Method for arranging four separators of circulating fluidized bed boiler in parallel

A technology of circulating fluidized bed and four separators, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc., can solve the problem of uneven gas-solid flow and difficulty in uniformity of gas-solid flow in the four circulation loops Guarantee, large deviation between bed temperature and steam temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

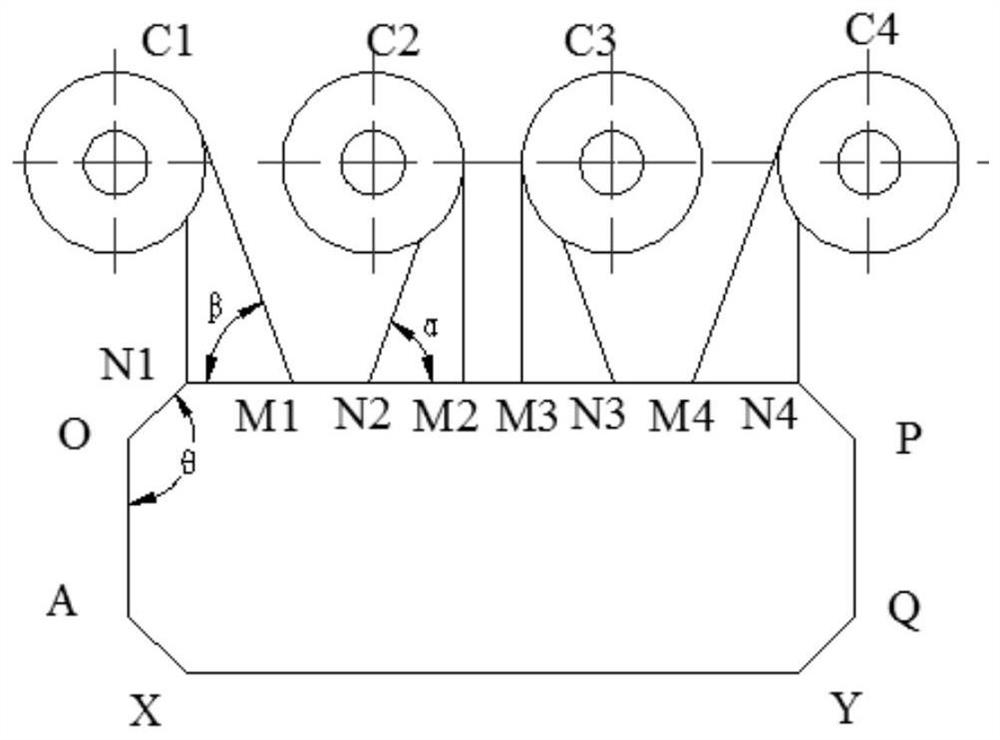

[0073] like figure 1 As shown, a circulating fluidized bed boiler with four separators arranged side by side, including:

[0074] Furnace, the cross-section of the furnace is octagonal, consisting of a front wall, a rear wall, a left wall, a right wall and four cut-cornea walls. The cross-section of the furnace is axisymmetric about these two center lines; the left wall of the furnace OA, the right wall PQ, the left rear cut angle ON1 and the right rear cut angle PN4, the left front cut angle AX and the right front cut angle YQ are about the front and rear walls of the furnace The center line of the vertical furnace section is axisymmetric;

[0075] Four cyclone separators, including the first cyclone separator C1, the second cyclone separator C2, the third cyclone separator C3 and the fourth cyclone separator C4, are arranged side by side on the furnace rear wall N1N4 in sequence.

[0076] Among them, the four cyclone separators are all composed of inlet flue and cylinder, ...

Embodiment 2

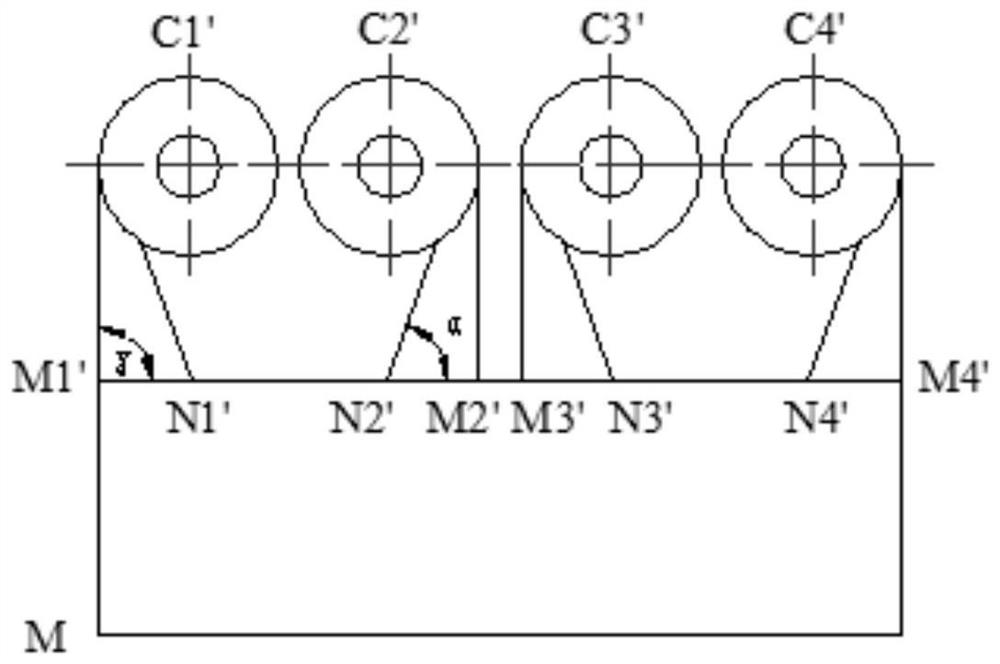

[0091] like figure 2 As shown, a circulating fluidized bed boiler with four separators arranged side by side, including:

[0092] The furnace is composed of four membrane walls, the front wall, the rear wall, the left side wall and the right side wall. Axisymmetric;

[0093] Four cyclone separators, including the first cyclone separator C1', the second cyclone separator C2', the third cyclone separator C3' and the fourth cyclone separator C4', are arranged side by side on the rear wall of the furnace; the four cyclone separators The four cyclone separators are all composed of an inlet flue and a cylinder, and the structure and size of the cylinders of the four cyclone separators are the same; the first cyclone separator C1', the fourth cyclone separator C4', the second cyclone separator C2' It is arranged axisymmetrically with the third cyclone separator C3' with respect to the center line of the front and rear walls of the furnace.

[0094] The outer side walls of the inl...

Embodiment 3

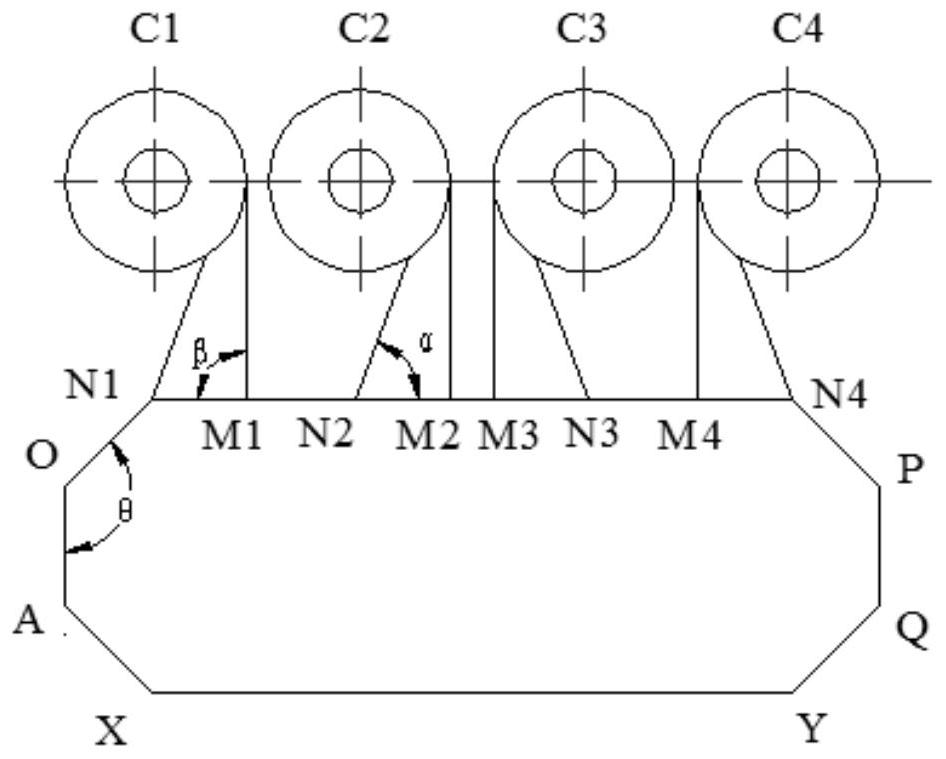

[0107] like image 3 As shown, a circulating fluidized bed boiler with four separators arranged side by side, the difference between this embodiment and embodiment 1 is that the angle β of the outer side wall of the inlet flue of the four cyclone separators is between 90° and 105°; The angle α between the inner side wall of the inlet flue of a cyclone separator is between 60° and 80°; the angle θ between the left wall of the furnace and the left rear chamfered furnace wall is between 120° and 150°;

[0108] And, the positions of the inlet flues of the first cyclone separator C1 and the second cyclone separator C2 satisfy the following relationship:

[0109] M1N2=(1.0~1.5)×M2M3+N2M2 / 2×cotα

[0110] 2×N1O×OA×sinθ+N1X^2×cotα=2×M1N2×(0.8~1.2)×N1X

[0111] Among them, N1O is the distance between N1 and O; OA is the distance between O and A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com