An air distribution device for a circulating fluidized bed boiler

A technology of circulating fluidized bed and air distribution device, applied in the field of air distribution device, can solve the problems of flow deviation of front and rear wall water-cooled tube screens, heat deviation of rear wall water-cooled tube screen, hydrodynamic force, large difference in pipeline resistance, etc. Achieve the effect of reducing thermal deviation and hydrodynamic deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

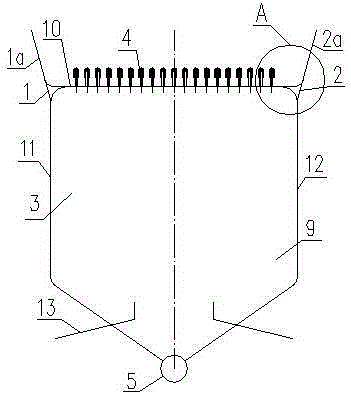

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

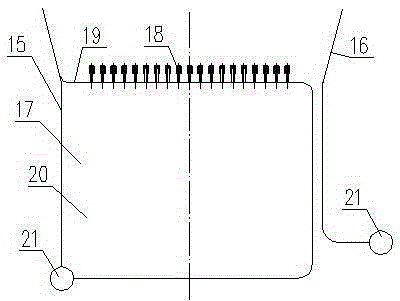

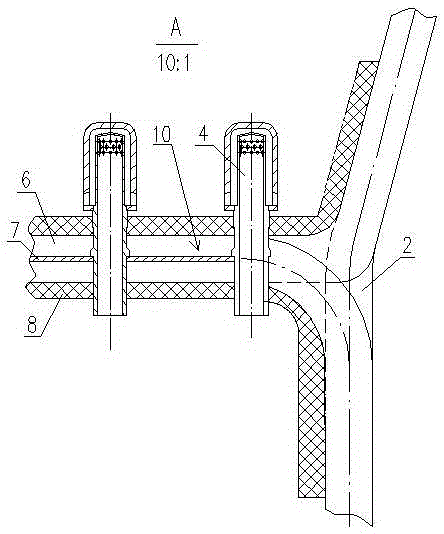

[0015] Such as Figure 2 to Figure 3 As shown, the air distribution device of the circulating fluidized bed boiler includes a front wall water-cooled wall tube panel 1, a rear wall water-cooled wall tube panel 2, left and right side walls 3, several air cap devices 4, and a lower header 5, The front wall water-cooled wall tube panel 1 includes a bent front upper tube panel 1a, a horizontal section tube panel, a front front wall middle tube panel, an inclined front front wall lower tube panel, a rear middle tube panel, and an inclined rear lower tube panel screen; rear wall water wall tube panel 2 includes bent rear upper tube panel 2a, horizontal section tube panel, front middle tube panel, inclined front lower tube panel, rear rear wall middle tube panel, inclined rear rear wall lower tube panel Screen;

[0016] The tube panels 6 of the horizontal section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com