Circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, applied in the field of thermal equipment, can solve problems such as safety hazards, circulating fluidized bed boiler hazards, economic losses, etc., and achieve the effects of improving safety, increasing strength, and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

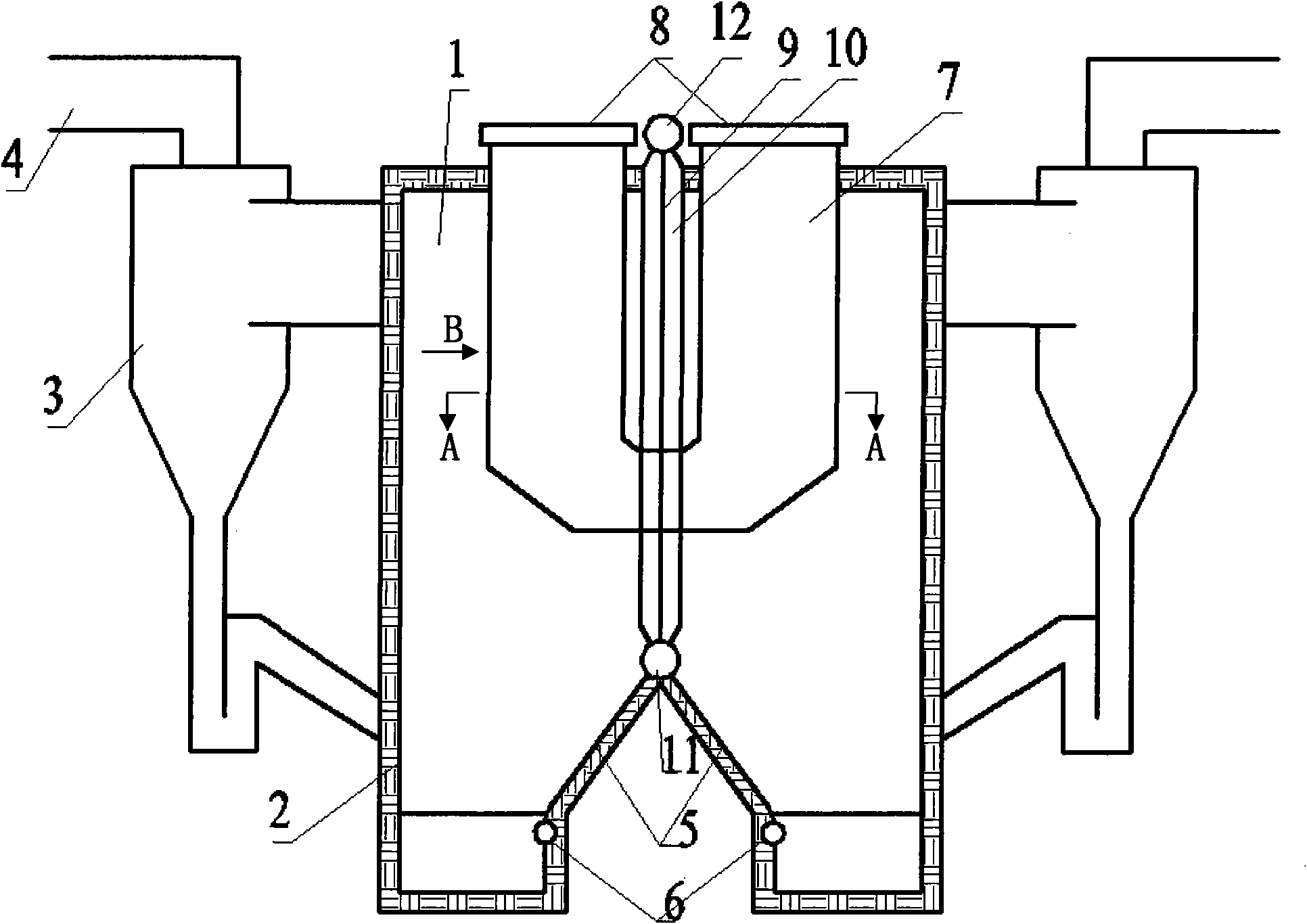

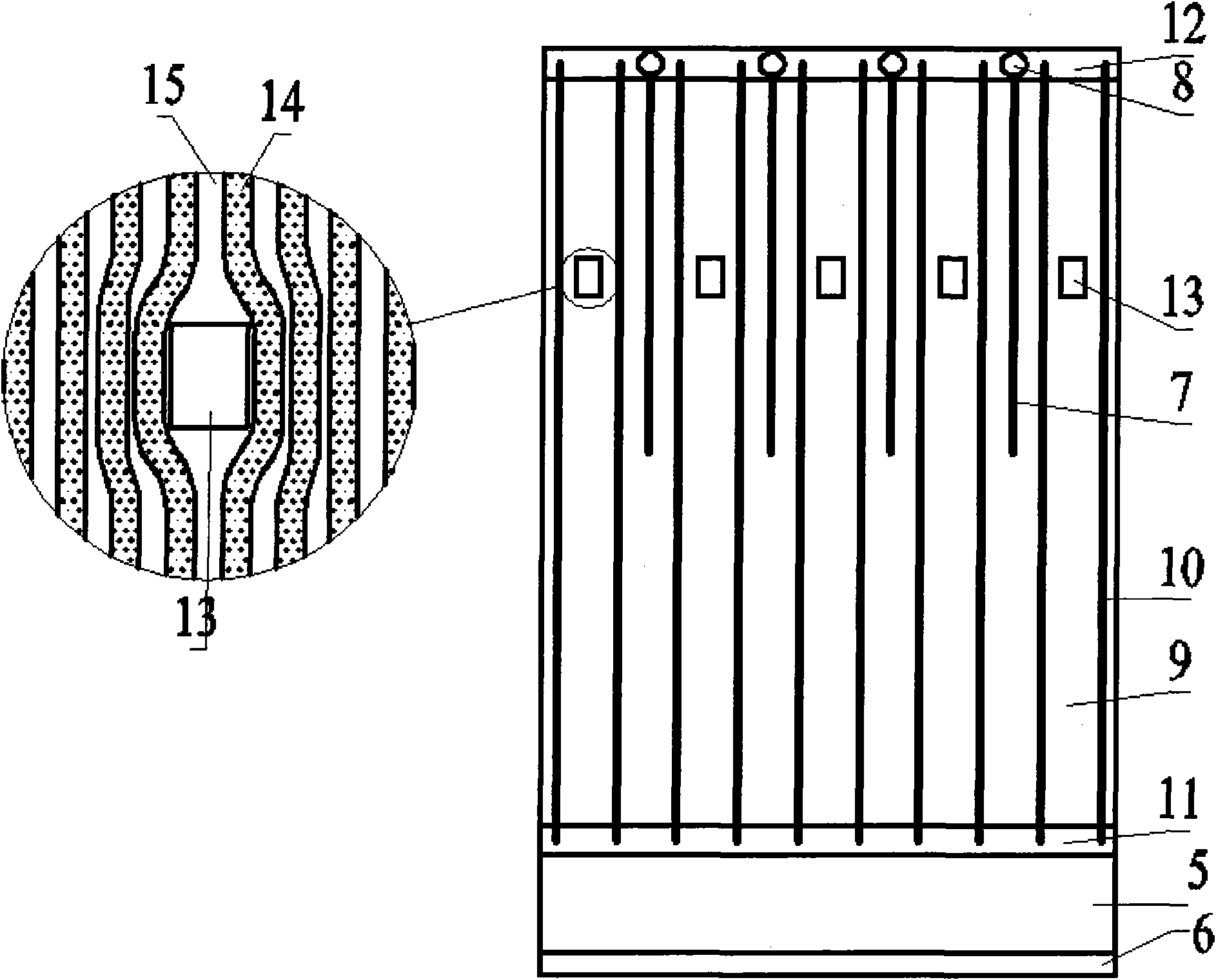

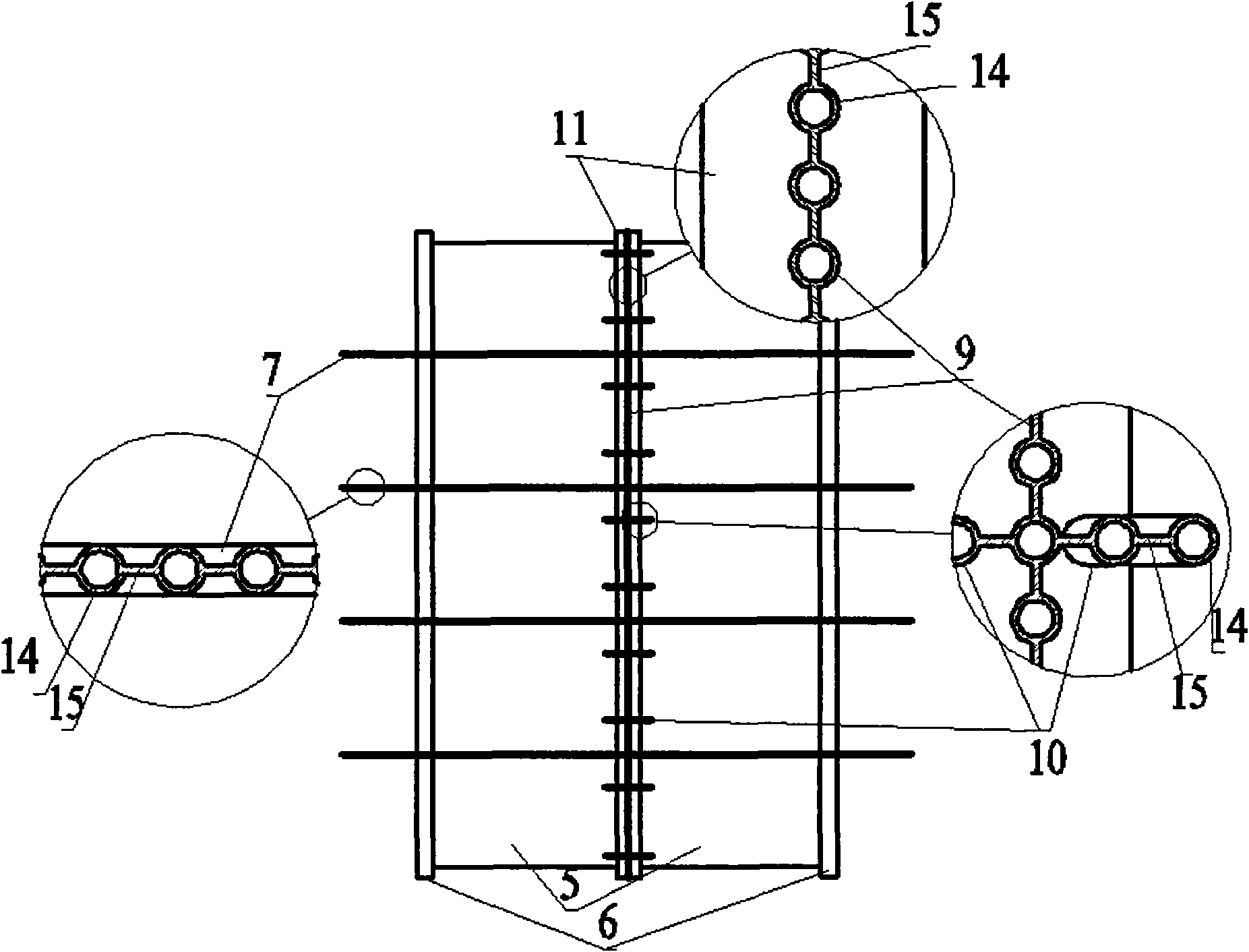

[0016] figure 1 It is a schematic diagram of the overall structure of the circulating fluidized bed boiler provided by the present invention. The boiler includes a symmetrically arranged pant-leg furnace 1, a water-cooled wall 2 in the furnace, a separator 3 symmetrically distributed on both sides of the furnace, a tail flue 4, two air chambers at the bottom of the furnace, and two air chambers respectively. Header 6. The circulating fluidized bed boiler is provided with a header 11 at the fork at the bottom of the furnace. A group of intermediate membrane walls 9 are sent upward, and the intermediate membrane walls are connected to the furnace top header 12 outside the furnace, and the furnace is divided into two completely symmetrical parts. It is close to but not welded, and can be freely expanded and contra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com