary air nozzles 6 at the bottom can hold the falling unburned coal powder, so that the combustion can be carried out fully; the primary air duct 5 is provided with a vertical partition 9, ...

Embodiment 2

[0036] Such as Figure 8 to Figure 14 As shown, the difference of the combustion system between this embodiment and the first embodiment is: 1) the angle between the axis 33 of the light primary air nozzle in the primary air duct 5 and the diagonal line of the furnace is changed to 2°, and the angle between the thick primary air nozzle The axis 32 and the light primary air spout axis 33 included angles are changed to 10°; the main secondary air spout 6 is provided with a vertical partition 24, and the main secondary air spout 6 is divided into horizontally arranged secondary direct blowing spouts 6c and The secondary deflected air nozzle 6d, the secondary direct blowing nozzle 6c and the secondary deflected wind nozzle 6d are provided with several transverse deflectors 26, and the angle between the axis 35 of the secondary direct blowing nozzle and the diagonal line of the furnace is thinner than that of the primary The angle between the air nozzle axis 33 and the furnace diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com