Biomass circulating fluidized bed boiler

A circulating fluidized bed and biomass technology, applied in the field of fluidized bed boilers, can solve problems such as uneven heating of the inlet air, thermal deviation, boiler wear, etc., to reduce the content of fly ash combustibles, reduce thermal deviation, and ensure combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

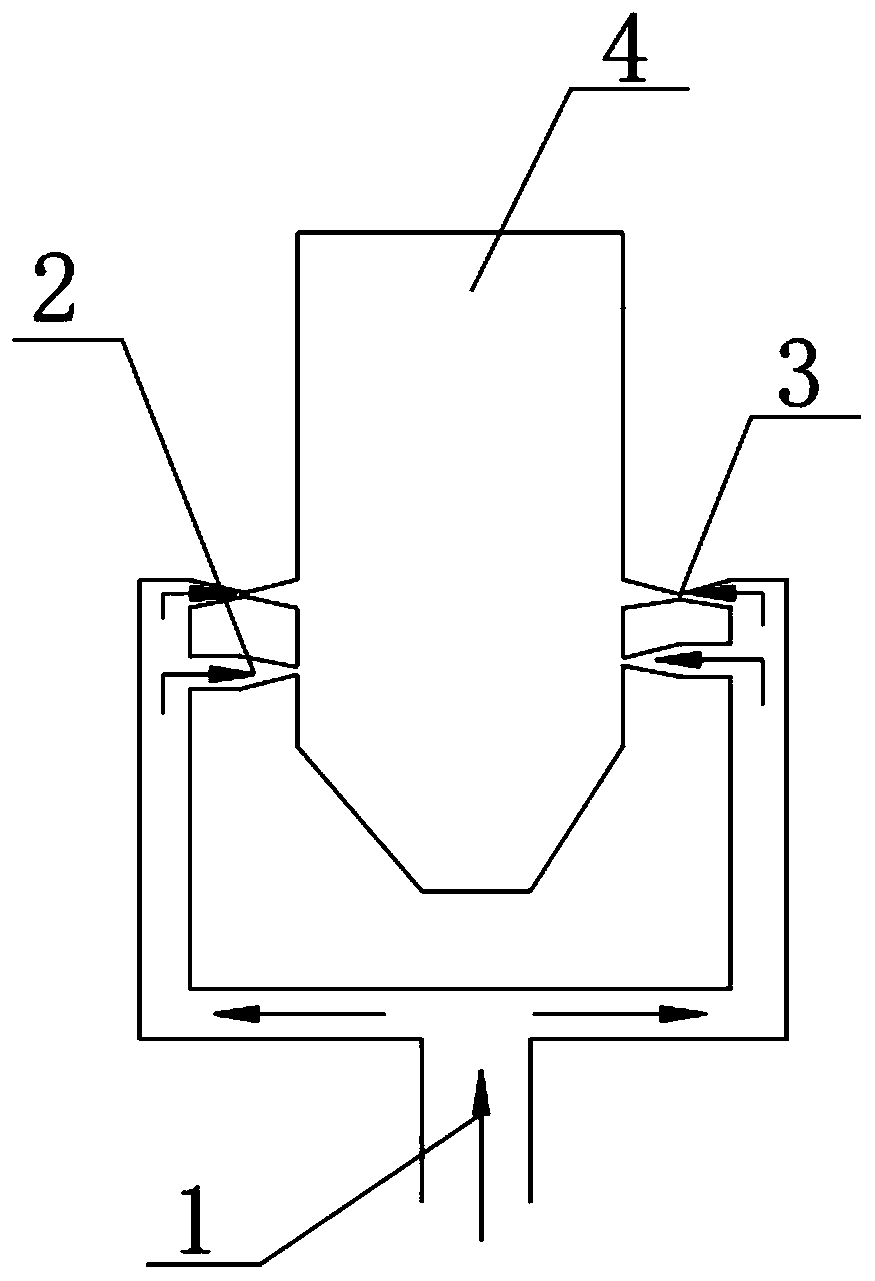

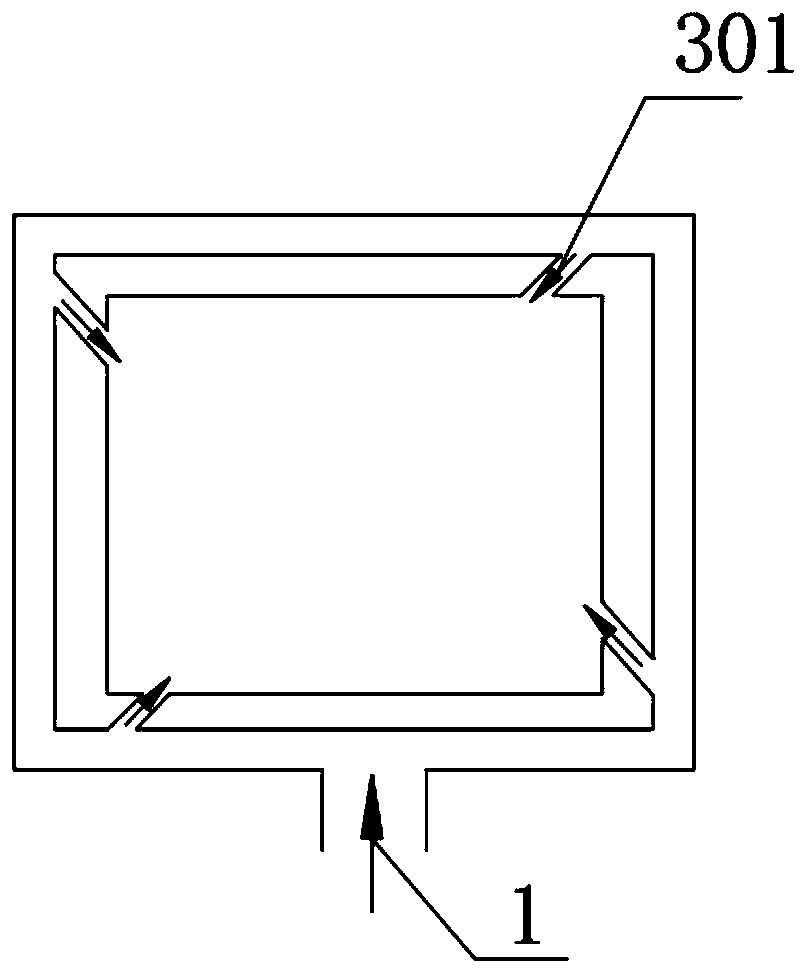

[0026] Such as Figure 1-Figure 2 As shown, according to an embodiment of a biomass circulating fluidized bed boiler provided by the present invention, it includes a furnace 4 with a rectangular cross-section, the outer wall of the furnace 4 is provided with a water-cooled wall, and the water-cooled wall is wrapped on the side wall of the furnace 4 , the water-cooled wall is provided with a plurality of annular cooling pipes, and the cooling pipes are wrapped on the side wall of the furnace 4 to dissipate heat. The furnace 4 is fixedly equipped with an air supply duct, which communicates with the interior of the furnace 4, and the air supply duct Including primary air supply duct and secondary air supply duct.

[0027] In this implementation, a power supply is also included, and the power supply is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com