Octagonal hearth circulating fluidized bed boiler with multiple separators

A circulating fluidized bed, octagonal technology, applied in the field of large circulating fluidized bed boilers, can solve problems such as the influence of cyclone separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

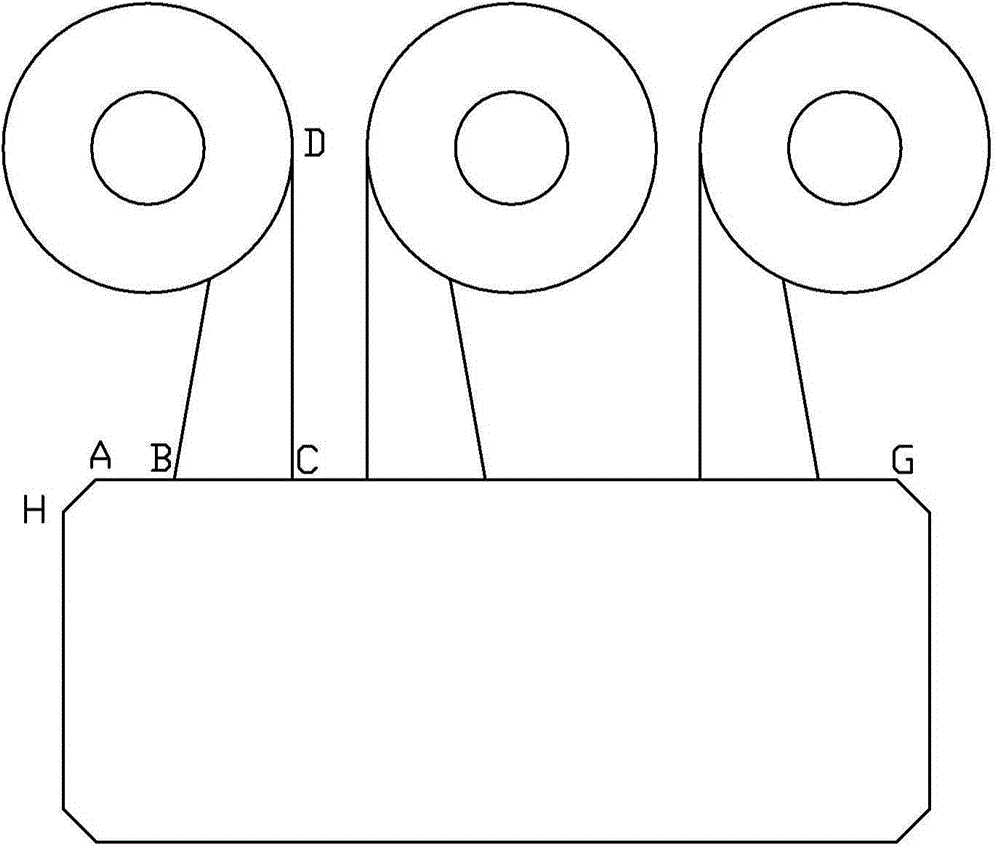

[0043] Such as figure 2 Shown is an octagonal furnace circulating fluidized bed boiler with multi-cyclone separators of the present invention.

[0044] The cross-section of the furnace is octagonal, with eight side walls, which are the front wall, rear wall, left side wall, and right side wall of the furnace, and four membrane-type water-cooled walls that cut corners with these four side walls. The cross-section of the furnace is axisymmetric about the line connecting the center points of the front and rear walls of the furnace and the line connecting the center points of the left and right side walls of the furnace.

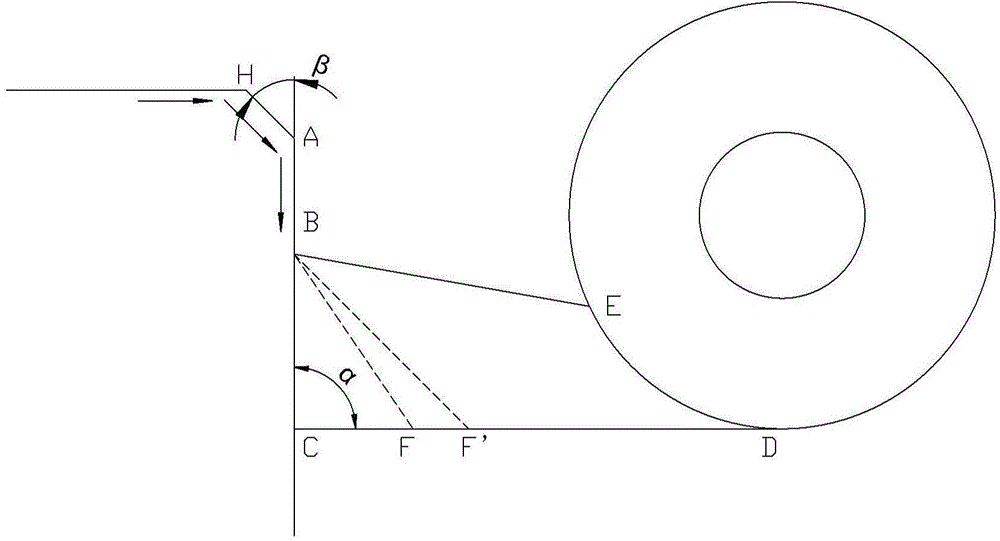

[0045] One group and three cyclone separators are arranged on the rear wall AG of the furnace. The two cyclone separators located on the outside are arranged inwardly, and the tangential side is perpendicular to the rear wall of the furnace, that is, the angle α between the tangential side of the separator inlet flue and the rear wall of the furnace is 90°. A...

Embodiment 2

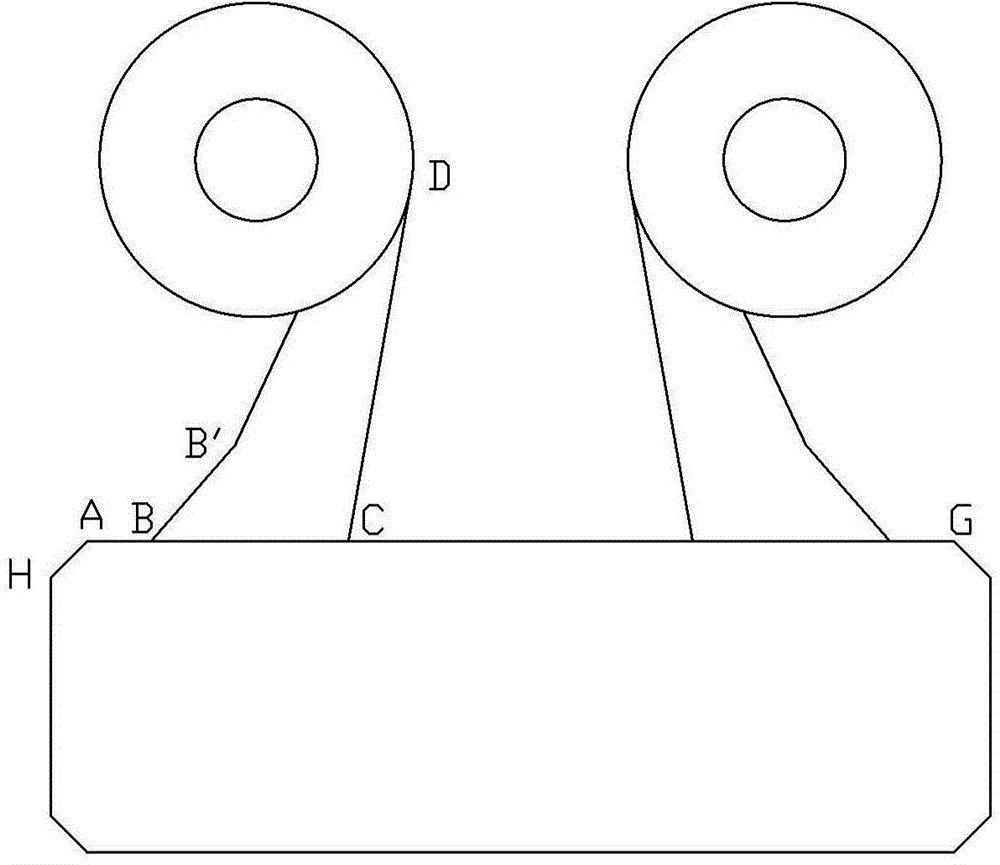

[0048] Such as image 3 Shown is an octagonal furnace circulating fluidized bed boiler with multi-cyclone separators of the present invention. The cross-section of the furnace is octagonal, with eight side walls, which are the front wall, rear wall, left side wall, and right side wall of the furnace, and four membrane-type water-cooled walls that cut corners with these four side walls. The cross-section of the furnace is axisymmetric about the line connecting the center points of the front and rear walls of the furnace and the line connecting the center points of the left and right side walls of the furnace.

[0049] One set and two cyclone separators are arranged on the rear wall AG of the furnace. The two cyclone separators are arranged inwardly, and the tangential edge of the inlet flue of the separator forms an angle of 110° with the rear wall of the furnace. The inlet flue of the separator has a flaring section BB', that is, the hypotenuse of the inlet flue of the separ...

Embodiment 3

[0052] Such as Figure 4 Shown is an octagonal furnace circulating fluidized bed boiler with multi-cyclone separators of the present invention. Two groups, each group of three cyclone separators are arranged on the left wall and the right wall of the furnace. Each set of outermost cyclone separators is inscribed, the distance between the hypotenuse of the inlet flue and the cut angle AH is AB, and the inner wall of the tangential side of the separator forms an angle of 100° with the left and right side walls of the furnace. The inlet section of the inlet flue of the separator has a flared section BB'. The cross-sections of the inlet flues of the two cyclone separators outside each group are axisymmetric with respect to the center line of the furnace, which is the line connecting the center points of the left and right walls of the furnace.

[0053] The distance between the hypotenuse of the inlet flue of each group of outer two separators and the cut angle AH is AB, the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com